Head gasket sealing issues

#1

Elite Member

Thread Starter

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

I already had a thread in media section, but it was kind of off topic and not getting much traffic, so I will make a more on topic thread here.

Short story. I have a major issue with getting the head gasket to seal. Upon first start up I end up with coolant smoke in the exhaust and a car that stumbles on accel. Pulling the spark plugs, you can see pools of coolant and/or oil on the pistons.

I pulled my engine and trans about a month ago with plans to "freshen up" the head and replace clutch, along with other little things. The biggest reason I pulled it was to replace the head gasket, since my compression check showed me that 1 and 4 were high, in the 180-190 range, but 2 and 3 were only 150-160. So I assumed it was most likely the head gasket, since I was slowely losing oil and coolant to somewhere internally.

First inspection with head and block apart did not show any visible signs of a gasket failure. I went ahead with the rebuild as planned. Had the head machined, I asked for them to remove .015 of material from the head. The work looked good but Im not thinking the head machine work has to be at fault for my head gasket sealing issue. I have gone through 2 head gaskets and will be doing this for the 3rd time next weekend. I dont have an accurate enough straight edge to check, but Im confident the block is fine, since I havent heard anyone say they have ever actually seen a warped BP block.

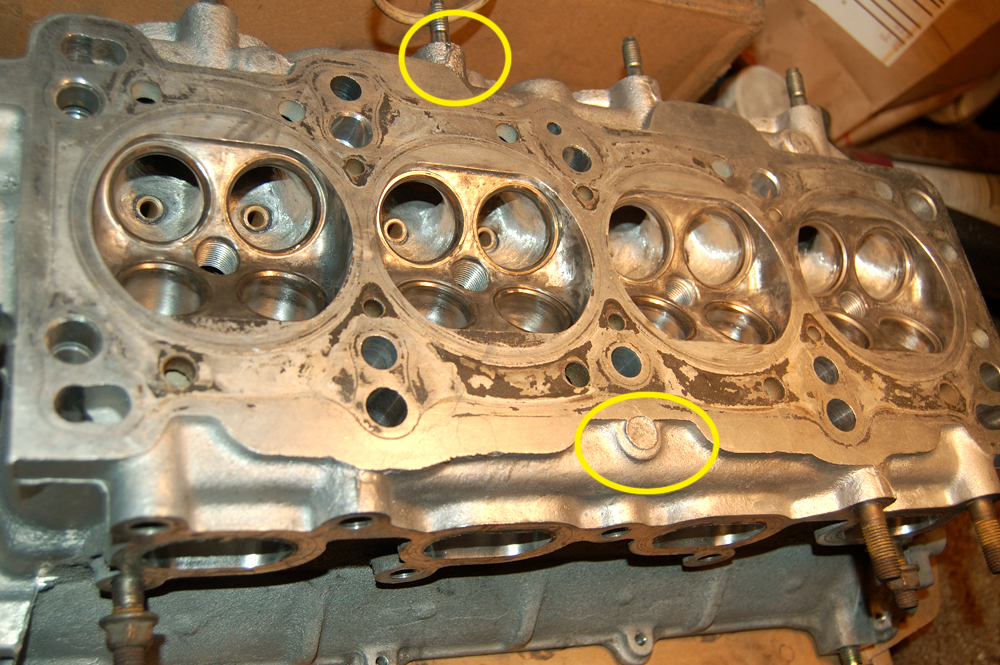

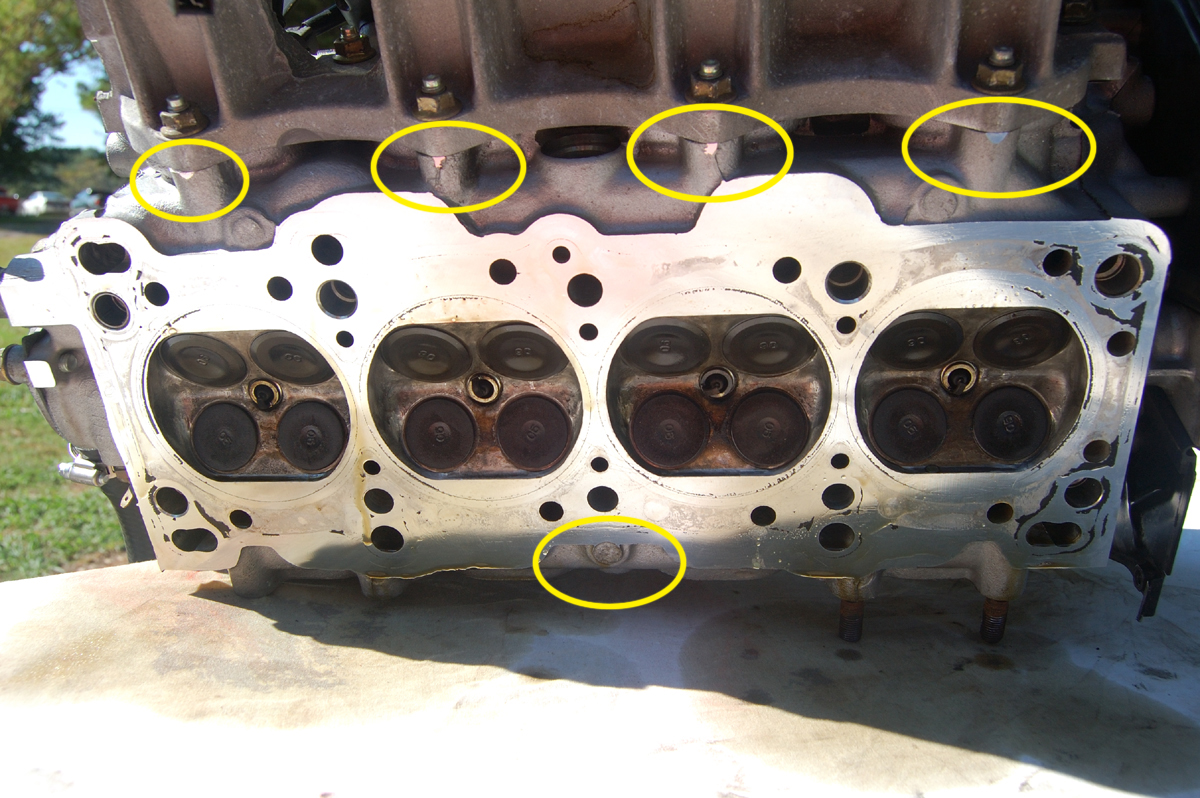

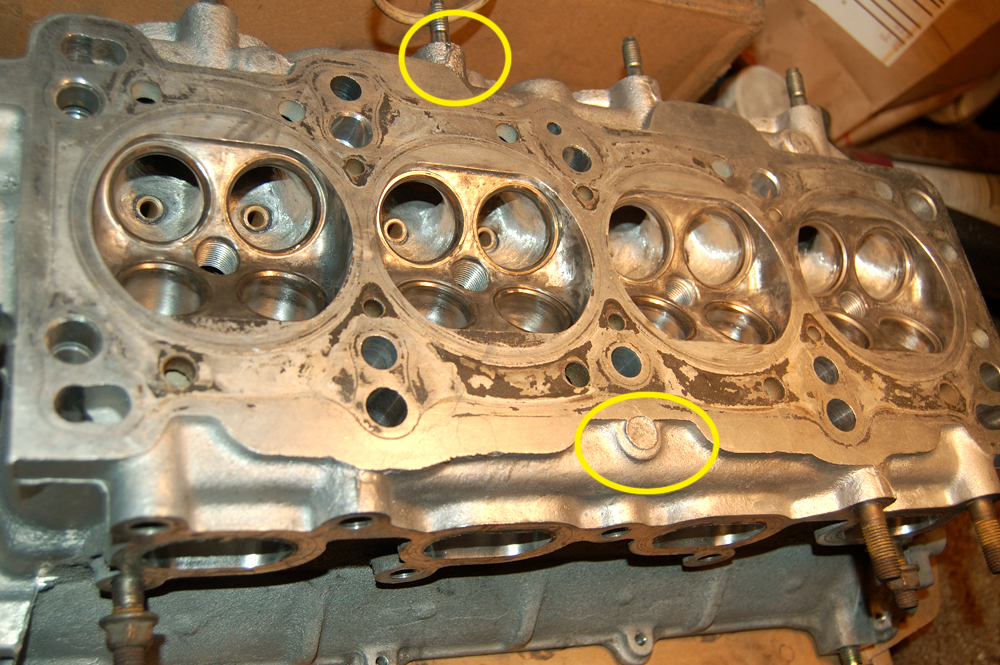

Anyway, my qeustion now, having exhausted every other option that I know, how badly would a crooked head hurt compression. Im guessing having the head bolts not pulling evenly would cause a difference in force from side to side. Im thinking the intake side had more material removed than the exahust side, which would explain the head gasket looking less compressed on the intake side. Here are 2 pictures that kind of tipped me off to this latest idea.

Here is pre machining, you can see the casting marks on the intake stud castings. My focus is mostly on the lower circle.

