Tell me if this DIY spring rate tester will work

#1

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

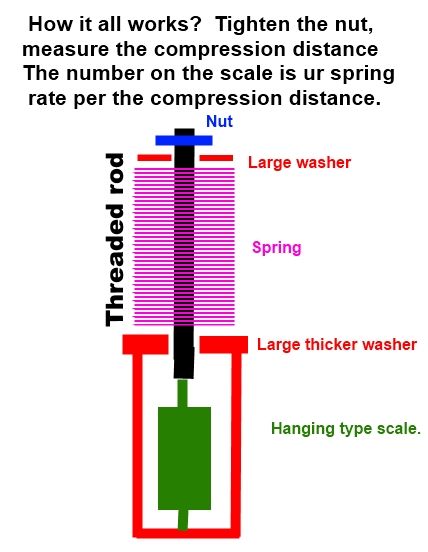

Long story short, I have access to a ton of coilover springs, and they are not marked for rate.

I need to be able to test a bunch of springs efficiently and quickly.

So, I came up with a portable setup that I can operate all by myself, and drafted a very technical drawing of the said setup.

It needs to be as cheap as possible, and it must be portable so I can fit it in the trunk of the Miata.

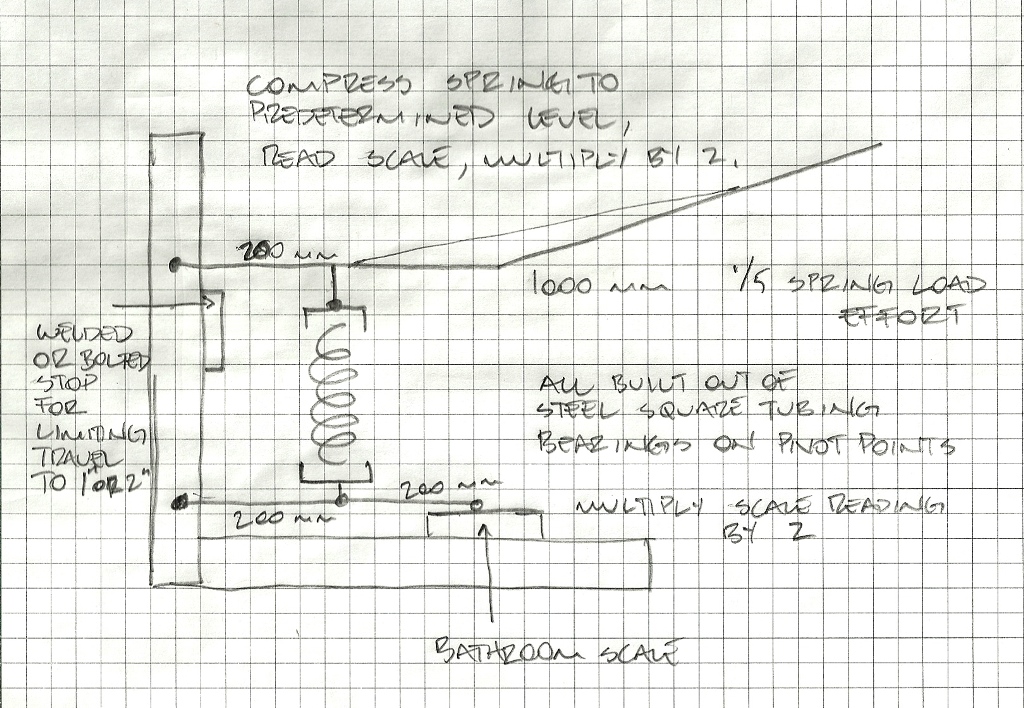

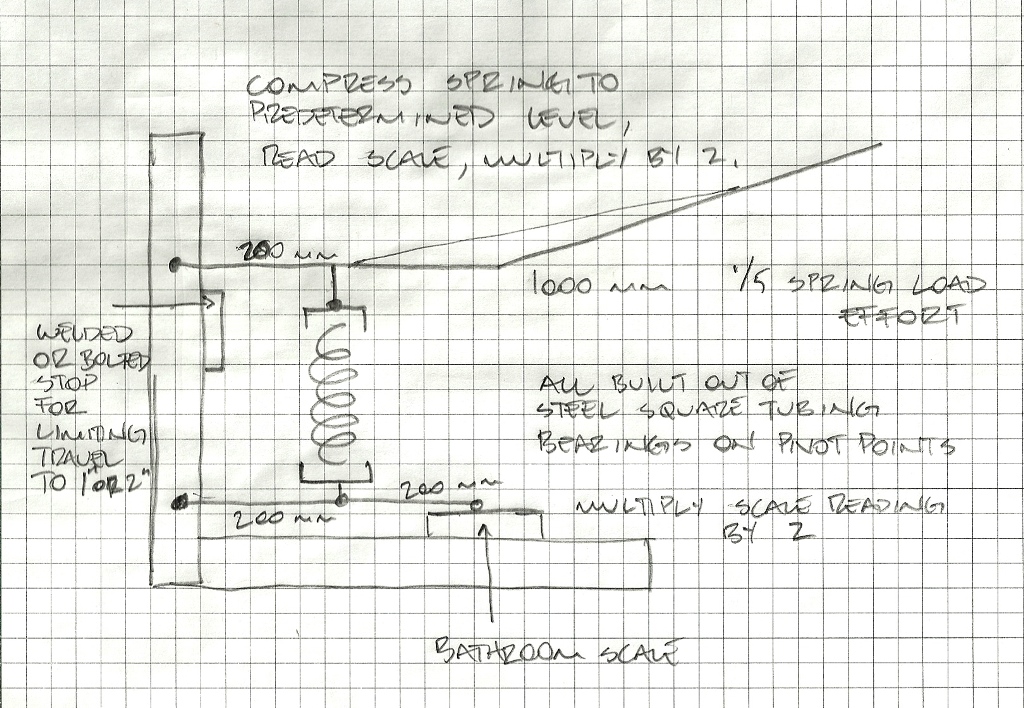

So, here's my idea:

I will be using a bathroom scale, and they all go to 150 Kg max.

I figured if I use a lever system and place the load of the spring in the middle, I would essentially extend the scale's range to 300 kg (661 lbs).

The "arm" compressing the spring will have a stop to limit compression travel to 1 inch. Once the arm hits the stop, all I need to do is read the bathroom scale and multiply the readout by 2.

I can quickly bolt the frame together out of square tubing, and make the long arm in 2 pieces.

There will be a metal or wood plate on the bathroom scale to distribute the force evenly.

What do you think guys?

I need to be able to test a bunch of springs efficiently and quickly.

So, I came up with a portable setup that I can operate all by myself, and drafted a very technical drawing of the said setup.

It needs to be as cheap as possible, and it must be portable so I can fit it in the trunk of the Miata.

So, here's my idea:

I will be using a bathroom scale, and they all go to 150 Kg max.

