Decking Plate / Head Porting

#1

Senior Member

Thread Starter

iTrader: (3)

Join Date: May 2008

Location: Fargo, ND

Posts: 533

Total Cats: 3

So, Don't hate me if it is listed and I couldn't find it which is way possible... But I'm trying to figure out if anyone around here uses a decking plate (not 100% on the term) which as far as I understand is a piece of steel that one has machined to bolt onto the block for boring, so that it mimics the torque of the head on the block, and will give you near perfectly round cylinder bores, better numbers for your compression test, and limit chances of blow-by.

I know when I was a part of the 16v VW community we had a guy in Ohio who had spent about $400 to get one machined and he rented it out to me for $50 plus deposit, which was nice, and it made a lot of difference as far as oil went, not a drop between oilchanges. Anyway, looking to see if anyone has one or if I should make one?

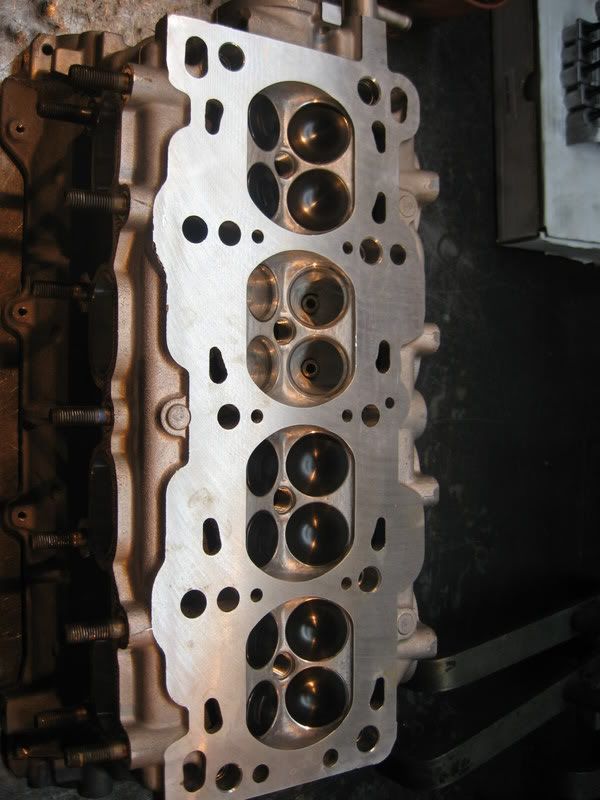

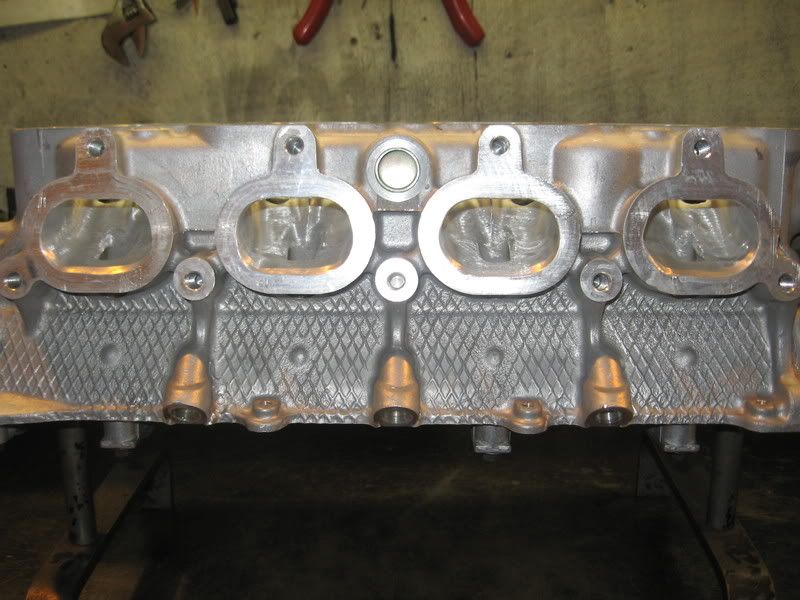

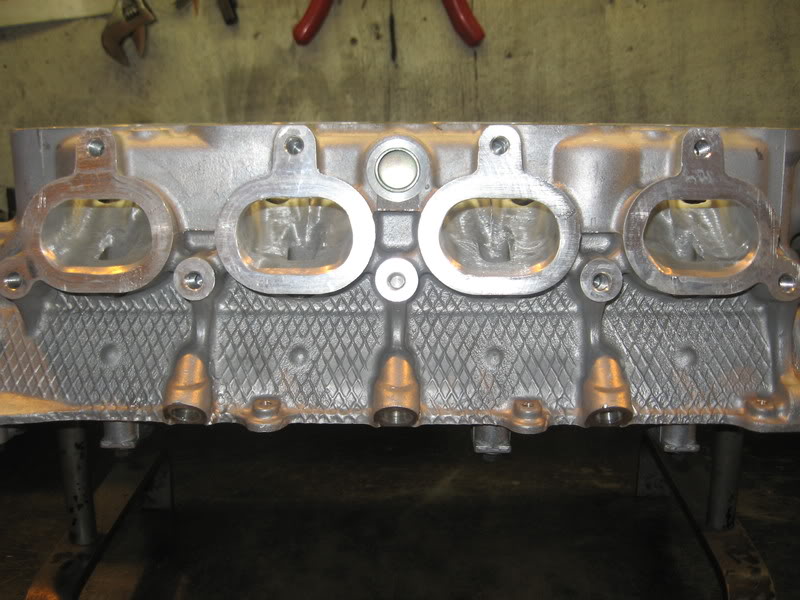

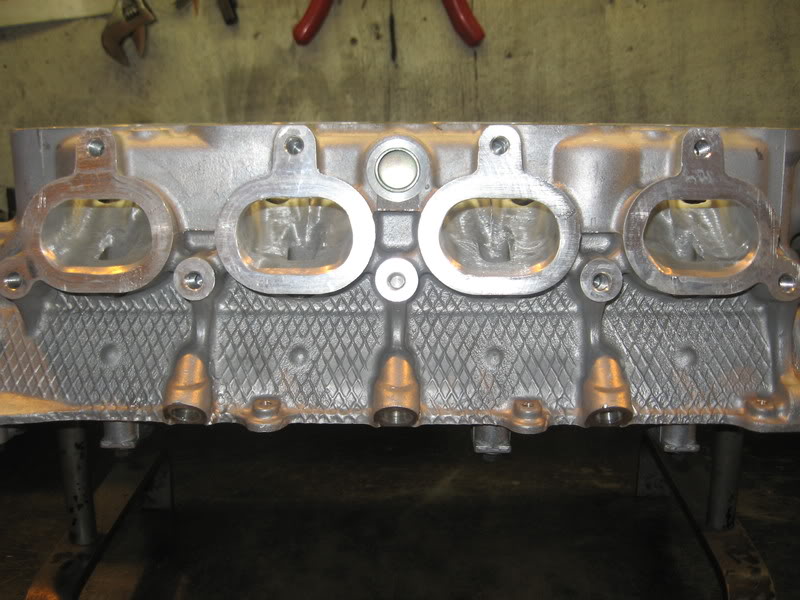

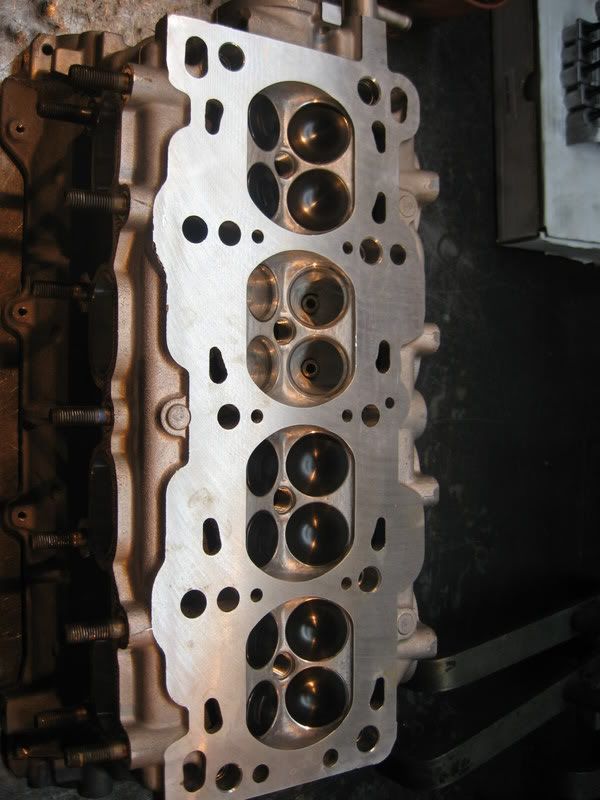

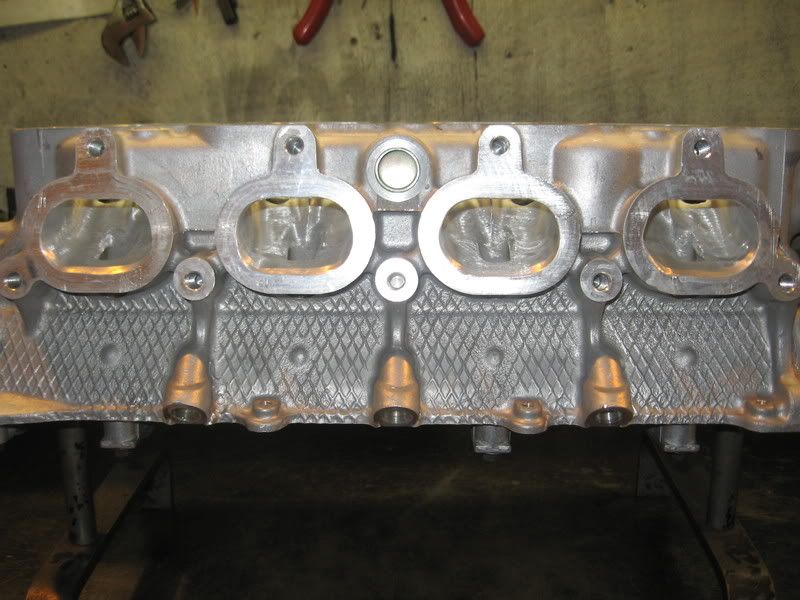

And also, has anyone dealt with porting our heads? I've got an msm, which is near identical to the 99 head in that it has no vvt with it. Just looking to see what sort of gains are possible and what a good shop would be to get it done at. I'm not confident enough to do it myself due to the sensitivity of the port sizes on the bp engine.

