Why do Rotrex suck at torque?

#62

Rotrex owner: "hai gays, building a rotrex, wat injectors???"

Perez, Scott, 18psi, et, al: "trubos are better becuz torques!!"

Every damn thread

Next time you're in California, I'll give you a ride in a Miata with a Rotrex. You can drive it too. Careful, it tends to break the tires loose when leaving lights if you get more than about 40% TPS even at fairly low revs. Then you can write a dissertation on how unrelentingly miserable and unfulfilling the experience was.

__________________

Last edited by emilio700; 12-14-2015 at 08:43 PM. Reason: speling

#63

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,019

Total Cats: 6,587

This is just one of those situations in which I acknowledge that I am not a guru-level source of subject-matter knowledge, and instead ask myself "Which OEMs or professional racing teams are using this technology, as opposed to some readily-available alternative?"

Centrifugal superchargers were not uncommon in OEM automotive applications during the period of the 1930s-1950s, a time in which they were also a dominant technology in military aircraft.

In subsequent years, advances in precision machining, metallurgy and lubrication technology enabled other methods of forced induction to become dominant.

So I ask, right here in 2015, which top-level professional racing teams are using centrifugal superchargers? Which OEM automakers are using them?

Or have we just latched onto them because they seem esoteric and unique, and it's tempting to believe that we've discovered some hidden secret?

Centrifugal superchargers were not uncommon in OEM automotive applications during the period of the 1930s-1950s, a time in which they were also a dominant technology in military aircraft.

In subsequent years, advances in precision machining, metallurgy and lubrication technology enabled other methods of forced induction to become dominant.

So I ask, right here in 2015, which top-level professional racing teams are using centrifugal superchargers? Which OEM automakers are using them?

Or have we just latched onto them because they seem esoteric and unique, and it's tempting to believe that we've discovered some hidden secret?

#64

This is just one of those situations in which I acknowledge that I am not a guru-level source of subject-matter knowledge, and instead ask myself "Which OEMs or professional racing teams are using this technology, as opposed to some readily-available alternative?"

Centrifugal superchargers were not uncommon in OEM automotive applications during the period of the 1930s-1950s, a time in which they were also a dominant technology in military aircraft.

In subsequent years, advances in precision machining, metallurgy and lubrication technology enabled other methods of forced induction to become dominant.

So I ask, right here in 2015, which top-level professional racing teams are using centrifugal superchargers? Which OEM automakers are using them?

Or have we just latched onto them because they seem esoteric and unique, and it's tempting to believe that we've discovered some hidden secret?

Centrifugal superchargers were not uncommon in OEM automotive applications during the period of the 1930s-1950s, a time in which they were also a dominant technology in military aircraft.

In subsequent years, advances in precision machining, metallurgy and lubrication technology enabled other methods of forced induction to become dominant.

So I ask, right here in 2015, which top-level professional racing teams are using centrifugal superchargers? Which OEM automakers are using them?

Or have we just latched onto them because they seem esoteric and unique, and it's tempting to believe that we've discovered some hidden secret?

Your rational, linear engineer thinking ignores all the reasons people like them, posted on this board ad infinitum. We like them because they makes us happy. Last time I did a reality check, that was enough. Car goes fast, breaks less, costs less.

Much the same way you have trouble relating to cyclists that spend their discretionary income on lightweight high performance bicycles. you just.. don't.. get it.

__________________

#65

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,019

Total Cats: 6,587

I asked a serious question, you responded with an ad homimem attack.

If you don't believe me vis-a-vis the "which pros are using it" test, do some searching of my past posts. I've used this precise wording in the inquisition of electric superchargers, magic oil filters, magic oil treatments, HHO generators, things involving magnets and perpetual motion, and a number of other technologies which just didn't seem to pass the sniff test.

I've sometimes been wrong. Occasionally you've been the one to illuminate me.

But I apply the same logic to a sacred cow, and suddenly I'm an antagonist?

No. Being offended isn't a "get out of logic free" card. You're a smart guy whose opinion I genuinely respect, and you can do better than this.

Yes, I made a couple of snarky, tongue-in-cheek statements a few years ago when Hustler did a 180° flip from "talk of carbon fiber will get you banned" to "check out my new CF frame," and you'll never let me forget it.

