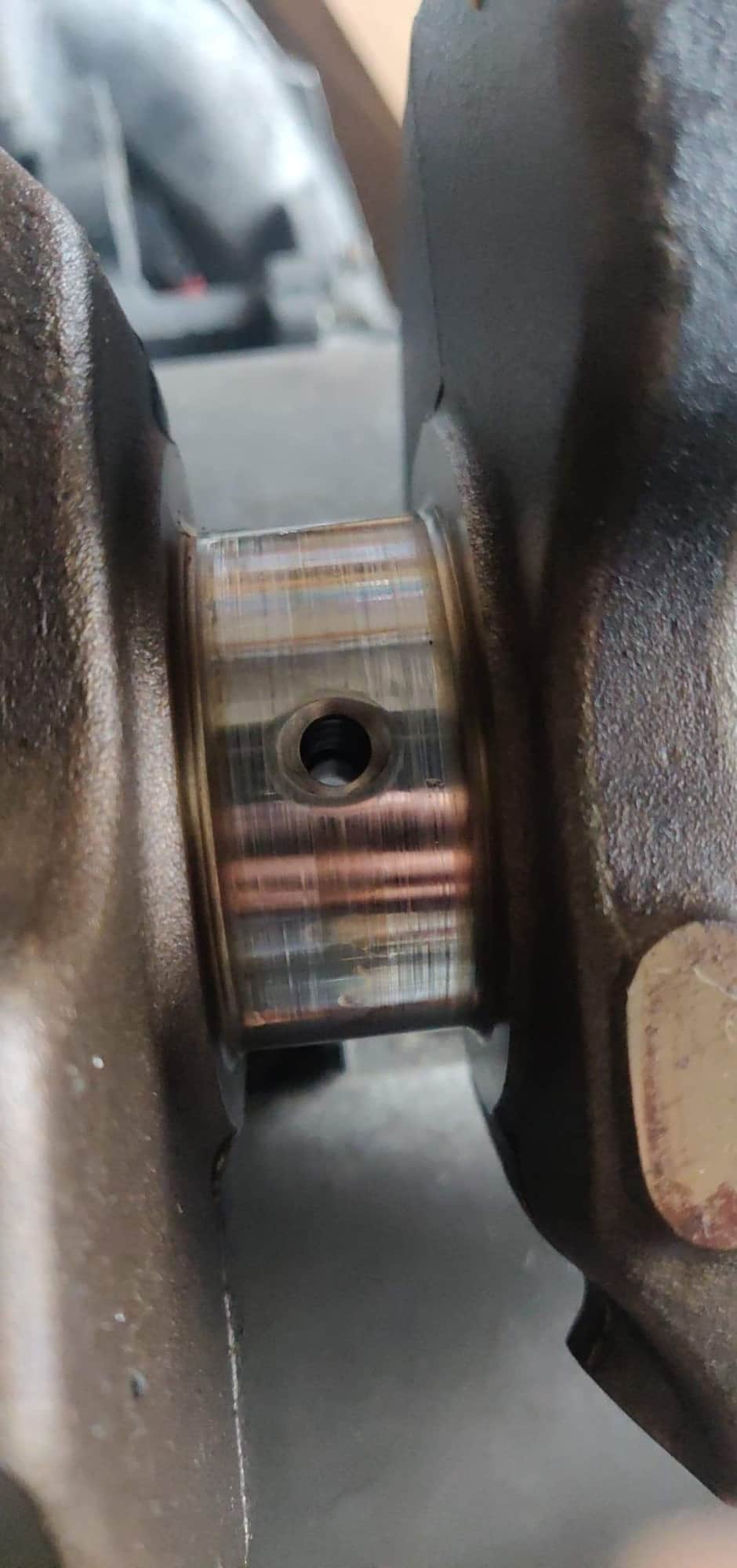

Crankshaft grind down .010?

#4

Only cranks that are commonly "re-heat treated" after work are aircraft which have to be by law.

Car stuff is commonly heat treated at the factory (Japanese/German stuff ) but it's THIN and not done to the same level as aircraft stuff is.

Having a crank re-treated is EXPENSIVE as most of the shops that do this are doing aircraft of industrial stuff.

I prefer to use factory cranks that have not been ground for my go fast builds but...

I've never seen a recut crank fail because the metal was too soft.

Lots of folks use ground cranks on big HP builds on all brands of manufacture.

More important on a regrind is a gentler (larger) radius on all of the "edges/corners" and high quality work.

On a REALLY serious build this radius can be so large that bearings with a 45 degree clearance cut on the outside edges is some times a requirement.

I haven't seen this on a BP build yet.

In my book having the crankshaft re-balanced is more important than having it re-heat treated.

Car stuff is commonly heat treated at the factory (Japanese/German stuff ) but it's THIN and not done to the same level as aircraft stuff is.

Having a crank re-treated is EXPENSIVE as most of the shops that do this are doing aircraft of industrial stuff.

I prefer to use factory cranks that have not been ground for my go fast builds but...

I've never seen a recut crank fail because the metal was too soft.

Lots of folks use ground cranks on big HP builds on all brands of manufacture.

More important on a regrind is a gentler (larger) radius on all of the "edges/corners" and high quality work.

On a REALLY serious build this radius can be so large that bearings with a 45 degree clearance cut on the outside edges is some times a requirement.

I haven't seen this on a BP build yet.

In my book having the crankshaft re-balanced is more important than having it re-heat treated.

#5

Only cranks that are commonly "re-heat treated" after work are aircraft which have to be by law.

Car stuff is commonly heat treated at the factory (Japanese/German stuff ) but it's THIN and not done to the same level as aircraft stuff is.

Having a crank re-treated is EXPENSIVE as most of the shops that do this are doing aircraft of industrial stuff.

I prefer to use factory cranks that have not been ground for my go fast builds but...

I've never seen a recut crank fail because the metal was too soft.

Lots of folks use ground cranks on big HP builds on all brands of manufacture.

More important on a regrind is a gentler (larger) radius on all of the "edges/corners" and high quality work.

On a REALLY serious build this radius can be so large that bearings with a 45 degree clearance cut on the outside edges is some times a requirement.

I haven't seen this on a BP build yet.

In my book having the crankshaft re-balanced is more important than having it re-heat treated.

Car stuff is commonly heat treated at the factory (Japanese/German stuff ) but it's THIN and not done to the same level as aircraft stuff is.

Having a crank re-treated is EXPENSIVE as most of the shops that do this are doing aircraft of industrial stuff.

I prefer to use factory cranks that have not been ground for my go fast builds but...

I've never seen a recut crank fail because the metal was too soft.

Lots of folks use ground cranks on big HP builds on all brands of manufacture.

More important on a regrind is a gentler (larger) radius on all of the "edges/corners" and high quality work.

On a REALLY serious build this radius can be so large that bearings with a 45 degree clearance cut on the outside edges is some times a requirement.

I haven't seen this on a BP build yet.

In my book having the crankshaft re-balanced is more important than having it re-heat treated.

Thread

Thread Starter

Forum

Replies

Last Post