Oil cooler tech

#81

Basic design theory, use the biggest darn cooler I could find and put it in an accessible, easy-to-mount/service location:

My shopping list:

Oil Cooler: $125 (Canton Racing Products 23-520 Canton Racing Oil Coolers - Free Shipping on All Orders @ JEGS)

Thermostatic Sandwich Plate: $35 (Derale 15732 Derale Remote Oil Filter Kits, Mounts, and Adapters - Free Shipping on All Orders @ JEGS)

Hose: $24 (JEGS Performance Products 110930 JEGS Pro-Flo 350 Series Nylon Braided Hose - Free Shipping on All Orders @ JEGS)

Sandwich Plate Fittings: 2 x $6 (JEGS Performance Products 110108 JEGS AN to NPT Adapter Fittings - Free Shipping on All Orders @ JEGS)

Oil Cooler Fittings: 2 x $6 (JEGS Performance Products 110110 JEGS AN to NPT Adapter Fittings - Free Shipping on All Orders @ JEGS)

Sandwich Plate Hose End Fittings: 2 x $19 (JEGS Performance Products 110013 JEGS AN Hose End Fittings - Black - Free Shipping on All Orders @ JEGS)

Oil Cooler Hose End Fittings: 2 x $20 (JEGS Performance Products 110023 JEGS AN Hose End Fittings - Black - Free Shipping on All Orders @ JEGS)

Total: $286 + Free S&H

Some other notes about this setup:

1. Use a Wix 51626 or NAPA Gold 1626 Oil Filter.

2. Fill with 5 Qts (both the cooler and the filter are large).

3. Check oil level within 1 hour of last running engine. Because the oil cooler is bottom fed, some have reported that it could drain after long periods of time leading to a high oil level indication (I haven't observed this myself).

Last edited by hornetball; 08-22-2014 at 09:44 AM.

#84

Elite Member

iTrader: (2)

Join Date: May 2008

Location: Portland, Oregon

Posts: 3,468

Total Cats: 365

I'm going to say no, don't do that. For best airflow, fans need an airspace surrounding them. The FM shroud is spaced out from the rad to provide that airspace. The fan(s) then creates a more uniform low pressure zone across the back of the radiator.

By placing a heat exchanger in there, you have done two things - increased the resistance to flow for air moving through, and decreased the efficiency of the fan trying to pull air through. You will effectively stall the fan.

Somebody correct me if I'm wrong. This is what I think will happen.

By placing a heat exchanger in there, you have done two things - increased the resistance to flow for air moving through, and decreased the efficiency of the fan trying to pull air through. You will effectively stall the fan.

Somebody correct me if I'm wrong. This is what I think will happen.

#85

I think Richard is right. I would say for track use, especially if you've removed your AC condenser, go ahead and get rid of the AC fan to open up that space. It will provide better radiator flow too. Fans are great for slow driving or sitting, but nothing beats the airflow that forward motion and good ducting provide.

#86

My recollection of various m.net threads in the past was that people have seen +20F at the oil filter location compared to the sump. A quick use of my google fu found one of the threads I remembered: Oil temperature differences between the sump and the oil filter

Great info, thanks for sharing.

Last edited by matthewdesigns; 08-19-2014 at 10:57 AM.

#87

I'm going to say no, don't do that. For best airflow, fans need an airspace surrounding them. The FM shroud is spaced out from the rad to provide that airspace. The fan(s) then creates a more uniform low pressure zone across the back of the radiator.

By placing a heat exchanger in there, you have done two things - increased the resistance to flow for air moving through, and decreased the efficiency of the fan trying to pull air through. You will effectively stall the fan.

Somebody correct me if I'm wrong. This is what I think will happen.

By placing a heat exchanger in there, you have done two things - increased the resistance to flow for air moving through, and decreased the efficiency of the fan trying to pull air through. You will effectively stall the fan.

Somebody correct me if I'm wrong. This is what I think will happen.

Those fans have a much more linear airflow vs. static pressure curve compared to other fans. They still flow a great deal even with a bunch of heat exchangers from what I have read, so I wouldn't use the word "stall" unless they are bolted to a wall. They pull a manly amount of amps. Also, different fans reach peak efficiency at different static pressures, but in general peak efficiency is reached when the fan is placed under a decent resistance, about 1/3-1/2 of the static pressure where the fan reaches 0 airflow(stall). There is even a chance that the extra resistance will place the fan into its peak efficiency static pressure. Peak efficiency for the fan does not mean peak performance though.