If you don't believe me vis-a-vis the "which pros are using it" test, do some searching of my past posts. I've used this precise wording in the inquisition of electric superchargers, magic oil filters, magic oil treatments, HHO generators, things involving magnets and perpetual motion, and a number of other technologies which just didn't seem to pass the sniff test.

I've sometimes been wrong. Occasionally you've been the one to illuminate me.

But I apply the same logic to a sacred cow, and suddenly I'm an antagonist?

No. Being offended isn't a "get out of logic free" card. You're a smart guy whose opinion I genuinely respect, and you can do better than this.

Much the same way you have trouble relating to cyclists that spend their discretionary income on lightweight high performance bicycles. you just.. don't.. get it.

#66

I don't think the superchargers have had the same development on the miata platform that turbos have. There is no disputing the fact that turbos have great 'bang for the buck' streetlevel power which is where 90% of the miata crowd sit but there are some big issues when it comes to track work. Most of those are resolved with the newer kits, however how long has it taken to get all the issues sorted?

There are some current high power twin screw / roots setups that are generating a great level of power (and torque). Other than the work Emilio has done with the Rotrex, there aren't really many other setups on the forums that are building high hp Rotrex's targeted for track. This doesn't mean that they aren't suited to it... it just means no-one has posted it on a forum.

If you look in the Honda time attack and track racing space there are countless Rotrex builds... and they win over turbos. Why? They are pushing very high HP but have drivable, linear power delivery, no lag and can run all day without issues.

Given that we are stuck with torque limited gear boxes, a Rotrex should be the ideal match and I'll go as far as saying it theoretically could be faster than a turbo on a race track. My target Rotrex torque curve would be a flat line, and if set up correctly could sit at 280 - 300 ft lbs all the way to rev limit, right at the boundary of the strength of the gearbox. It's basically a 2 x multiplication of my existing N/A power curve. With the right sized Rotrex I think 450whp is easily achievable without destroying boxes. Who wouldn't want to drive that?

There are some current high power twin screw / roots setups that are generating a great level of power (and torque). Other than the work Emilio has done with the Rotrex, there aren't really many other setups on the forums that are building high hp Rotrex's targeted for track. This doesn't mean that they aren't suited to it... it just means no-one has posted it on a forum.

If you look in the Honda time attack and track racing space there are countless Rotrex builds... and they win over turbos. Why? They are pushing very high HP but have drivable, linear power delivery, no lag and can run all day without issues.

Given that we are stuck with torque limited gear boxes, a Rotrex should be the ideal match and I'll go as far as saying it theoretically could be faster than a turbo on a race track. My target Rotrex torque curve would be a flat line, and if set up correctly could sit at 280 - 300 ft lbs all the way to rev limit, right at the boundary of the strength of the gearbox. It's basically a 2 x multiplication of my existing N/A power curve. With the right sized Rotrex I think 450whp is easily achievable without destroying boxes. Who wouldn't want to drive that?

#69

intake heat? plz try harder

also, look at that spool

but for realzies, I kinda wonder the same thing as joe: why do neither modern race teams nor oem's run one?

like, I'm actually curious about this.

money can't be it cause developing all the plumbing and manifolds and hot parts can't be cheap

packaging can't be it for obvious reasons.

there are plenty of oem's targeted for the "drive it from the dealership straight to the race track" crowd, and they all use either big engines or roots types sc or turbos (and many of said turbos have said "rotrex torque curve" just like so many here seem to think is impossibru). I've seen a few here and there (like the early koenigggggseggggggggggggggggggsoggggg) use something crazy like twin centris, but that was more for cool factor than anything. and they use turbos on all their cars now

also, look at that spool

but for realzies, I kinda wonder the same thing as joe: why do neither modern race teams nor oem's run one?

like, I'm actually curious about this.

money can't be it cause developing all the plumbing and manifolds and hot parts can't be cheap

packaging can't be it for obvious reasons.

there are plenty of oem's targeted for the "drive it from the dealership straight to the race track" crowd, and they all use either big engines or roots types sc or turbos (and many of said turbos have said "rotrex torque curve" just like so many here seem to think is impossibru). I've seen a few here and there (like the early koenigggggseggggggggggggggggggsoggggg) use something crazy like twin centris, but that was more for cool factor than anything. and they use turbos on all their cars now

Last edited by 18psi; 12-15-2015 at 01:53 AM.

#70

I don't understand why you'd try to use a centrifugal to make a flat torque curve -- a positive displacement supercharger does that naturally, and will be way more efficient than throwing away 3/4 of the centrifugal's boost at redline.

