99/00 1.8 BP Head inspection

#1

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

I was shipped a head to inspect and go through.

Not a super fancy build, but just a solid rebuild.

The head was packaged well for shipping.

This is the inner box

Wrapped in plastic

I did not need the cam gears, but they will be cleaned and returned.

Out of the plastic.

2 layers of cardboard.

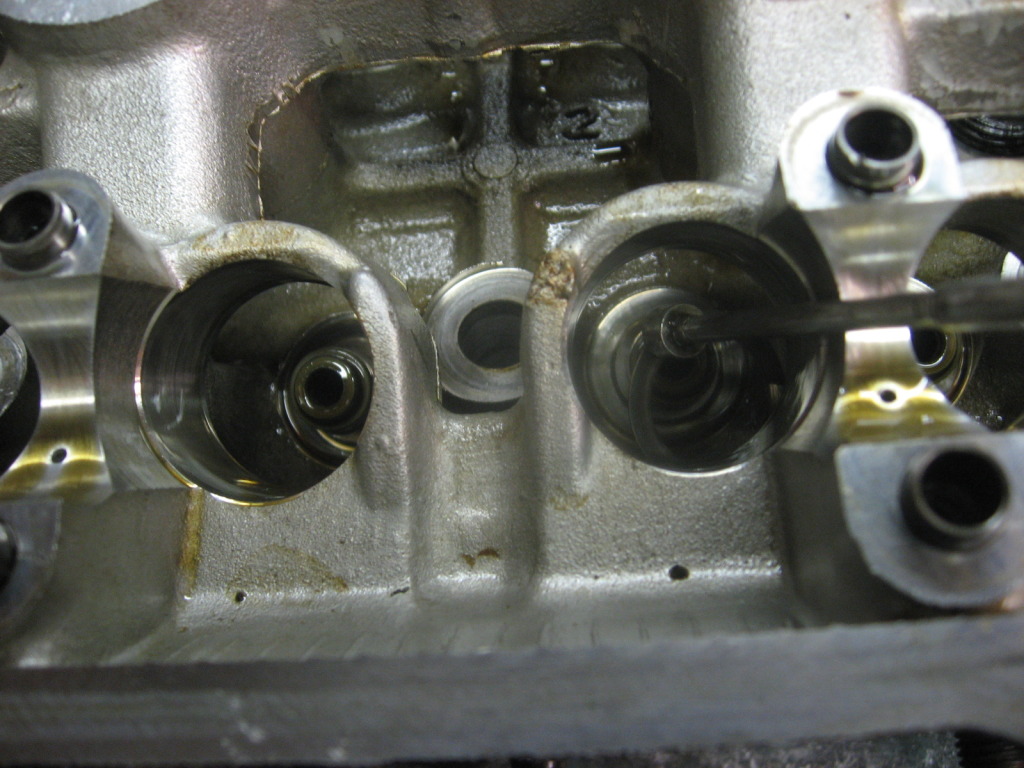

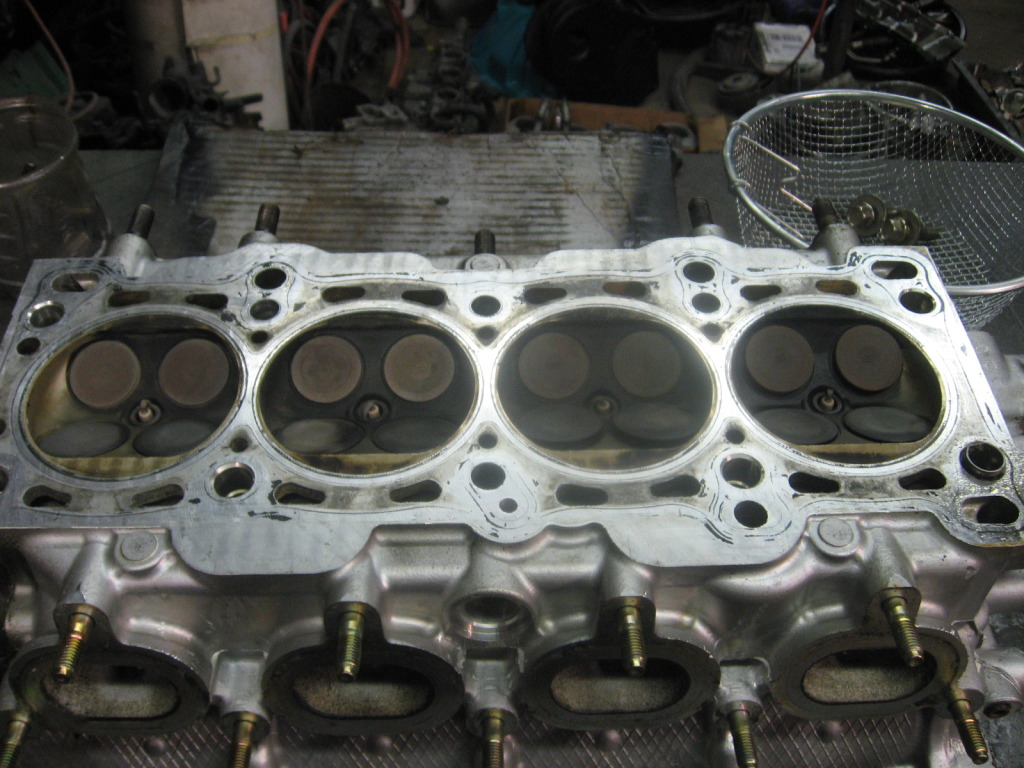

The head looks good to the eyeball, oily, but no sludge build up

The HG surface looks ok, no pitting or heavy rot

