Compression Ratios and Forced Induction

#101

well it's certainly interesting data and helpful.

but comparing the better fuel in the higher compression car at the end did somewhat skew the results. you dont have the LC/HB/better fuel combination to compare to.

You have before/after dyno plots to compare? I dont care if they have numbers on them as long as they are scaled the same.

but comparing the better fuel in the higher compression car at the end did somewhat skew the results. you dont have the LC/HB/better fuel combination to compare to.

You have before/after dyno plots to compare? I dont care if they have numbers on them as long as they are scaled the same.

#103

I don't think two examples from two people is "proof", especially since neither case is documented. omaharma has a good story anyways. He's just stating a real world example. Nothing wrong with that. But I wouldn't say combining his post with ray sir 6's means it's the only way and it defines the answer. I mean, I've seen a single turbo 302 mustang pick up spool by dropping compression.

Originally this thread started out with jc rotor claiming that a 11:1 motor at 15PSI would make MORE power than an 8:1 running 24PSI because his 11:1 motor is more than 43% efficient at turning chemical energy into mechanical energy. I think it's understood that something more like 11:1 at 15PSI is ~= 8:1 at 20PSI. Something like that. The argument now is which spools faster. All the people I know that build boosted motors are looking for maximum power, not maximum efficiency (since they run 1/4 mile or a track that does not have a fuel factor in it like having to pit). They drop static compression very low and turn the boost way up. Makes more power. How much more, I dunno, but it puts the numbers down at the 1/4 mile.

Originally this thread started out with jc rotor claiming that a 11:1 motor at 15PSI would make MORE power than an 8:1 running 24PSI because his 11:1 motor is more than 43% efficient at turning chemical energy into mechanical energy. I think it's understood that something more like 11:1 at 15PSI is ~= 8:1 at 20PSI. Something like that. The argument now is which spools faster. All the people I know that build boosted motors are looking for maximum power, not maximum efficiency (since they run 1/4 mile or a track that does not have a fuel factor in it like having to pit). They drop static compression very low and turn the boost way up. Makes more power. How much more, I dunno, but it puts the numbers down at the 1/4 mile.

#104

I wanted to put more in my last post but got interrupted. So on the issue of using a higher octane fuel skewing the results, I do not agree. What I am supporting is with all other things equal, which includes timing, which may require higher octane, you will be better off with HC/LB. This is a race engine and so I was giving real results based on that. But, I learned enough from it to translate it into this. If we are talking about engines that use pump gas only, the HC/LB is still going to have a flatter power curve.

8:1 w/ 10psi VS 10:1 w/ 5psi - which should both run on pump gas - the HC/LB is going to respond better and give better overall performance. With that said, there are certainly circumstances that have to be taken into consideration that patsmx5 eluded to.

If we are talking drag race only with no traction problems from a dig, the story could change. At this point we are not worried about light time or spool time if we can build boost at the line. With my truck, I build 20psi on the brakes in pre-stage and then ease it to the 2nd light. When the tree drops I am almost instantly at full boost.

However, usually in the case of LC and huge boost numbers as pat referred to, they are monster turbos and the engine makes no low end power to speak of. You put me next to one of those on the road already going 5mph where they can't preload the turbo and I'll race it with my bicycle.

Why do you think there is an old saying among "old" racers that there is no replacement for displacement? If we move this into the v8 world - and please excuse me for doing so on a miata forum - one could build a 350ci engine to produce 525 peak hp. Another guy could build a 500ci engine producing 500 peak hp falling 25hp short of the other guy. I still want the larger, lower hp, engine. Why? Because if you look at the power curve it is applying more power to the drivetrain for a longer period of time. In other words, if you measured power output over the entire rpm range and then took an average, the lower peak hp engine would have a higher power average.

So pat, the claim of the 11:1@15psi making more power than the 8:1@24psi could possibly be true if looking at average power over the entire rpm range. Peak power makes no difference in real world application. 500hp for a duration of 800rpms will not keep up with 400hp for a duration of 2000rpms.

