loose downpipe nuts. support bracket

#1

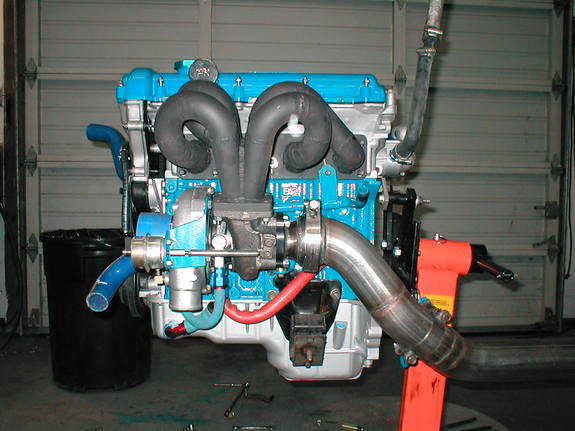

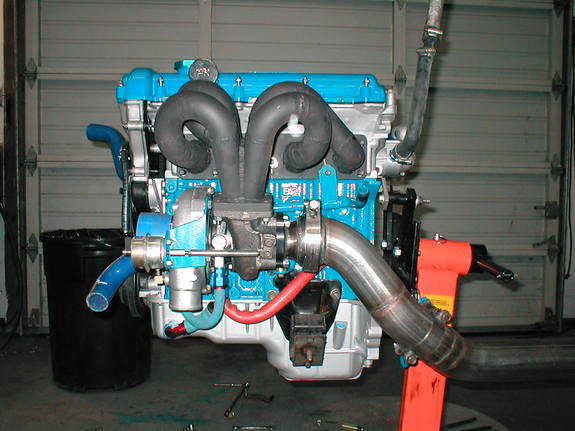

so trying to get some small issues worked out after my last track event.

my car came with a custom down pipe,which bolts to a flex joint mated to a 3' straight pipe.

one turbo stud was damaged so I removed and replaced it. I used high end locking nuts from o34 motorsports left over from my audi to secure the downpipe to the turbo. everytime I track the bolts come loose and they are lost.

the exhaust is only supported by the down pipe bolts and at the rear of the car by a two sided exhaust hanger (left and right)

do you guys think I would be better off doing a second traditional flexible exhaust hanger support to the rear of the flex joint or do a solid support to the front of the trans before the flex joint, or perhaps both?

might be kinda dumb but I just want to try a bolt on solution to see if it works. the exhaust is nice tig welds and and I dont have a tig guy handy in my area right now and I don't to glob it up with some jack job mess welding job.

my car came with a custom down pipe,which bolts to a flex joint mated to a 3' straight pipe.

one turbo stud was damaged so I removed and replaced it. I used high end locking nuts from o34 motorsports left over from my audi to secure the downpipe to the turbo. everytime I track the bolts come loose and they are lost.

the exhaust is only supported by the down pipe bolts and at the rear of the car by a two sided exhaust hanger (left and right)

do you guys think I would be better off doing a second traditional flexible exhaust hanger support to the rear of the flex joint or do a solid support to the front of the trans before the flex joint, or perhaps both?

might be kinda dumb but I just want to try a bolt on solution to see if it works. the exhaust is nice tig welds and and I dont have a tig guy handy in my area right now and I don't to glob it up with some jack job mess welding job.

Last edited by psreynol; 05-14-2013 at 09:37 PM.

#2

a lot of guys run setups similar to this: Flyin' Miata : Turbochargers : Parts and upgrades : 1990-97 2.5" FM exhaust brace

which gives you a hard attachment to the front of the tranny. I bought the above kit from FM, and then realized it won't work with my downpipe. I've been meaning to fabricate one but have been putting it off for other more pressing projects.

which gives you a hard attachment to the front of the tranny. I bought the above kit from FM, and then realized it won't work with my downpipe. I've been meaning to fabricate one but have been putting it off for other more pressing projects.

#5

Senior Member

iTrader: (7)

Join Date: Oct 2011

Location: Horse and Buggy, PA

Posts: 704

Total Cats: 21

a lot of guys run setups similar to this: Flyin' Miata : Turbochargers : Parts and upgrades : 1990-97 2.5" FM exhaust brace

which gives you a hard attachment to the front of the tranny. I bought the above kit from FM, and then realized it won't work with my downpipe. I've been meaning to fabricate one but have been putting it off for other more pressing projects.

which gives you a hard attachment to the front of the tranny. I bought the above kit from FM, and then realized it won't work with my downpipe. I've been meaning to fabricate one but have been putting it off for other more pressing projects.

/threadjack

#7

Inconel studs seem to make the biggest difference of all the tricks ever tried to keep bolted connections to turbine housing from falling apart.

That said my personal experience is that not supporting the downpipe at the transmission flywheel housing or there about dramatically increases the failure rate of turbine connections and exhaust manifolds.