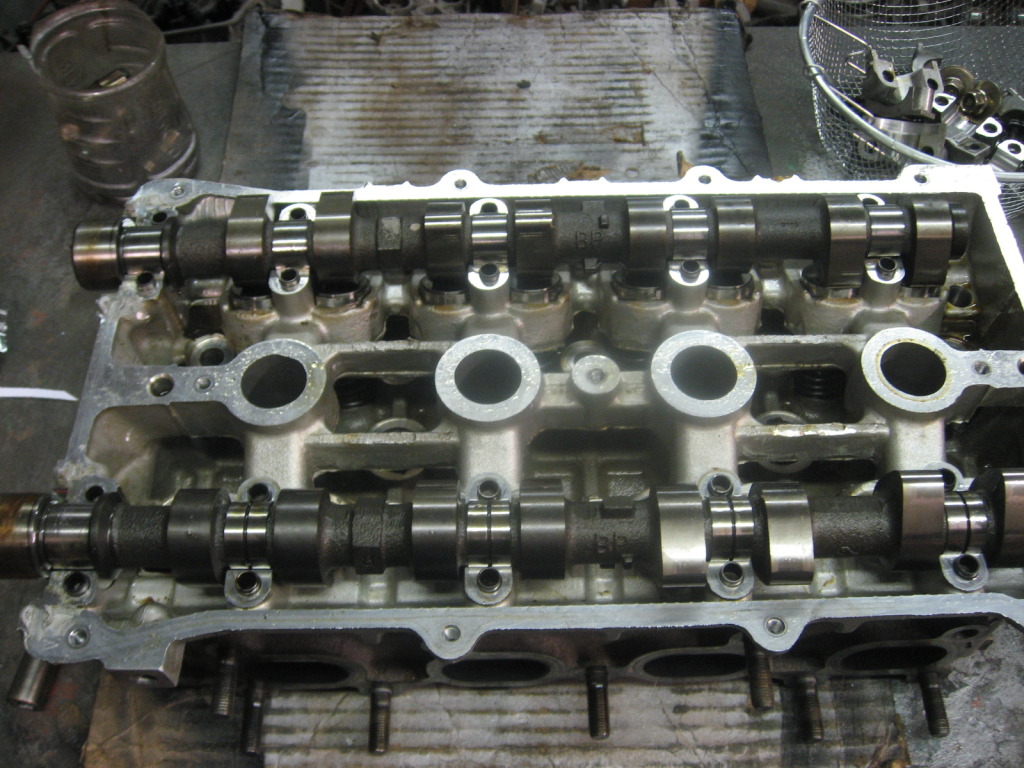

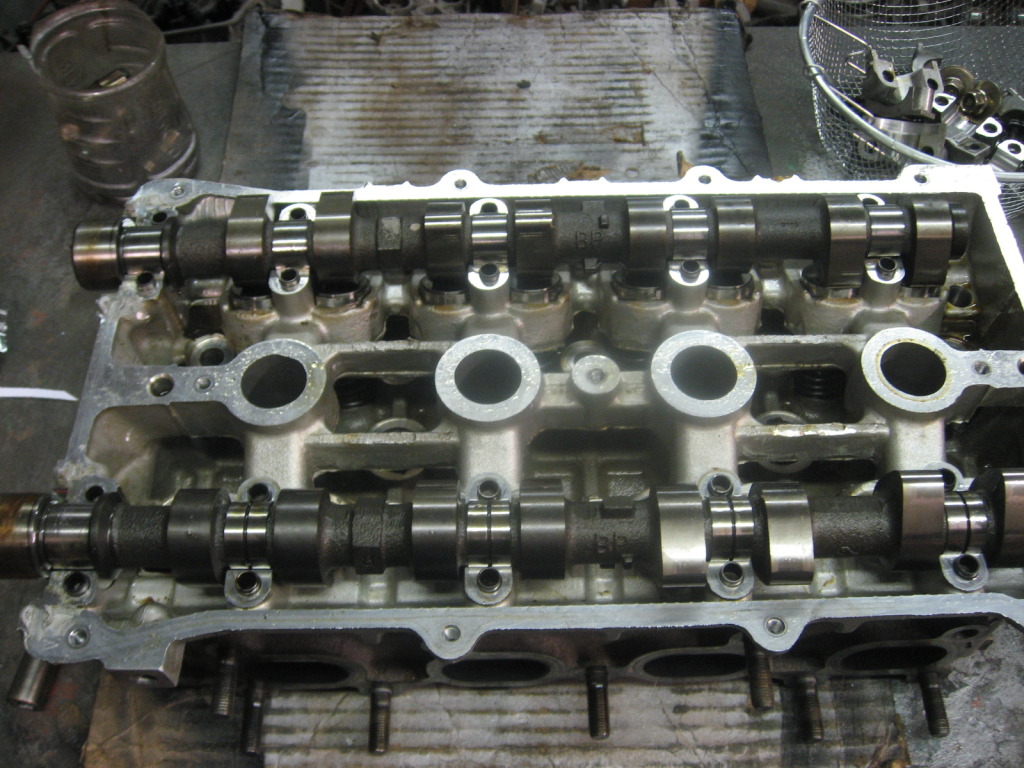

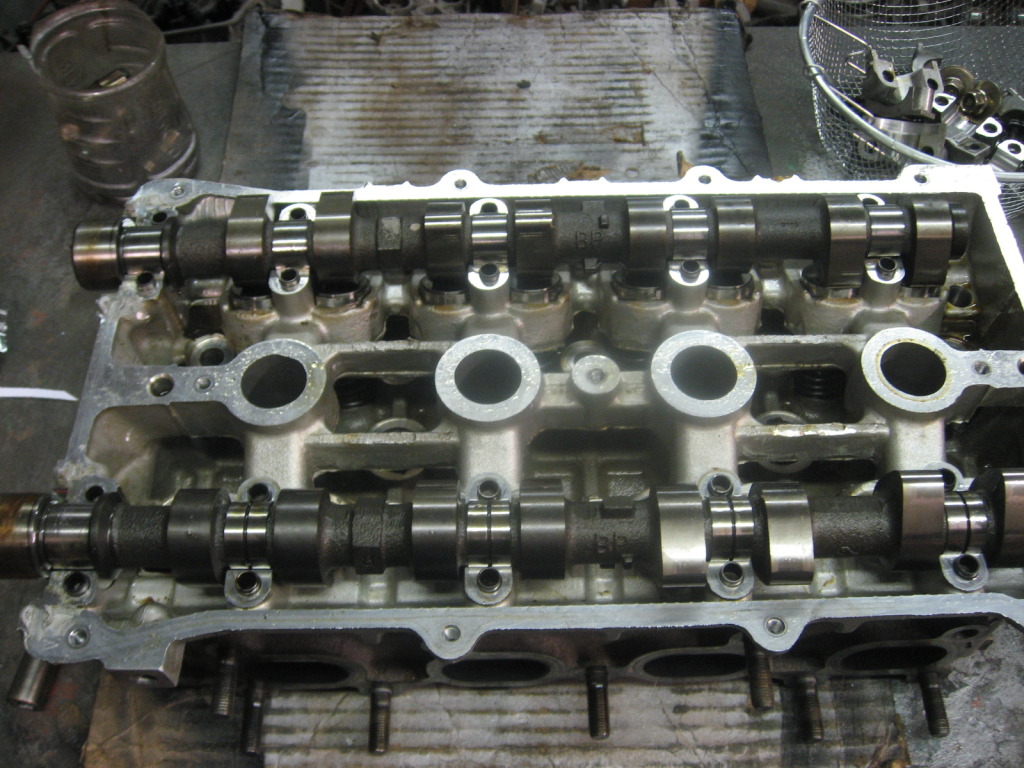

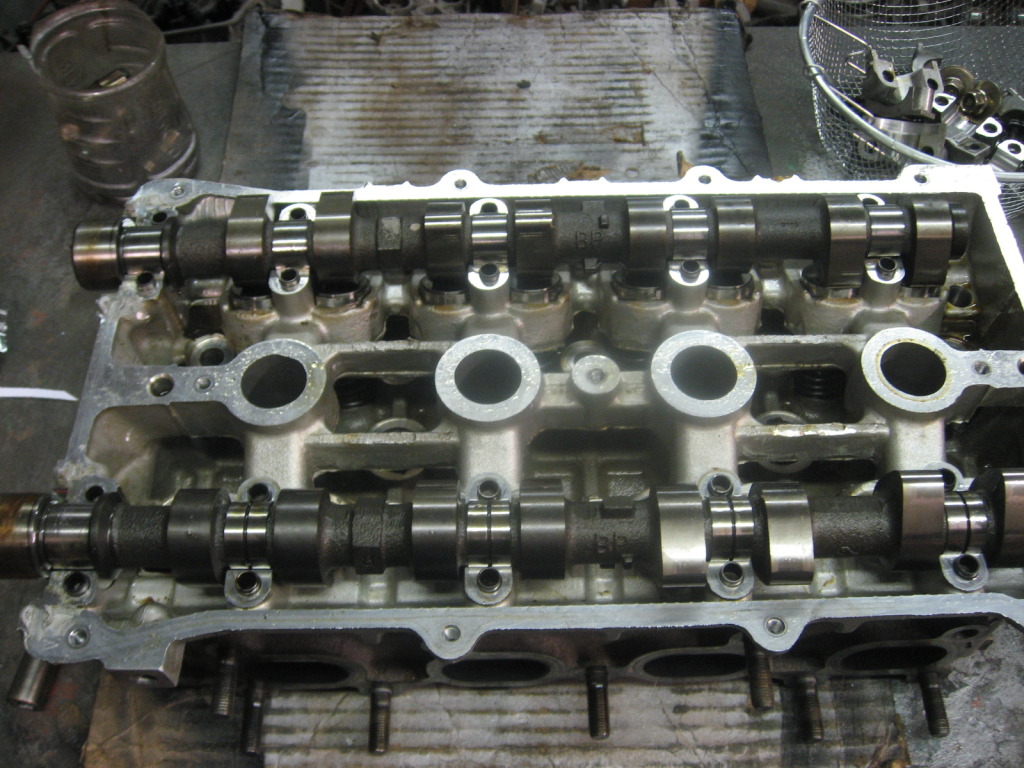

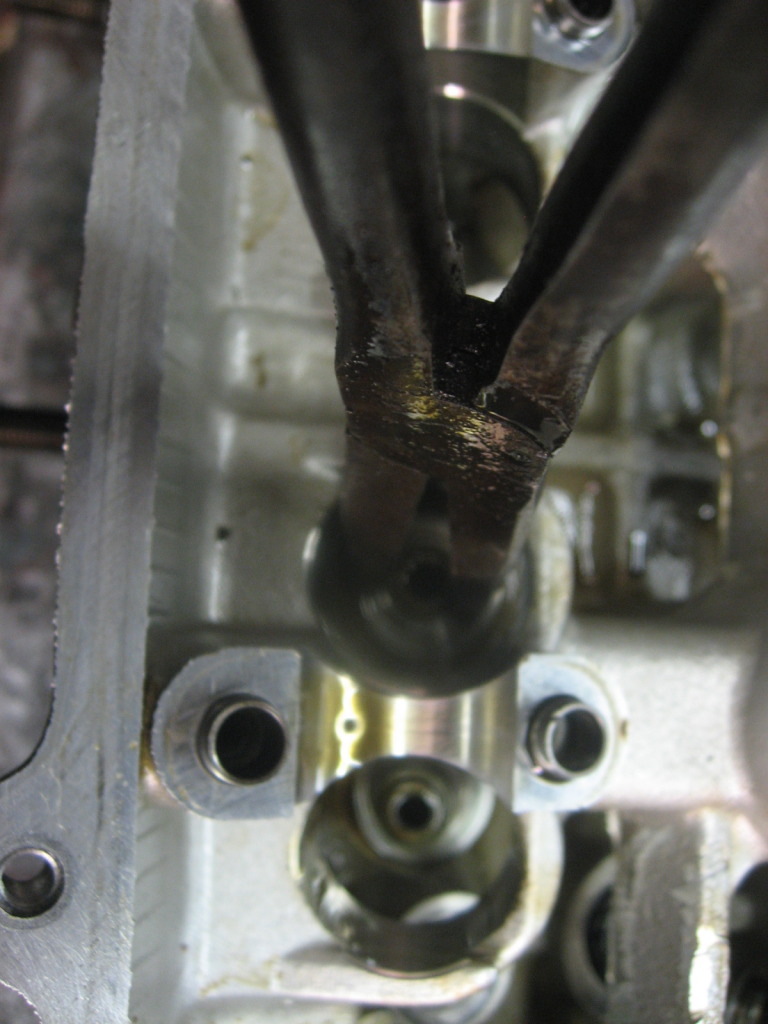

Removing the cams

The cam towers look good, no scratches or scoring