8:1 w/ 10psi VS 10:1 w/ 5psi - which should both run on pump gas - the HC/LB is going to respond better and give better overall performance. With that said, there are certainly circumstances that have to be taken into consideration that patsmx5 eluded to.

If we are talking drag race only with no traction problems from a dig, the story could change. At this point we are not worried about light time or spool time if we can build boost at the line. With my truck, I build 20psi on the brakes in pre-stage and then ease it to the 2nd light. When the tree drops I am almost instantly at full boost.

However, usually in the case of LC and huge boost numbers as pat referred to, they are monster turbos and the engine makes no low end power to speak of. You put me next to one of those on the road already going 5mph where they can't preload the turbo and I'll race it with my bicycle.

Why do you think there is an old saying among "old" racers that there is no replacement for displacement? If we move this into the v8 world - and please excuse me for doing so on a miata forum - one could build a 350ci engine to produce 525 peak hp. Another guy could build a 500ci engine producing 500 peak hp falling 25hp short of the other guy. I still want the larger, lower hp, engine. Why? Because if you look at the power curve it is applying more power to the drivetrain for a longer period of time. In other words, if you measured power output over the entire rpm range and then took an average, the lower peak hp engine would have a higher power average.

So pat, the claim of the 11:1@15psi making more power than the 8:1@24psi could possibly be true if looking at average power over the entire rpm range. Peak power makes no difference in real world application. 500hp for a duration of 800rpms will not keep up with 400hp for a duration of 2000rpms.

#105

Elite Member

iTrader: (15)

Join Date: Dec 2007

Location: San Antonio, Texas

Posts: 4,847

Total Cats: 27

Just so everyone knows, and at the risk of repeating myself, this is not possible. There is no way you are going to get 43% efficiency (chemical energy to mechanical energy) out of a 'normal' piston engine (no exotic materials or weird cycles) especially under boost when the motor is running rich. I just want to be sure no one is grabbing this number and running with it.

#108

Let's use Garrett Turbo 103 math again to dispute this. I'll use my stock motor and I am gonna change the BSFC to be less efficient since LC motors are, as we all agree. It's the % that is in question.

http://www.turbobygarrett.com/turbobygarrett/images/tech_center/tech_103/formula3.jpg[/IMG]

HP = 218 flywheel hp

A/F = 11

BSFC = .512

Everyone should be able to agree that a LC motor requires more fuel to make the same power, so I am using the 12% (4% per CR point of difference) rule that we are all saying is feasible.

Therefore WA = 20.4629 lb/min

WA = 20.4629

R = 639.6

Tm = 106 (datalogged)

VE = .9652

Now the 12% rule also applies to the VE. The range for the VE on a 4-valve is 95-99.

N = 7500

Vd = 97.632

You come up with 7407848.09544 divided by 353379.024

That equals approx. 20.963, but you have to subract atmosphere, which is 14.7

So that equals 6.263 psi to make the same power.

So the math says I'm right again.

Did the formulas from Garrett Turbo 103.

HP = 218 flywheel hp

A/F = 11

BSFC = .5

Therefore WA = 19.98 lb/min

WA = 19.98

R = 639.6

Tm = 106 (datalogged)

VE = .97

N = 7500

Vd = 97.632

You come up with 7233031.728 divided by 355136.

That equals 20.3669, but you have to subract atmosphere, which is 14.7

So that equals 5.6669 psi.

HP = 218 flywheel hp

A/F = 11

BSFC = .5

Therefore WA = 19.98 lb/min

WA = 19.98

R = 639.6

Tm = 106 (datalogged)

VE = .97

N = 7500

Vd = 97.632

You come up with 7233031.728 divided by 355136.

That equals 20.3669, but you have to subract atmosphere, which is 14.7

So that equals 5.6669 psi.

