Forged bottom end get in here!!!

#1

I'm Miserable!

Thread Starter

iTrader: (1)

Join Date: Mar 2010

Location: North Carolina

Posts: 464

Total Cats: 0

Just finished my 1.8 turbo setup, but its on a limited stock engine and is daily driven. Im in the market for building me an eventual replacement 1.8, not planned for but capable of being daily driven, but im new to engine building/planning and searching the forums has only gotten me so far, Ive looked around at different con-rod and piston combos, prices, "claims" of each products, and price comparisons between the products. What im looking for is suggestions from the experienced forged crowd.

Planning for,

MS1 Standalone (current engine management)

550cc injectors

190hp fuel pump

T3 .50 trim (current turbo)

99 head (unsure of cam/valvetrain combination, open to suggestions )

)

18-20psi with water/meth injection. 280+whp range is the goal

83.5mm bore

8.5-9.0 CR (in this range)

ARP Fasteners

BEGi Intake Manifold

etc etc...

If my above hardware plans arent capable of such goals, do correct me and leave a suggestion!

Just really wanting to find out peoples opinions/suggestions on different rod/piston combinations that are capable of my goals and the legitmacy of each products "claims" of reliability and power as well as good price.

Planning for,

MS1 Standalone (current engine management)

550cc injectors

190hp fuel pump

T3 .50 trim (current turbo)

99 head (unsure of cam/valvetrain combination, open to suggestions

)

)18-20psi with water/meth injection. 280+whp range is the goal

83.5mm bore

8.5-9.0 CR (in this range)

ARP Fasteners

BEGi Intake Manifold

etc etc...

If my above hardware plans arent capable of such goals, do correct me and leave a suggestion!

Just really wanting to find out peoples opinions/suggestions on different rod/piston combinations that are capable of my goals and the legitmacy of each products "claims" of reliability and power as well as good price.

Last edited by na8psi; 05-09-2010 at 07:53 PM.

#3

I'm Miserable!

Thread Starter

iTrader: (1)

Join Date: Mar 2010

Location: North Carolina

Posts: 464

Total Cats: 0

I'm really interested in learning about the advantages and disadvantages of going with 84mm bore over 83.5mm other then slight displacement bump? Is a stock head gasket still compatible?

#4

I am pretty sure that 84 mm is the limit that you could bore and use a stock head gasket. It is what I have, and the gasket appears to barely fit.

Another advantage of having a larger bore size is that the cylinder head flows better. There is a larger gap from the edge of the valve to the bore walls, so the air/fuel charge is not dammed up by the cylinder walls.

If you plan on doing any significant head work, with larger valves, I would strongly consider going to a larger bore size than 84 mm. Head gaskets are available for the larger bore sizes.

Another advantage of having a larger bore size is that the cylinder head flows better. There is a larger gap from the edge of the valve to the bore walls, so the air/fuel charge is not dammed up by the cylinder walls.

If you plan on doing any significant head work, with larger valves, I would strongly consider going to a larger bore size than 84 mm. Head gaskets are available for the larger bore sizes.

#5

I'm Miserable!

Thread Starter

iTrader: (1)

Join Date: Mar 2010

Location: North Carolina

Posts: 464

Total Cats: 0

I am pretty sure that 84 mm is the limit that you could bore and use a stock head gasket. It is what I have, and the gasket appears to barely fit.

Another advantage of having a larger bore size is that the cylinder head flows better. There is a larger gap from the edge of the valve to the bore walls, so the air/fuel charge is not dammed up by the cylinder walls.

If you plan on doing any significant head work, with larger valves, I would strongly consider going to a larger bore size than 84 mm. Head gaskets are available for the larger bore sizes.

Another advantage of having a larger bore size is that the cylinder head flows better. There is a larger gap from the edge of the valve to the bore walls, so the air/fuel charge is not dammed up by the cylinder walls.

If you plan on doing any significant head work, with larger valves, I would strongly consider going to a larger bore size than 84 mm. Head gaskets are available for the larger bore sizes.

#7

Aside from recommending larger injectors, if you couldn't hit 280whp WITHOUT meth on that setup @ 18-20psi I would have to say that you are doing something wrong. I made 235whp on that same turbo on a 1.6 @12psi, 20 psi on a 99' 1.8 should net you closer to 350whp+. To be honest, I'm fully expecting that with my new manifold/downpipe/exhaust I will be right around 250whp @12psi. You need to assess your tune.