Here is post machining, you can see the lower circle hasnt seemed to change, but the intake stud castings have had what looks to be a pretty major amount of material removed. Would you guys agree with this assessment or are my eyes fooling me? The machine shop I took the head too was called "Engine Rebuilders" and it looked to be a small 2 or 3 man operation, and Im not sure how good of work they do. It only cost me $30 and what was pretty much a handshake transaction, no paper work. Maybe that should have been a warning.

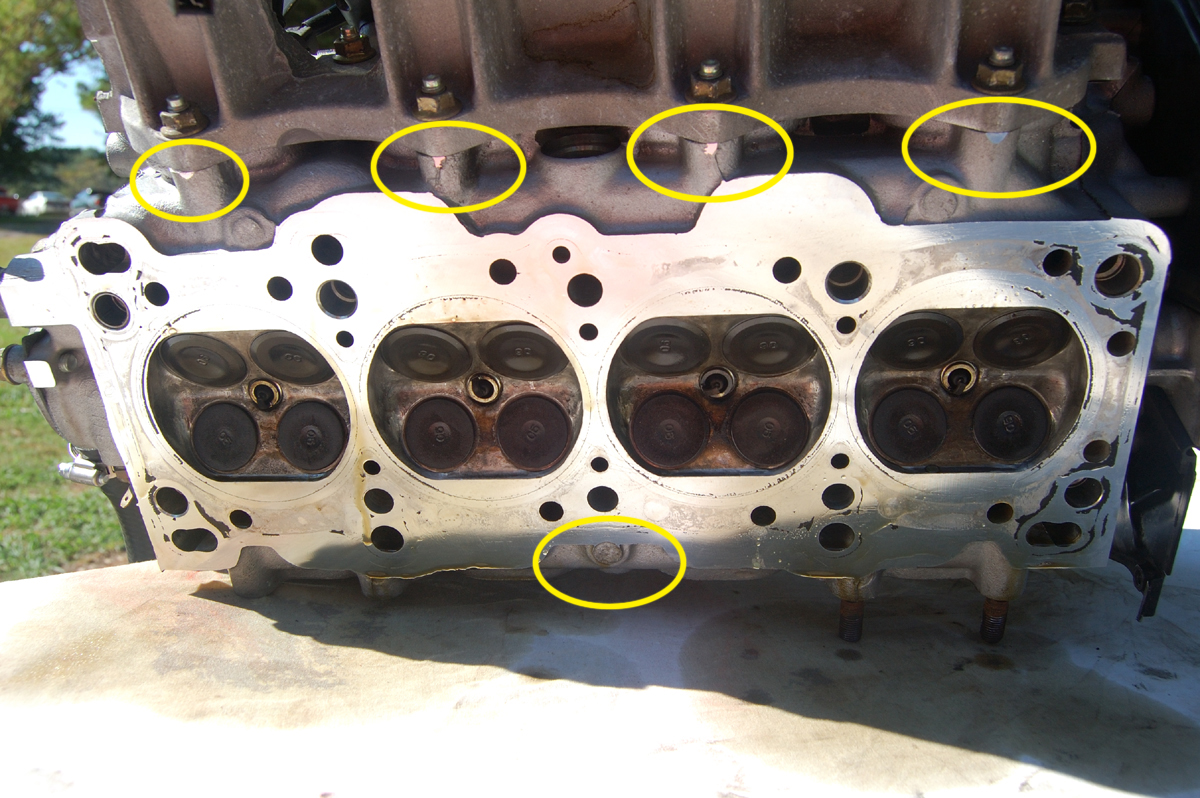

Here is one of head gasket #1, failure after only about half an hour and 10 miles of driving. The 2nd gasket failed right away and never held at all. You can see the rings around the cylinders have dead spots on the intake side, which to me means less force on that side/more contact on the exhaut side of the head. Make sense?

I can see no other reason this damn thing would be leaking like it does. If anyone else has any ideas, please feel free to chime in. I cant get much help at miata.net, people seen to have gotten tired of my problems

(Sorry the pictures are a bit small, but maybe you can see what I am talking about. I also have more build info/progress in my cardomain in my signature link if anyone cares)

Short story. I have a major issue with getting the head gasket to seal. Upon first start up I end up with coolant smoke in the exhaust and a car that stumbles on accel. Pulling the spark plugs, you can see pools of coolant and/or oil on the pistons.

I pulled my engine and trans about a month ago with plans to "freshen up" the head and replace clutch, along with other little things. The biggest reason I pulled it was to replace the head gasket, since my compression check showed me that 1 and 4 were high, in the 180-190 range, but 2 and 3 were only 150-160. So I assumed it was most likely the head gasket, since I was slowely losing oil and coolant to somewhere internally.