Anyway, this is all premeptive, as I still need management and another 20k miles on the engine before I can justify starting my rebuild, but parts are accruing.. I know, I know, god forbid anyone actually plan an engine build.

I know when I was a part of the 16v VW community we had a guy in Ohio who had spent about $400 to get one machined and he rented it out to me for $50 plus deposit, which was nice, and it made a lot of difference as far as oil went, not a drop between oilchanges. Anyway, looking to see if anyone has one or if I should make one?

And also, has anyone dealt with porting our heads? I've got an msm, which is near identical to the 99 head in that it has no vvt with it. Just looking to see what sort of gains are possible and what a good shop would be to get it done at. I'm not confident enough to do it myself due to the sensitivity of the port sizes on the bp engine.

Anyway, this is all premeptive, as I still need management and another 20k miles on the engine before I can justify starting my rebuild, but parts are accruing.. I know, I know, god forbid anyone actually plan an engine build.

#3

Senior Member

Thread Starter

iTrader: (3)

Join Date: May 2008

Location: Fargo, ND

Posts: 533

Total Cats: 3

What do you think, though, have you had any experience using one? My only experience was with my vw, and I know those bastards love to suck oil past the rings, partially do to tight tolerances from the factory, and partially because its 2.0vw nature to rattle a bit. Great motor though.

If Miata's have been rebuilt this long without one, hard to say what benefit it will offer. Although, I'd guess +200 compression numbers, for starters.

#4