HP = 218 flywheel hp

A/F = 11

BSFC = .512

Everyone should be able to agree that a LC motor requires more fuel to make the same power, so I am using the 12% (4% per CR point of difference) rule that we are all saying is feasible.

Therefore WA = 20.4629 lb/min

WA = 20.4629

R = 639.6

Tm = 106 (datalogged)

VE = .9652

Now the 12% rule also applies to the VE. The range for the VE on a 4-valve is 95-99.

N = 7500

Vd = 97.632

You come up with 7407848.09544 divided by 353379.024

That equals approx. 20.963, but you have to subract atmosphere, which is 14.7

So that equals 6.263 psi to make the same power.

So the math says I'm right again.

Last edited by ray_sir_6; 10-02-2008 at 06:22 PM.

#109

So he had a bad tune, bad HG, or was running bad gas. I'm sorry, but you CAN NOT spool faster on a LC motor unless other changes are made. Ask ANY turbo company. I talked to Forced Performance and Wiseco, they both said the same thing. Everything the same except the CR with a STOCK ecu (so not even tuning), a HC/LB will spool faster.

#110

I have been trying to get this across to them, but their faulty math is better than a real world expert's experience. Even funnier, is I just used that math to prove I was right. They just can't figure out that their math is just a simple equation to give an ESTIMATE of POSSIBLE outcomes.

#111

Let's use Garrett Turbo 103 math again to dispute this. I'll use my stock motor and I am gonna change the BSFC to be less efficient since LC motors are, as we all agree. It's the % that is in question.

http://www.turbobygarrett.com/turbobygarrett/images/tech_center/tech_103/formula3.jpg[/IMG]

HP = 218 flywheel hp

A/F = 11

BSFC = .512

Everyone should be able to agree that a LC motor requires more fuel to make the same power, so I am using the 12% (4% per CR point of difference) rule that we are all saying is feasible.

Therefore WA = 20.4629 lb/min

WA = 20.4629

R = 639.6

Tm = 106 (datalogged)

VE = .9748

Now the 12% rule also applies to the VE. The range for the VE on a 4-valve is 95-99.

N = 7500

Vd = 97.632

You come up with 7407848.09544 divided by 356893.776.

That equals approx. 20.756, but you have to subract atmosphere, which is 14.7

So that equals 6.056 psi to make the same power.

So the math says I'm right again.

http://www.turbobygarrett.com/turbobygarrett/images/tech_center/tech_103/formula3.jpg[/IMG]

HP = 218 flywheel hp

A/F = 11

BSFC = .512

Everyone should be able to agree that a LC motor requires more fuel to make the same power, so I am using the 12% (4% per CR point of difference) rule that we are all saying is feasible.

Therefore WA = 20.4629 lb/min

WA = 20.4629

R = 639.6

Tm = 106 (datalogged)

VE = .9748

Now the 12% rule also applies to the VE. The range for the VE on a 4-valve is 95-99.

N = 7500

Vd = 97.632

You come up with 7407848.09544 divided by 356893.776.

That equals approx. 20.756, but you have to subract atmosphere, which is 14.7

So that equals 6.056 psi to make the same power.

So the math says I'm right again.

So why don't you run your math again and "prove" me wrong. Go ahead, try.

#112

Lol. Look up what BSFC is as you obviously don't know. I'll give you a hint. It's the ratio of unit fuel/unit power. Fuel is in the numerator and power is in the denominator. Guess what happens to BSFC when the denominator gets bigger?

So why don't you run your math again and "prove" me wrong. Go ahead, try.

So why don't you run your math again and "prove" me wrong. Go ahead, try.

Brake Specific Fuel Consumption (BSFC). BSFC describes the fuel flow rate required to generate each horsepower. General values of BSFC for turbocharged gasoline engines range from 0.50 to 0.60 and higher.

Lower BSFC means that the engine requires less fuel to generate a given horsepower. Race fuels and aggressive tuning are required to reach the low end of the BSFC range described above.