First inspection with head and block apart did not show any visible signs of a gasket failure. I went ahead with the rebuild as planned. Had the head machined, I asked for them to remove .015 of material from the head. The work looked good but Im not thinking the head machine work has to be at fault for my head gasket sealing issue. I have gone through 2 head gaskets and will be doing this for the 3rd time next weekend. I dont have an accurate enough straight edge to check, but Im confident the block is fine, since I havent heard anyone say they have ever actually seen a warped BP block.

Anyway, my qeustion now, having exhausted every other option that I know, how badly would a crooked head hurt compression. Im guessing having the head bolts not pulling evenly would cause a difference in force from side to side. Im thinking the intake side had more material removed than the exahust side, which would explain the head gasket looking less compressed on the intake side. Here are 2 pictures that kind of tipped me off to this latest idea.

Here is pre machining, you can see the casting marks on the intake stud castings. My focus is mostly on the lower circle.

Here is post machining, you can see the lower circle hasnt seemed to change, but the intake stud castings have had what looks to be a pretty major amount of material removed. Would you guys agree with this assessment or are my eyes fooling me? The machine shop I took the head too was called "Engine Rebuilders" and it looked to be a small 2 or 3 man operation, and Im not sure how good of work they do. It only cost me $30 and what was pretty much a handshake transaction, no paper work. Maybe that should have been a warning.

Here is one of head gasket #1, failure after only about half an hour and 10 miles of driving. The 2nd gasket failed right away and never held at all. You can see the rings around the cylinders have dead spots on the intake side, which to me means less force on that side/more contact on the exhaut side of the head. Make sense?

I can see no other reason this damn thing would be leaking like it does. If anyone else has any ideas, please feel free to chime in. I cant get much help at miata.net, people seen to have gotten tired of my problems

(Sorry the pictures are a bit small, but maybe you can see what I am talking about. I also have more build info/progress in my cardomain in my signature link if anyone cares)

#2

Senior Member

iTrader: (8)

Join Date: Mar 2006

Location: Indianapolis, IN

Posts: 1,105

Total Cats: 229

Are you re-using the old head bolts, or do you have new bolts or ARP studs? Head bolts are generally TTY (torque to yield) bolts that stretch out when they reach the proper torque, and therefore are supposed to be replaced after each use. Also, if the threads in the block are dirty or have crap in them, it can also make the head bolts bottom out too soon or give inaccurate torque readings. I am assuming that you are using the torque specs and tightening sequence in the FSM, correct?

#3

Elite Member

Thread Starter

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

As far as I know the Miata does not use TTY bolts. TTY have to be tightened using a different method, not just a wrench. They go by degrees and a complicated magic dance to get them right. Yes I am torqueing them to correct factory specs using the recommended pattern. Wether or not my wrench was 100% correct is still a debate. Im going to try and barrow a good dial type wrench this next time to be sure.

#5

TTY bolts can be torqued as you allude to, or they can be torqued to a specific yield and -then- turned a number of degrees. I would not be surprised if there was another manner for them to be installed, it depends on the material of the bolts, the H/G, and what the manufacturer believes is ideal.

AFAIK, damn near everything has TTY headbolts.

#7

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

I just realized that back in 1999 when I put the head back on my vw, I followed the TTY specs in the factory manual for the ARP studs, not the recommended torque. However, everything worked fine.

#8

Like I said before get a straight edge.

Then you can check everything. Then there is no ASSuming anything. ASSumptions will **** you up every time.

Also, take the head to a shop and make sure it's not cracked. They will chemically check it for cracks.

You don't need studs.

And I don't see why they would cut the bottom of the intake manifold area. That's not level with the deck, though it is on the same plane.

Then you can check everything. Then there is no ASSuming anything. ASSumptions will **** you up every time.

Also, take the head to a shop and make sure it's not cracked. They will chemically check it for cracks.

You don't need studs.

And I don't see why they would cut the bottom of the intake manifold area. That's not level with the deck, though it is on the same plane.

#10

Elite Member

Thread Starter

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

Cant tell if thats sarcasm or if you really mean it. I havent done much porting in the past, and it was a pain in the *** using only a dremel and $40 worth of bits. Got the exhaust ports smoothed out, removed a pretty major ridge just under the valve seats and smoothed it out. Opened up the intake side and removed the inside diameter, or the floor of the port where it had a bit of a piece sticking out. Probably did little or nothing for flow, but at least I feel better about it. Smoothed the cc a bit and removed some casting junk. Cleaned valves, new valve seals and other related head junk. If this head does end up being crooked, Im not sure if I can take off enough material to flatten it without having my compression go way up. Its already ~.015 removed, would probably need that much more to level it up. Might not be too much for a low boost application though.

