My 99's Journey from the dark side to enlightenment.

#141

Dude, trust me, this is pretty much their standard for doing business these days.

The worst part is that they are getting away with this crap for a long time now simply because they USED to be a solid/honest company that ran well and made cool parts for our cars. We all loved and respected them, and now they can operate like crap because of their reputation in the past. I doubt that will keep going on for too much longer though.

I'm not going to go into detail about how many flat out lies Stephanie bs'd me with, and that was for a SIMPLE log manifold and S downpipe that I was waiting for over a month. I believe I still have the email string saved. After I threw a fit and started getting really vocal online, Corky contacted me personally and asked to tell him what the problem was. I did, he apologized, told me "we'll pound on Steph for all this crap so she stops doing it", and finally after that I had a tracking number for my parts.

These horror stories like yours are literally everywhere. Just do some searching and you come up with dozens of horror stories exactly like yours. It's the standard now for them. And the worst part? They completely and utterly deny it. 100% denial.

Its so sad, but I can't see them operating this way for too much longer and staying in business. Unless of course they are doing other stuff on the side (or doing miata parts on the side of a bigger business). I just don't see it. You can't possibly have a successful company in this day and age that is run this way.

The worst part is that they are getting away with this crap for a long time now simply because they USED to be a solid/honest company that ran well and made cool parts for our cars. We all loved and respected them, and now they can operate like crap because of their reputation in the past. I doubt that will keep going on for too much longer though.

I'm not going to go into detail about how many flat out lies Stephanie bs'd me with, and that was for a SIMPLE log manifold and S downpipe that I was waiting for over a month. I believe I still have the email string saved. After I threw a fit and started getting really vocal online, Corky contacted me personally and asked to tell him what the problem was. I did, he apologized, told me "we'll pound on Steph for all this crap so she stops doing it", and finally after that I had a tracking number for my parts.

These horror stories like yours are literally everywhere. Just do some searching and you come up with dozens of horror stories exactly like yours. It's the standard now for them. And the worst part? They completely and utterly deny it. 100% denial.

Its so sad, but I can't see them operating this way for too much longer and staying in business. Unless of course they are doing other stuff on the side (or doing miata parts on the side of a bigger business). I just don't see it. You can't possibly have a successful company in this day and age that is run this way.

Last edited by 18psi; 09-13-2014 at 08:58 PM.

