DIY Head Porting

#21

Would be interested to see a comparison since this method would be ultra repeatable.

I think for most, this wouldn't be as DIY, but a service that is otherwise financially taxing. Not everyone is privy to such awesome techniques. I'd be interested in pricing but this is one of those black magic areas that I wouldn't have the experience of knowing the difference for the amount of $ spent.

This looks fantastic though, and I can appreciate you sharing the steps and methods as you are now.

I think for most, this wouldn't be as DIY, but a service that is otherwise financially taxing. Not everyone is privy to such awesome techniques. I'd be interested in pricing but this is one of those black magic areas that I wouldn't have the experience of knowing the difference for the amount of $ spent.

This looks fantastic though, and I can appreciate you sharing the steps and methods as you are now.

#24

Emilio's CNC heads are cut with a 5 axis machine with probably hundreds of hours of 3D modeling time, machining and several prototype heads as tests. You really need the extra two axis to get the cutter into the ports. Even then it's a challenge due to the angles in the ports.

I think I could cut the ports with my machine but I'd need a ball cutter that has a bit of overhang. I figure I can make a rubber mold from my race head intake and exhaust ports, then photoscan them to generate the surface model and use that to cnc. Maybe do a few ports and average them. I know that head flows well so its an excellent starting point.

From here I'll most likely do some CNCing of the bowls as they are fairly critcal and I'll hand port the rest.

#29

+1 more Giggidy

You might as well look at the larger (7mm) exhaust valves cause they're sodium filled. I would imagine you could use Mazda or Nissan valve guides. Simple matter of making them fit.

I have some seat time on a few of these heads at this point and it helps to have a good set of headphones to listen to your favorite whatever. If you feel it's necessary, you can CC the combustion chambers and the intake runners in the head. 180-320 is common on the intake surface. 400 grit and then a light buff is sufficient for the exhaust.

cheers- JB

You might as well look at the larger (7mm) exhaust valves cause they're sodium filled. I would imagine you could use Mazda or Nissan valve guides. Simple matter of making them fit.

I have some seat time on a few of these heads at this point and it helps to have a good set of headphones to listen to your favorite whatever. If you feel it's necessary, you can CC the combustion chambers and the intake runners in the head. 180-320 is common on the intake surface. 400 grit and then a light buff is sufficient for the exhaust.

cheers- JB

#31

You might as well look at the larger (7mm) exhaust valves cause they're sodium filled. I would imagine you could use Mazda or Nissan valve guides. Simple matter of making them fit.

I have some seat time on a few of these heads at this point and it helps to have a good set of headphones to listen to your favorite whatever. If you feel it's necessary, you can CC the combustion chambers and the intake runners in the head. 180-320 is common on the intake surface. 400 grit and then a light buff is sufficient for the exhaust.

cheers- JB

I have some seat time on a few of these heads at this point and it helps to have a good set of headphones to listen to your favorite whatever. If you feel it's necessary, you can CC the combustion chambers and the intake runners in the head. 180-320 is common on the intake surface. 400 grit and then a light buff is sufficient for the exhaust.

cheers- JB

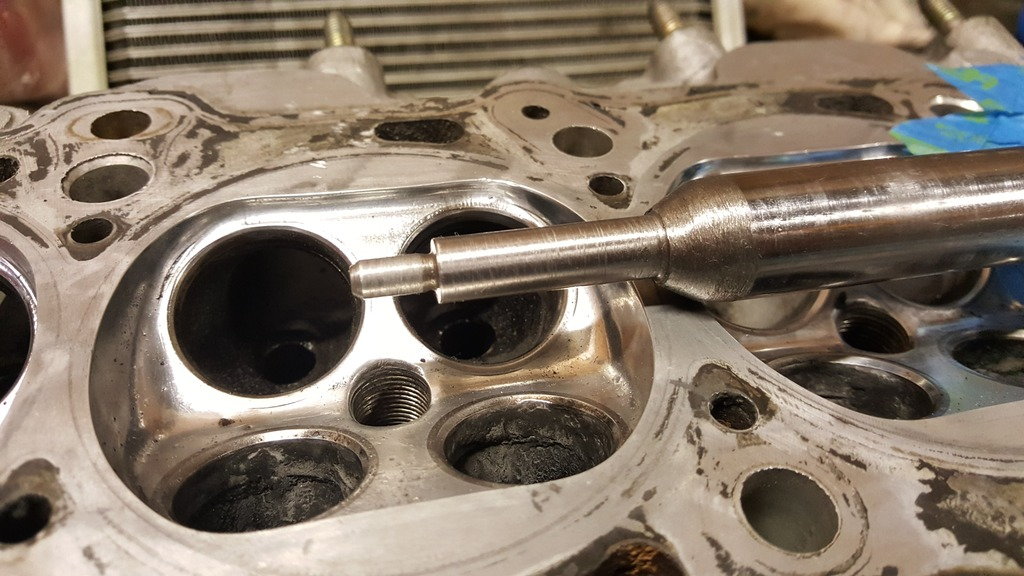

As a side note, I made a tool to punch out the valve guides as I need them out to port the head properly. I lathed it out of some 4140 as the valve guides are in pretty tight.

#32

Did you knock them out from the lifter side or the port side. we always use an end mill and cut down the stock guides from lifter side until the circlip comes loose. then we knock them out by hand from the lifter side. seems to help from pulling metal through.

I vote 5 or 5.5mm valve stems its lighter and flows more. no brainer if you are going to change valve stem diameter.

I vote 5 or 5.5mm valve stems its lighter and flows more. no brainer if you are going to change valve stem diameter.

#33

Did you knock them out from the lifter side or the port side. we always use an end mill and cut down the stock guides from lifter side until the circlip comes loose. then we knock them out by hand from the lifter side. seems to help from pulling metal through.

I vote 5 or 5.5mm valve stems its lighter and flows more. no brainer if you are going to change valve stem diameter.

I vote 5 or 5.5mm valve stems its lighter and flows more. no brainer if you are going to change valve stem diameter.

I think I'll pick up an air hammer to install the new ones.

#35

Awesome... I also thought that maybe I could pull them through with a threaded rod and tighten them in with a nut. Freezing them makes more sense but I guess you have to move quick. Anything special to get the heights correct? I have another head so I figured I'd measure the installed height from that and match.

#39

I have purchased the bronze miata guides from miataroadster. I can also get tapered carbide 6 flute reamers designed for bronze valve guides that are meant to produce an excellent finish without the need for honing. From the specs it looks like Mazda speced the valve stems so that the required tollerences are correct for a 6mm hole in the guide. The Nissan valves seem to be the same. Given I'm trying to do as much as possible DIY, my plan was to purchase a 6mm reamer and give it a go on the new installed guides. I think it should be fine but I'm open to suggestions here given I really don't know how it should be done.