CHRA/turbine bolts relaxing.

#1

Tour de Franzia

Thread Starter

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

My CHRA bolts are relaxing again, but luckily the Inco safety wire kept them safe.

Those bolts in the pic, with the safety wire.

TiAL doesn't understand the need for a failsafe, drilled inconel bolt. So I'm stuck using the standard crap metal bolt supplied by TiAL. I stretched the bolts again at Houston, but thanks to the safety wire I drove the car in the last session of the day, then drove the car 5-hours home.

I contacted ARTech tonight and I'm going to drop the car off with him to build a crane connecting at the compressor housing. I'd appreciate it if you guys could ***** through with pictures of turbo cranes and we can get a good plan for fixing this relaxing hardware. I don't really know which direction to go, hanging the crane to the compressor housing looks easy, hitting the turbine is going to take some serious effort and be a real bitch to service because the turbo is so low and so close the to the engine mount.

All I know is I want a crane strong enough to hold the motor.

Those bolts in the pic, with the safety wire.

TiAL doesn't understand the need for a failsafe, drilled inconel bolt. So I'm stuck using the standard crap metal bolt supplied by TiAL. I stretched the bolts again at Houston, but thanks to the safety wire I drove the car in the last session of the day, then drove the car 5-hours home.

I contacted ARTech tonight and I'm going to drop the car off with him to build a crane connecting at the compressor housing. I'd appreciate it if you guys could ***** through with pictures of turbo cranes and we can get a good plan for fixing this relaxing hardware. I don't really know which direction to go, hanging the crane to the compressor housing looks easy, hitting the turbine is going to take some serious effort and be a real bitch to service because the turbo is so low and so close the to the engine mount.

All I know is I want a crane strong enough to hold the motor.

Last edited by hustler; 02-24-2011 at 03:55 PM.

#2

Tour de Franzia

Thread Starter

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

http://www.bufkinengineering.com/turbo_bracket.htm

http://www.honda-tech.com/showthread.php?t=2069621

What not to do

What are these funky mount thingies (made from pipe) called?

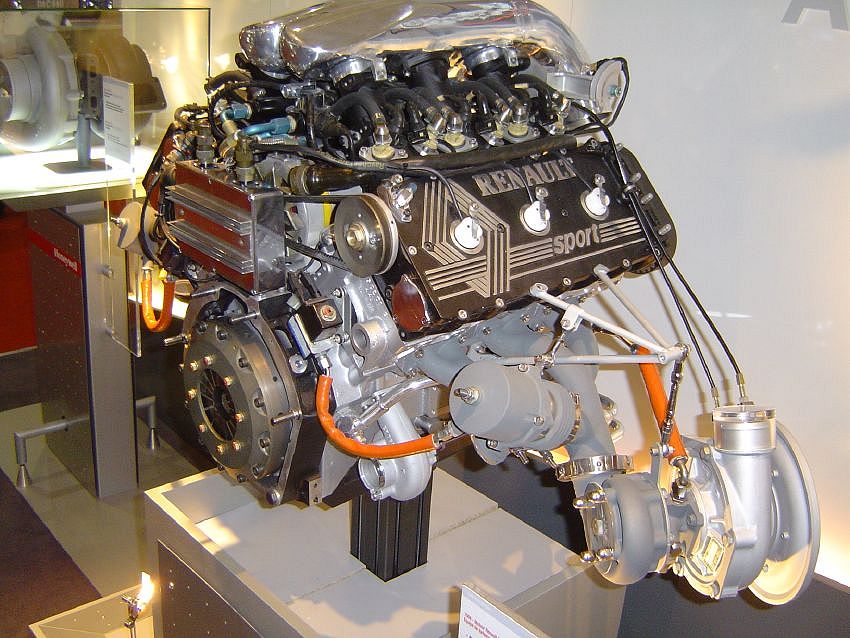

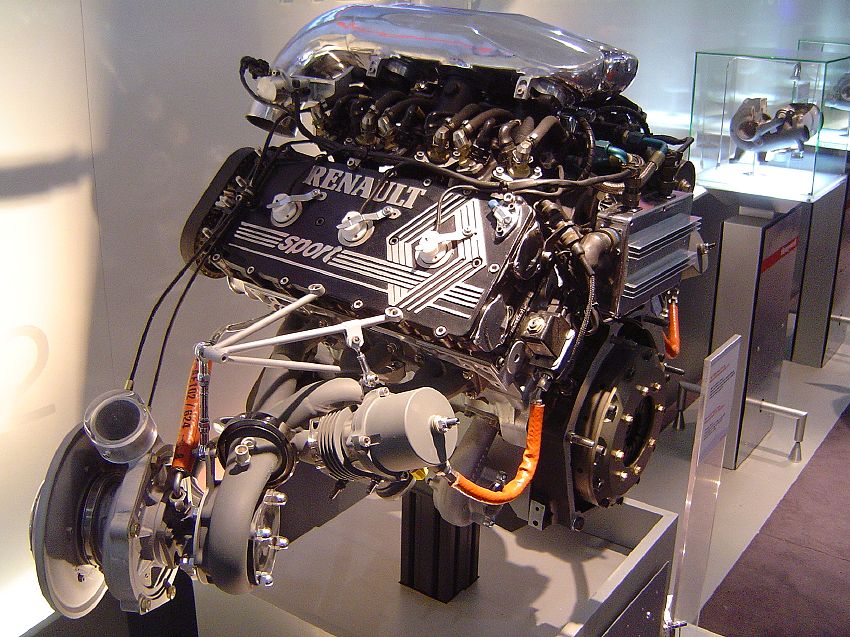

oh my god:

