BEGi Coolant Spacer Problem

#1

Elite Member

Thread Starter

iTrader: (15)

Join Date: Jan 2007

Location: Murfreesboro,TN

Posts: 2,042

Total Cats: 265

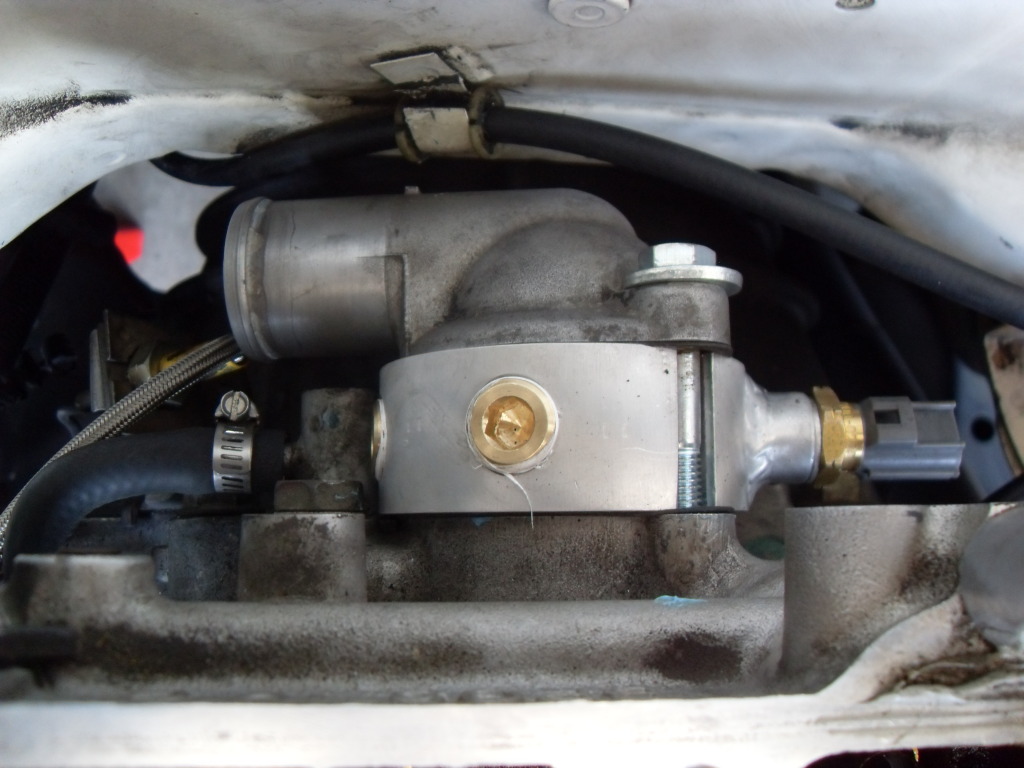

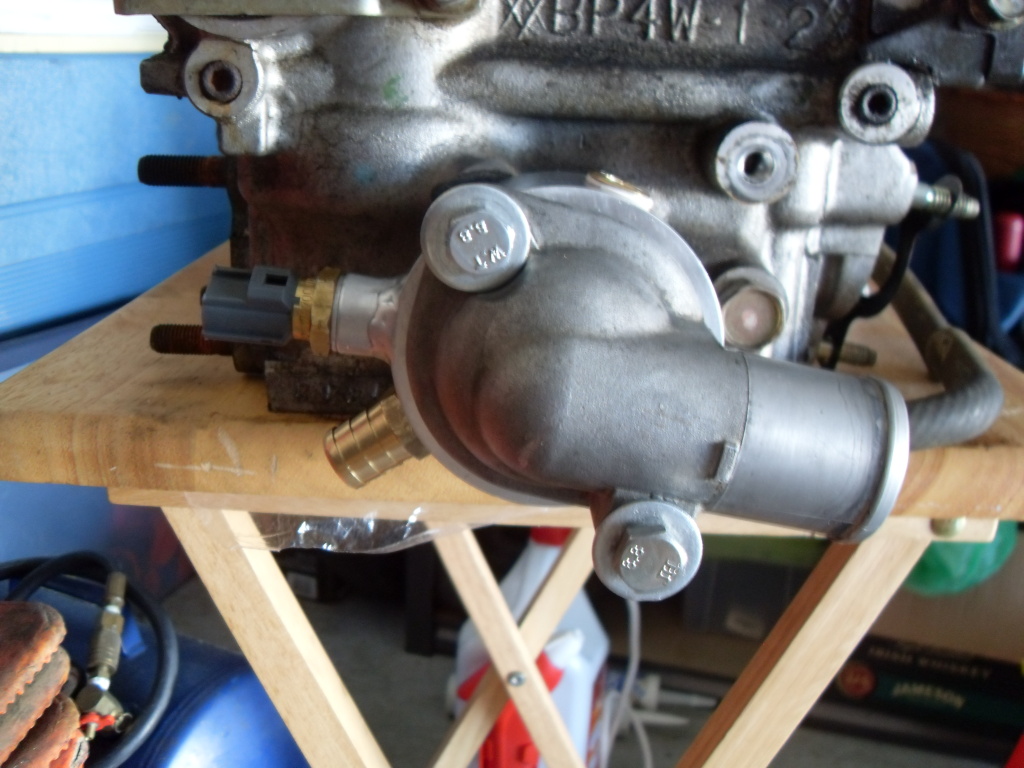

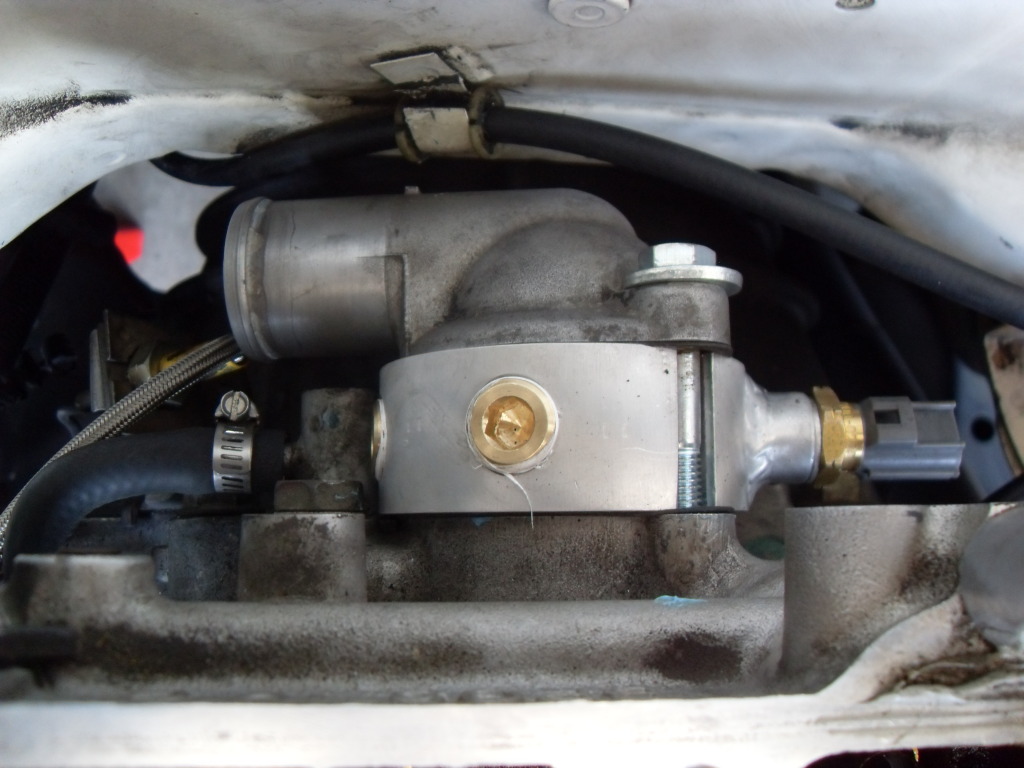

I am doing the coolant reroute on my car using the BEGi thermostat spacer on my '96 motor. Everything was going well until I tried to put the heater hose on. I found that the heater hose barb was hitting transmission bell housing  . I've got a few ideas how to fix it, I was just wondering if anyone else has had this issue?

. I've got a few ideas how to fix it, I was just wondering if anyone else has had this issue?

Looking at picture, my fittings maybe machined a little off from the slots for the bolts a few degrees. I'm going to try to tap the hole a little further and make sure that the housing is clocked as far as a I dare when I tighten down everything.

. I've got a few ideas how to fix it, I was just wondering if anyone else has had this issue?

. I've got a few ideas how to fix it, I was just wondering if anyone else has had this issue?Looking at picture, my fittings maybe machined a little off from the slots for the bolts a few degrees. I'm going to try to tap the hole a little further and make sure that the housing is clocked as far as a I dare when I tighten down everything.