--Ian

#71

As for race teams, I suspect the main reason is that the rules just don't make centrifugal superchargers competitive. Most race series that allow different types of engines set limits on boost and displacement, and in that kind of environment the small thermodynamic efficiency win of the turbo over a belt-driven supercharger actually matters. In a street car it's in the noise compared to all of the other factors, but a high-dollar race series is going to develop the engine to where they'll notice.

--Ian

#72

if you're bored, google "why don't oem's use centrifugal superchargers?" and see that this has been discussed on every other forum

one of the more amusing replies:

one of the more amusing replies:

A positive displacement supercharger always provides boost, yet robs crankshaft power.

A turbocharger does not always provide boost, but does not rob crankshaft power.

A centrifugal does not always provide boost, and yet always robs crankshaft power.

A turbocharger does not always provide boost, but does not rob crankshaft power.

A centrifugal does not always provide boost, and yet always robs crankshaft power.

#73

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

Given that we are stuck with torque limited gear boxes, a Rotrex should be the ideal match and I'll go as far as saying it theoretically could be faster than a turbo on a race track. My target Rotrex torque curve would be a flat line, and if set up correctly could sit at 280 - 300 ft lbs all the way to rev limit, right at the boundary of the strength of the gearbox. It's basically a 2 x multiplication of my existing N/A power curve. With the right sized Rotrex I think 450whp is easily achievable without destroying boxes. Who wouldn't want to drive that?

You are doing a substantial disservice to yourself by trying to argue that the powerband is "as good" or "nearly as good" as a turbocharger's powerband. It's not. Period, end of discussion. The single largest flaw of the Rotrex is its powerband, and it's inherent to the design of the system. CF blowers do several things very well, but a wide powerband is not one of them. Rotrex-powered cars are fast on track in spite of their powerband. As I stated before, I've seen the dyno charts from very high horsepower Rotrex cars, and they are not flattering in the slightest. They give up substantial midrange power to turbocharged cars, and as a result, they will never have the same acceleration potential exiting corners. They make up for this by delivering that power in a way that is easiest for the driver to apply the available power most effectively, but you cannot apply what does not exist. If your argument is that a Rotrex delivers high RPM power and is thus suited well for the track, I would be inclined to call your real-world track experience into question.

Your comments regarding "intake heat" belie your level of understanding regarding forced induction systems in general. Intake heat is a function of intake temperature, compressor efficiency, and intercooler efficiency. Turbos and Rotrex systems have (essentially) the same compressor efficiency, because they both use a turbo-style compressor wheel. Thus, turbochargers do not generate more "intake heat" than Rotrexes do. Espousing that sort of Tom Van Dan Elsen-level bullshit here will not go well.

#74

For OEMs it's easy, they don't do it because centrifugals suck on street cars. It's the same reason they put teeny tiny turbos on their turbocharged motors -- low end torque is what sells cars.

As for race teams, I suspect the main reason is that the rules just don't make centrifugal superchargers competitive. Most race series that allow different types of engines set limits on boost and displacement, and in that kind of environment the small thermodynamic efficiency win of the turbo over a belt-driven supercharger actually matters. In a street car it's in the noise compared to all of the other factors, but a high-dollar race series is going to develop the engine to where they'll notice.

--Ian

As for race teams, I suspect the main reason is that the rules just don't make centrifugal superchargers competitive. Most race series that allow different types of engines set limits on boost and displacement, and in that kind of environment the small thermodynamic efficiency win of the turbo over a belt-driven supercharger actually matters. In a street car it's in the noise compared to all of the other factors, but a high-dollar race series is going to develop the engine to where they'll notice.

--Ian

Racing wise, I think they are starting to get used on race cars. Nearly all of the open wheelers running locally have them now. Most other race cars are based off a production car so if they have turbo's you're not going to pull them off to run a supercharger. High end supercars can run turbos or whatever F/I they want since they have the development dollars to refine them to their specs. So that pretty much reduces the scope to N/A factory cars that need more power. Miatas, most Hondas... what else?

Centrifugals make boost with the square of the RPM, so if you want 15 psi at 7200, it'll be making 3.75 psi at 3600. If you want 15 at 3600 you're making 60 at 7200, so you're throwing 45 of that away with a "bleed off" strategy.