Overall, I think you are right though, there definately isn't a reason to introduce this compromise into the system unless there is nowhere else for the oil cooler to be mounted. For peak performance, even though those fans pull a lot of air, I would say it's not as much as a well ducted system without the FM shroud and fans, unless the fans are even stonger than I think they are.

#88

Elite Member

iTrader: (2)

Join Date: May 2008

Location: Portland, Oregon

Posts: 3,468

Total Cats: 365

They are not; I have the full FM Stage 2 airflow kit. With the shroud spaced as far out as I could get it (one set of the spacers, couldn't stack two of them) along with ok-but-not-great ducting, I couldn't keep the coolant temps from climbing on warm track days.

2012 : 70F ambient day : 228F reported on my Scangauge on track.

Next step was to remove the shroud and second fan, and improve the ducting.

2013: 82F ambient day : 215F reported on my Scangauge on track.

Further improved my ducting (minor gains), removed the AC

2014: 90F ambient day : 207F reported on my Scangauge on track.

I'm not knocking FM's airflow kit at all, it's nice and well made. But it's a solution for a different problem than that of on-track cooling. The airflow obstruction from a radiator shroud is simply enormous.

Edited for timeline change data.

2012 : 70F ambient day : 228F reported on my Scangauge on track.

Next step was to remove the shroud and second fan, and improve the ducting.

2013: 82F ambient day : 215F reported on my Scangauge on track.

Further improved my ducting (minor gains), removed the AC

2014: 90F ambient day : 207F reported on my Scangauge on track.

I'm not knocking FM's airflow kit at all, it's nice and well made. But it's a solution for a different problem than that of on-track cooling. The airflow obstruction from a radiator shroud is simply enormous.

Edited for timeline change data.

Last edited by Mobius; 08-19-2014 at 03:18 PM.

#90

They are not; I have the full FM Stage 2 airflow kit. With the shroud spaced as far out as I could get it (one set of the spacers, couldn't stack two of them) along with ok-but-not-great ducting, I couldn't keep the coolant temps from climbing on warm track days. 70F ambient day:228F reported on my Scangauge on track.

Since that time I have improved my ducting, removed the AC, and removed both the rear shroud and the second Spal fan. Results -

90F ambient day: 207F reported on my Scangauge on track.

I'm not knocking FM's airflow kit at all, it's nice and well made. But it's a solution for a different problem than that of on-track cooling. The airflow obstruction from a radiator shroud is simply enormous.

Since that time I have improved my ducting, removed the AC, and removed both the rear shroud and the second Spal fan. Results -

90F ambient day: 207F reported on my Scangauge on track.

I'm not knocking FM's airflow kit at all, it's nice and well made. But it's a solution for a different problem than that of on-track cooling. The airflow obstruction from a radiator shroud is simply enormous.

It seems you wouldn't want to mount the oil cooler inside the FM shroud because that would further reduce the effectiveness of a kit that already isn't effective enough for some users on track.

First hand experience wins. How much improvement do you think was netted from A/C condenser removal? I can't decide how large of an obstruction it is, but for daily driving in TX, the car simply has to have A/C. My ideal setup would still have A/C, but a reroute, really efficient radiator, ducting, louvers from Singular Motorsports

, and now I'm thinking to skip the FM shroud and just mount a couple fans on the radiator, which should be enough for the street, and remove one fan when I get to the track.

, and now I'm thinking to skip the FM shroud and just mount a couple fans on the radiator, which should be enough for the street, and remove one fan when I get to the track.I'm really grateful for threads like this and the cooling system one, even though recently this has drifted more towards overall cooling system and not just oil coolers.

Since this is the oil cooler thread, I think oil selection may be a decent topic. Recently, I switched to the Rotella T6 that is so popular here. Strange thing though, my engine seems to not like it very much. The car now has a light stumble at about 2200 RPM when the oil is cold, such as starting my first drive of the day. It has no issue when warm at all. My car is a 2004 w/VVT, I think it is the VVT actuator complaining, but I don't see why because shouldn't the RT6 5W-40 behave the about the same(when cold) as the 5W-20 M1 I was running? Anyone have experience with your car not liking RT6?

Last edited by Dustin1824; 08-19-2014 at 03:14 PM. Reason: Added oil selection experience followed by question

#91

Elite Member

iTrader: (2)

Join Date: May 2008

Location: Portland, Oregon

Posts: 3,468

Total Cats: 365

Edited post #88 to reflect timeline change data.