#11

Aside from recommending larger injectors, if you couldn't hit 280whp WITHOUT meth on that setup @ 18-20psi I would have to say that you are doing something wrong. I made 235whp on that same turbo on a 1.6 @12psi, 20 psi on a 99' 1.8 should net you closer to 350whp+. To be honest, I'm fully expecting that with my new manifold/downpipe/exhaust I will be right around 250whp @12psi. You need to assess your tune.

did you use the same dyno?

my 92 9000 dynoed 265whp and 330ftlbs on a dynoject, and then a few months later running the same configuration, it did 235whp and 286 ftlbs on a mustang dyno

#14

Stiffer springs will do one thing for you if you have not upgraded the cam. Rob Horsepower!

You may also consider using shim under lifters. They are much lighter than stock, and will net you a little more power.

Edit: Considering your goals, stick with the smallest overbore. We want to keep as many viable blocks around as possible at the rate we are blowing them up.

#15

I'm Miserable!

Thread Starter

iTrader: (1)

Join Date: Mar 2010

Location: North Carolina

Posts: 464

Total Cats: 0

If you plan to run the stock cam or a very small upgrade, I would not change the valve springs. Stiffer valve springs should only be used if they are needed to control a very high reving motor from a cam with a lot of duration and lift. If you have budgeted for valve springs, I would go with new valves with undercut stems instead, and ditch stiffer valvesprings. You will not need to fool with the valve seat (other than lapping) and you will get a little better air flow.

Stiffer springs will do one thing for you if you have not upgraded the cam. Rob Horsepower!

You may also consider using shim under lifters. They are much lighter than stock, and will net you a little more power.

Edit: Considering your goals, stick with the smallest overbore. We want to keep as many viable blocks around as possible at the rate we are blowing them up.

Stiffer springs will do one thing for you if you have not upgraded the cam. Rob Horsepower!

You may also consider using shim under lifters. They are much lighter than stock, and will net you a little more power.

Edit: Considering your goals, stick with the smallest overbore. We want to keep as many viable blocks around as possible at the rate we are blowing them up.

MSQ posted for your elegant but experienced ridicule! lol if I did not load the right file or did something wrong do tell lol, I've never just loaded a spark map alone to here.

#16

I see your problem.

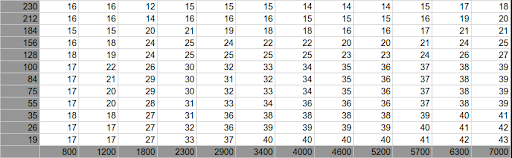

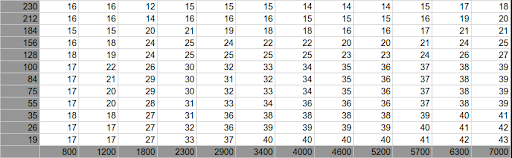

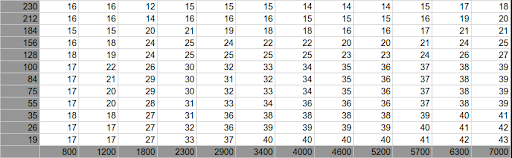

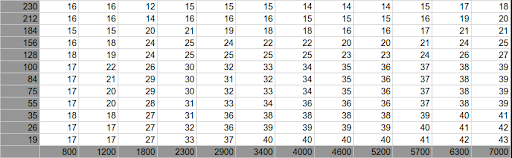

Your spark map:

My spark map:

(Sorry for the shitty, uncolorized format)

Notice the curve it has? It ramps up during spool up, then drops down towards peak torque (to prevent knock) it then ramps back up to keep torque flat(ter) till redline.

Note: If you use this and blow your **** up, I hold no responsibility for it. This works well in my car, but I have reason to believe that other people might not be as fortunate.

Your spark map:

My spark map:

(Sorry for the shitty, uncolorized format)

Notice the curve it has? It ramps up during spool up, then drops down towards peak torque (to prevent knock) it then ramps back up to keep torque flat(ter) till redline.

Note: If you use this and blow your **** up, I hold no responsibility for it. This works well in my car, but I have reason to believe that other people might not be as fortunate.

#17

I'm Miserable!

Thread Starter

iTrader: (1)

Join Date: Mar 2010

Location: North Carolina

Posts: 464

Total Cats: 0

I see your problem.

Your spark map:

My spark map:

(Sorry for the shitty, uncolorized format)

Notice the curve it has? It ramps up during spool up, then drops down towards peak torque (to prevent knock) it then ramps back up to keep torque flat(ter) till redline.

Note: If you use this and blow your **** up, I hold no responsibility for it. This works well in my car, but I have reason to believe that other people might not be as fortunate.

Your spark map:

My spark map:

(Sorry for the shitty, uncolorized format)

Notice the curve it has? It ramps up during spool up, then drops down towards peak torque (to prevent knock) it then ramps back up to keep torque flat(ter) till redline.

Note: If you use this and blow your **** up, I hold no responsibility for it. This works well in my car, but I have reason to believe that other people might not be as fortunate.