I have a machine shop telling me they have an HLA BP head for sale, already machined, new seats and guides for $200. I might take him up on that. Mine probably wouldnt hurt to have new guides and seats anyway. Trade my core for his. Of course all of the "porting" work would be lost, but I can do it again, but better this time knowing what I need to do.

Straight edge... I can bring myself to find a piece of stock and have it machined just to check my block. Like pretty much everyone I have talked to, there is no way the block could be warped.

I have a machine shop telling me they have an HLA BP head for sale, already machined, new seats and guides for $200. I might take him up on that. Mine probably wouldnt hurt to have new guides and seats anyway. Trade my core for his. Of course all of the "porting" work would be lost, but I can do it again, but better this time knowing what I need to do.

Straight edge... I can bring myself to find a piece of stock and have it machined just to check my block. Like pretty much everyone I have talked to, there is no way the block could be warped.

#12

Elite Member

Thread Starter

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

Im not going to drop the money for a chunk of metal and pay to have it milled to check the deck when I can just pay someone to do it for me. I will rarely need a straight edge, and dont really have a good place to store one where it might not get bent up.

Im still going to check it of course, its common sense that if you have the head fixed to check the block (which I didnt do the first time because of my rush, and expecting it all to go smoothly like it had in the past). Sorry if I sounded unappreciative of your advice, I do appreciate it.

#13

Correct me if I'm wrong:

You bought this car and the head gasket leaked for unknown reasons. So you get the head surfaced and replaced HG. The shop never confirms/denies that the head is even warped. You ASSume that the head was warped and surfacing it will fix the problem.

And it still leaked. But you suspect the staple caused the problem.

So you replaced the head gasket again.

And it still leaks.

Yet you won't accept that the deck could be warped, and won't even buy a straight edge to check it. So now what? Pay to have the head resurfaced, again, third new head gasket, and try again? So if the third head gasket leaks will you consider that a warped deck is a very real possibility? Who said the engine has never been overheated? How do you know it hasn't been? You don't, end of story. Who said mazda decked it properly? Nobody. You don't know. How do you know the deck didn't warp on its own from insufficient artificial aging before being decked originally? You don't. Fact is you have no clue if the deck is right. For that matter, you don't know that the head isn't cracked internally because it has not been checked.

In case you haven't figured it out, you need to stop making ASSumptions and start logically diagnosing the problem. There are many possibilities. You could blindly have the head and deck resurfaced without first verifying they were warped, but then you don't know if your fixing the problem nor would you know if there was even a reason to resurface them in the first place. You could have the head and deck both resurfaced and have the same problem, and come to find out the head is cracked because you ASSumed it wasn't and didn't have it checked. Now you've ported, polished, and decked a head twice that was garbage when you bought the car.

Figure up what your total time porting is worth to you, your total time spent changing the head gasket is worth, twice, and the total cost of all associated machine work and parts used thus far.

Then tell me how much it would have cost to have a machine shop rebuild the head and check the deck of the block with a straight edge. Here's it's 200 to rebuild a 16 valve head and that includes, acid vatting it, cut the seats, grind the valves, chemically check the head for cracks, and surface it if it's not perfect. They'll check the deck of the block for 10 bucks or loan a straight edge with a deposit + 10 dollars.

You bought this car and the head gasket leaked for unknown reasons. So you get the head surfaced and replaced HG. The shop never confirms/denies that the head is even warped. You ASSume that the head was warped and surfacing it will fix the problem.

And it still leaked. But you suspect the staple caused the problem.

So you replaced the head gasket again.

And it still leaks.

Yet you won't accept that the deck could be warped, and won't even buy a straight edge to check it. So now what? Pay to have the head resurfaced, again, third new head gasket, and try again? So if the third head gasket leaks will you consider that a warped deck is a very real possibility? Who said the engine has never been overheated? How do you know it hasn't been? You don't, end of story. Who said mazda decked it properly? Nobody. You don't know. How do you know the deck didn't warp on its own from insufficient artificial aging before being decked originally? You don't. Fact is you have no clue if the deck is right. For that matter, you don't know that the head isn't cracked internally because it has not been checked.

In case you haven't figured it out, you need to stop making ASSumptions and start logically diagnosing the problem. There are many possibilities. You could blindly have the head and deck resurfaced without first verifying they were warped, but then you don't know if your fixing the problem nor would you know if there was even a reason to resurface them in the first place. You could have the head and deck both resurfaced and have the same problem, and come to find out the head is cracked because you ASSumed it wasn't and didn't have it checked. Now you've ported, polished, and decked a head twice that was garbage when you bought the car.