I don't like the FM part that much however because of the U-bolt clamp. I tried a similar setup and found the U-bolt was always loose and keeping tightening it just would crush the U-bolt into the pipe after a few track heat cycles the U-bolt would be loose again and the pipe would develop a crushed in groove where the U-bolt contacted it with its clamping force. The clamp design needs about an inch wide contact surface between it and the pipe all around it so it develops less contact pressure on the pipe and will thermally expand and contract with the pipe. I fabricated my own clamp like this and it has been in service for several years now and seems to be a robust solution.

Bob

That said my personal experience is that not supporting the downpipe at the transmission flywheel housing or there about dramatically increases the failure rate of turbine connections and exhaust manifolds.

I don't like the FM part that much however because of the U-bolt clamp. I tried a similar setup and found the U-bolt was always loose and keeping tightening it just would crush the U-bolt into the pipe after a few track heat cycles the U-bolt would be loose again and the pipe would develop a crushed in groove where the U-bolt contacted it with its clamping force. The clamp design needs about an inch wide contact surface between it and the pipe all around it so it develops less contact pressure on the pipe and will thermally expand and contract with the pipe. I fabricated my own clamp like this and it has been in service for several years now and seems to be a robust solution.

Bob

Last edited by bbundy; 05-15-2013 at 12:34 PM.

#9

Inconel studs seem to make the biggest difference of all the tricks ever tried to keep bolted connections to turbine housing from falling apart.

That said my personal experience is that not supporting the downpipe at the transmission flywheel housing or there about dramatically increases the failure rate of turbine connections and exhaust manifolds.

I don't like the FM part that much however because of the U-bolt clamp. I tried a similar setup and found the U-bolt was always loose and keeping tightening it just would crush the U-bolt into the pipe after a few track heat cycles the U-bolt would be loose again and the pipe would develop a crushed in groove where the U-bolt contacted it with its clamping force. The clamp design needs about an inch wide contact surface between it and the pipe all around it so it develops less contact pressure on the pipe and will thermally expand and contract with the pipe. I fabricated my own clamp like this and it has been in service for several years now and seems to be a robust solution.

Bob

That said my personal experience is that not supporting the downpipe at the transmission flywheel housing or there about dramatically increases the failure rate of turbine connections and exhaust manifolds.

I don't like the FM part that much however because of the U-bolt clamp. I tried a similar setup and found the U-bolt was always loose and keeping tightening it just would crush the U-bolt into the pipe after a few track heat cycles the U-bolt would be loose again and the pipe would develop a crushed in groove where the U-bolt contacted it with its clamping force. The clamp design needs about an inch wide contact surface between it and the pipe all around it so it develops less contact pressure on the pipe and will thermally expand and contract with the pipe. I fabricated my own clamp like this and it has been in service for several years now and seems to be a robust solution.

Bob

so where did you attach the bracket? same spot on the rear of the trans like the FM bracket or did you find another spot? I need to attach it to the front of the bell housing, pre flex joint.

#10

#12

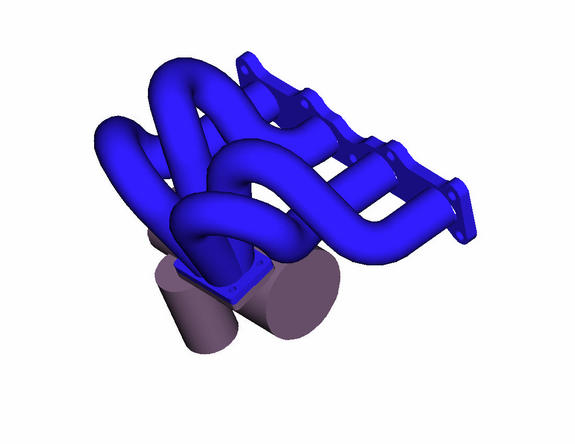

I modified a stock OEM bracket that mounts to two of the big bell housing bolts. Just needed to move the weld nut location on it a bit. To fit up with my downpipe configuration. Attached picture you can make out flat strap clam shell clamp. One of the bolts is long and threads into the bell housing bracket very similar to the OEM downpipe bracket the cars come with but has the nut position modified by about an inch.

that looks awesome. I'm going to do that. so many of the oem parts are missing on my car it is crazy. I had no idea that part even existed. one of the challenges of making a previously modded car a track. thanks for the help.

#13

I modified a stock OEM bracket that mounts to two of the big bell housing bolts. Just needed to move the weld nut location on it a bit. To fit up with my downpipe configuration. Attached picture you can make out flat strap clam shell clamp. One of the bolts is long and threads into the bell housing bracket very similar to the OEM downpipe bracket the cars come with but has the nut position modified by about an inch.

Thanks for posting that reference.

Op, you can get M8x1.25 inconel studs from the 300zx turbo that should work for you for like 5 bucks a pop. I have a link in the epic studs loosening thread.