I don't understand why you'd try to use a centrifugal to make a flat torque curve -- a positive displacement supercharger does that naturally, and will be way more efficient than throwing away 3/4 of the centrifugal's boost at redline.

I don't understand why you'd try to use a centrifugal to make a flat torque curve -- a positive displacement supercharger does that naturally, and will be way more efficient than throwing away 3/4 of the centrifugal's boost at redline.

https://www.miataturbo.net/superchar...t-proto-80788/

Get that graph and scale it up 25% so that the torque hits 290 @ 6500 and taper it up a bit more so you hit 300 @ 8000... and that's the power curve I'm talking about.

I'm not really sure why I'm bothering arguing... Wait 12 months when I get around to putting one on my car and I'll show you what I mean.

#75

Yes, we'd all like to drive your magical, non-existent Rotrex setup that makes flat torque. Unfortunately, it doesn't exist, and comparing turbos that do exist to superchargers that don't exist is a stupid thing to do. If someone designs a transmission for the blower that can raise shaft speed beyond what the crank can provide, then that's great, but today, that system does not exist, so debating its merits is a worthless endeavor.

You are doing a substantial disservice to yourself by trying to argue that the powerband is "as good" or "nearly as good" as a turbocharger's powerband. It's not. Period, end of discussion. The single largest flaw of the Rotrex is its powerband, and it's inherent to the design of the system. CF blowers do several things very well, but a wide powerband is not one of them. Rotrex-powered cars are fast on track in spite of their powerband. As I stated before, I've seen the dyno charts from very high horsepower Rotrex cars, and they are not flattering in the slightest. They give up substantial midrange power to turbocharged cars, and as a result, they will never have the same acceleration potential exiting corners. They make up for this by delivering that power in a way that is easiest for the driver to apply the available power most effectively, but you cannot apply what does not exist. If your argument is that a Rotrex delivers high RPM power and is thus suited well for the track, I would be inclined to call your real-world track experience into question.

Your comments regarding "intake heat" belie your level of understanding regarding forced induction systems in general. Intake heat is a function of intake temperature, compressor efficiency, and intercooler efficiency. Turbos and Rotrex systems have (essentially) the same compressor efficiency, because they both use a turbo-style compressor wheel. Thus, turbochargers do not generate more "intake heat" than Rotrexes do. Espousing that sort of Tom Van Dan Elsen-level bullshit here will not go well.

You are doing a substantial disservice to yourself by trying to argue that the powerband is "as good" or "nearly as good" as a turbocharger's powerband. It's not. Period, end of discussion. The single largest flaw of the Rotrex is its powerband, and it's inherent to the design of the system. CF blowers do several things very well, but a wide powerband is not one of them. Rotrex-powered cars are fast on track in spite of their powerband. As I stated before, I've seen the dyno charts from very high horsepower Rotrex cars, and they are not flattering in the slightest. They give up substantial midrange power to turbocharged cars, and as a result, they will never have the same acceleration potential exiting corners. They make up for this by delivering that power in a way that is easiest for the driver to apply the available power most effectively, but you cannot apply what does not exist. If your argument is that a Rotrex delivers high RPM power and is thus suited well for the track, I would be inclined to call your real-world track experience into question.

Your comments regarding "intake heat" belie your level of understanding regarding forced induction systems in general. Intake heat is a function of intake temperature, compressor efficiency, and intercooler efficiency. Turbos and Rotrex systems have (essentially) the same compressor efficiency, because they both use a turbo-style compressor wheel. Thus, turbochargers do not generate more "intake heat" than Rotrexes do. Espousing that sort of Tom Van Dan Elsen-level bullshit here will not go well.

You are right about the intake heat, a turbo will be slightly hotter but not by much, nothing that matters much anyway... so I'll happily back down on that one. The lag however will always be there, well until the F1 turbos and their electric engines become mainstream. I'm just trying to point out that a Rotrex set up the correct way on a very developed engine will be highly effective on a race track. It doesn't have to "suck at torque" like everyone thinks it does. Emilio has already shown that with his initial C30-74 tests. Put a C30-94 on that same motor and it's basically where I think a Rotrex on a miata should be and would probably be very close to the magical setup I'm trying to present. Someone needs to go out and prove it...