I figured if I use a lever system and place the load of the spring in the middle, I would essentially extend the scale's range to 300 kg (661 lbs).

The "arm" compressing the spring will have a stop to limit compression travel to 1 inch. Once the arm hits the stop, all I need to do is read the bathroom scale and multiply the readout by 2.

I can quickly bolt the frame together out of square tubing, and make the long arm in 2 pieces.

There will be a metal or wood plate on the bathroom scale to distribute the force evenly.

What do you think guys?

#2

If nothing else it'll let you assign your own rating to each spring, which will enable you to match sets and rank them within the group: this matches this, these are heavier than those. Give it a shot. Heck, measure a spring you know the value of to figure out how close you get and multiply each spring by that factor...

#4

It should work. You might want to consider how you compress the spring from the top to try and avoid transverse loading. If you have an idea of what you're spring rates are, use that to estimate the compressed length and attach your pivot at the appropriate height so that it's as close to parallel with the ground as possible in the compressed state. Also make sure that your bottom beam is as close to parallel with the ground as possible or the scale and pin won't share the load equally.

#5

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,647

Total Cats: 3,009

I have a better idea. Use mathematics and a set of dial calipers to do it the right way. A formula exists for determining spring rates. I've seen it published a number of times, including in the book by Herb Adams called "Chassis Engineering". I'm sure it is on teh interwebz somewhere.