Figure up what your total time porting is worth to you, your total time spent changing the head gasket is worth, twice, and the total cost of all associated machine work and parts used thus far.

Then tell me how much it would have cost to have a machine shop rebuild the head and check the deck of the block with a straight edge. Here's it's 200 to rebuild a 16 valve head and that includes, acid vatting it, cut the seats, grind the valves, chemically check the head for cracks, and surface it if it's not perfect. They'll check the deck of the block for 10 bucks or loan a straight edge with a deposit + 10 dollars.

#14

The one time I had experience with this, a customer I had sold a set of ARPs (when I worked at Overland Parts ten years ago) did the same thing, but with catastrophic results. Straight-4, crushed the landings where the bolt heads met the head itself. He was not happy, but luckily had a mirror to find the guilty party.

#15

Elite Member

Thread Starter

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

Correct me if I'm wrong:

You bought this car and the head gasket leaked for unknown reasons. So you get the head surfaced and replaced HG. The shop never confirms/denies that the head is even warped. You ASSume that the head was warped and surfacing it will fix the problem.

Well I assumed the issue was just the head gasket, not really a warped head or block. I figured a new head gasket would fix it. For the first 8-10 months I owned the car, it didnt lose a drop of oil or coolant, only after 15k miles did it start to lose coolant and oil. Even then I wasnt 100% sure it was a head gasket, but that is the only thing I can think of that would cause me to suddenly start losing both, along with feeling a slight loss in power. I never really asked the shop to check, just that I wanted it resurfaced. Probably would have been a good idea to have them check it just to know, but I didnt.

And it still leaked. But you suspect the staple caused the problem.

Yes, I assumed it must be, because I figured with a smooth resurfaced head and what I assumed was a smooth block, it should have sealed just fine.

So you replaced the head gasket again.

Yes

And it still leaks.

Yes again

Yet you won't accept that the deck could be warped, and won't even buy a straight edge to check it. So now what? Pay to have the head resurfaced, again, third new head gasket, and try again? So if the third head gasket leaks will you consider that a warped deck is a very real possibility? Who said the engine has never been overheated? How do you know it hasn't been? You don't, end of story. Who said mazda decked it properly? Nobody. You don't know. How do you know the deck didn't warp on its own from insufficient artificial aging before being decked originally? You don't. Fact is you have no clue if the deck is right. For that matter, you don't know that the head isn't cracked internally because it has not been checked.

No, I said I wont pay to have one made for me, but I would rather have a shop check it, or if they do indeed loan them out for a fee, I would do it that way. I dont want to do the extra leg work of finding suitable stock to have a straight edge made. I will know more when its checked, but am again assuming the head isnt right, because just by looking at it, I can tell one side has had more removed than the other. Thats not to say it was correct to begin with, but it would make sense it was since it worked fine for 115k miles.

In case you haven't figured it out, you need to stop making ASSumptions and start logically diagnosing the problem. There are many possibilities. You could blindly have the head and deck resurfaced without first verifying they were warped, but then you don't know if your fixing the problem nor would you know if there was even a reason to resurface them in the first place. You could have the head and deck both resurfaced and have the same problem, and come to find out the head is cracked because you ASSumed it wasn't and didn't have it checked. Now you've ported, polished, and decked a head twice that was garbage when you bought the car.

Thats why I am doing it right this time and having everything checked, or checking it myself. I was just wanting input from people on my observation about the head being crooked to see if maybe I had found the problem.

Figure up what your total time porting is worth to you, your total time spent changing the head gasket is worth, twice, and the total cost of all associated machine work and parts used thus far.

Probably more than it was worth.

Then tell me how much it would have cost to have a machine shop rebuild the head and check the deck of the block with a straight edge. Here's it's 200 to rebuild a 16 valve head and that includes, acid vatting it, cut the seats, grind the valves, chemically check the head for cracks, and surface it if it's not perfect. They'll check the deck of the block for 10 bucks or loan a straight edge with a deposit + 10 dollars.

Probably less. I was just going by previous experiances where nothing had gone wrong, and hoping the same would happen here. Just happens that I assumed wrong this time, and things did go wrong. You live and you learn I guess.

You bought this car and the head gasket leaked for unknown reasons. So you get the head surfaced and replaced HG. The shop never confirms/denies that the head is even warped. You ASSume that the head was warped and surfacing it will fix the problem.