Lower BSFC means that the engine requires less fuel to generate a given horsepower. Race fuels and aggressive tuning are required to reach the low end of the BSFC range described above.

CR and BSFC

Compression ratio rc is inversely proportional to BSFC due to higher thermal efficiency.

That is, higher compression ratio yields lower specific fuel consumption.

Sorry, but I got this right, too.

#113

Your numbers are wrong sir. In YOUR example YOU said you had higher compression. If that's the case, your BSFC will be lower. I'm talking about YOUR example, you know, the one YOU posted?

Go ahead, calulate the correct BSFC for your high comp motor, plug that number in, and see what your correct formula yields.

Go ahead, calulate the correct BSFC for your high comp motor, plug that number in, and see what your correct formula yields.

#114

Your numbers are wrong sir. In YOUR example YOU said you had higher compression. If that's the case, your BSFC will be lower. I'm talking about YOUR example, you know, the one YOU posted?

Go ahead, calulate the correct BSFC for your high comp motor, plug that number in, and see what your correct formula yields.

Go ahead, calulate the correct BSFC for your high comp motor, plug that number in, and see what your correct formula yields.

My numbers are right. Your eyes are broken.

It actually needed .2 psi MORE to make the same horsepower.

My eyes are broken, too...you were talking about the VE. I gave it BETTER VE, not worse. I'll fix that in that post.

Last edited by ray_sir_6; 10-02-2008 at 06:23 PM.

#116

Which example is which then? Besides, you can't just multiply 12% by BSFC. Your BSFC is still wrong. Again, look up what it is and you will see.

And what is your example proving anyways? That a lower boost motor takes more PSI to make the same power? No ****. How much though? According to your wrong numbers you use a 1/3 of a pound less boost to make the same power. That's not right now, is it? If that were so, you'd be only a percent or two more efficient at most. Redo your math, it's wrong. Damn.

And what is your example proving anyways? That a lower boost motor takes more PSI to make the same power? No ****. How much though? According to your wrong numbers you use a 1/3 of a pound less boost to make the same power. That's not right now, is it? If that were so, you'd be only a percent or two more efficient at most. Redo your math, it's wrong. Damn.

#117

Which example is which then? Besides, you can't just multiply 12% by BSFC. Your BSFC is still wrong. Again, look up what it is and you will see.

And what is your example proving anyways? That a lower boost motor takes more PSI to make the same power? No ****. How much though? According to your wrong numbers you use a 1/3 of a pound less boost to make the same power. That's not right now, is it? If that were so, you'd be only a percent or two more efficient at most. Redo your math, it's wrong. Damn.

And what is your example proving anyways? That a lower boost motor takes more PSI to make the same power? No ****. How much though? According to your wrong numbers you use a 1/3 of a pound less boost to make the same power. That's not right now, is it? If that were so, you'd be only a percent or two more efficient at most. Redo your math, it's wrong. Damn.

That shows that the HC motor is 12% more efficient, and using that idea that it would require that much more boost to make the same power. Increase the power and the gap will widen. We are talking about a HC/LB motor, so change the whp level to 350hp and the difference will jump.

#118

You are STILL doing your math wrong.

1) You can't just tack on .012 to BSFC. 12% in a decimal form is .12 anyways.... Look up BSFC for the 13th. time.

Nevermind, I'll explain.

BSFC = (mass of fuel/unit time) divided by (Power)

Do we agree so far? Let me know if you have a problem with my math ANYWHERE, ok?

Say an 8:1 motor has BSFC of .5 (generally accepted value, but arbitrary for this analysis).

Are we ok?

For example, for 100hp, (50 units of fuel/time) divided by (100 HP)=.5

Are we on the same page so far? Agreed?

And YOU CLAIM your 11:1 motor can make 12% more power burning the same amount of fuel. Right? Same amount of input and 12% more efficient, right? So if I make 100 HP on my low boost motor, you'll turn out 112 HP, right?