#14

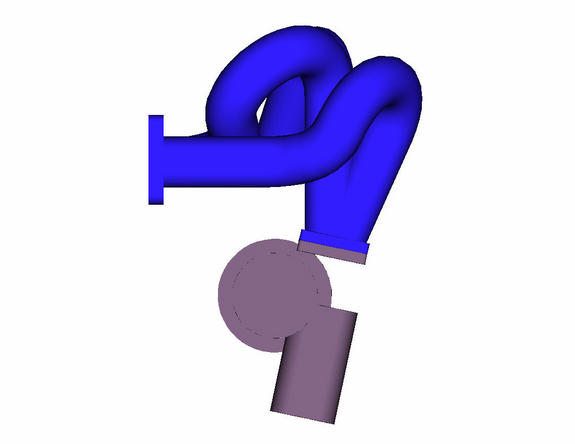

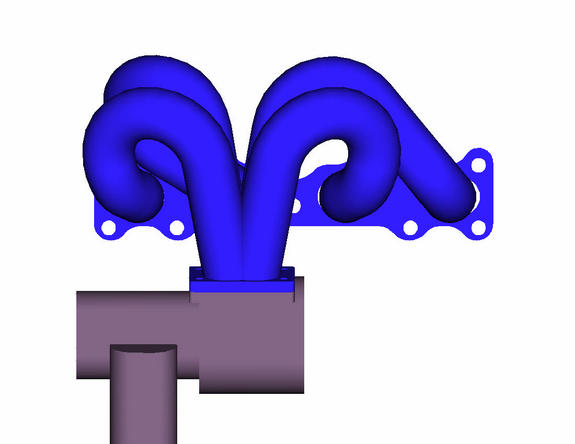

Wow bob, that looks 100% like the manifold I was going to make for my car until I ran into EFRhitblock. Super weird coincidence. *edit, except my cylinders 1 & 2 are swapped compared to that and I have an extra bend in the cylinder 4.

Thanks for posting that reference.

Op, you can get M8x1.25 inconel studs from the 300zx turbo that should work for you for like 5 bucks a pop. I have a link in the epic studs loosening thread.

Thanks for posting that reference.

Op, you can get M8x1.25 inconel studs from the 300zx turbo that should work for you for like 5 bucks a pop. I have a link in the epic studs loosening thread.

#15

This is the 1.25" sch40 manifold right? This was my design I was talking about it being similar to. I wish I could have been able to use any sort of symmetry. And gotten better than having them all within 1/2" of each other lengthwise. I also have no idea how you managed to make up that kind of length on cylinder 2 and have it on the port closer to the head.

#16

This is the 1.25" sch40 manifold right? This was my design I was talking about it being similar to. I wish I could have been able to use any sort of symmetry. And gotten better than having them all within 1/2" of each other lengthwise. I also have no idea how you managed to make up that kind of length on cylinder 2 and have it on the port closer to the head.

#17

It also puts 1 & 4 and 2 & 3 on opposite corners of the collector which mean the pulses run in a circle with the firing order. This can't be a bad thing.

I have the MSM turbo configuration in my car and it is nicely braced to the block so my manifold bolts have never been a significant problem. The downpipe on my configuration was another story however. I battled them for two seasons before taking the 'hammer to kill a fly' approach and drilled the turbo for M10, reamed out the DP holes and bought Savington's inconel kit. Now my downpipe stays put. I use the M8 Nissan studs on the manifold/turbo now because there isn't clearance to tap to M10.

I also have the FM brace but I modified it to fit my DP which is BEGi's SGDP for the MSM and is closer to 2.75" at the exit. It crushes the pipe like Bob describes so I will need to do something closer to his design sooner rather than later.

I have the MSM turbo configuration in my car and it is nicely braced to the block so my manifold bolts have never been a significant problem. The downpipe on my configuration was another story however. I battled them for two seasons before taking the 'hammer to kill a fly' approach and drilled the turbo for M10, reamed out the DP holes and bought Savington's inconel kit. Now my downpipe stays put. I use the M8 Nissan studs on the manifold/turbo now because there isn't clearance to tap to M10.

I also have the FM brace but I modified it to fit my DP which is BEGi's SGDP for the MSM and is closer to 2.75" at the exit. It crushes the pipe like Bob describes so I will need to do something closer to his design sooner rather than later.

#18

you guys with manifold talk are fracking up my thread.

what do you think about these nuts? for down pipe /turbo?

https://www.034motorsport.com/hardwa...5-p-18954.html

I got a couple good butt clamps to kinda copy FM exhaust bracket but the clearance is somewhat of a issue. I want my downpipe supported pre flex joint so the fm kit for something similar will not work.

I'm thinking about welding 2 tabs or bung on the downpipe so i can tie the downpipe to the exhaust manifold. not sure if would be better to tie the downpipe to the manifold or the transmission. in theory the trans would be better. thoughts?

what do you think about these nuts? for down pipe /turbo?

https://www.034motorsport.com/hardwa...5-p-18954.html

I got a couple good butt clamps to kinda copy FM exhaust bracket but the clearance is somewhat of a issue. I want my downpipe supported pre flex joint so the fm kit for something similar will not work.

I'm thinking about welding 2 tabs or bung on the downpipe so i can tie the downpipe to the exhaust manifold. not sure if would be better to tie the downpipe to the manifold or the transmission. in theory the trans would be better. thoughts?