Well I assumed the issue was just the head gasket, not really a warped head or block. I figured a new head gasket would fix it. For the first 8-10 months I owned the car, it didnt lose a drop of oil or coolant, only after 15k miles did it start to lose coolant and oil. Even then I wasnt 100% sure it was a head gasket, but that is the only thing I can think of that would cause me to suddenly start losing both, along with feeling a slight loss in power. I never really asked the shop to check, just that I wanted it resurfaced. Probably would have been a good idea to have them check it just to know, but I didnt.

And it still leaked. But you suspect the staple caused the problem.

Yes, I assumed it must be, because I figured with a smooth resurfaced head and what I assumed was a smooth block, it should have sealed just fine.

So you replaced the head gasket again.

Yes

And it still leaks.

Yes again

Yet you won't accept that the deck could be warped, and won't even buy a straight edge to check it. So now what? Pay to have the head resurfaced, again, third new head gasket, and try again? So if the third head gasket leaks will you consider that a warped deck is a very real possibility? Who said the engine has never been overheated? How do you know it hasn't been? You don't, end of story. Who said mazda decked it properly? Nobody. You don't know. How do you know the deck didn't warp on its own from insufficient artificial aging before being decked originally? You don't. Fact is you have no clue if the deck is right. For that matter, you don't know that the head isn't cracked internally because it has not been checked.

No, I said I wont pay to have one made for me, but I would rather have a shop check it, or if they do indeed loan them out for a fee, I would do it that way. I dont want to do the extra leg work of finding suitable stock to have a straight edge made. I will know more when its checked, but am again assuming the head isnt right, because just by looking at it, I can tell one side has had more removed than the other. Thats not to say it was correct to begin with, but it would make sense it was since it worked fine for 115k miles.

In case you haven't figured it out, you need to stop making ASSumptions and start logically diagnosing the problem. There are many possibilities. You could blindly have the head and deck resurfaced without first verifying they were warped, but then you don't know if your fixing the problem nor would you know if there was even a reason to resurface them in the first place. You could have the head and deck both resurfaced and have the same problem, and come to find out the head is cracked because you ASSumed it wasn't and didn't have it checked. Now you've ported, polished, and decked a head twice that was garbage when you bought the car.

Thats why I am doing it right this time and having everything checked, or checking it myself. I was just wanting input from people on my observation about the head being crooked to see if maybe I had found the problem.

Figure up what your total time porting is worth to you, your total time spent changing the head gasket is worth, twice, and the total cost of all associated machine work and parts used thus far.

Probably more than it was worth.

Then tell me how much it would have cost to have a machine shop rebuild the head and check the deck of the block with a straight edge. Here's it's 200 to rebuild a 16 valve head and that includes, acid vatting it, cut the seats, grind the valves, chemically check the head for cracks, and surface it if it's not perfect. They'll check the deck of the block for 10 bucks or loan a straight edge with a deposit + 10 dollars.

Probably less. I was just going by previous experiances where nothing had gone wrong, and hoping the same would happen here. Just happens that I assumed wrong this time, and things did go wrong. You live and you learn I guess.

Also, once a chunk of metal is machined crooked, how do they go about making it true again. Seems like it would be hard to do without a reference to what it was before.

I may just buy the head that the guy offered me though. I would lose my work, which was probably 15-20 hours worth, but it might be less hassle. I may save that route for later, if I find out something is wrong with my head, or it will need too much taken off to make it right.

Thanks again.

#16

Anyway, thanks again. A shop will really loan out their straight edges? I figured with them being so sensitive they wouldnt want them in the hands of people who wouldnt take care of them.

Also, once a chunk of metal is machined crooked, how do they go about making it true again. Seems like it would be hard to do without a reference to what it was before.

I may just buy the head that the guy offered me though. I would lose my work, which was probably 15-20 hours worth, but it might be less hassle. I may save that route for later, if I find out something is wrong with my head, or it will need too much taken off to make it right.

Thanks again.

Also, once a chunk of metal is machined crooked, how do they go about making it true again. Seems like it would be hard to do without a reference to what it was before.

I may just buy the head that the guy offered me though. I would lose my work, which was probably 15-20 hours worth, but it might be less hassle. I may save that route for later, if I find out something is wrong with my head, or it will need too much taken off to make it right.

Thanks again.

It's not hard to make something flat. You could give them a huge steel ball and they can make it perfectly flat anywhere you want. You mount the part in a vise and put a flat on it, put that flat on the magnetic vise of surface grinder and make a pass, flip the part and surface again. Two perfectly parallel surfaces.

If the same shop that surfaced your head is the ones offerinig this other one, I'd be careful. First find out if the one they surfaced for you is perfectly flat. If it ain't spot on I'd walk away.