Are we ok?

So then, your BSFC is: (50 units of fuel/time) divided by (112 HP)= .446

Am I right?

1) You can't just tack on .012 to BSFC. 12% in a decimal form is .12 anyways.... Look up BSFC for the 13th. time.

Nevermind, I'll explain.

BSFC = (mass of fuel/unit time) divided by (Power)

Do we agree so far? Let me know if you have a problem with my math ANYWHERE, ok?

Say an 8:1 motor has BSFC of .5 (generally accepted value, but arbitrary for this analysis).

Are we ok?

For example, for 100hp, (50 units of fuel/time) divided by (100 HP)=.5

Are we on the same page so far? Agreed?

And YOU CLAIM your 11:1 motor can make 12% more power burning the same amount of fuel. Right? Same amount of input and 12% more efficient, right? So if I make 100 HP on my low boost motor, you'll turn out 112 HP, right?

Are we ok?

So then, your BSFC is: (50 units of fuel/time) divided by (112 HP)= .446

Am I right?

#119

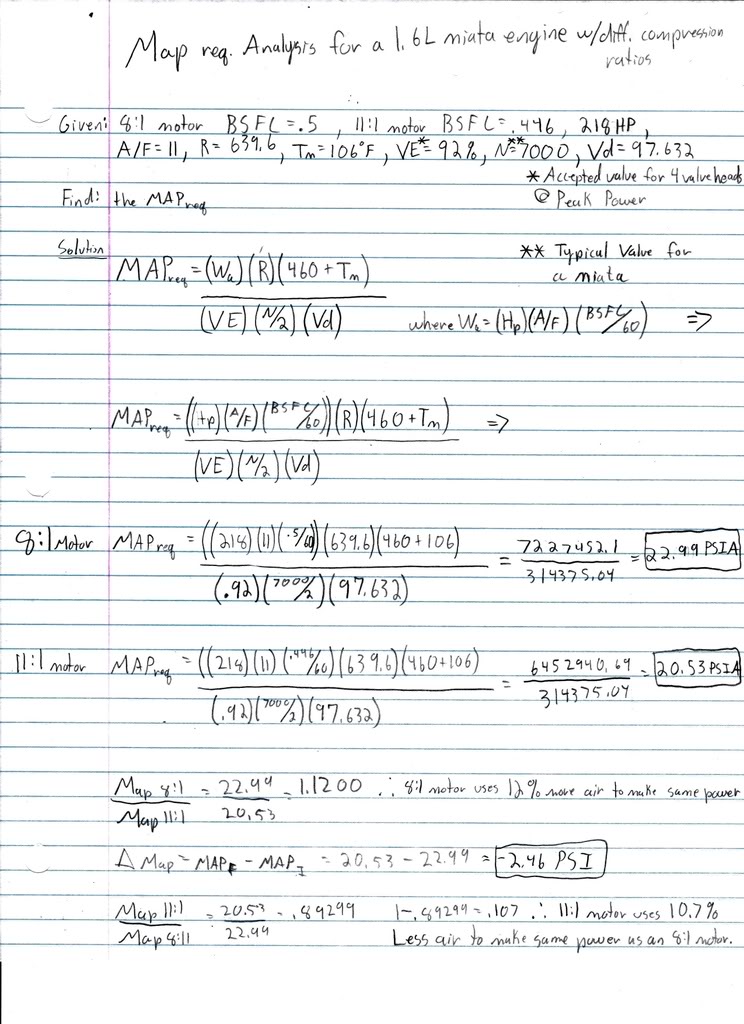

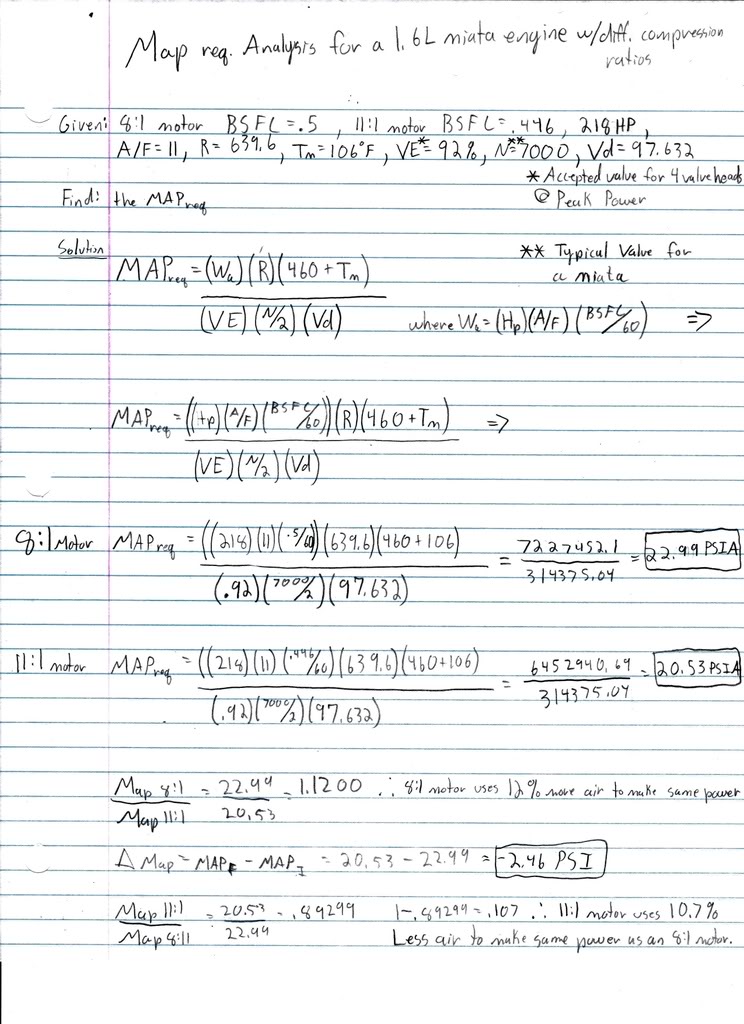

So do you agree with my BSFC numbers?

If they're right, then for a given HP, the difference in PSIA should be 12%, no? Let me see if I can figure out how to use that fancy correct formula of yours that you don't seem to know how to use and see if I get a 12% delta between the two using my BSFC's I calculated above....