The AC condenser removal was worth quite a bit as you can see. There is the removal of the raw airflow obstruction of course, but also the ducting is simpler and more effective without it. No aggravating holes for the condenser lines etc.

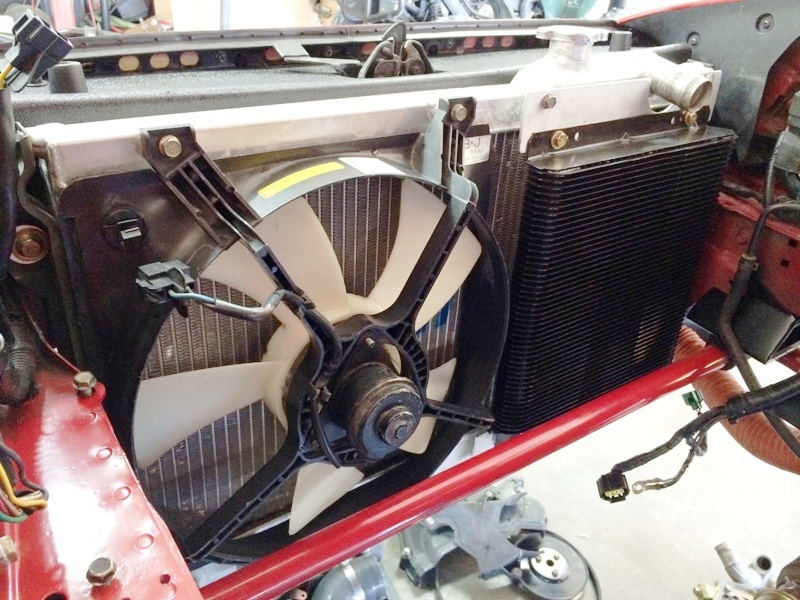

Edit. To bring this full circle back to oil specifically, I now have room to mount an oil cooler to the back of the radiator as Mr. Hyde has done. I had plans to mount a small one on the passenger side exterior frame rail in the front bumper, but have abandoned those. Oil line routing would have put the lines at significant risk of abrasion plus I'm not sure the tiny snowmobile-based oil cooler I selected for the job will flow enough. I tried to find data but simply couldn't. So in the best mt.net tradition I will follow a path proven by others. Singular Motorsports hood louvers (thanks Ryan!) should ensure I have plenty of overall heat rejection capacity.

I like the backside of the radiator for two reasons. 1) it's easy and convenient for hose routing. 2) There is some built-in moderation of oil temps using that air. I only want to knock 20-30F or so off my peak oil temps, and under normal freeway driving conditions the oil won't be over-cooled. Maybe in freezing temps I will put a blockoff plate on it.

The AC condenser removal was worth quite a bit as you can see. There is the removal of the raw airflow obstruction of course, but also the ducting is simpler and more effective without it. No aggravating holes for the condenser lines etc.

Edit. To bring this full circle back to oil specifically, I now have room to mount an oil cooler to the back of the radiator as Mr. Hyde has done. I had plans to mount a small one on the passenger side exterior frame rail in the front bumper, but have abandoned those. Oil line routing would have put the lines at significant risk of abrasion plus I'm not sure the tiny snowmobile-based oil cooler I selected for the job will flow enough. I tried to find data but simply couldn't. So in the best mt.net tradition I will follow a path proven by others. Singular Motorsports hood louvers (thanks Ryan!) should ensure I have plenty of overall heat rejection capacity.

I like the backside of the radiator for two reasons. 1) it's easy and convenient for hose routing. 2) There is some built-in moderation of oil temps using that air. I only want to knock 20-30F or so off my peak oil temps, and under normal freeway driving conditions the oil won't be over-cooled. Maybe in freezing temps I will put a blockoff plate on it.

#93

I think you want to turn the oil cooler over so the fittings are on the top to prevent gravity drain back into the pan. Alternately, a loop in the lines would also work (top of the loop higher than the cooler).

As it is now, each time you restart after the cooler has drained back in to the oil pan, you are effectively performing a dry start until you displace all the air and again pressurize the system with oil.

How long does it take to build oil pressure following a hour or longer off time?

#94

I think you want to turn the oil cooler over so the fittings are on the top to prevent gravity drain back into the pan. Alternately, a loop in the lines would also work (top of the loop higher than the cooler).