#5

Elite Member

Thread Starter

iTrader: (15)

Join Date: Jan 2007

Location: Murfreesboro,TN

Posts: 2,042

Total Cats: 265

Thanks Adam for your blog. I've used it a as a reference on this project. I took my assembly and lined it up with your picture and its appears mine is a few degrees off from yours (though the barb had as many threads showing).

Unfortunately, I galled the threads up messing with it yesterday, so I'm going to have to take the spacer to the machine shop at work anyway. I'm going to get them to tap it a little further and maybe open up the slots some more so I can clock over a few more degrees.

Unfortunately, I galled the threads up messing with it yesterday, so I'm going to have to take the spacer to the machine shop at work anyway. I'm going to get them to tap it a little further and maybe open up the slots some more so I can clock over a few more degrees.

#6

Now that you mention tapping, I remember also having to do that. I could only thread mine in like 2 threads. Years ago, I got pissed off having to run to the hardware store every time I needed a tap, so I splurged on a master set. It's nice to have every tap at hand. I don't even think about cleaning threads now, so it slipped my mind to type about it on my site.

Get those threads opened up and you should be in business.

Get those threads opened up and you should be in business.

#7

Elite Member

Thread Starter

iTrader: (15)

Join Date: Jan 2007

Location: Murfreesboro,TN

Posts: 2,042

Total Cats: 265

Yeah. I was only using about 3 threads on the barb. Luckily the company I work for has a machine shop for tool and die maintenance and manufacture. I think once everything is said and done, I'll send Begi and email about the issues I had.

#8

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,181

Total Cats: 1,133

These are the threads you're supposed to use sealant on. Not only does it help seal the threads, but it lubricates them so you can tighten them further and get a better seal. Some say that's it's main purpose.

And I prefer teflon goo to the tape.

And I prefer teflon goo to the tape.

#9

Elite Member

Thread Starter

iTrader: (15)

Join Date: Jan 2007

Location: Murfreesboro,TN

Posts: 2,042

Total Cats: 265

Yeah, I tried tape the first time. I thought maybe that is what was keeping me from threading the barb all the way in. So I removed it, cleaned the threads and stupidly didn't lubricate the threads the 2nd time (which galled the threads). Although I didn't get it to thread any deeper. Next time, I'll put a little dab of thread sealer on it.

#11

Great spacer, Adam had inspired me. I had a few problems with mine but Stephanie took care of everything. My threads seemed to be a tad to tight, I had actually rounded one of the plugs when I was installing (the allen head plug) so I had to take a grinder and smooth it out so it wouldn't hit the trans. Much easier to install with the engine/trans out of the car rather than fighting with the firewall.

#15

I had no issues with the threads on my BEGI spacer. The only downside I see to NPT is that it requires both the fabricator and the assembler to have a clue what they're doing. I work in the machine shop of an engineering firm that builds million dollar robotic systems for the big automotive manufacturers, and it's extremely rare that we use something other than NPT or one of it's derivatives. And these machines are made to reliably run 24/7 for years at a time. Not saying they're the best/only option, but I've had no complaints/issues using properly installed NPT stuff on my cars.

#18

Elite Member

iTrader: (2)

Join Date: Jan 2007

Location: Los Angeles, CA

Posts: 8,682

Total Cats: 130

Wow, my begi spacer has the positioning of everything totally different. What a surprise.

My extra temp sensor bung is 180* opposed from the other fittings. It uselessly points down at the bellhousing.

Ugh

My extra temp sensor bung is 180* opposed from the other fittings. It uselessly points down at the bellhousing.

Ugh

#19

My spacer is exactly the same but I mounted it flipped over from what's in the picture. Aka, the face that's currently touching his tstat housing is touching my cylinder head. The raised bung with the temp sensor is at the top, the one beside it (with the heater hose barb in his picture) is plugged, the one that's on top in his picture is the one that I used for the heater hose, and the other port is plugged and pointing straight down at the bellhousing. The heater hose points straight out the side, just like stock.

#20

Elite Member

Thread Starter

iTrader: (15)

Join Date: Jan 2007

Location: Murfreesboro,TN

Posts: 2,042

Total Cats: 265

My educated guess is that they didn't want the stock sensor to close to the top of the spacer for fear of getting an air bubble trapped in there.

Although I do have access to both aux ports for extra sensors (still using stock oil cooler and throttle body defrost), where I noticed that Adam mentioned one of his aux ports was directly behind the fitting.

Although I do have access to both aux ports for extra sensors (still using stock oil cooler and throttle body defrost), where I noticed that Adam mentioned one of his aux ports was directly behind the fitting.