The custom fabrication thread! (Post pics of stuff you have made)

#322

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

Tacked up an intake pipe last night for a customers car.

Pretty pleased with the fitment. I just need to finish weld it tonight and build the exhaust system so I can get this car out of my shop!

More pictures on my facebook page for subscribers!

Matt

Pretty pleased with the fitment. I just need to finish weld it tonight and build the exhaust system so I can get this car out of my shop!

More pictures on my facebook page for subscribers!

Matt

#326

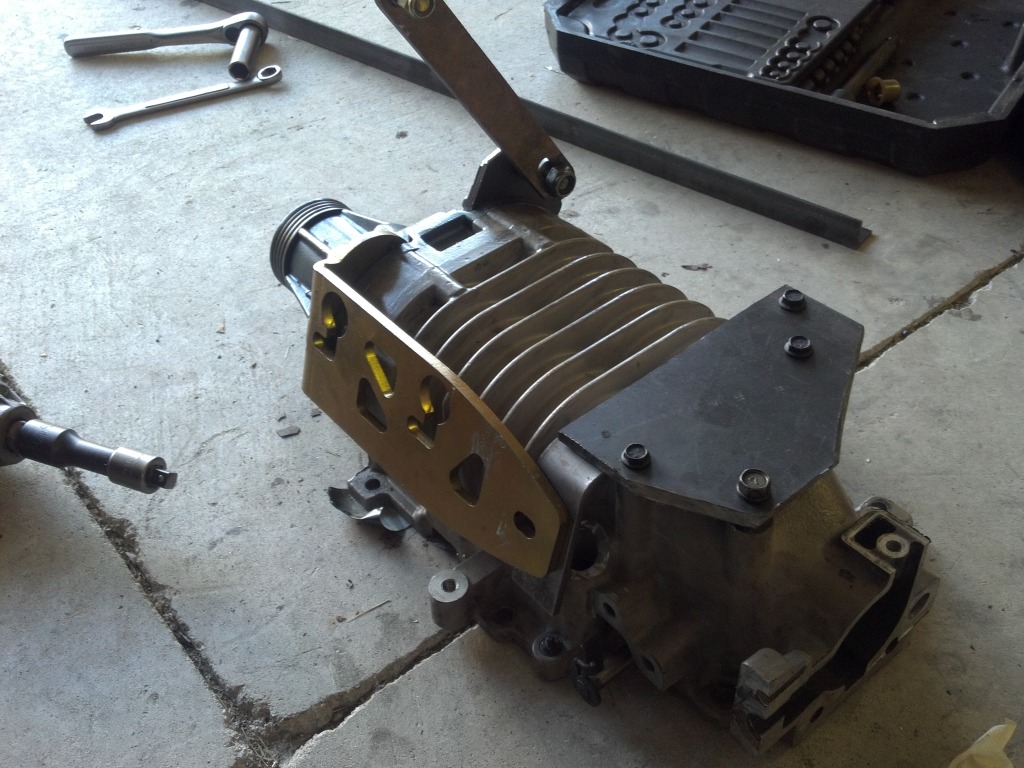

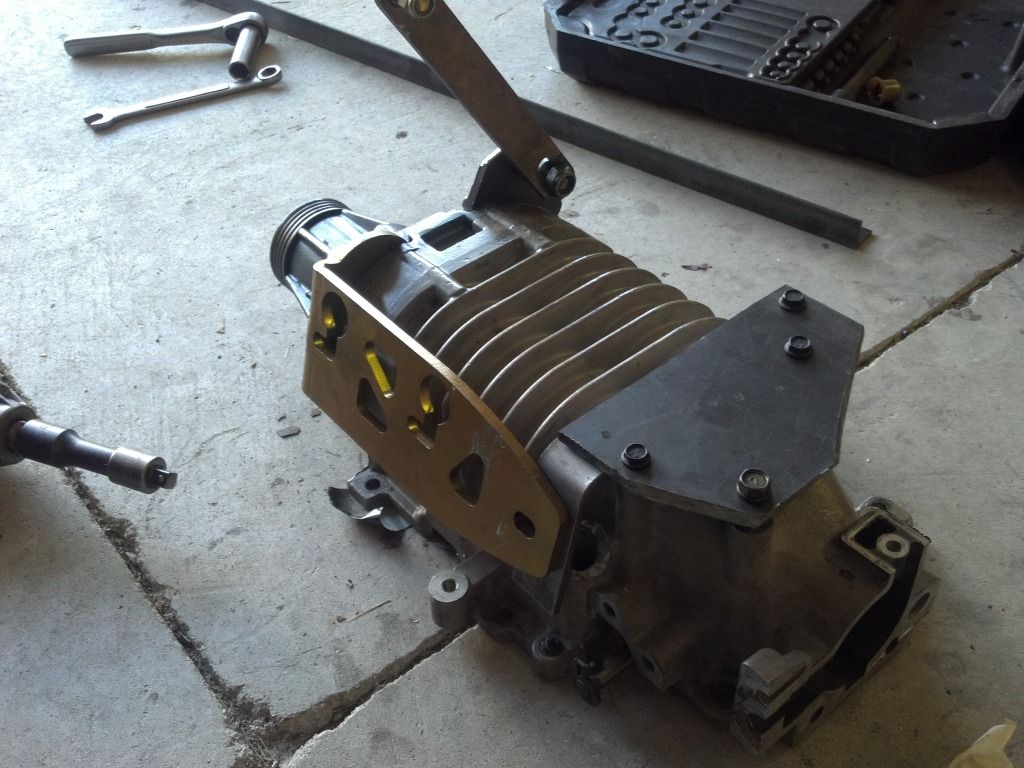

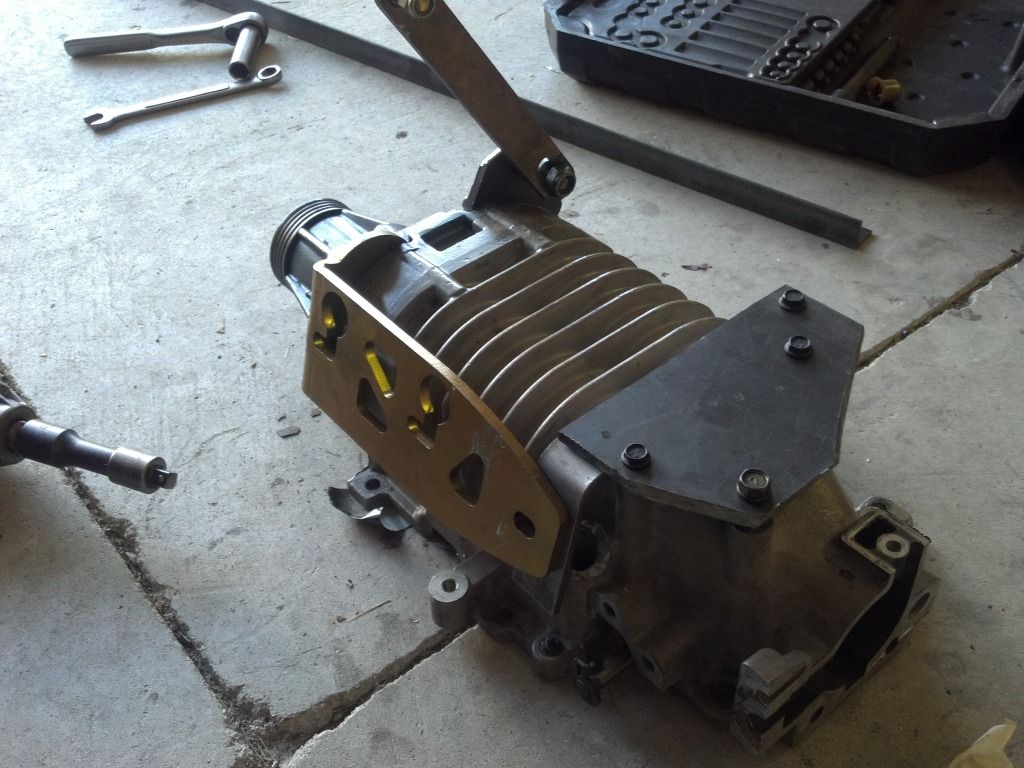

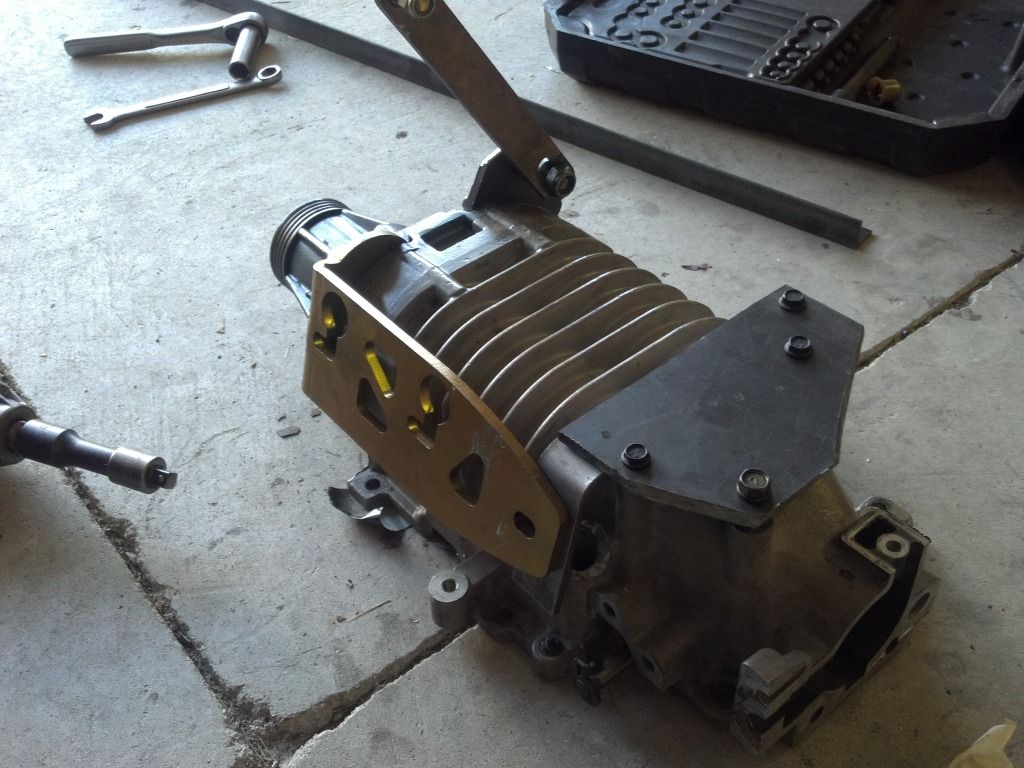

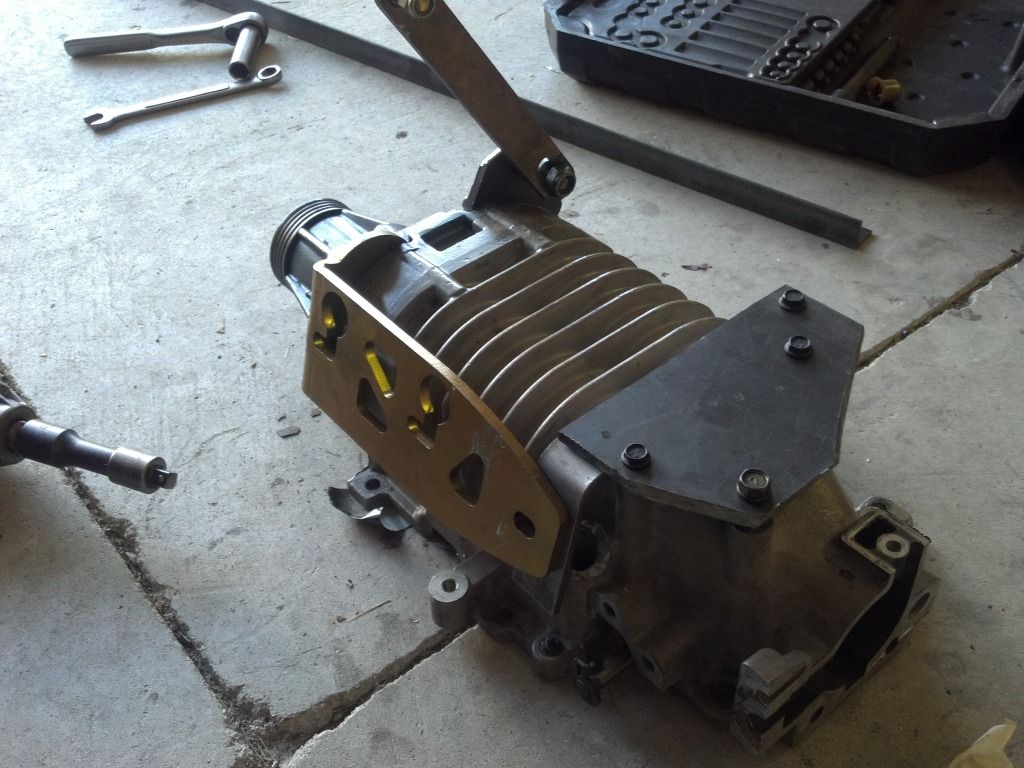

Not as nice as most of the stuff here. Also let the flame war begin for the supercharger content. Modified a Buick M62 to work on my car.

Then decided to learn aluminum and remake the manifold. Beware noob aluminum welds made with a mig spoolgun ahead. Still a lot of work left to do.

Then decided to learn aluminum and remake the manifold. Beware noob aluminum welds made with a mig spoolgun ahead. Still a lot of work left to do.

#328

Not as nice as most of the stuff here. Also let the flame war begin for the supercharger content. Modified a Buick M62 to work on my car.

Then decided to learn aluminum and remake the manifold. Beware noob aluminum welds made with a mig spoolgun ahead. Still a lot of work left to do.

Then decided to learn aluminum and remake the manifold. Beware noob aluminum welds made with a mig spoolgun ahead. Still a lot of work left to do.

#331

Straight enough for you? One advantage of a super low mount.

