DIY manifold

#201

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

I picked up all sorts of cool welding things today. When I get home I will post pictures. Once I get a 220v outlet installed this weekend I should be ready to weld.

I also remember Hustler posting that link about the brake cleaner a while back. I will make sure none is used on items that will be welded together.

I also remember Hustler posting that link about the brake cleaner a while back. I will make sure none is used on items that will be welded together.

#203

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Having spent quite some time in the ER after walking into a building where someone essentially did this, I recommend against this course of action. Treatment involves breathing A LOT of vapor through a respirator, something like 2-4 liters of solution that is combination of saline and something else while they constantly monitor you blood chemistry.

My ? F - Would not breathe again.

? F - Would not breathe again.

y u no has 220v dryer hookup?

My

? F - Would not breathe again.

? F - Would not breathe again.I picked up all sorts of cool welding things today. When I get home I will post pictures. Once I get a 220v outlet installed this weekend I should be ready to weld.

I also remember Hustler posting that link about the brake cleaner a while back. I will make sure none is used on items that will be welded together.

I also remember Hustler posting that link about the brake cleaner a while back. I will make sure none is used on items that will be welded together.

#204

Dann

#207

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Got a box today:

When I made my order, I sent them an email and asked if the had a "premium" option for the BP flange, and offered to pay for the upgrade. They said they didn't have the code, but they would work on it and get back to me. 30 days later I still didn't have flanges, so I sent them an email. They responded in minutes and admitted they had forgotten to do it, apologized, and then got it in the mail less than 48 hours later. What do you know? They gave me the "premium" upgrade for free THAT is how you do business!

THAT is how you do business!

