How to remove a broken bolt

#1

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

How to remove a Broken Bolt

There are many different methods.

This is one of the more common methods using an EZ-Out

This method works best on bolts that broke due to being over tighten.

The EZ-out method has little success on cross threaded or rusted bolts.

The tools needed are few.

Drill

Proper size drill bit

A good sharp center punch

Hammer

Crescent wrench

Proper size EZ-OUT

There is two different styles of EZ-out, A left handed spiral flute and a straight flute.

I will be using a spiral flute in this removal.

The spiral flute will screw down and get a firm “bite” on the inside of the broken bolt.

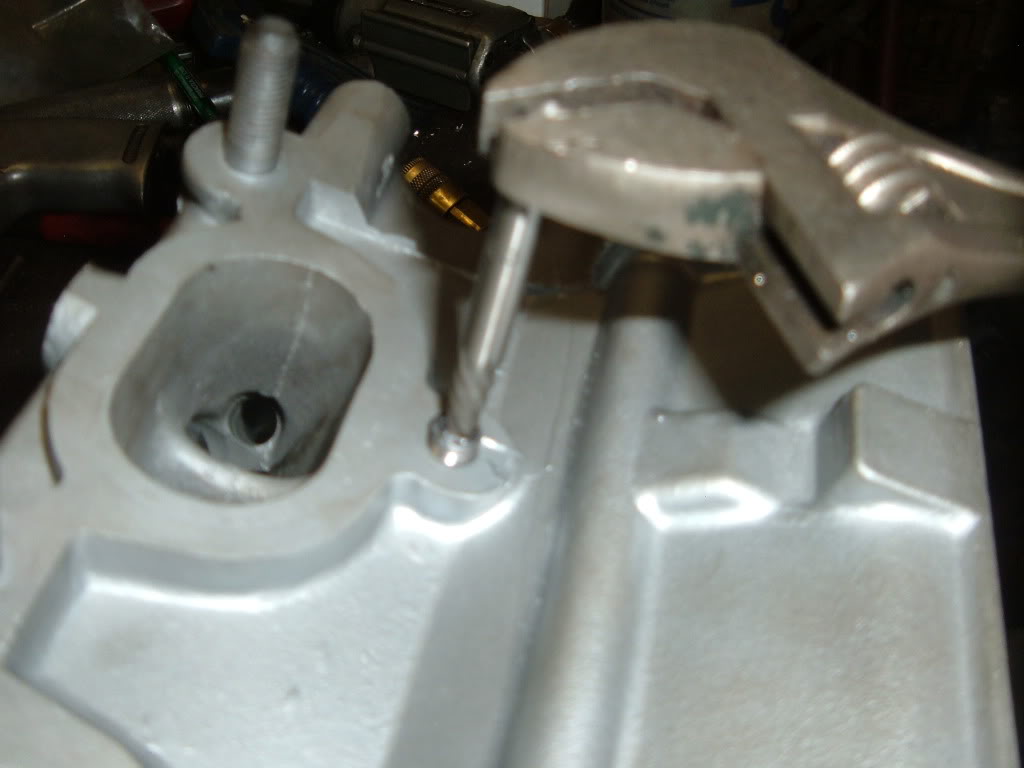

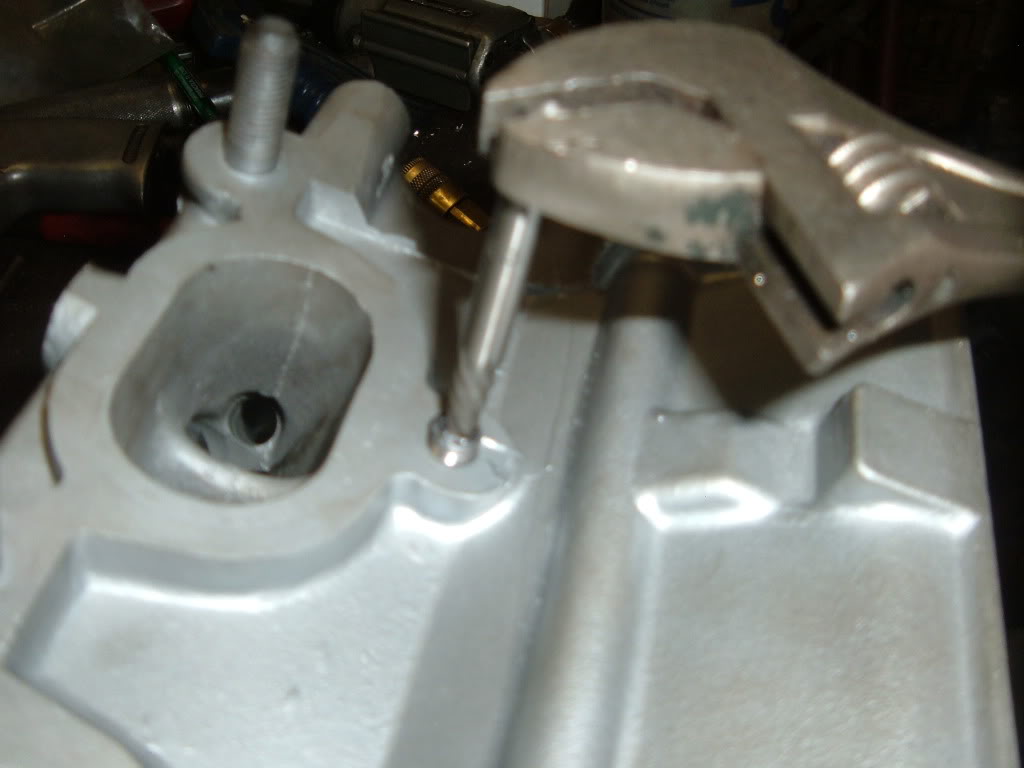

First with the hammer and center punch, knock a good divit as close as possible to the center of the bolt.