Suspension Coil Spring Rate Design Equations Formulas Calculator

Another one:http://www.acxesspring.com/spring-co...alculator.html

Another one: http://www.calculatoredge.com/mech/hspring.htm

Another one: Coil Spring Rate Calculations by Wallace Racing

FORMULA:

spring rate =

modulus of spring steel X wire diameter^4

--------------------------------------------------------------------

8 X number of active coils X mean coil diameter^3

*modulus of spring steel = 11,250,000 pounds/inch^2 = 78,500 newtons/millimeter^2

I have successfully tested this formula on stock Miata springs of a known rate and aftermarket springs of a known rate. I then used it to determine the approximate rates of some additional springs I had around. The modulus of spring steel is a constant.

Suspension Coil Spring Rate Design Equations Formulas Calculator

Another one:http://www.acxesspring.com/spring-co...alculator.html

Another one: http://www.calculatoredge.com/mech/hspring.htm

Another one: Coil Spring Rate Calculations by Wallace Racing

FORMULA:

spring rate =

modulus of spring steel X wire diameter^4

--------------------------------------------------------------------

8 X number of active coils X mean coil diameter^3

*modulus of spring steel = 11,250,000 pounds/inch^2 = 78,500 newtons/millimeter^2

I have successfully tested this formula on stock Miata springs of a known rate and aftermarket springs of a known rate. I then used it to determine the approximate rates of some additional springs I had around. The modulus of spring steel is a constant.

#9

Haken, your bathroom scale with a lever arm should work, but I think the assembly will want to tip over when you lean on the lever. It's like a giant pair of pliers with one handle too short.

Controlling how far the spring is compressed will be tricky. The hard stop would need to be adjusted for different free lengths....

Basically, your approach is to compress a known distance then measure the force. But, I like Scott's idea better: load the spring with a known force and measure the distance. No bathroom scales required.

Controlling how far the spring is compressed will be tricky. The hard stop would need to be adjusted for different free lengths....

Basically, your approach is to compress a known distance then measure the force. But, I like Scott's idea better: load the spring with a known force and measure the distance. No bathroom scales required.

#10

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,647

Total Cats: 3,009

It needs to be as cheap as possible, and it must be portable so I can fit it in the trunk of the Miata.

#15

2 Props,3 Dildos,& 1 Cat

iTrader: (8)

Join Date: Jun 2005

Location: Fake Virginia

Posts: 19,338

Total Cats: 573

the OP's apparatus will have a lot of extra crap adding to the reading on the scale.

the weight of the rig and the weight of the spring will be in there too, which just confuses things.

I would rather see the bottom of the thing fixed, then a series of masses hung on the long lever arm so that you know the total force at the top of the spring (weight of machine + weight or moment of masses on lever arm) and a measurement scale next to the spring that you can slide and retain with some sort of screw or wing nut.

Put the spring in with the bar raised off it, set the zero at the top of the spring, then load with a known force.

Or just turn yours on its side so the scale is unloaded until the spring is compressed.

the weight of the rig and the weight of the spring will be in there too, which just confuses things.

I would rather see the bottom of the thing fixed, then a series of masses hung on the long lever arm so that you know the total force at the top of the spring (weight of machine + weight or moment of masses on lever arm) and a measurement scale next to the spring that you can slide and retain with some sort of screw or wing nut.

Put the spring in with the bar raised off it, set the zero at the top of the spring, then load with a known force.

Or just turn yours on its side so the scale is unloaded until the spring is compressed.

#16

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

I have a better idea. Use mathematics and a set of dial calipers to do it the right way. A formula exists for determining spring rates. I've seen it published a number of times, including in the book by Herb Adams called "Chassis Engineering". I'm sure it is on teh interwebz somewhere.

#17

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

the OP's apparatus will have a lot of extra crap adding to the reading on the scale.

the weight of the rig and the weight of the spring will be in there too, which just confuses things.

I would rather see the bottom of the thing fixed, then a series of masses hung on the long lever arm so that you know the total force at the top of the spring (weight of machine + weight or moment of masses on lever arm) and a measurement scale next to the spring that you can slide and retain with some sort of screw or wing nut.

Put the spring in with the bar raised off it, set the zero at the top of the spring, then load with a known force.