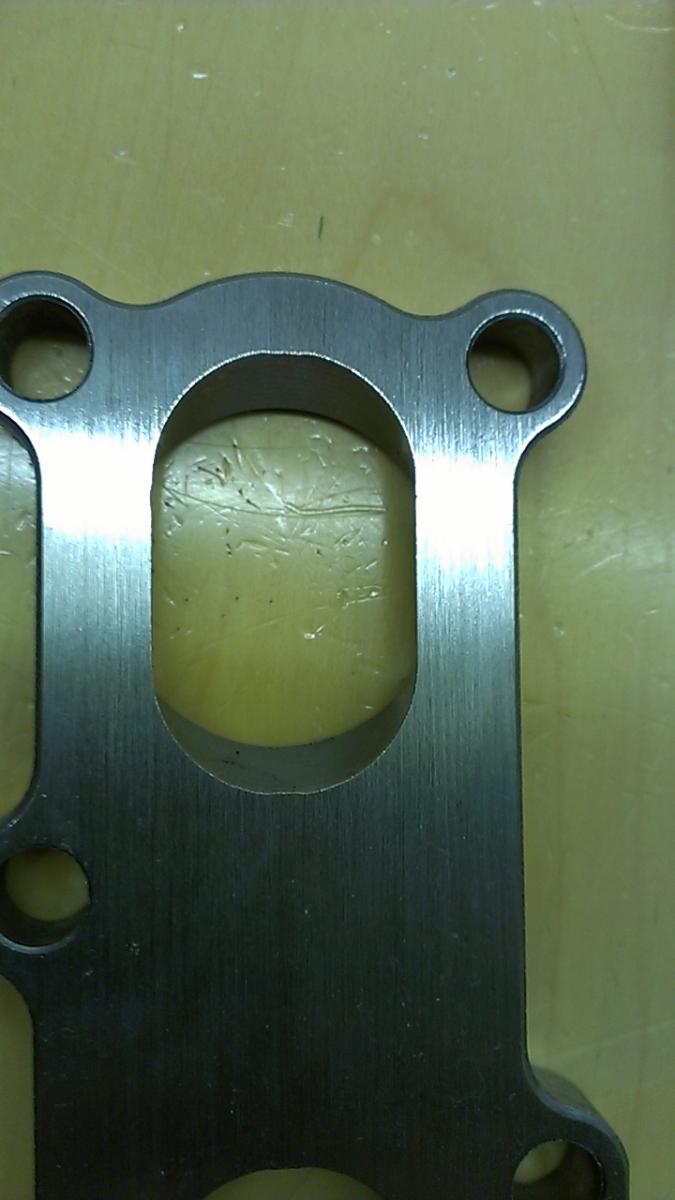

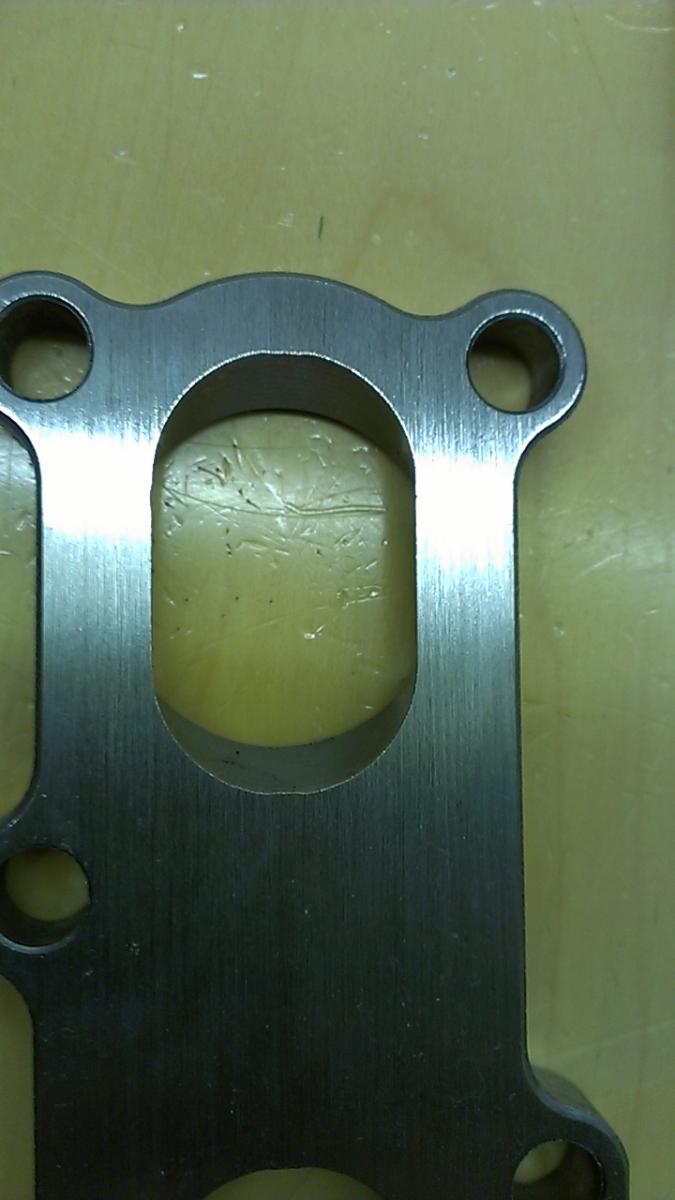

Manifold side with relief for 1.5" Sch 40 pipe:

straight on

little closer

slight angle

The transitions on these were really well done! I was a bit apprehensive at first, but I'm really happy with the work they did.