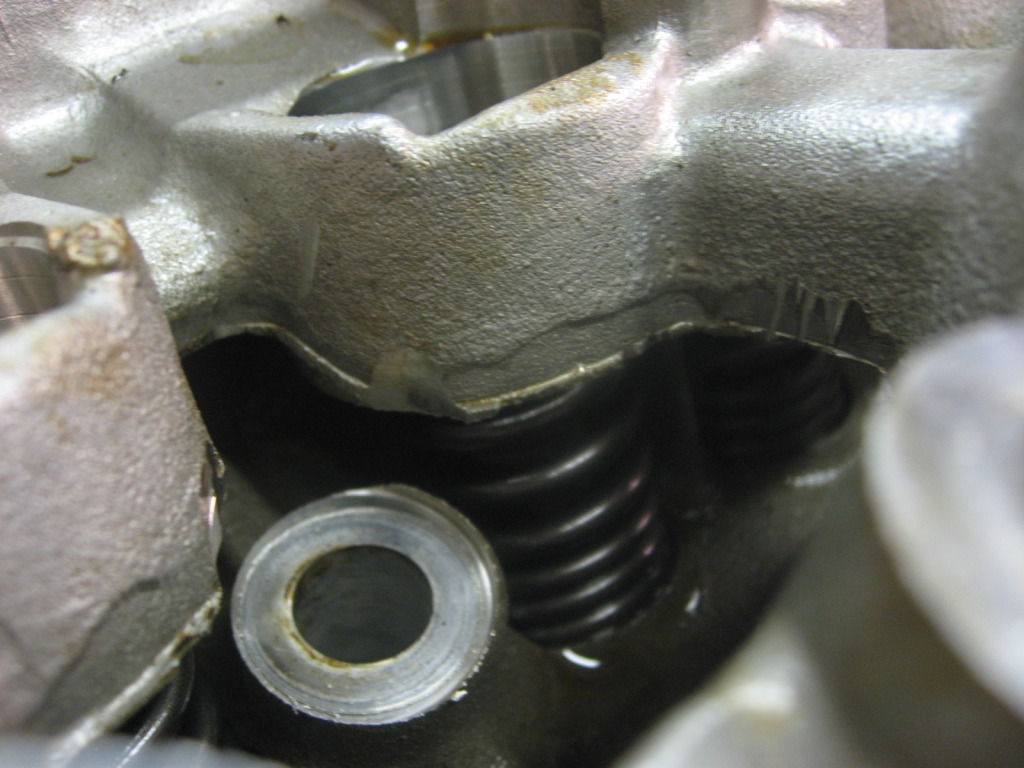

Stock springs

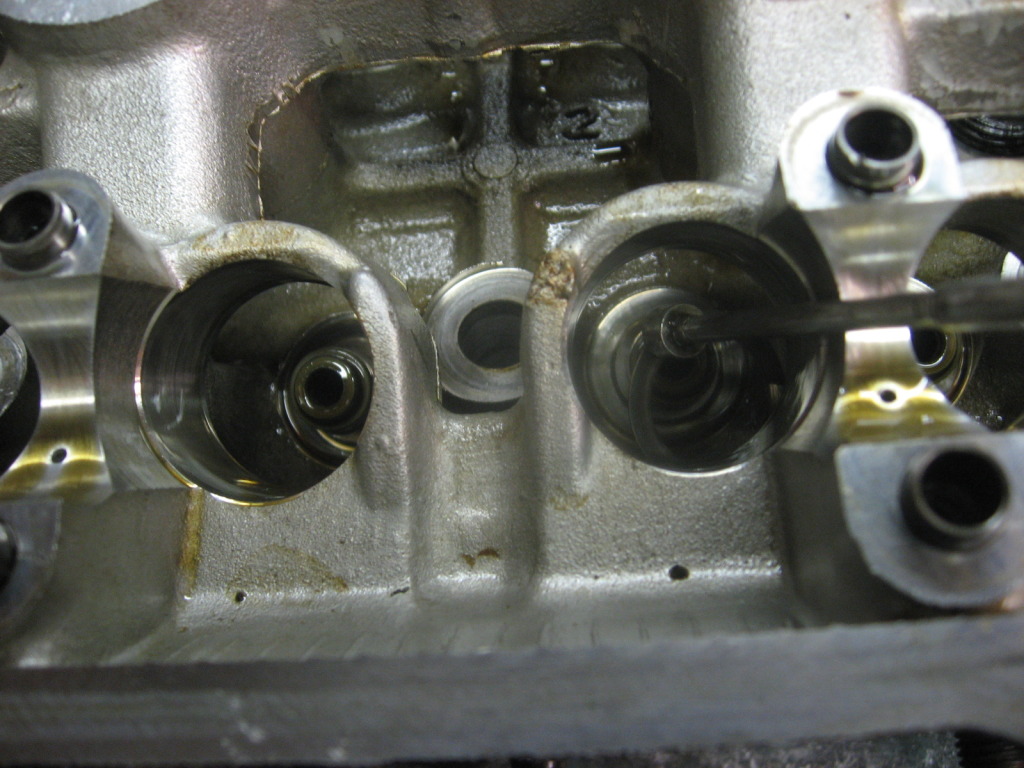

Valve springs removed

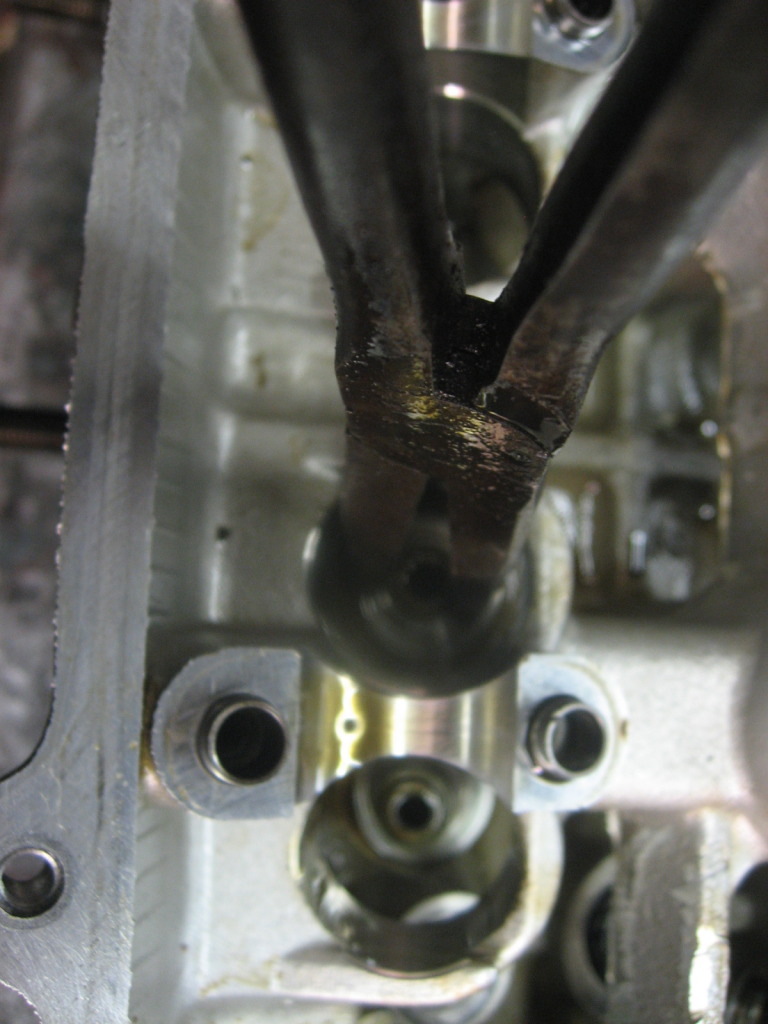

Pulling the valve stem seals

The old seals

Removing the spring shims

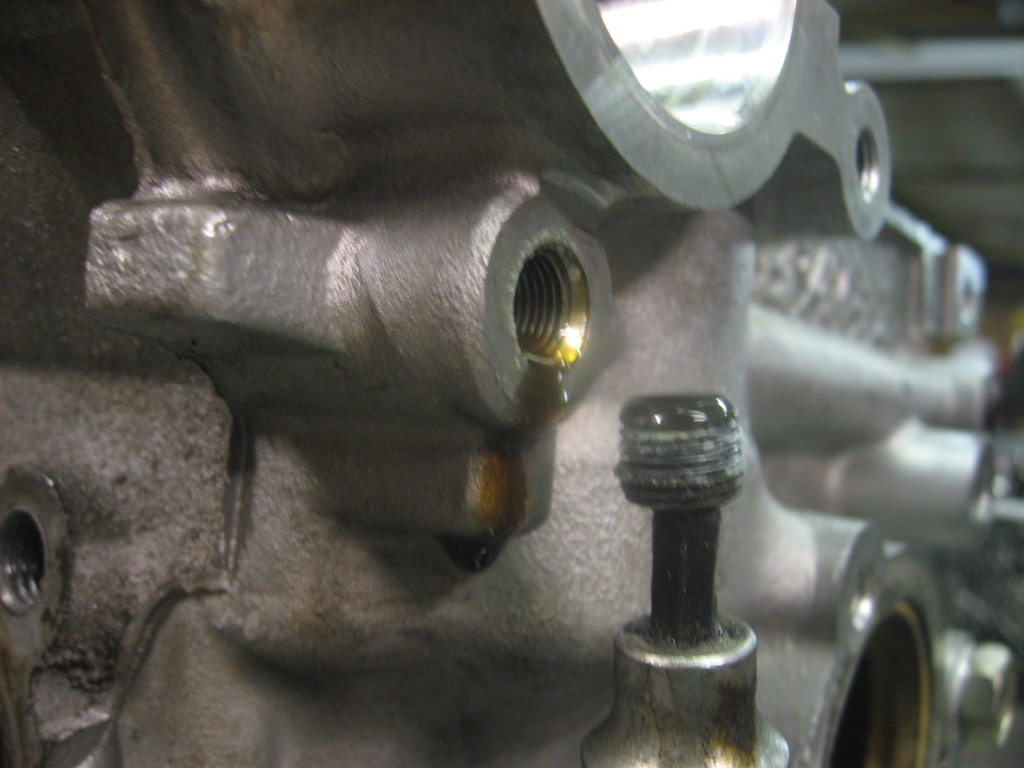