Or just turn yours on its side so the scale is unloaded until the spring is compressed.

the weight of the rig and the weight of the spring will be in there too, which just confuses things.

I would rather see the bottom of the thing fixed, then a series of masses hung on the long lever arm so that you know the total force at the top of the spring (weight of machine + weight or moment of masses on lever arm) and a measurement scale next to the spring that you can slide and retain with some sort of screw or wing nut.

Put the spring in with the bar raised off it, set the zero at the top of the spring, then load with a known force.

Or just turn yours on its side so the scale is unloaded until the spring is compressed.

I could always reset the scale to 0 before applying force. That would zero out all the weight resting on the scale, and give me a net force value.

#18

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

Haken, your bathroom scale with a lever arm should work, but I think the assembly will want to tip over when you lean on the lever. It's like a giant pair of pliers with one handle too short.

Controlling how far the spring is compressed will be tricky. The hard stop would need to be adjusted for different free lengths....

Basically, your approach is to compress a known distance then measure the force. But, I like Scott's idea better: load the spring with a known force and measure the distance. No bathroom scales required.

Controlling how far the spring is compressed will be tricky. The hard stop would need to be adjusted for different free lengths....

Basically, your approach is to compress a known distance then measure the force. But, I like Scott's idea better: load the spring with a known force and measure the distance. No bathroom scales required.

I will be primarily measuring 8" springs. I can always drill the post to accept different length springs, too.

#19

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

I have a better idea. Use mathematics and a set of dial calipers to do it the right way. A formula exists for determining spring rates. I've seen it published a number of times, including in the book by Herb Adams called "Chassis Engineering". I'm sure it is on teh interwebz somewhere.

Suspension Coil Spring Rate Design Equations Formulas Calculator

Another one:Spring Constant Calculator

Another one: Helical Spring Calculators - Spring Index, Spring Rate, Shear Stress, Deflection

Another one: Coil Spring Rate Calculations by Wallace Racing

FORMULA:

spring rate =

modulus of spring steel X wire diameter^4

--------------------------------------------------------------------

8 X number of active coils X mean coil diameter^3

*modulus of spring steel = 11,250,000 pounds/inch^2 = 78,500 newtons/millimeter^2

I have successfully tested this formula on stock Miata springs of a known rate and aftermarket springs of a known rate. I then used it to determine the approximate rates of some additional springs I had around. The modulus of spring steel is a constant.

Suspension Coil Spring Rate Design Equations Formulas Calculator

Another one:Spring Constant Calculator

Another one: Helical Spring Calculators - Spring Index, Spring Rate, Shear Stress, Deflection

Another one: Coil Spring Rate Calculations by Wallace Racing

FORMULA:

spring rate =

modulus of spring steel X wire diameter^4

--------------------------------------------------------------------

8 X number of active coils X mean coil diameter^3

*modulus of spring steel = 11,250,000 pounds/inch^2 = 78,500 newtons/millimeter^2

I have successfully tested this formula on stock Miata springs of a known rate and aftermarket springs of a known rate. I then used it to determine the approximate rates of some additional springs I had around. The modulus of spring steel is a constant.

And, no, you are not right.

A formula tells you what the result "should be".

It does not take into account factors such as defective materials, aging, sloppily applied thick paint layer that could affect the caliper reading for wire diameter, treatment failures, etc...

I will be sitting down to measure a few hundred - if not more - springs in someone's place of business, causing as little disruption as possible.

Popping the springs in a contraption where I could jot down a reading on a label in the space of maybe 10 seconds is a great advantage for me.

Being the practical and empirical guy I am, I will relish in the comfort of weeding out the bad springs the naked eye would not be able identify.

Also, what if the manufacturer cheaped out and used some weird steel wire instead of spring steel? The formula would not know that.

That's why I want to see real deflection, and real results.

Having said all this, I still need to come up with data such as number of coils and coil spacing for an 8" spring with an inside diameter of 2.5".

Desired spring rate is 300, 275 and 225 lbs, respectively.

Available wire diameters are 8, 8.5, 9, 9.5, 10 and 10.5 mm. (Al spring steel)

I found a manufacturer who is currently producing suspension springs for a few OEM brands. The owner is wiling to custom make springs for me if I provide all the pertinent data. He will do shot peening and powdercoating, as well.

