The custom fabrication thread! (Post pics of stuff you have made)

#941

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

No brace or crane.

Never broke.

What I did have a serious problem with though, was flange warping.

Both the turbo and head flanges warped twice. I re-surfaced them and they still warped again.

No idea why. Bought the flanges from Weirtec, they were 3/8 iirc, guess I shoulda gone 1/2

Never broke.

What I did have a serious problem with though, was flange warping.

Both the turbo and head flanges warped twice. I re-surfaced them and they still warped again.

No idea why. Bought the flanges from Weirtec, they were 3/8 iirc, guess I shoulda gone 1/2

#943

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

No brace or crane.

Never broke.

What I did have a serious problem with though, was flange warping.

Both the turbo and head flanges warped twice. I re-surfaced them and they still warped again.

No idea why. Bought the flanges from Weirtec, they were 3/8 iirc, guess I shoulda gone 1/2

Never broke.

What I did have a serious problem with though, was flange warping.

Both the turbo and head flanges warped twice. I re-surfaced them and they still warped again.

No idea why. Bought the flanges from Weirtec, they were 3/8 iirc, guess I shoulda gone 1/2

If the pipes didn't fit well before you welded, they will have even more issues after welding. That's why you hear so much about fit up in the fab world.

#944

SadFab CEO

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

On it's own yes, a full triangle is always better. But in this situation it would have been redundant and just added weight as the structure between the hinges creates the vertical. If anything, I would have added a piece perpendicular to the bottom tube up to the top hinge.

#946

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

On it's own yes, a full triangle is always better. But in this situation it would have been redundant and just added weight as the structure between the hinges creates the vertical. If anything, I would have added a piece perpendicular to the bottom tube up to the top hinge.

Edit: oops you totally said that in the post above. Its too early.

#947

SadFab CEO

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

its all good lol, thanks for backing me up. but yes, to add to my point, the structure behind the firewall where the hinges bolt is substantial. the idea is to tie that section into the shock tower structures, or as close to, as the area between them is floppy.

#948

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Also I'm pretty sure that the forces the fender brace are countering are when the front sees compression and flexes up. If this is the case ten the forces will directly in line with the tube. Am I right about my analysis of the forces or do fender braces serve a different purpose?

#949

SadFab CEO

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

Also I'm pretty sure that the forces the fender brace are countering are when the front sees compression and flexes up. If this is the case ten the forces will directly in line with the tube. Am I right about my analysis of the forces or do fender braces serve a different purpose?

the upper tube should be in compression with the forces directed from front to rear, and the lower show be in combo bending/tension, or maybe just bending- upwards.

edit: actually the lower is a total guess without knowing where the pivot point is.