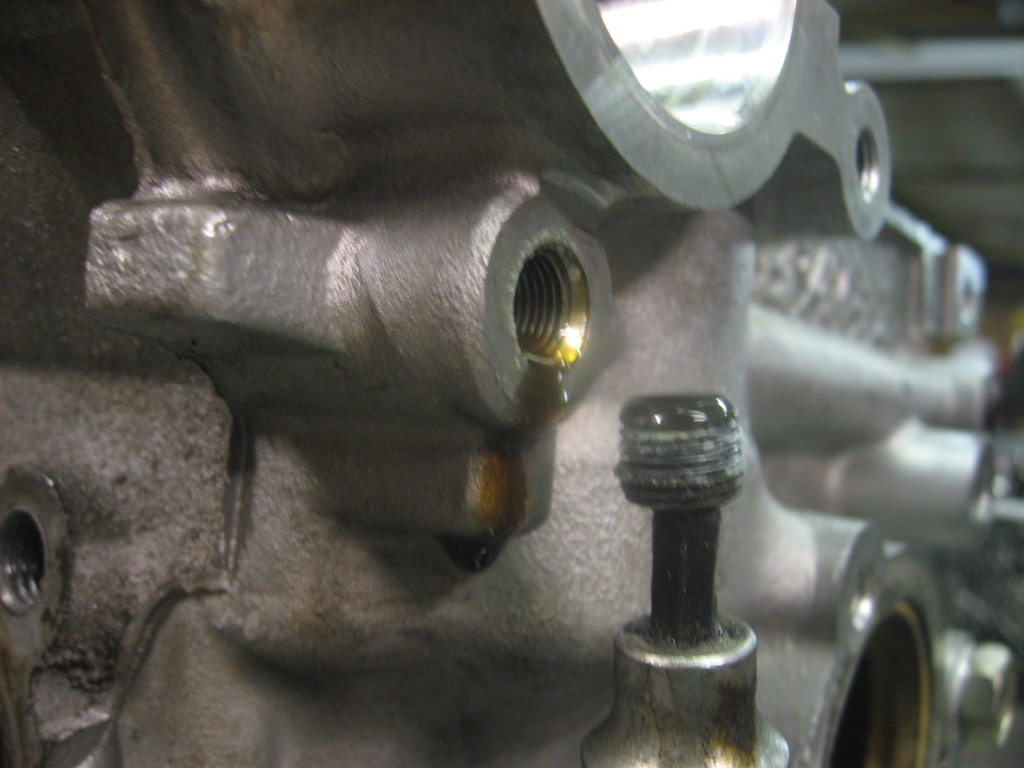

Removing the oil galley plugs

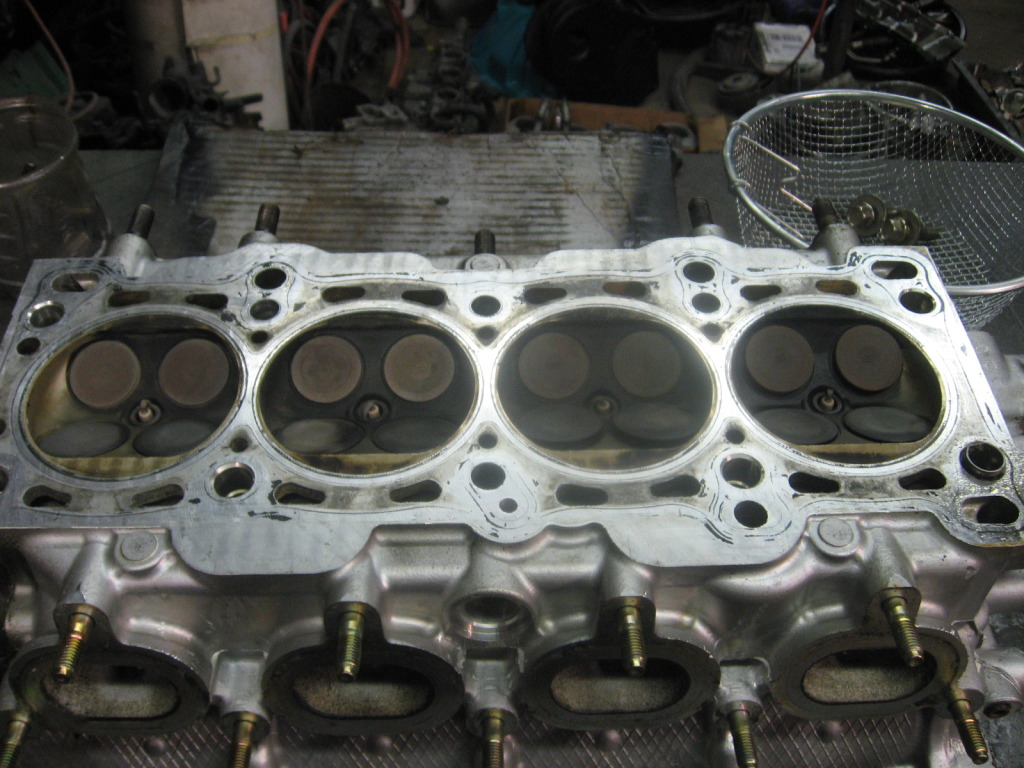

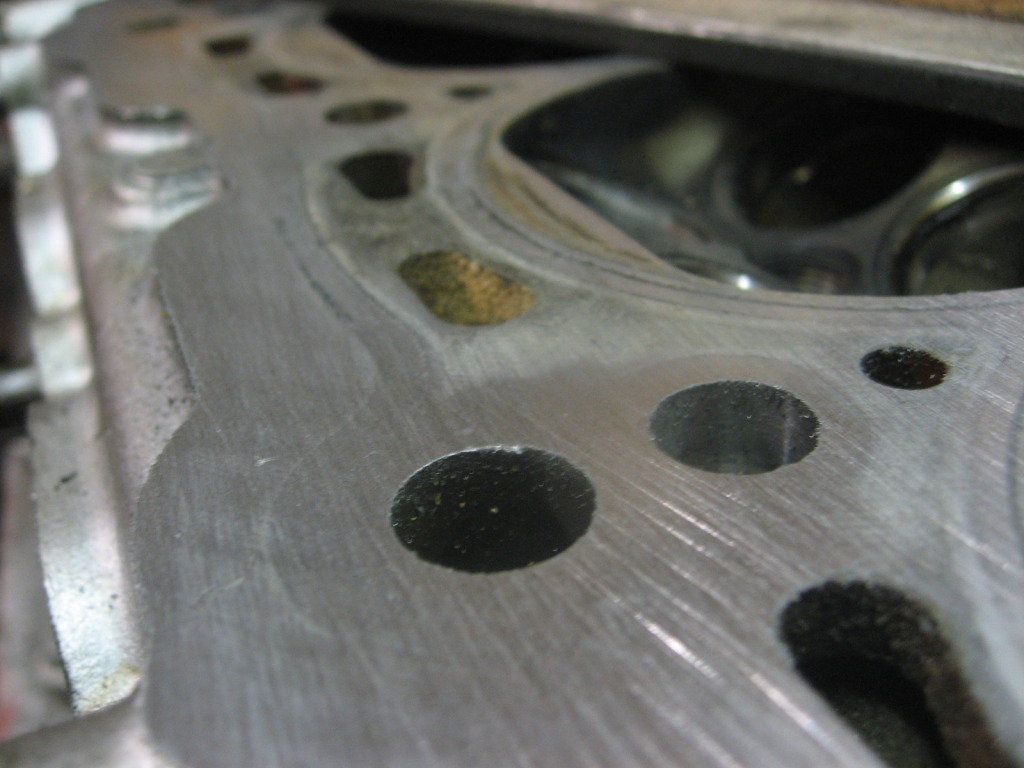

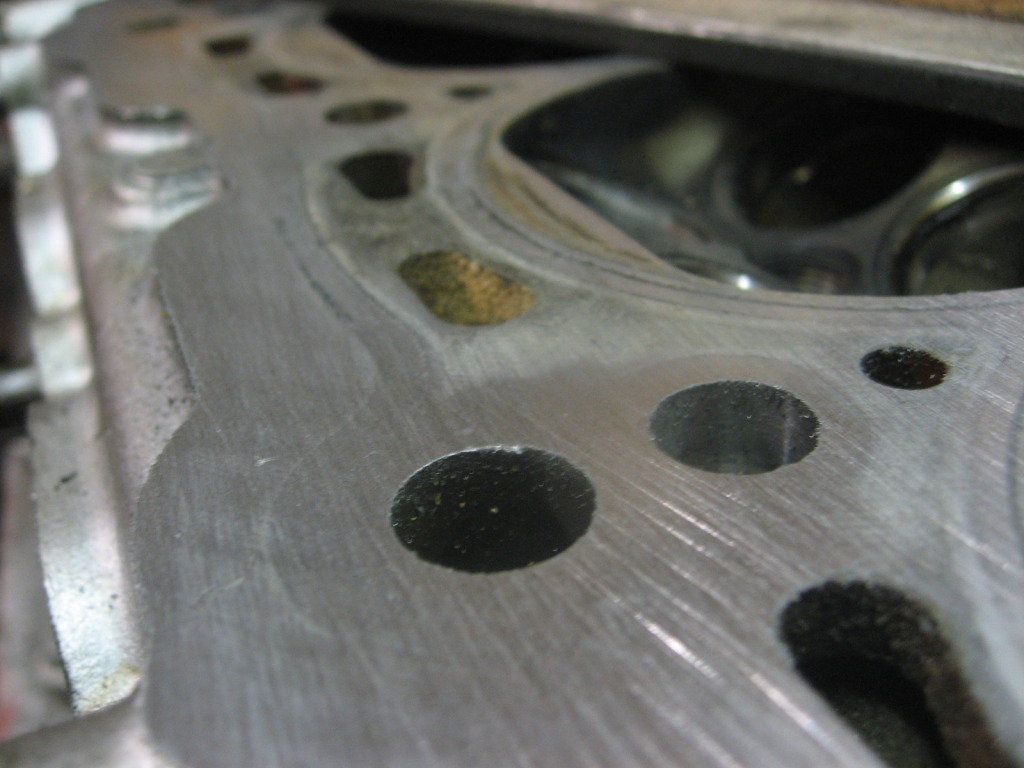

Cleaning the HG surface

The long board barely scratches the surface