I will also take a trip to the Fiat plant in Turkey to use their shock dyno in their R&D lab once I revalve my shocks.

#20

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,019

Total Cats: 6,587

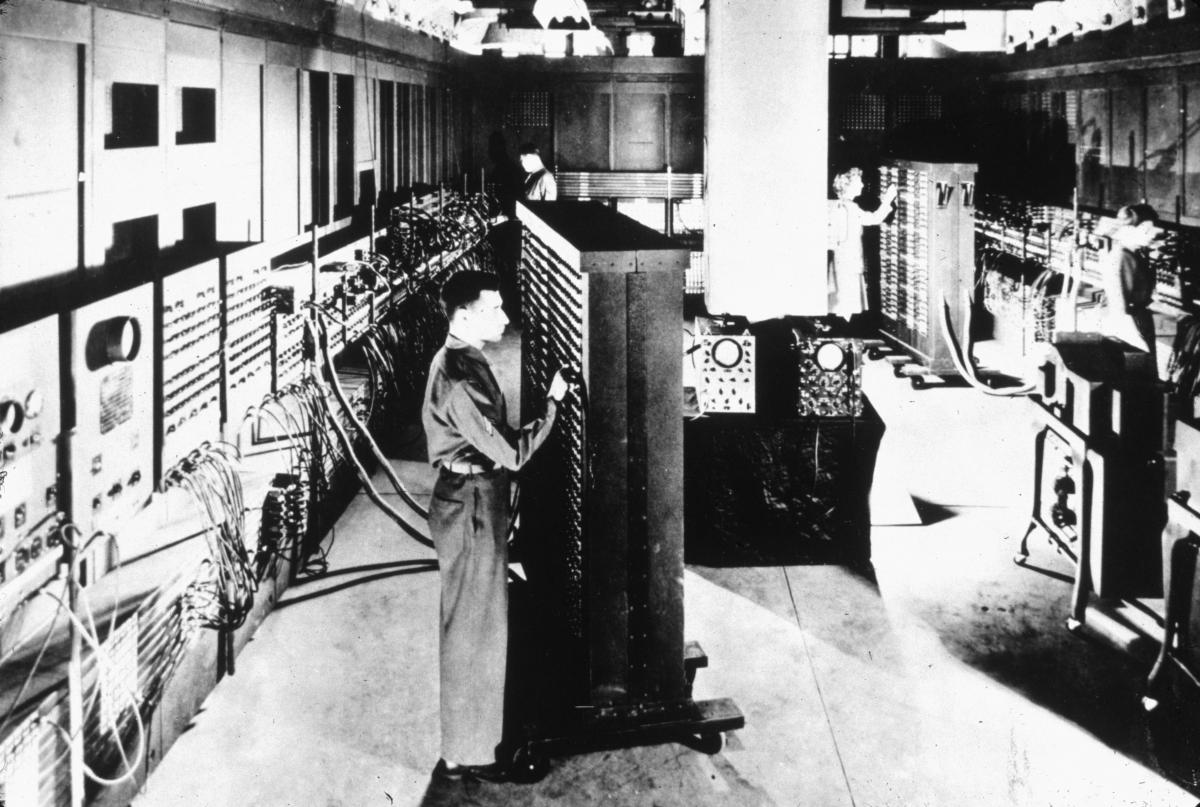

Oh, look at Mr. Hotshot here, with his calculator that weighs less than a hundred pounds!

Not all of us can afford that kind of technology, friend. If you get a chance some day, come visit the real world where calculators still have their own air-conditioning systems.

\

\

But seriously. I think that the mathematical approach is probably going to yield more accurate answers than something involving a bathroom scale. The basic idea behind the scale contraption is a sound one, but I don't think I'd go that way myself from a practical standpoint.

Not all of us can afford that kind of technology, friend. If you get a chance some day, come visit the real world where calculators still have their own air-conditioning systems.

\

\But seriously. I think that the mathematical approach is probably going to yield more accurate answers than something involving a bathroom scale. The basic idea behind the scale contraption is a sound one, but I don't think I'd go that way myself from a practical standpoint.