As it is now, each time you restart after the cooler has drained back in to the oil pan, you are effectively performing a dry start until you displace all the air and again pressurize the system with oil.

How long does it take to build oil pressure following a hour or longer off time?

As it is now, each time you restart after the cooler has drained back in to the oil pan, you are effectively performing a dry start until you displace all the air and again pressurize the system with oil.

How long does it take to build oil pressure following a hour or longer off time?

#95

That would be a nice spot for an oil cooler but my boosted miata still had over heating issues with two fans one staying on permanently. Then again this was in 118 degree weather. I might put it above my intercooler in front of the radiator. I just don't want to cover too much air flow to the radiator. Anyone ever put one into the cowl? Maybe even put hood risers to pull the heat?

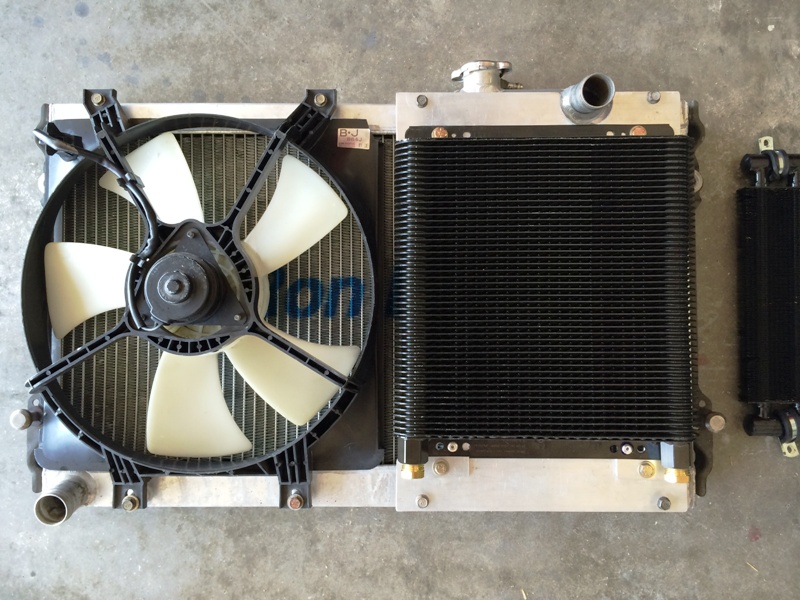

#96

I basically copied MR. Hyde's setup and ditched one of my fans and ran my oil cooler behind the radiator. I don't have an oil temp gauge but I did notice that going from no oil cooler to cooler that I had more consistent oil pressure as the car got hot during a session, this was on 2 different days where the ambient temperature was hovering around 90. I like this solution because it doesn't block flow to the radiator and for the pacific NW which isn't consistently hot like CA or Texas it helps bring the oil up to temp faster on cooler days which are quite common. I plan to add a temp gauge over the winter to monitor it.

The cooler itself is a small Setrab unit that I purchased used from Roush Yates for a killer deal. It has high density foam on the leading edges to seal it against the radiator.

The cooler itself is a small Setrab unit that I purchased used from Roush Yates for a killer deal. It has high density foam on the leading edges to seal it against the radiator.

#97

I'd agree. Oil coolers come like this OE (i.e.: MB Cosworth powered 190e 2.3 & 2.5-16). I ran mine like this for over 3k miles w/o issue- and oil pressure was instant on startup. And I've seen countless race cars like this. That said, there are numerous sources out there that state ports should either be vertical, or on top, but not on bottom for the reason stated. Personal choice I suppose.

re: greddygalant - and it even looks like a low profile smaller fan could fit on the back of the oil cooler if needed for a street car. In my fan research I ran across OE compact 5-9" ATV/motorcycle fans that pulled 300-500cfm and were cheap used on eBay.

re: greddygalant - and it even looks like a low profile smaller fan could fit on the back of the oil cooler if needed for a street car. In my fan research I ran across OE compact 5-9" ATV/motorcycle fans that pulled 300-500cfm and were cheap used on eBay.

#98

Can an FM oil cooler (or any oil cooler) increase oil PSI? I installed one when I was preparing for FI. Next I installed gauges. My oil pressure is 20-25 at idle once the synthetic oil is warmed up but my running PSI is 75 PSI. Since I didn't have gauges BEFORE I installed the FM oil cooler I can't be sure if it has anything to do with it. My sensor is in one of the lines to the oil cooler right at the filter location. I'm wondering if the cooler lines are too small