Honda Intake - No welding req

#22

Great looking project! I hope the dyno results match or exceed your expectations.

A few questions...

1. What alloy did you use for the new flange?

2. Can you share details of the weld process which you used?

I assume TIG welded...?

Any special prep or post treatment (ex: heating components before welding)?

What welding machine did you use and what were the (approximate) settings (ex: amps, volts)?

3. Would you be able/willing to share the CAD file for the flange?

Please let us know how the dyno sessions go!

Thanks

A few questions...

1. What alloy did you use for the new flange?

2. Can you share details of the weld process which you used?

I assume TIG welded...?

Any special prep or post treatment (ex: heating components before welding)?

What welding machine did you use and what were the (approximate) settings (ex: amps, volts)?

3. Would you be able/willing to share the CAD file for the flange?

Please let us know how the dyno sessions go!

Thanks

#23

Great looking project! I hope the dyno results match or exceed your expectations.

A few questions...

1. What alloy did you use for the new flange?

2. Can you share details of the weld process which you used?

I assume TIG welded...?

Any special prep or post treatment (ex: heating components before welding)?

What welding machine did you use and what were the (approximate) settings (ex: amps, volts)?

3. Would you be able/willing to share the CAD file for the flange?

Please let us know how the dyno sessions go!

Thanks

A few questions...

1. What alloy did you use for the new flange?

2. Can you share details of the weld process which you used?

I assume TIG welded...?

Any special prep or post treatment (ex: heating components before welding)?

What welding machine did you use and what were the (approximate) settings (ex: amps, volts)?

3. Would you be able/willing to share the CAD file for the flange?

Please let us know how the dyno sessions go!

Thanks

2. I didn't weld it, I had a friend weld it. I know he used a TIG and had to put the flange and manifold in an oven due to the thickness. Other than that I think good welding is more art / magic than settings. I'm thinking of taking a welding class as it would be nice to be able to do this sort of stuff myself.

3. Sure, CAD file is here: https://lastpixel.box.com/s/vwdgkpy6...hd984iew4my92a

One thing to note, this is for a BP engine, also when it was welded the flange shrunk a little lengthways. This just meant I had to file the holes a little. Also the ports on this CAD file are to suit by head which is ported to match the gasket. The version "NA8_Intlet_Flange_For_Honda.DWG" is slightly modified so that the widths of the end ports are reduced 3mm so that they can be ground on an angle once the runners are welded on.

Dyno is tomorrow or Wednesday. I'll report back when it's done.

here are a few pics of it all mounted up and ready to go. I still need to tidy up the wiring, it's just temporary to get me through to the dyno.

#25

Works fine for me, but I may have been lucky. I only did it cause the radiator was cheap and I hadn't read up on cooling on the forums. I figured if my car was cool with the thin stock NA6 one then a thicker smaller one would be fine. There's been a bit of discussion about it in the cooling thread but generally I wouldn't put one in a street car. My car happens to be balanced, but this may have been a fluke between radiator sizing, engine heat output and coolant flow.

Tracking my car on hot days (35 deg C) I see a max of around 92 deg C in the logs. That with 4 very fast WOT laps, but looking at the graph it would sit there forever.

- My car is used for sprints and track work only.

- Engine has a simple coolant re-route, no heater, no thermostat, oil cooler.

- Radiator is a Honda ASI radiator which seems to work very efficiently.

- The radiator is ducted in on the LHS, RHS is where I'll built an airbox but at the moment it's a void.

Tracking my car on hot days (35 deg C) I see a max of around 92 deg C in the logs. That with 4 very fast WOT laps, but looking at the graph it would sit there forever.