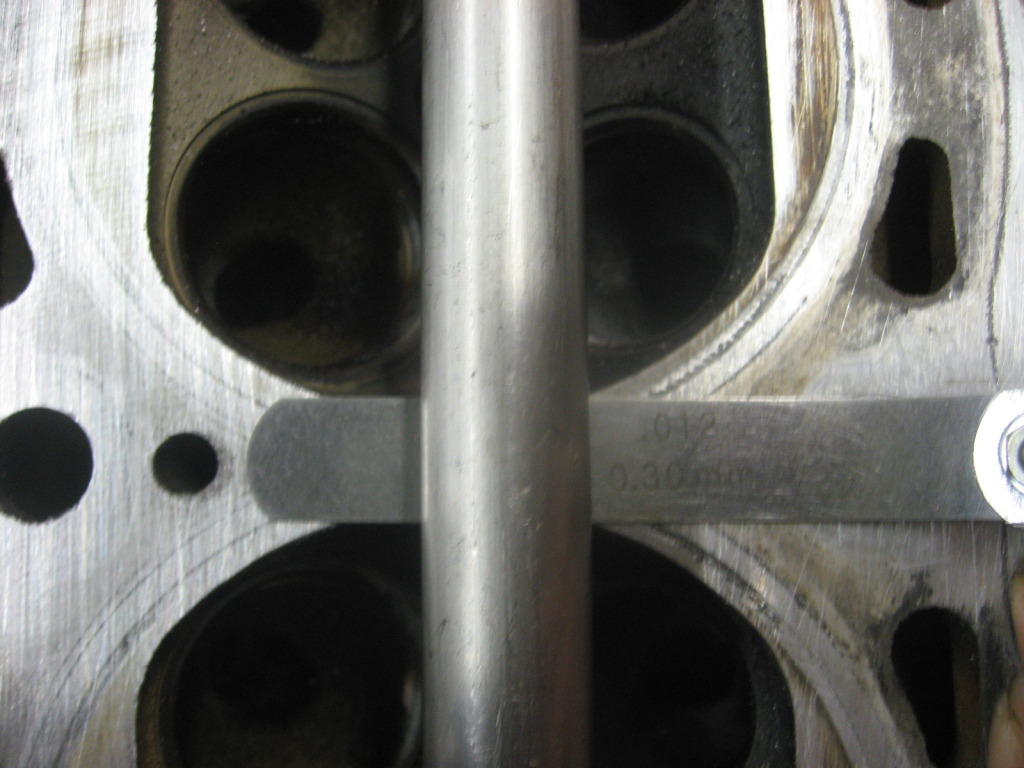

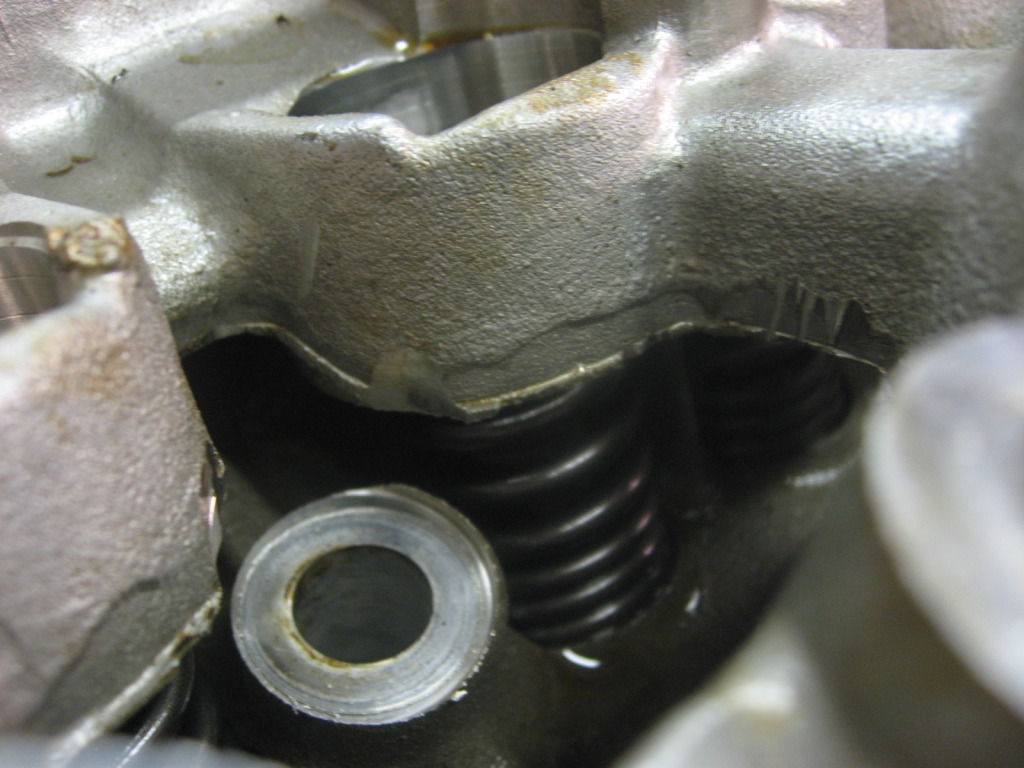

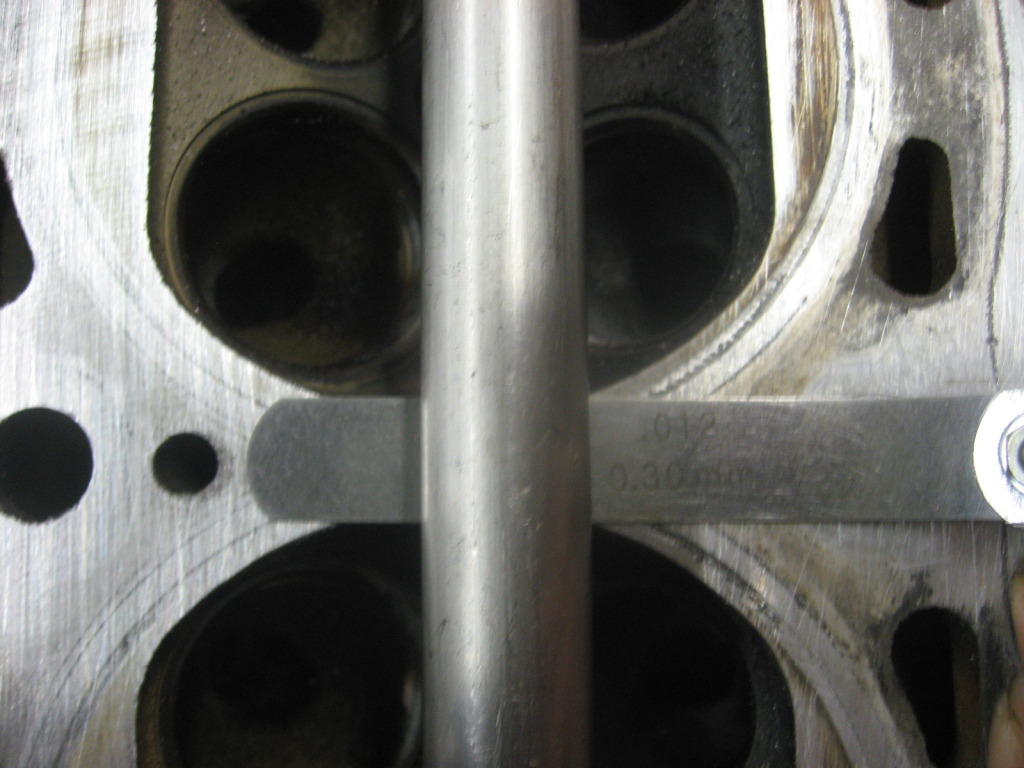

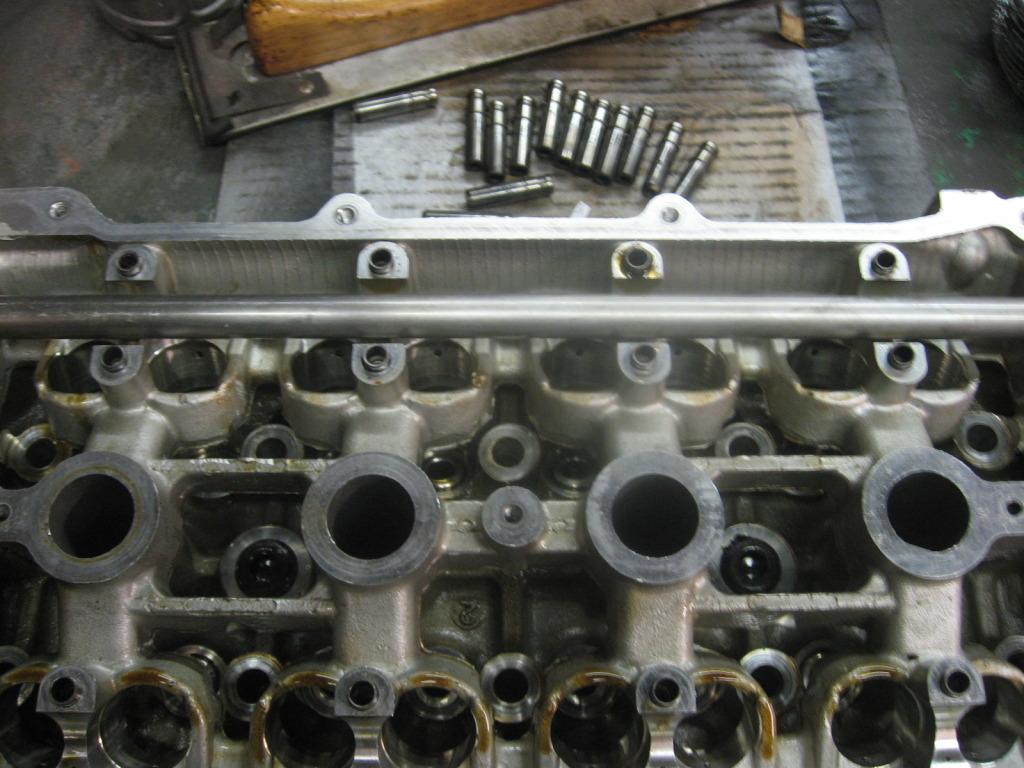

The Machinist round edge and the feeler gauge

You can see the gap, This head is warped a fair amount.

A .012 is sticky under the round bar