#950

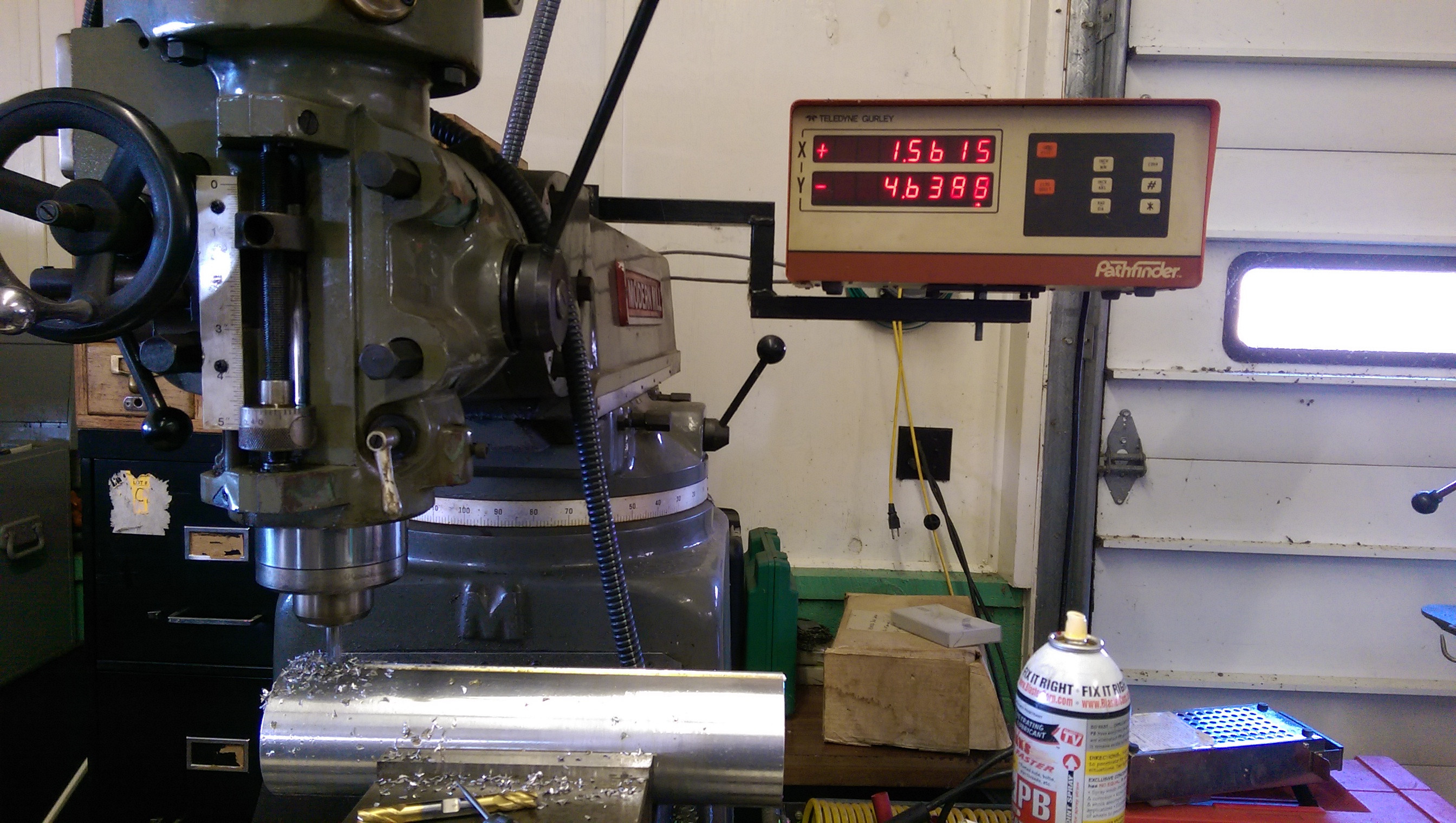

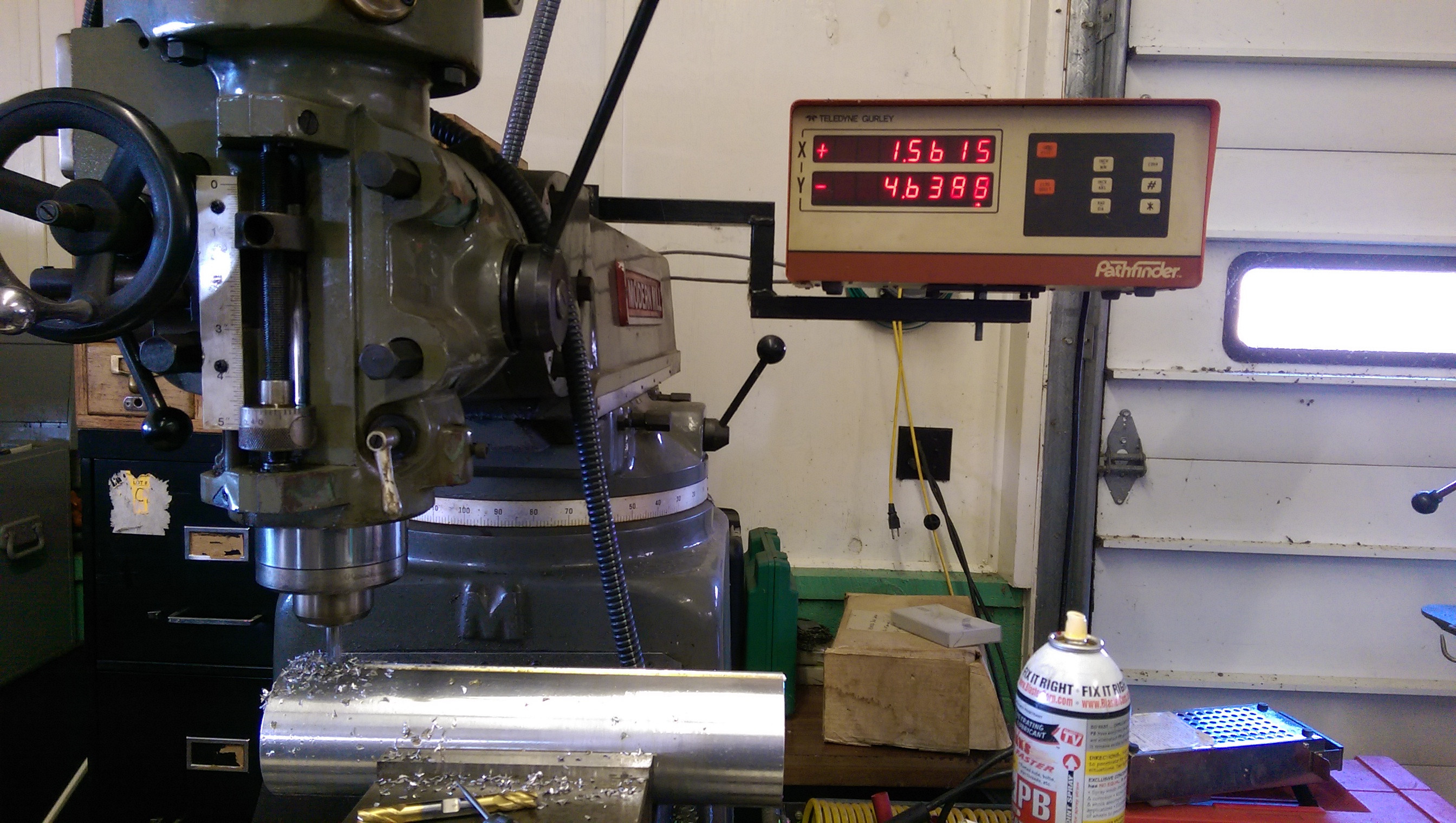

My grandfather and I made some coolant spacers, as I thought they would be a good starter project for me to try my hand at some machine work. And I enjoyed spending the time with him, as they live ~7hrs away and we don't make it up there as often as I'd like to. I have the equipment local to me to make more, just needed some help getting my feet wet. Took it slow, measured lots and took slim layers at a time. Super pleased with how they turned out. Just need to machine the bung and tig it on.

#951

No brace or crane.

Never broke.

What I did have a serious problem with though, was flange warping.

Both the turbo and head flanges warped twice. I re-surfaced them and they still warped again.

No idea why. Bought the flanges from Weirtec, they were 3/8 iirc, guess I shoulda gone 1/2

Never broke.

What I did have a serious problem with though, was flange warping.

Both the turbo and head flanges warped twice. I re-surfaced them and they still warped again.

No idea why. Bought the flanges from Weirtec, they were 3/8 iirc, guess I shoulda gone 1/2