This is done so the drill bit will not walk around when you start to drill.

Now with the drill bit in the drill motor.

I am using a 1/8 inch drill bit, the broken bolt is a 8mm (5/16ths)

Drill appox. 1/8th to 1/4th inch down the center of the bolt.

Drill as straight as possible.

Some times it will be necessary to drill all the way through the bolt.

Blow all the metal chips out of the bolt hole.

Now take the EZ-Out and tap in to the hole you just drilled.

Now using the square on the back end of the EZ-out.

Gently apply pressure to the broken bolt, until you feel movement.

If you apply too much pressure, and snap the EZ-Out off in the hole, you will have more serious issues.

There are many different methods.

This is one of the more common methods using an EZ-Out

This method works best on bolts that broke due to being over tighten.

The EZ-out method has little success on cross threaded or rusted bolts.

The tools needed are few.

Drill

Proper size drill bit

A good sharp center punch

Hammer

Crescent wrench

Proper size EZ-OUT

There is two different styles of EZ-out, A left handed spiral flute and a straight flute.

I will be using a spiral flute in this removal.

The spiral flute will screw down and get a firm “bite” on the inside of the broken bolt.

First with the hammer and center punch, knock a good divit as close as possible to the center of the bolt.

This is done so the drill bit will not walk around when you start to drill.

Now with the drill bit in the drill motor.

I am using a 1/8 inch drill bit, the broken bolt is a 8mm (5/16ths)

Drill appox. 1/8th to 1/4th inch down the center of the bolt.

Drill as straight as possible.

Some times it will be necessary to drill all the way through the bolt.

Blow all the metal chips out of the bolt hole.

Now take the EZ-Out and tap in to the hole you just drilled.

Now using the square on the back end of the EZ-out.

Gently apply pressure to the broken bolt, until you feel movement.

If you apply too much pressure, and snap the EZ-Out off in the hole, you will have more serious issues.

#5

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

The quick awnser..... You are screwed.

Depending on what you were removing the broken bout out of when you snapped the EZ out, it could be cheaper and quicker to replace the part.

I have sold heads to people that boken EZ outs in studs and bolts.

I have taken 3-4 hours working to remove broken EZ outs. Sort of hard to hand a $150-$200 bill to some one for that.

Depending on what you were removing the broken bout out of when you snapped the EZ out, it could be cheaper and quicker to replace the part.

I have sold heads to people that boken EZ outs in studs and bolts.

I have taken 3-4 hours working to remove broken EZ outs. Sort of hard to hand a $150-$200 bill to some one for that.

#7

We had a landing gear trunnion (the thing that holds the front wheel on an aircraft) that came in to our shop. They broke off an EZ out. We used our EDM to burn out the EZ out. Sent it back to them. Instead of trying another EZ out they drilled out the bolt and dug out the threads that were left over but buggered up the threads in the trunnion so they ran a tap down to chase the threads. Broke the tap. Sent it back to us and we EDM'ed out the broken tap. All in all, they had well over a grand in removing that broken bolt but a new trunnion was about $18K so it was still cheap. Just would have been cheaper had they not screwed it up the first or second time, though.

#10

I broke an EZ-out in a motorcycle frame once. Several dulled drill bits later, I decided there was no way in hell i was going to get the tool-steel out. I drilled/tapped a hole next to it, fortunately it was a low-tolerance application. Since then, my preferred method for removing stuck bolts has been to drill out the bolt entirely and re-tap the hole. If my drill is centered right, I've been able to hit the same threads in the past, effectively unchanging the part.

#11

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,178

Total Cats: 1,129

---- the ------- easy outs. I think that's a JP quote even.

Sorry, as much as I love your threads you won't get much easy out love from mt.net, I'm surprised more of the haters haven't chimed in yet. Maybe they're off stewing in their rage. I know I've read plenty of stories of people ruining lots of parts with them. I've used them successfully, but I've also had them break.

Sorry, as much as I love your threads you won't get much easy out love from mt.net, I'm surprised more of the haters haven't chimed in yet. Maybe they're off stewing in their rage. I know I've read plenty of stories of people ruining lots of parts with them. I've used them successfully, but I've also had them break.

#12

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

Curly, I understand, EZ outs work best when the fastner has sheared off, now if the faster was over torqued and snapped off, or cross threaded, or rusted (bimetal oxidadation) then they are worthless, and another method will have to be used.

#15

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

Sheared off to me means a lateral load on the fastner caused it to break, with out over loading the engaugement threads.

Over torqued = streched on the axial, overloading of the engaugment threads.

Over torqued = streched on the axial, overloading of the engaugment threads.