I've never used one although I wish I would have. If I had to do it again I would use a deck plate (if available) and ZGS rings. My builder toleranced the motor for boost so I guess it's a little "looser" but I'm getting a little more blowby than desired.

I've never looked into it but I suspect you can cut the cost of the plate substantially if you did some legwork yourself. Scrap steel is pretty cheap, and if you took it to a waterjet place to rough cut then a machinist to finish it you'd probably save some bucks.

I've never looked into it but I suspect you can cut the cost of the plate substantially if you did some legwork yourself. Scrap steel is pretty cheap, and if you took it to a waterjet place to rough cut then a machinist to finish it you'd probably save some bucks.

#5

Senior Member

Thread Starter

iTrader: (3)

Join Date: May 2008

Location: Fargo, ND

Posts: 533

Total Cats: 3

Good point. I'm also an engineering student with full access to our machine room. We don't have a ton, but I think I could rough it out myself, and probably tap holes for the studs, just the cylinder bores themselves would be the tough part. I have no idea why you would want "loose" bores in any situation, much less boosted. You could be letting (likely are, blowby) boost past the rings, stripping the oil from the bores = bad.

Where would one get ZGS rings, btw? I'm still sourcing pistons, and a few other small things.

Where would one get ZGS rings, btw? I'm still sourcing pistons, and a few other small things.

#7

LOL, I think you'll have some difficulty roughing out a 50 lb 2" thick plate of steel without the proper equipment.