http://www.midlana.com/Diaries/Old%2.../2009June_Dec/

#4

I don't have much to contribute... but, aren't these type things usually better placed under the turbo. This would place your 'crane' in compression instead of tension and should be more effective at supporting the weight and damping vibrations. Also, Midlana is freaking sweet, I can't wait for it to be done so I can buy the book.

#5

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,176

Total Cats: 1,680

Have you talked to any machine shops about drilling the holes in the inconel bolts? I have briefly talked to Savington about him doing my future setup and I believe he knows a machine shop that will do it.

#7

I think so but i mean **** dude you are the only one that I have seen thats had this problem as much as you do. Might as well do something like that F1 example and something on the bottom of the turbo as well this way the bastard never moves. If its worth doing, in this instance, it seems like its worth over doing imo

#10

Elite Member

iTrader: (16)

Join Date: Oct 2006

Location: Las Cruces, NM

Posts: 1,647

Total Cats: 524

I know I'm a noob at this, but some of those braces in the pics have the support on the turbine side, using the very bolts that get loose. You may want to focus on the setups that are on the compressor side.

#12

I like the single adjustable bottom support best, but this will only work if you have something to attach it to underneath the turbo. Nest is the fancy five point. In your case it will probably only need to be a four point because your turbo setup is not sticking way out off the motor. The key to the latter setup is that all of the weight is being supported by the side of the block via the attachment point at the exhaust stud. The valve cover connections are only stabilizers. You do not want a lot of torque on those valve cover points

#13

In fact the bolt to the turbo boss was only used, in the OEM Mazda installation, to locate the turbo on the bracket rather than be in high tension supporting it's weight all the time. Therefore no breakage or stretching.

#15

-Brad

#16

Tour de Franzia

Thread Starter

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

I think so but i mean **** dude you are the only one that I have seen thats had this problem as much as you do. Might as well do something like that F1 example and something on the bottom of the turbo as well this way the bastard never moves. If its worth doing, in this instance, it seems like its worth over doing imo

I fully intent for ARTech to make something "fancy", and significantly overdone.

I like the single adjustable bottom support best, but this will only work if you have something to attach it to underneath the turbo. Nest is the fancy five point. In your case it will probably only need to be a four point because your turbo setup is not sticking way out off the motor. The key to the latter setup is that all of the weight is being supported by the side of the block via the attachment point at the exhaust stud. The valve cover connections are only stabilizers. You do not want a lot of torque on those valve cover points

This is how it was done on factory turbo bp's for wrc. They had a boss cast into the bottom of the turbo which bolted to a bracket that was bolted to the block. Obviously you wouldn't have the boss on the turbo but adding a flange off the (help me out here) compressor clocking bolts would have the same effect and not introduce another part to stretch under heat.

In fact the bolt to the turbo boss was only used, in the OEM Mazda installation, to locate the turbo on the bracket rather than be in high tension supporting it's weight all the time. Therefore no breakage or stretching.

In fact the bolt to the turbo boss was only used, in the OEM Mazda installation, to locate the turbo on the bracket rather than be in high tension supporting it's weight all the time. Therefore no breakage or stretching.

your intution serves you well. I am an engineer, and I'll add this: These supports are longish tubes like columns. If they are simply supported by rod ends on both sides (3degrees of freedom) they will hold more load before failing in tnesion rather than compression all other things being equal. That said, a reasonably sized thin wall tube that does have 3DOF at both ends can take ALOT of force, look at push rod suspensions on formula cars and kit cars and the like; it is very important if you go this route to ensure that the push rod has 3dof at both ends all the way though the range of motion though. If it binds at either end the forces go through the roof and the likelihood of it buckling under load is greatly increased.

-Brad

-Brad

I'd also like to add that considering my occupation, your post is the best piece of advice I've ever received from Baton Rouge.

Oh man, I think I'm getting warmer on this deal.

#20

Tour de Franzia

Thread Starter

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

There is no room in this thread for people to tell me that a year of driving twisty-roads is anything close to what the Miata Challenge crew is doing in one lap. Now that I'm on the gas longer thanks to the new shocks, the problem is back.

Just think about TWS, I ran 45-minutes non-stop at one point, which means about 23 times I took the car from 80mph-150mph in one stint. When was the last time you hung the tack at 5500rpm in 6th? It's another world out there, and it's a cruel one. Trail-braking from 150-70mph, through an apron, into a corner...that's duty cycle. I can't complain about snugging-up my nuts 3-4 times per year, but I'm mainly doing this so I don't have to order more bolts and snap these in the turbine housing.