Last edited by Madjak; 12-15-2015 at 03:02 AM. Reason: spelling

#76

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

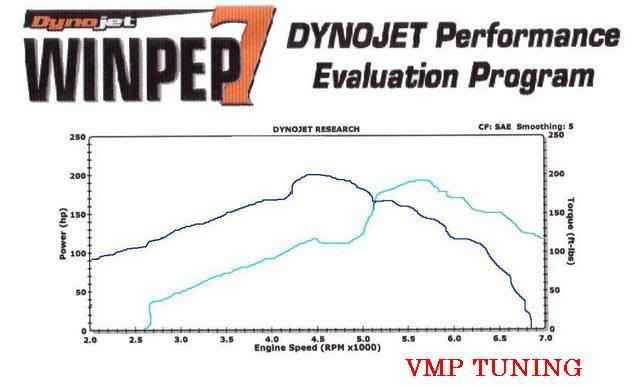

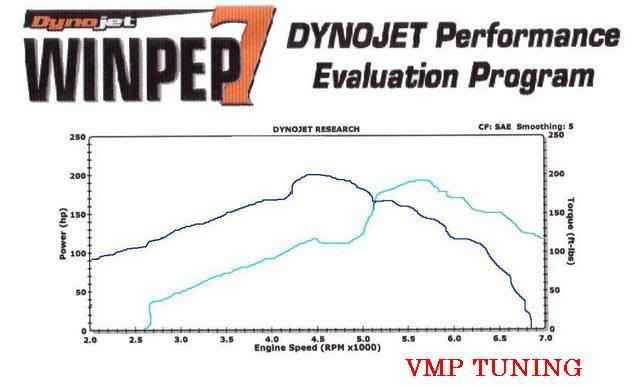

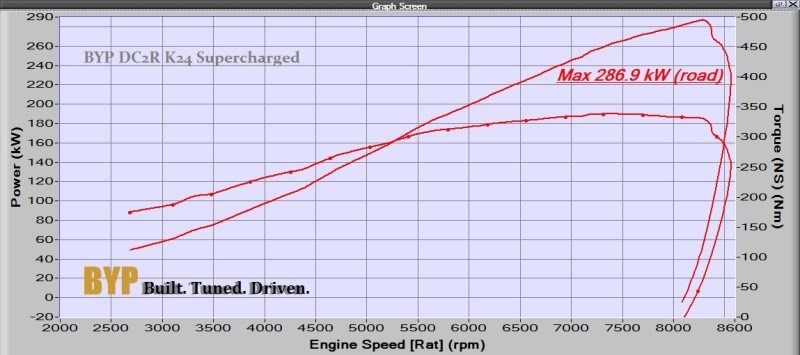

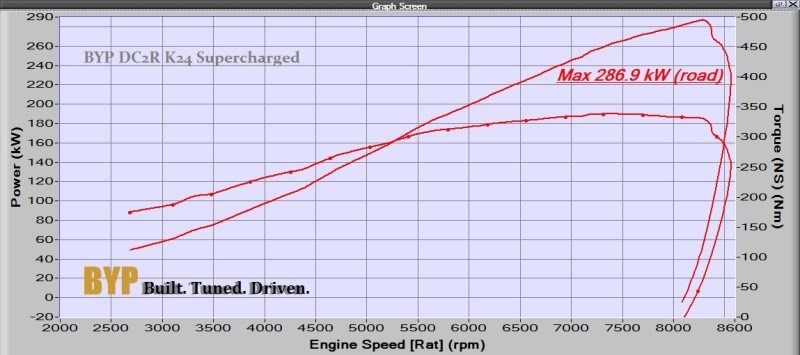

Does this look flat to you? In any way? 350whp Rotrex:

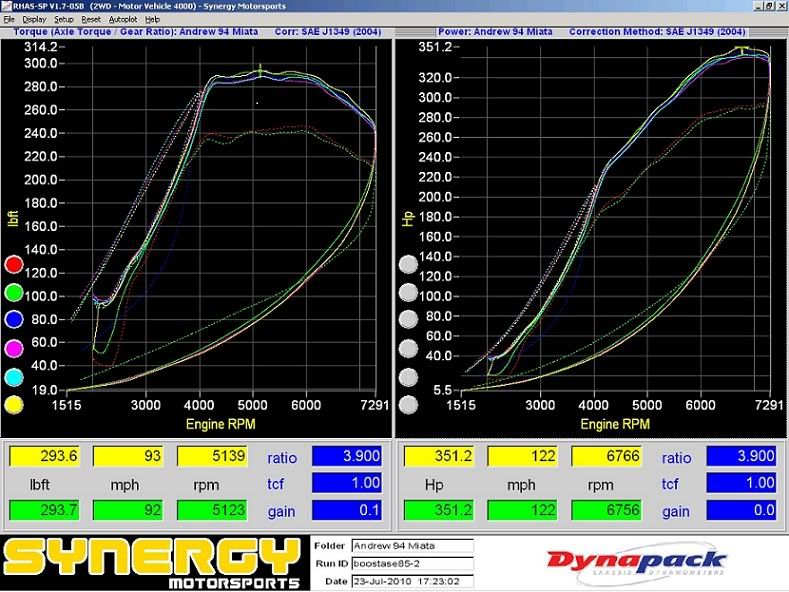

My 350whp turbo car:

Shall we compare?

Rotrex vs Turbo

4000rpm: 140whp vs 200whp

5000rpm: 210whp vs 270whp

6000rpm: 280whp vs 330whp

7000rpm: 350whp vs 340whp

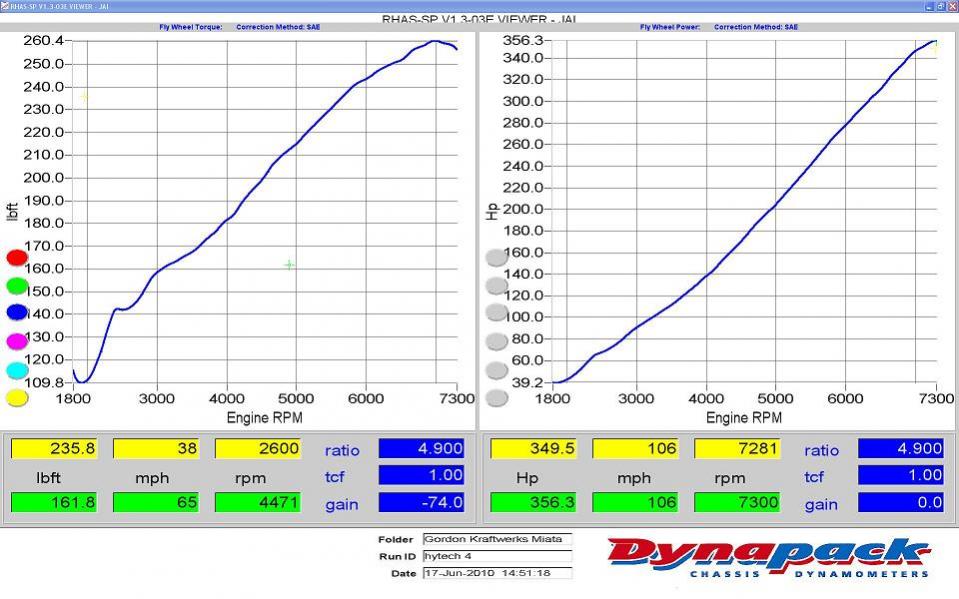

Let's cherry-pick the Rotrex build in your favor just to emphasize my point. Here's a very well-prepped Rotrex. 11:1 bottom end, ported/+1 valves BP4W head, Skunk2 intake manifold, 264* cams, E85.

My turbo car. 8.6:1 bottom end, stock BP6D head, Skunk2 intake manifold, stock cams, 100 octane. (chart reads hub torque, divide by 3.909 for WTQ)

Let's compare:

Rotrex vs Turbo

5000rpm: 175whp vs 230whp

6000rpm: 230whp vs 280whp

7000rpm: 280whp vs 290whp

Are we done now?

https://www.miataturbo.net/superchar...t-proto-80788/

Get that graph and scale it up 25% so that the torque hits 290 @ 6500 and taper it up a bit more so you hit 300 @ 8000... and that's the power curve I'm talking about.

Get that graph and scale it up 25% so that the torque hits 290 @ 6500 and taper it up a bit more so you hit 300 @ 8000... and that's the power curve I'm talking about.

You are right about the intake heat, a turbo will be slightly hotter but not by much

I want to be perfectly clear: I am not a hater like a few others here. I like the Rotrex. I've driven several examples in anger and enjoyed every single one of them. They have some unique strengths (inherent reliability and response) and they are a great choice for people who value those strengths. It just so happens that the Rotrex also has an inherent weakness, and turbos happen to be very strong in that particular area (powerband). To me, this issue is very much a "different strokes for different folks" deal.