It's common practice to run a performance motor with a little more piston to bore clearance than stock. Stock cast pistons expand less than forged racing pistons. Temperatures are typically higher in a boosted motor, facilitating more clearance. Wiseco recommends .001" additional clearance for boost.

Childs & Albert used to make Zero Gap Secondary rings but it looks like they went belly up. Total seal makes something similar. You can get them at Summit.

It's common practice to run a performance motor with a little more piston to bore clearance than stock. Stock cast pistons expand less than forged racing pistons. Temperatures are typically higher in a boosted motor, facilitating more clearance. Wiseco recommends .001" additional clearance for boost.

Childs & Albert used to make Zero Gap Secondary rings but it looks like they went belly up. Total seal makes something similar. You can get them at Summit.

#10

Senior Member

Thread Starter

iTrader: (3)

Join Date: May 2008

Location: Fargo, ND

Posts: 533

Total Cats: 3

Good to know they have one available.

#13

Senior Member

Thread Starter

iTrader: (3)

Join Date: May 2008

Location: Fargo, ND

Posts: 533

Total Cats: 3

Shipping won't be as bad as you think. It isn't oversized, just overweight. I would guess less than 50 to ship. Hard to say for sure. I know I just payed $30 to have two brake rotors and calipers sent via fedex, i think, or else us post. That was probably more than this plate. The components were off an audi v8 (4klbs, heavy brakes).

#14

Sorry about the terrible grammer in some of my posts,got a bunch of kids.I havent decided if I will rent it out,Ive got the sides milled down,and just need too millthe mating surfaces,To be ground.Then the bolt pattern and the bores.I have it drilled for hot water temperature correction already,Thats the way V-8 drag/race are bored

#15

Senior Member

Thread Starter

iTrader: (3)

Join Date: May 2008

Location: Fargo, ND

Posts: 533

Total Cats: 3

Grammar.

But anyway, It wouldn't be a bad idea to rent her out, after you're done to recoup some of the cost. I have never heard about the hot water correction before, I think I understand what you mean, but could you elaborate? Always good to learn something.

#18

Senior Member

Thread Starter

iTrader: (3)

Join Date: May 2008

Location: Fargo, ND

Posts: 533

Total Cats: 3

I should mention, we are destroying these hunks of metal, they won't actually go in the pipeline

Its to make sure the machine that welds them is capable of making quality welds.

#19

are you guys useing torque plates and hand honing your blocks?????, if you hand honing your not getting anywhere near a ideal finish and cross hatch nor straight concentric and properly sized bores.

i work for a performance machine shop, using them on cast iron blocks dosnt show as much as aluminum blocks, they dont stress as much. but they are a good thing to use, we have them for all the V8 stuff, i should make one for a miata, but that is an expensive peice of metal, even if it was 1" thick it would be fine, all you need is something the thickness of the deck of the the head.

as for head porting, if you want to ship you head to CT, my shop can do what ever you want as far as a miata engine, including flow testing, pm me if you want more details.

i work for a performance machine shop, using them on cast iron blocks dosnt show as much as aluminum blocks, they dont stress as much. but they are a good thing to use, we have them for all the V8 stuff, i should make one for a miata, but that is an expensive peice of metal, even if it was 1" thick it would be fine, all you need is something the thickness of the deck of the the head.

as for head porting, if you want to ship you head to CT, my shop can do what ever you want as far as a miata engine, including flow testing, pm me if you want more details.

#20

Senior Member

Thread Starter

iTrader: (3)

Join Date: May 2008

Location: Fargo, ND

Posts: 533

Total Cats: 3

are you guys useing torque plates and hand honing your blocks?????, if you hand honing your not getting anywhere near a ideal finish and cross hatch nor straight concentric and properly sized bores.

i work for a performance machine shop, using them on cast iron blocks dosnt show as much as aluminum blocks, they dont stress as much. but they are a good thing to use, we have them for all the V8 stuff, i should make one for a miata, but that is an expensive peice of metal, even if it was 1" thick it would be fine, all you need is something the thickness of the deck of the the head.

as for head porting, if you want to ship you head to CT, my shop can do what ever you want as far as a miata engine, including flow testing, pm me if you want more details.

i work for a performance machine shop, using them on cast iron blocks dosnt show as much as aluminum blocks, they dont stress as much. but they are a good thing to use, we have them for all the V8 stuff, i should make one for a miata, but that is an expensive peice of metal, even if it was 1" thick it would be fine, all you need is something the thickness of the deck of the the head.

as for head porting, if you want to ship you head to CT, my shop can do what ever you want as far as a miata engine, including flow testing, pm me if you want more details.