Cgeck this, 1.5" straight pipe loosely sitting in, and running through it, it will flow thats for sure

Snaking up through the chassis, great clearance everywhere.

Just tacked, and missing the V band flange between the flexy and the cat, but looking great so far.

Dann

#333

It was being final ported in that photo.

I know where you are going with this, it was welded with another 2 flanges bolted to it and I welded on ONLY the little 2" long starter pipes first, and then welded the rest of the manifold to those.

This way you have great access to all the welds that are usually tricky on a small manifold thats so awkward like this. This way you can get 100% nice strong welds with no excuses and you can work on the entry to the runner (porting) on a bench, much easier and better for me anyway.

Dann

I know where you are going with this, it was welded with another 2 flanges bolted to it and I welded on ONLY the little 2" long starter pipes first, and then welded the rest of the manifold to those.

This way you have great access to all the welds that are usually tricky on a small manifold thats so awkward like this. This way you can get 100% nice strong welds with no excuses and you can work on the entry to the runner (porting) on a bench, much easier and better for me anyway.

Dann

#335

You two make me want to re-do mine. I had my dad do the cuts while I was at school, lets just say it has some interesting pie cuts in it and it closer to the transmission and the trans tunnel than I would like it. Its also very short so that I could put the o2 sensor and the flex pipe section after the downpipe. Speaking of flex pipes, what kind do we like? Vibrant?

#337

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,892

Total Cats: 399

You two make me want to re-do mine. I had my dad do the cuts while I was at school, lets just say it has some interesting pie cuts in it and it closer to the transmission and the trans tunnel than I would like it. Its also very short so that I could put the o2 sensor and the flex pipe section after the downpipe. Speaking of flex pipes, what kind do we like? Vibrant?

Craftsman. I can get more specs once I get home if you need it.

I like most things vibrant. Only thing i dont like of theirs is their aluminum piping.

I have had no problem with vibrant aluminum pipe

#338

You guys buy exhaust hangers pre-made? I figured you would just buy 304 rod and cut and bend. The 304 rod metal drop I bought for the price of 1 pre made hanger should be able to do like 8 hangers.

For the flex joint, I'm guessing those are the ones labeled turbo flex joints rather than standard? I wasnt aware that you could get a smooth lined flex joint and not one with bellows inside, which is why I was considering not running one.

For the flex joint, I'm guessing those are the ones labeled turbo flex joints rather than standard? I wasnt aware that you could get a smooth lined flex joint and not one with bellows inside, which is why I was considering not running one.

#339

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

I use the smooth liner 6" long vibrant flexes.

Craftsman. I can get more specs once I get home if you need it.

Same here, but their stainless exhaust hanger rods are not stainless. They rust just as quickly as their mild hangers. Full suck. They may have changed them since I last bought them, the guys there are very receptive to criticism/comments, and actually seem to care about making a quality product.

I have had no problem with vibrant aluminum pipe

Craftsman. I can get more specs once I get home if you need it.

Same here, but their stainless exhaust hanger rods are not stainless. They rust just as quickly as their mild hangers. Full suck. They may have changed them since I last bought them, the guys there are very receptive to criticism/comments, and actually seem to care about making a quality product.

I have had no problem with vibrant aluminum pipe

Vibrant aluminum piping is fine, but I found some other piping that is 2mm wall vs 1.2mm that welds a lot nicer and has a nicer feel as a part.

Is the belt sander just a store bought 4x36, or something with a little more oomph?

6'' Bench Top Disc Sander: Get the Perfect Finish with Tools at Sears

#340

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,892

Total Cats: 399

You guys buy exhaust hangers pre-made? I figured you would just buy 304 rod and cut and bend. The 304 rod metal drop I bought for the price of 1 pre made hanger should be able to do like 8 hangers.

For the flex joint, I'm guessing those are the ones labeled turbo flex joints rather than standard? I wasnt aware that you could get a smooth lined flex joint and not one with bellows inside, which is why I was considering not running one.

For the flex joint, I'm guessing those are the ones labeled turbo flex joints rather than standard? I wasnt aware that you could get a smooth lined flex joint and not one with bellows inside, which is why I was considering not running one.

RE:Flex, the turbo flex is what I meant for the 3" pipe. I use their smooth liner (straight pipe inside the bellows) for my wastegate pipes. I love those. Smooth liner, lost of flex, not stiff. But Lars' did crack on at least 2 of the bellows.

Is the belt sander just a store bought 4x36, or something with a little more oomph?

6'' Bench Top Disc Sander: Get the Perfect Finish with Tools at Sears

6'' Bench Top Disc Sander: Get the Perfect Finish with Tools at Sears

For the price of the craftsman, I would consider the 1hp 6x48 harbor freight with a stand.

6" x 48" Belt and 9" Disc Combination Sander