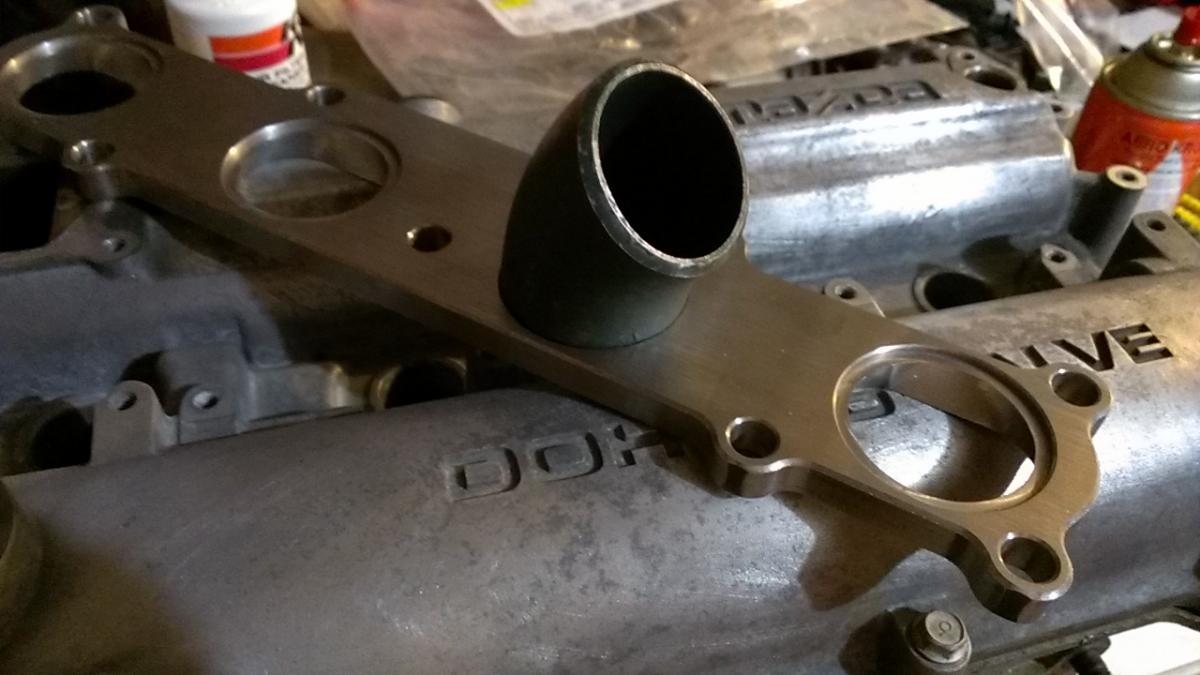

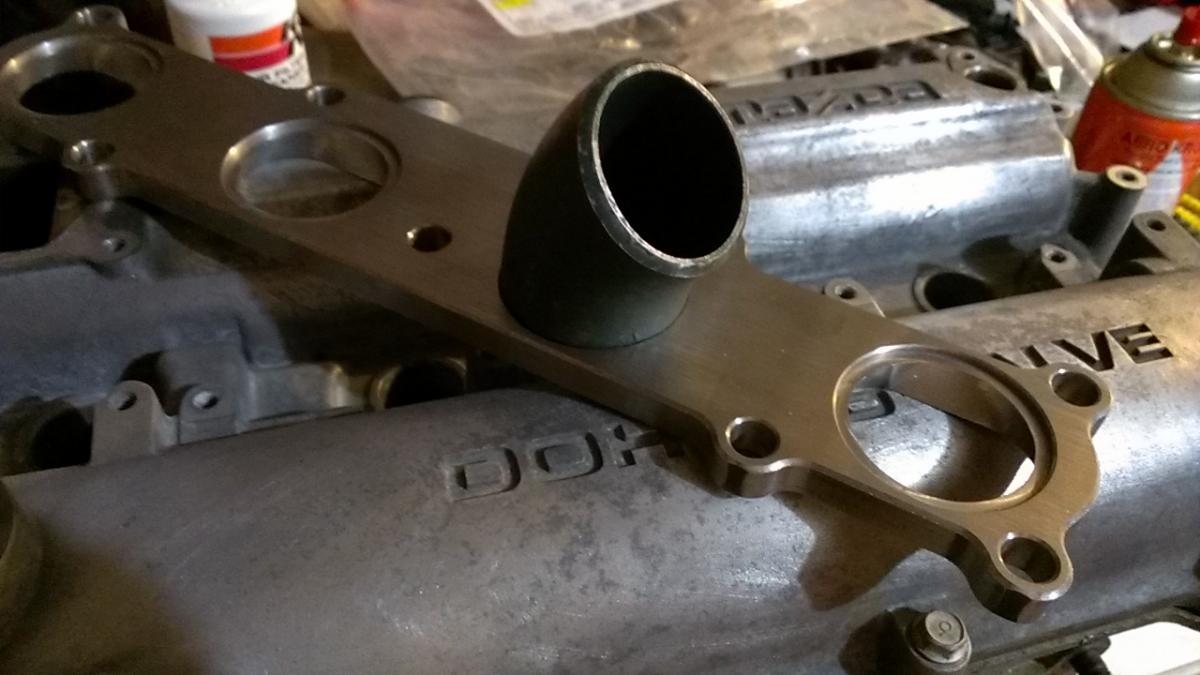

Head side exhaust port:

straight on

little closer

slight angle

Its mild and just a hair under 1/2" thick. I'll hit it with a caliper when I get home but I suspect they probably sanded it smooth. I want to get some pictures with an OEM exhaust manifold gasket tonight and see how close this is. Everything on these flanges is great, these guys really went the extra mile to break all the sharp edges on all the corners and radii. Everything has a nice 45° break on it. The port edges are razor sharp, but I expected that and suspect I'll have to abuse them with the die grinder after welding anyway.

Even with the delay, A+ would buy again

Mazda 18L Header Manifold Flange Standard - MAZDA18LHF - BMC Racing Products

I told them I'd be posting pics and impressions on one of the Miata sites tonight, so hopefully they will get the "premium" option listed shortly.