When the head is thremal cleaned, I will straighten at the same time.

I would like to see less than .005 once done.

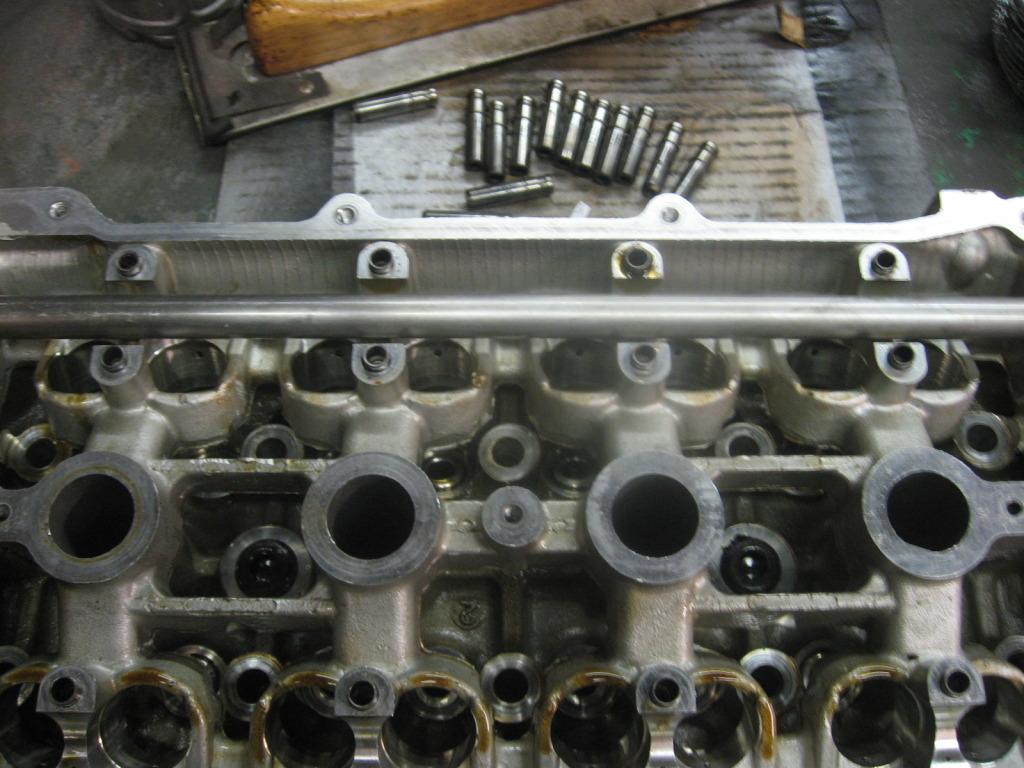

Checking the cam towers for distortion

No nocticable rock in the intake towers, minimal in the exhaust.