#26

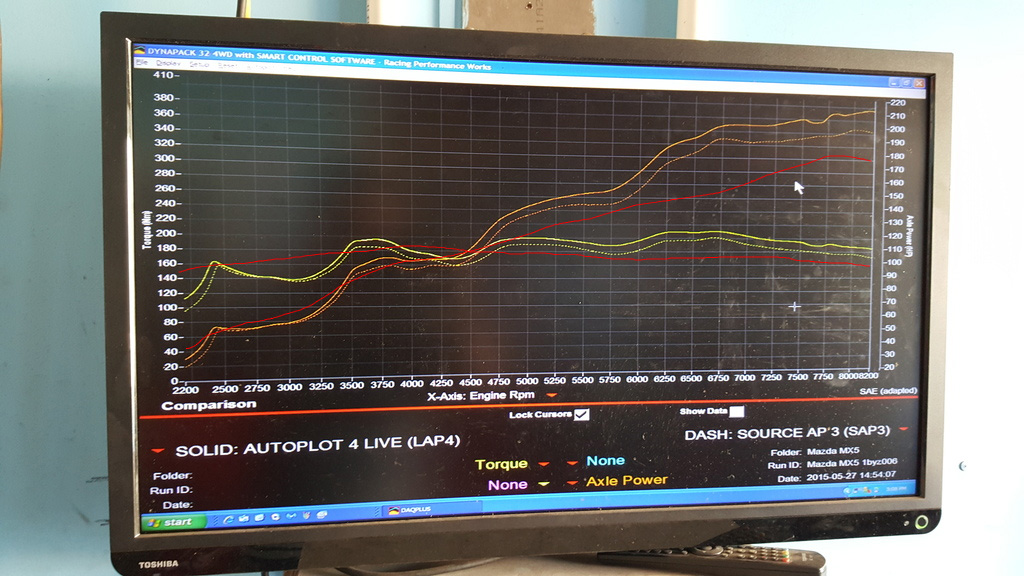

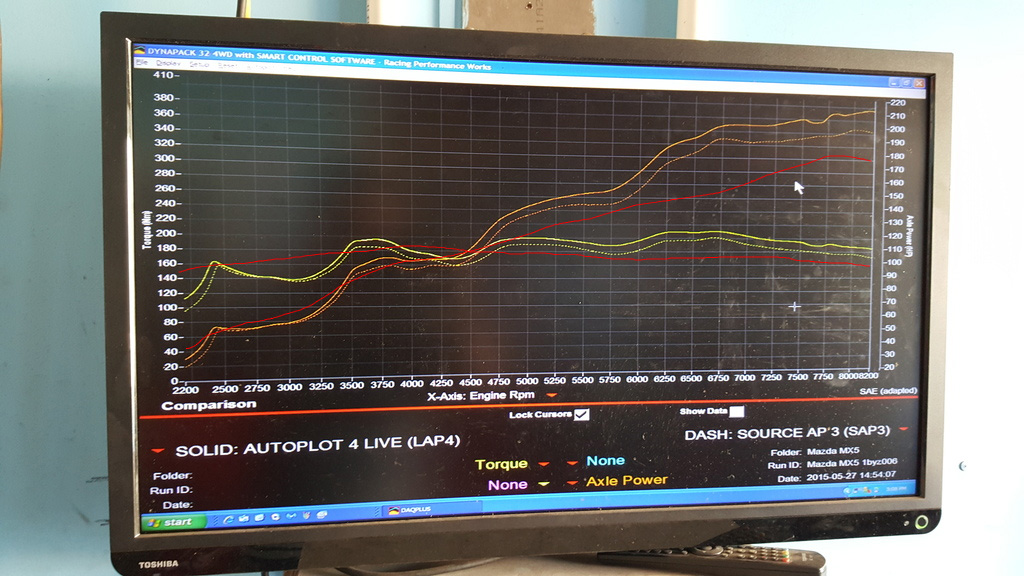

Dyno results are in...

Solid Line is E85

Dashed Line is 98 octane (95 Ron?)

Red overlay is the stock manifold (*Estimated from previous dyno - Dec 2014)

The engine really needed to run to 8500 rpm to get max power, it was still ramping up above 8000... reving to 8200 on the dyno was high enough for me.

My old IM (red line) made pretty much 180HP @7800 with a dead linear power curve. It tailed off above 7800 and had nice rounded top. Torque curve was very flat but trailed off at the upper revs.

New Honda manifold combined with very large cams causes a lot of manifold pressure fluctuations throughout the curve. This made tuning very difficult and you can see the lumps still final dyno graph. The Honda manifold looks really good from the 6250 through to 8200 where it has really flattened off the power graph. At 6750 I think I'm making over 40HP more than stock manifold (50HP on e85). The highest we saw on the various runs was around 215HP on e85.

All up this is much better than I had expected. Given I'm reving between 6000-8000 in most events this should give me a lot more power than previous.

Next event is this weekend so I'll report back once I've actually driven the car.

Solid Line is E85

Dashed Line is 98 octane (95 Ron?)

Red overlay is the stock manifold (*Estimated from previous dyno - Dec 2014)

The engine really needed to run to 8500 rpm to get max power, it was still ramping up above 8000... reving to 8200 on the dyno was high enough for me.

My old IM (red line) made pretty much 180HP @7800 with a dead linear power curve. It tailed off above 7800 and had nice rounded top. Torque curve was very flat but trailed off at the upper revs.

New Honda manifold combined with very large cams causes a lot of manifold pressure fluctuations throughout the curve. This made tuning very difficult and you can see the lumps still final dyno graph. The Honda manifold looks really good from the 6250 through to 8200 where it has really flattened off the power graph. At 6750 I think I'm making over 40HP more than stock manifold (50HP on e85). The highest we saw on the various runs was around 215HP on e85.

All up this is much better than I had expected. Given I'm reving between 6000-8000 in most events this should give me a lot more power than previous.

Next event is this weekend so I'll report back once I've actually driven the car.

#29

Yeah it probably would but I don't like turbos...

I run in an under 2000cc production sports class against Honda, lotus, toyota 86 GT etc. Put a turbo or sc on and I'm in a Group A class against exotics... like a supercharged lotus @600+ HP and very lightened race cars. This car is quicker than most turbo mx5s on the courses I run. On the track drivability trumps power.

I run in an under 2000cc production sports class against Honda, lotus, toyota 86 GT etc. Put a turbo or sc on and I'm in a Group A class against exotics... like a supercharged lotus @600+ HP and very lightened race cars. This car is quicker than most turbo mx5s on the courses I run. On the track drivability trumps power.

#31

One thing to note is that while the throttle cable bolts on perfectly and fits into the Honda throttle body, the throttle wheel is a smaller diameter than the Mazda one. Enough that accelerator movement is reduced to 2/3rds. This combined with the larger diameter throttle body will make the throttle a lot more sensitive. I haven't driven the car yet but I suspect it will have some impact on throttle control.

There may be larger ones I could source from a different throttle body, however for now I'm just going to machine up my own.

There may be larger ones I could source from a different throttle body, however for now I'm just going to machine up my own.

#32

Here is a video of the car running on a hill climb. Excuse the bad start and dodgy shifting but it was only the second run after changing to the Miata Roadster short shifter and 5th wasn't in the same spot as usual. My final run was a bit over 1 second quicker but the batteries died on the gopro.

Albany Windfarm 2015: https://youtu.be/4BCfCiIE3HU

Albany Windfarm 2015: https://youtu.be/4BCfCiIE3HU

#34

After driving the car I don't think I noticed any difference in throttle control. I suppose you can adjust to 25% less pedal movement easily enough, although if you watch the vids you can see I'm over reving when heel and toeing under brakes. It wouldn't take long to get used to it though.