FWIW I'm not talking out of my ***. I'm not a machinist, but I took 3 years of machine shop in H/S. I've surfaced 5-6 cylinder heads before and rebuilt all of them. And they all work flawlessly to this day. And I've made straight edges, "joe blocks", etc. Very familiar with a surface grinder. Even made a con rod w/ butchress threads for a punch press and it works...

#17

Elite Member

Thread Starter

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

I know how they clamp it in and machine it, but Im wondering how they make it... not crooked. It can be perfectly flat from side to side, but it might not be square. If they machined it crooked the first time, how do you go about finding what is square?

#18

Also they can use a dial indicator in the collet of the mill to check the deck for warpage at any pont.

And if they're a good shop they used a fly cutter large enough to cut the entire deck in one pass. And they used coolant to keep the head from heating and expanding, which would slightly cause it to expand and result in it being more and more crocked as it's machined. And they would have secured it very well, and locked the knee of the mill, and slightly snugged all the skegs such to minimize any play in the machine. All little stuff, but it all adds up.

#19

Elite Member

Thread Starter

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

Yeah I was thinking maybe they could use the machined area that the valve cover seals to. Wasnt sure if that would be exact enough though. This might be all the more reason to just purchase the head this shop has. $200, leak/crack tested, new guides and valve seats. I would have to do my port work again, but at least it should be right. They guarantee their work. Not sure of the details yet, but I will find out more soon. I will ask if they will be able to tell if its crooked or not. If it can be fixed I will just stick with my current head, after they check it over to be sure its not cracked or anything else major is wrong with it. Will see if they will loan me a straight edge while Im at it.

#20

Elite Member

Thread Starter

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

Ok, Im about to jump back on the problem this weekend. I THINK I have found the problem, at least I hope. I knew it might be something very simple, and something I would kick my *** over. Im thinking maybe it is the intake manifold bracket from the block holding the manifold up. Since the head has .015 removed, and the bracket has a bit of movement because of the holes being slightly larger than the bolts, it may be hitting early and holding things up. Ive been installing the head with manifold already bolted up, so this in my mind would for sure be a problem. From what I can recall, even before machining the head the bracket and manifold fit very closely and precisely, and a .015-.020 drop of the head would be that much of a gap holding it off.

I brought it to a different shop the other day and had it checked, head is perfectly flat and doesnt seem to be crooked. I test fitted the head to the block today with no head gasket or manifold and it sat perfectly. My .001 feeler gauge wouldnt go between anywhere, so that seems good.

I had the shop tell me that they thought the problem lied elsewhere, the oil control rings to be exact. I just cant see this being it. No way that all 4 oil rings just collapsed by themselves after sitting for a few weeks (at least Ive never seen or heard of it before). It ran well before with very little smoke on full throttle accel. Even if it were the rings, I dont see that allowing enough oil through to cause the engine to die at anything above idle, nor would that explain bubbling coolant at the radiator cap. So that idea is out the window, though Im still paranoid about it just because of my horrible luck.

But does my idea seem reasonable? Even if it pulled up at torque, it would still be less on the intake side. Thats exactly what I was guessing by looking at the markings and material left behind by the head gasket on the head. You can see much less material left behind on the intake side, mostly on 2 and 3, which would be right about where the bracket is. So this weekend I will again try it, sans manifold. I will also use Fel-Pro instead of OEM, and go with some copper spray. Ive never used the copper spray, but I have seen some people online say good things about it.

I brought it to a different shop the other day and had it checked, head is perfectly flat and doesnt seem to be crooked. I test fitted the head to the block today with no head gasket or manifold and it sat perfectly. My .001 feeler gauge wouldnt go between anywhere, so that seems good.

I had the shop tell me that they thought the problem lied elsewhere, the oil control rings to be exact. I just cant see this being it. No way that all 4 oil rings just collapsed by themselves after sitting for a few weeks (at least Ive never seen or heard of it before). It ran well before with very little smoke on full throttle accel. Even if it were the rings, I dont see that allowing enough oil through to cause the engine to die at anything above idle, nor would that explain bubbling coolant at the radiator cap. So that idea is out the window, though Im still paranoid about it just because of my horrible luck.

But does my idea seem reasonable? Even if it pulled up at torque, it would still be less on the intake side. Thats exactly what I was guessing by looking at the markings and material left behind by the head gasket on the head. You can see much less material left behind on the intake side, mostly on 2 and 3, which would be right about where the bracket is. So this weekend I will again try it, sans manifold. I will also use Fel-Pro instead of OEM, and go with some copper spray. Ive never used the copper spray, but I have seen some people online say good things about it.