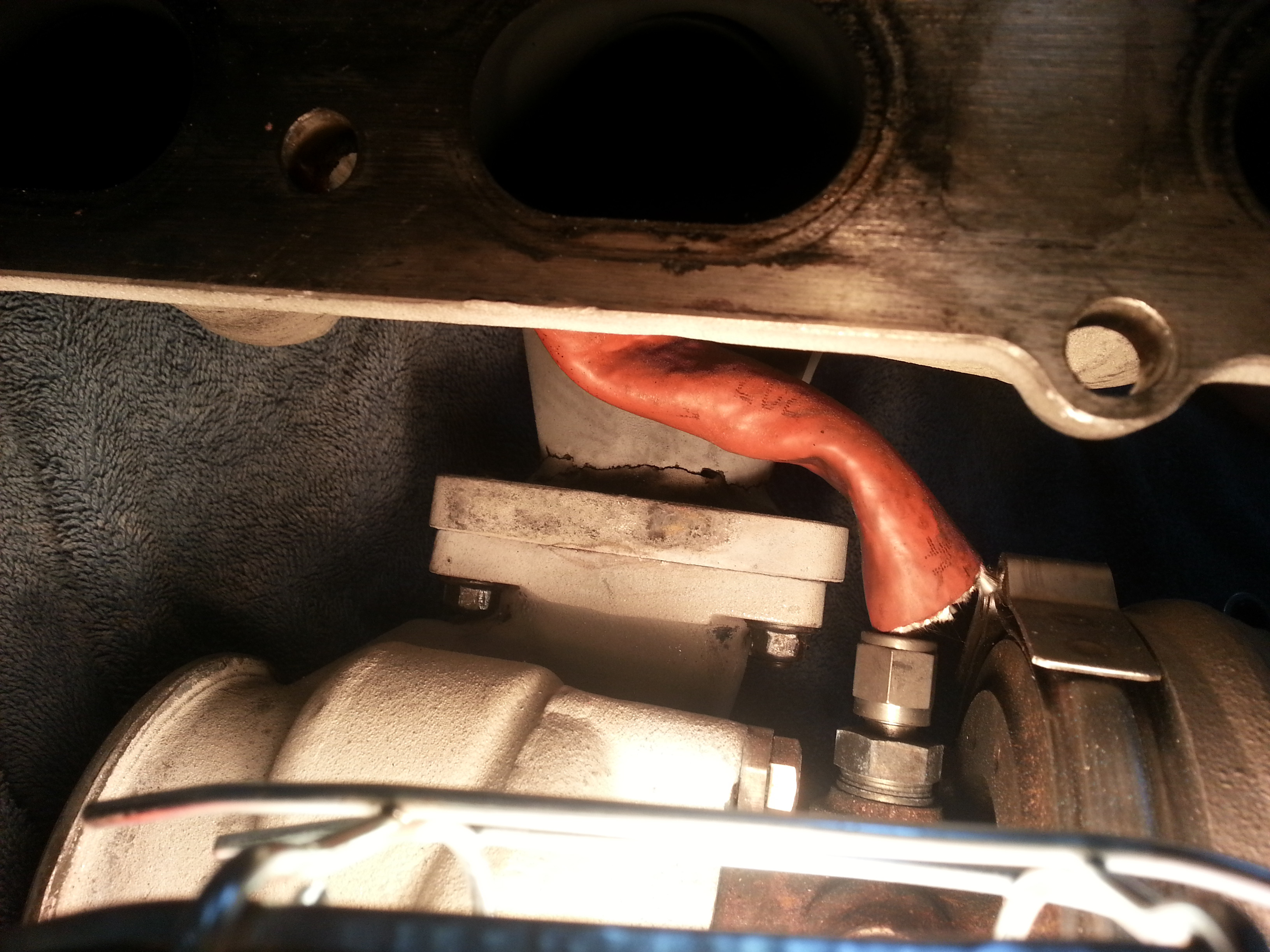

My manifold did crack though. The location was not someplace I was anticipating, so I'm going to blame it on poor welding.

But I fixed it and braced it. The outer fix weld looks a little shitty because I didnt do a good enough job getting the ceramic coating off.

#954

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

If the flanges are bolted, even with bad fit up you can still get it to look nice... But there is a high potential for warping with use if you didn't purge and get a full penetration weld.

Did you use a gas lens and have post flow set? That will keep your welds looking better if you cover the weld in argon post-flow.

M

#955

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

I don't like that style of manifold because the mitres required and quite sophisticated to get fitting right On cylinders 2 and 3 besides the compromise from a flow perspective from that design.

If the flanges are bolted, even with bad fit up you can still get it to look nice... But there is a high potential for warping with use if you didn't purge and get a full penetration weld.

Did you use a gas lens and have post flow set? That will keep your welds looking better if you cover the weld in argon post-flow.

M

If the flanges are bolted, even with bad fit up you can still get it to look nice... But there is a high potential for warping with use if you didn't purge and get a full penetration weld.

Did you use a gas lens and have post flow set? That will keep your welds looking better if you cover the weld in argon post-flow.

M