#77

Actually, the rods are subject to more force from RPM than they are from torque (as long as you arn't deting or pinging). Doubling the torque only increases stress on the rods somewhere between 20-50% (forget the exact number and don't feel like mathing) but the relation on rod stress to rpm is a 3rd or 4th power relation.

So a better metafore would be that you can load the bucket with a weak handle with a lot of rocks, if you move it very slowly. But a stronger handle will let you move the same rocks faster.

So a better metafore would be that you can load the bucket with a weak handle with a lot of rocks, if you move it very slowly. But a stronger handle will let you move the same rocks faster.

#78

I'm not trolling! I'm serious about this stuff. I'm also not attacking turbos, just showing alternative thinking.

There are hundreds of dyno charts out there, and yes lots of the very high power Rotrex have a concave power curve. But there are also plenty with a very flat torque curve in what I'm referring to as optimal for track work. The flow of the head, intake runner lengths, cams, exhaust etc all affect the curve. Given I haven't seen a Rotrex miata pushing more than 350whp I'm not sure what the outcome would be, though extrapolating other similar engines I think you can compare some results.

Here is the first example (and sorry it's a Honda).

Your cherry picked Miata Rotrex is also an excellent example, and close to the build that I'm proposing. To you happen to know what Rotrex is used on this car?

Also your comparison isn't really how I'd do it. I mean why match RPM's?.. I'm not arguing that a Rotrex can generate more power than a turbo at set rpm points so why limit the RPM to suit your turbo? Shouldn't the comparison be:

Rotrex vs Turbo

230whp @ 6000rpm vs 230whp @ 5000rpm

280whp @ 7000rpm vs 280whp @ 6000rpm

290whp @ 8000rpm vs 290whp @ 7000rpm

If the gearing is correct on these two cars they would have very similar track performance. You are going to have to rev a Rotrex BP engine to get it to work... target range would be the 6000 - 8500 range. Doesn't that validate my argument that a Rotrex can have torque and can be an excellent choice for a track car? Whether my magical build is realistic or not.

There are hundreds of dyno charts out there, and yes lots of the very high power Rotrex have a concave power curve. But there are also plenty with a very flat torque curve in what I'm referring to as optimal for track work. The flow of the head, intake runner lengths, cams, exhaust etc all affect the curve. Given I haven't seen a Rotrex miata pushing more than 350whp I'm not sure what the outcome would be, though extrapolating other similar engines I think you can compare some results.

Here is the first example (and sorry it's a Honda).

Your cherry picked Miata Rotrex is also an excellent example, and close to the build that I'm proposing. To you happen to know what Rotrex is used on this car?

Also your comparison isn't really how I'd do it. I mean why match RPM's?.. I'm not arguing that a Rotrex can generate more power than a turbo at set rpm points so why limit the RPM to suit your turbo? Shouldn't the comparison be:

Rotrex vs Turbo

230whp @ 6000rpm vs 230whp @ 5000rpm

280whp @ 7000rpm vs 280whp @ 6000rpm

290whp @ 8000rpm vs 290whp @ 7000rpm

If the gearing is correct on these two cars they would have very similar track performance. You are going to have to rev a Rotrex BP engine to get it to work... target range would be the 6000 - 8500 range. Doesn't that validate my argument that a Rotrex can have torque and can be an excellent choice for a track car? Whether my magical build is realistic or not.

Last edited by Madjak; 12-15-2015 at 05:47 AM. Reason: Img wasn't working

#79

Call me a retard but I am inclined to agree with madjak to a degree. If you want to pick dyno sheets from google image search im sure there is any shaped curves you want, it depends on all of the things in the head not just the size of the blower. For example you could easily build an engine which revs to 9 but whos VE falls off past 7 and has a really flat torque curve with a centri.

I also would be willing to bet he has never driven a decent turbo build which has TPS vs RPM scaled closed loop boost control.

The issue of turbochargers lacking instant response is also basically BS at 5000rpm onwards.

Dann

I also would be willing to bet he has never driven a decent turbo build which has TPS vs RPM scaled closed loop boost control.

The issue of turbochargers lacking instant response is also basically BS at 5000rpm onwards.

Dann

#80

You are right... I have never driven a car with closed loop boost control. I've only driven a well setup track WRX and older street libertys and a factory turbo mx5 on the track. All with substantial lag. I would really like to try driving one of your latest setups Dann as the dyno curves look stella.