Ill check it again after it is straigten

More to come.....

Not a super fancy build, but just a solid rebuild.

The head was packaged well for shipping.

This is the inner box

Wrapped in plastic

I did not need the cam gears, but they will be cleaned and returned.

Out of the plastic.

2 layers of cardboard.

The head looks good to the eyeball, oily, but no sludge build up

The HG surface looks ok, no pitting or heavy rot

Removing the cams

The cam towers look good, no scratches or scoring

Stock springs

Valve springs removed

Pulling the valve stem seals

The old seals

Removing the spring shims

Removing the oil galley plugs

Cleaning the HG surface

The long board barely scratches the surface

The Machinist round edge and the feeler gauge

You can see the gap, This head is warped a fair amount.

A .012 is sticky under the round bar

When the head is thremal cleaned, I will straighten at the same time.

I would like to see less than .005 once done.

Checking the cam towers for distortion

No nocticable rock in the intake towers, minimal in the exhaust.

Ill check it again after it is straigten

More to come.....

Last edited by BogusSVO; 12-21-2012 at 08:29 PM.

#5

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

[snip]

A .012 is sticky under the round bar

When the head is thremal cleaned, I will straighten at the same time.

I would like to see less than .005 once done.

[snip]

No nocticable rock in the intake towers, minimal in the exhaust.

Ill check it again after it is straigten

[snip]

A .012 is sticky under the round bar

When the head is thremal cleaned, I will straighten at the same time.

I would like to see less than .005 once done.

[snip]

No nocticable rock in the intake towers, minimal in the exhaust.

Ill check it again after it is straigten

[snip]

Glad you're back Bogus

#6

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

Yes if you mill a head .012 it will close up the combustion chambers.

The general rule of thumb is for every .007 milled the combustion chamber looses 1cc

So time this head is milled .012 -.014 it would be 2cc smaller.

When the head is set to be straightened, Ill post up.

I have salvaged heads that have had as much as .030-.035 warp across the bottom and had .005 or so cam tower warp.

Alot shops will not straighten a head, either they do not know how, or they just do not want to.

It takes some time, and sometimes you will not get all the warp out the first time.

Just a little more machine shop voodoo to show you all is why Ill straighten this one, instead of just grabbing a core to do.

The general rule of thumb is for every .007 milled the combustion chamber looses 1cc

So time this head is milled .012 -.014 it would be 2cc smaller.

When the head is set to be straightened, Ill post up.

I have salvaged heads that have had as much as .030-.035 warp across the bottom and had .005 or so cam tower warp.

Alot shops will not straighten a head, either they do not know how, or they just do not want to.

It takes some time, and sometimes you will not get all the warp out the first time.

Just a little more machine shop voodoo to show you all is why Ill straighten this one, instead of just grabbing a core to do.

#7

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Gotcha, makes more sense now. I could see why most shops would not want to touch a DOHC head with a twist in it. I know my guy took a hell of a cut on the FE D2TE heads in my truck, but that thing needs all the compression it can get so I wasn't really worried about it.

Out of curiosity, what's the factory max recommended cut on one of these heads, and how much does it take before you start screwing with timing?

Out of curiosity, what's the factory max recommended cut on one of these heads, and how much does it take before you start screwing with timing?

#9

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

Gotcha, makes more sense now. I could see why most shops would not want to touch a DOHC head with a twist in it. I know my guy took a hell of a cut on the FE D2TE heads in my truck, but that thing needs all the compression it can get so I wasn't really worried about it.

Out of curiosity, what's the factory max recommended cut on one of these heads, and how much does it take before you start screwing with timing?

Out of curiosity, what's the factory max recommended cut on one of these heads, and how much does it take before you start screwing with timing?

The min thickness on a BP engine? Humm Ill have to check my AREA spec book.

But most the time it is about .015.

When will the timing be effected, That starts the first time the head is milled, but on a DOHC it is not as noticable as a SOHC

Anytime the C2C of cams to crank is changed the mechicanical timing is changed.

Thanks!

#15

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

IIRC, the FSM says max cut on the head is .012 but people exceed that all the time. EP motors are cut .050", IIRC. You start screwing with the timing immediately, but you can correct for that with cam gears (or one cam gear and VVT tuning).

#16

I think I have a man-crush on BogusSVO. This gives me more motivation to get enrolled at The Most Respected Name in Motorsports Education - School of Automotive Machinists.

#18

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

Adjustable cam gears... what a great invention!

I think I have a man-crush on BogusSVO. This gives me more motivation to get enrolled at The Most Respected Name in Motorsports Education - School of Automotive Machinists.

I will oven bake, The torch method leaves ugly marks, and is an out of date method.

#19

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

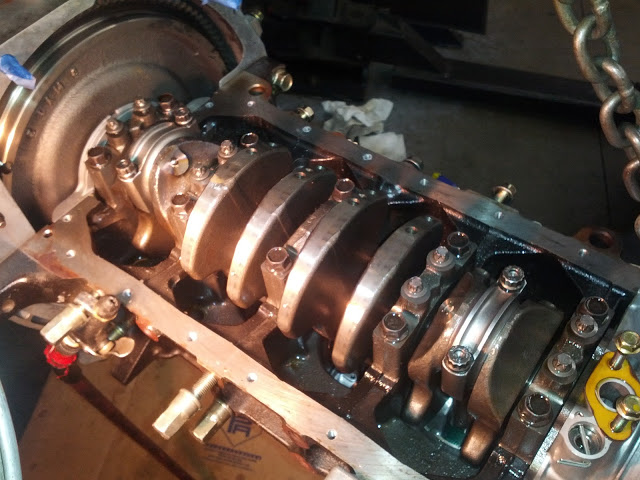

Well a few have shown intrest on how this will be done.

What is needed.

A steel plate, with properly placed holes.

A torque wrench, and socket

Pull bolts

Head bolt washers

Body washers

Anti-sieze

Shim stock

Place head bolt washers on the pull pins

Place the pull pins through the head bolt holes and through the steel plate.

Now coat the shim stock with anti-sieze and place under the head.

The anti-size will give the head some lube to slip on as the head straightens out.

Now place the washers on the pull pins, and snug the nuts down. Roll the head and fixture over and torque the pull pins.

The head and plate fixture will be placed in an oven for several hours, the temp will be watched closely, to bring it up to temp slowly, then stablized for a couple hours, then temp will be dropped slowly untill back to room temp.

What is needed.

A steel plate, with properly placed holes.

A torque wrench, and socket

Pull bolts

Head bolt washers

Body washers

Anti-sieze

Shim stock

Place head bolt washers on the pull pins

Place the pull pins through the head bolt holes and through the steel plate.

Now coat the shim stock with anti-sieze and place under the head.

The anti-size will give the head some lube to slip on as the head straightens out.

Now place the washers on the pull pins, and snug the nuts down. Roll the head and fixture over and torque the pull pins.

The head and plate fixture will be placed in an oven for several hours, the temp will be watched closely, to bring it up to temp slowly, then stablized for a couple hours, then temp will be dropped slowly untill back to room temp.