BAM: Here's my math and guess what? It's not wrong! Woo hoo! Someone can use Garrett's formulas correctly!

Conclusion:

8:1 motor will use 12% more volume of air to make the same HP as an 11:1 motor. (didn't I say that earlier?)

An 11:1 motor will use 10.7% less air than a 8:1 motor to make the same amount of power. (not 12% less. told ya.)

told ya.)

The change in boost between the two setups is 2.46 PSI. (not as extreme as you said now is it? ) The difference being 8.29 PSIG boost Vs. 5.83 PSIG

I win.

If they're right, then for a given HP, the difference in PSIA should be 12%, no? Let me see if I can figure out how to use that fancy correct formula of yours that you don't seem to know how to use and see if I get a 12% delta between the two using my BSFC's I calculated above....

BAM: Here's my math and guess what? It's not wrong! Woo hoo! Someone can use Garrett's formulas correctly!

Conclusion:

8:1 motor will use 12% more volume of air to make the same HP as an 11:1 motor. (didn't I say that earlier?)

An 11:1 motor will use 10.7% less air than a 8:1 motor to make the same amount of power. (not 12% less.

told ya.)

told ya.) The change in boost between the two setups is 2.46 PSI. (not as extreme as you said now is it? ) The difference being 8.29 PSIG boost Vs. 5.83 PSIG

I win.

Last edited by patsmx5; 10-02-2008 at 09:09 PM.