Just for reference, this is the "standard" flange listed on their website:

When I made my order, I sent them an email and asked if the had a "premium" option for the BP flange, and offered to pay for the upgrade. They said they didn't have the code, but they would work on it and get back to me. 30 days later I still didn't have flanges, so I sent them an email. They responded in minutes and admitted they had forgotten to do it, apologized, and then got it in the mail less than 48 hours later. What do you know? They gave me the "premium" upgrade for free

THAT is how you do business!

THAT is how you do business!Manifold side with relief for 1.5" Sch 40 pipe:

straight on

little closer

slight angle

The transitions on these were really well done! I was a bit apprehensive at first, but I'm really happy with the work they did.

Head side exhaust port:

straight on

little closer

slight angle

Its mild and just a hair under 1/2" thick. I'll hit it with a caliper when I get home but I suspect they probably sanded it smooth. I want to get some pictures with an OEM exhaust manifold gasket tonight and see how close this is. Everything on these flanges is great, these guys really went the extra mile to break all the sharp edges on all the corners and radii. Everything has a nice 45° break on it. The port edges are razor sharp, but I expected that and suspect I'll have to abuse them with the die grinder after welding anyway.

Even with the delay, A+ would buy again

Mazda 18L Header Manifold Flange Standard - MAZDA18LHF - BMC Racing Products

I told them I'd be posting pics and impressions on one of the Miata sites tonight, so hopefully they will get the "premium" option listed shortly.

Just for reference, this is the "standard" flange listed on their website:

#211

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

I agree!

I apologize in advance for the horrendous pictures, but the lighting in my garage is miserable. I started by sticking the flange on the untouched BP6D head in my garage last night and everything lines up perfectly. Ports look good, all the holes are in the right places, absolutely no complaints. I did notice that the ports on the flange are slightly oversize compared to an OEM gasket.

The gasket is the silver ring in the above pic between the head and the flange. Its not nearly as bad as it looks in the horrible picture. I'll probably hit it with a sharpe, trim the gasket to match the flange, then match the ports in the head to the trimmed gasket.

The 1.5" Schedule 40 drops right into the pocket with no issues.

On the inside, the weld el is eversoslightly smaller than the hole, but again, should be no more than a couple minutes work with a die grinder to smooth it out after its welded up.

The opening in the T25 flange is a bit larger than the turbine inlet on my SR20 terbo but it shouldn't be hard to open the housing up to match. Moar spoolz, amirite? I haven't tried it on the GT2560R yet. Either way I failed and did not take a picture. I also failed to check the thread size. I'm HOPING it is M8, but I have no earthly idea.

After conversing with the guys from Boerner, it sounds like they are willing to do any of their flanges in mild or stainless by request. I would expect the pricing on the BP premium flange in mild to be around $55-60 based on their other products, and probably closer to $90-100 in 304SS but don't ******* quote me on that. Shoot Sam an email and he can get you hooked up. Now that they have the code for the ports, it should be as simple as an email and a paypal transaction. When I inquired about the lack of Garrett T25 5 bolt flanges on their site, they told me they can do it, they just don't have them listed on the website. They said they have A LOT of other flanges for both foreign and domestic applications but they only list the popular ones on the site. No idea how the BP one got on there

I apologize in advance for the horrendous pictures, but the lighting in my garage is miserable. I started by sticking the flange on the untouched BP6D head in my garage last night and everything lines up perfectly. Ports look good, all the holes are in the right places, absolutely no complaints. I did notice that the ports on the flange are slightly oversize compared to an OEM gasket.

The gasket is the silver ring in the above pic between the head and the flange. Its not nearly as bad as it looks in the horrible picture. I'll probably hit it with a sharpe, trim the gasket to match the flange, then match the ports in the head to the trimmed gasket.

The 1.5" Schedule 40 drops right into the pocket with no issues.

On the inside, the weld el is eversoslightly smaller than the hole, but again, should be no more than a couple minutes work with a die grinder to smooth it out after its welded up.

The opening in the T25 flange is a bit larger than the turbine inlet on my SR20 terbo but it shouldn't be hard to open the housing up to match. Moar spoolz, amirite? I haven't tried it on the GT2560R yet. Either way I failed and did not take a picture. I also failed to check the thread size. I'm HOPING it is M8, but I have no earthly idea.

#214

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899