#142

Senior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2014

Location: Meridian, Mississippi

Posts: 628

Total Cats: 44

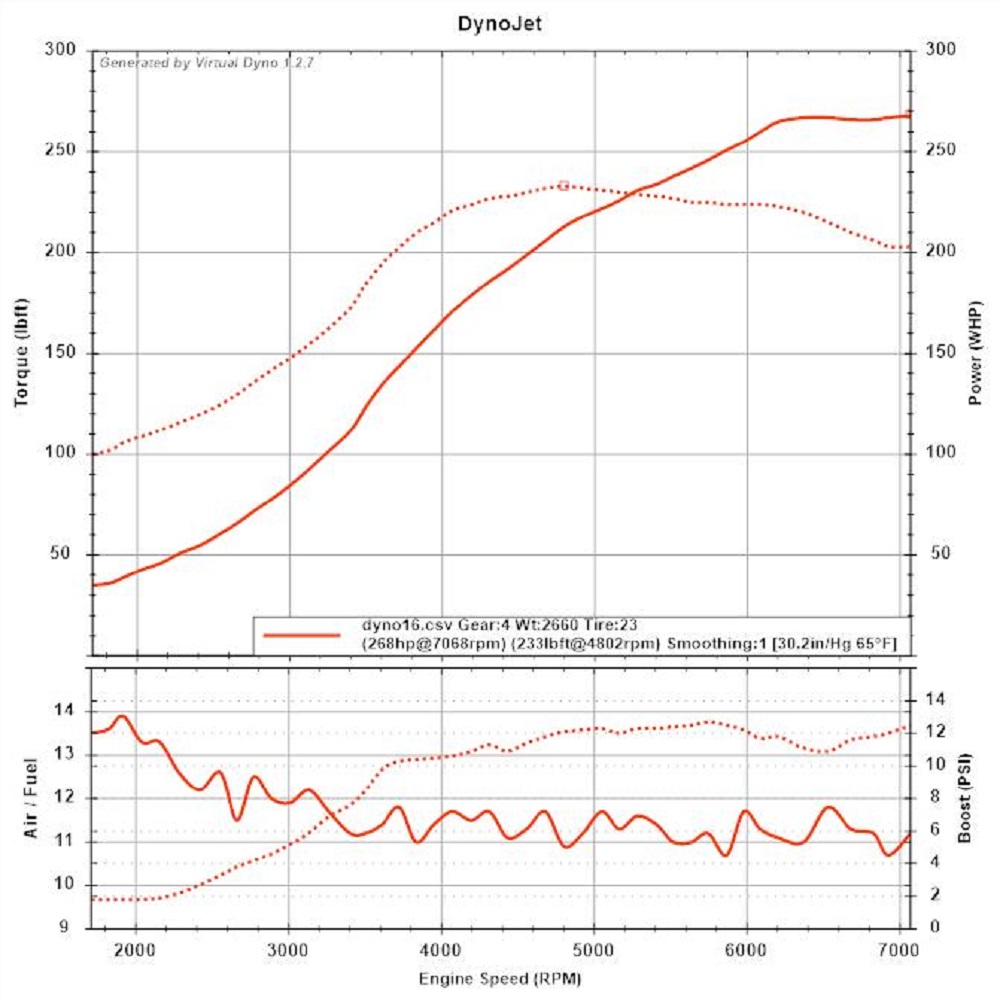

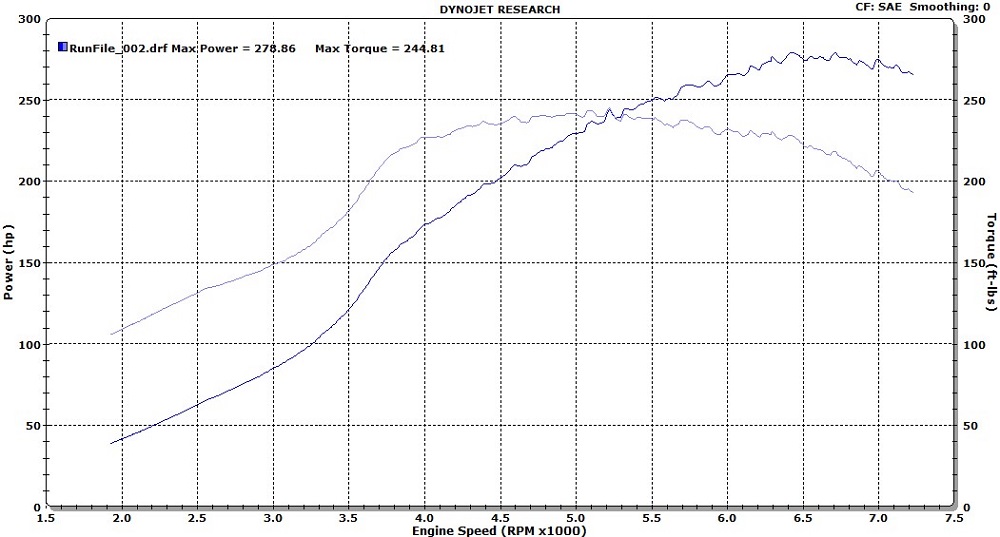

I am amazed by how accurate virtual dyno is when you have a correct car weight and accurate weather information for SAE correction!

Here is the virtual dyno of my car at 12.5 psi.

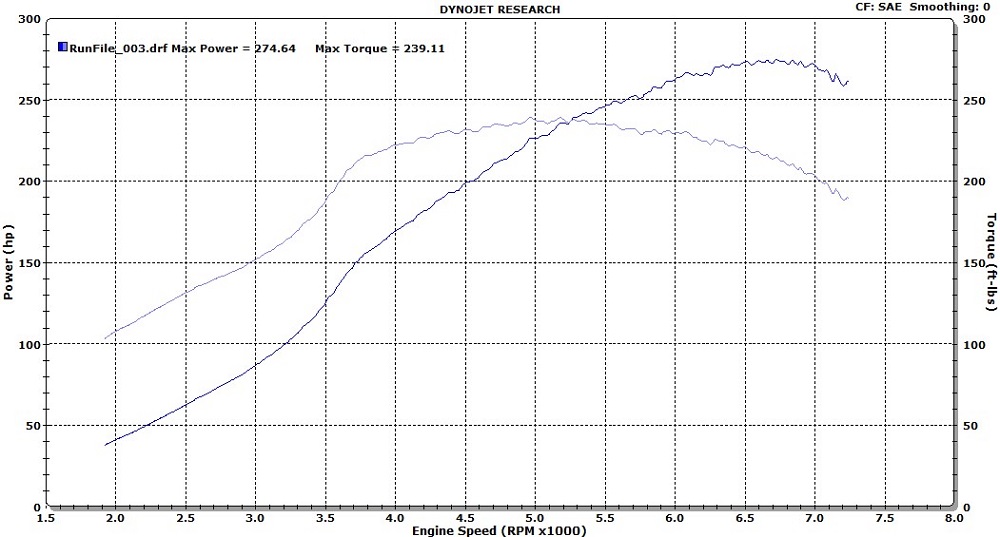

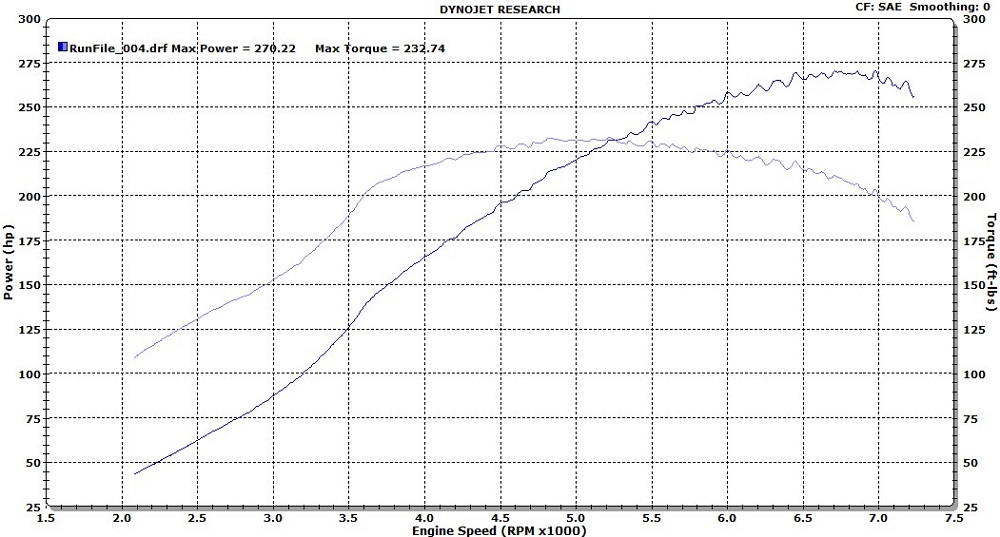

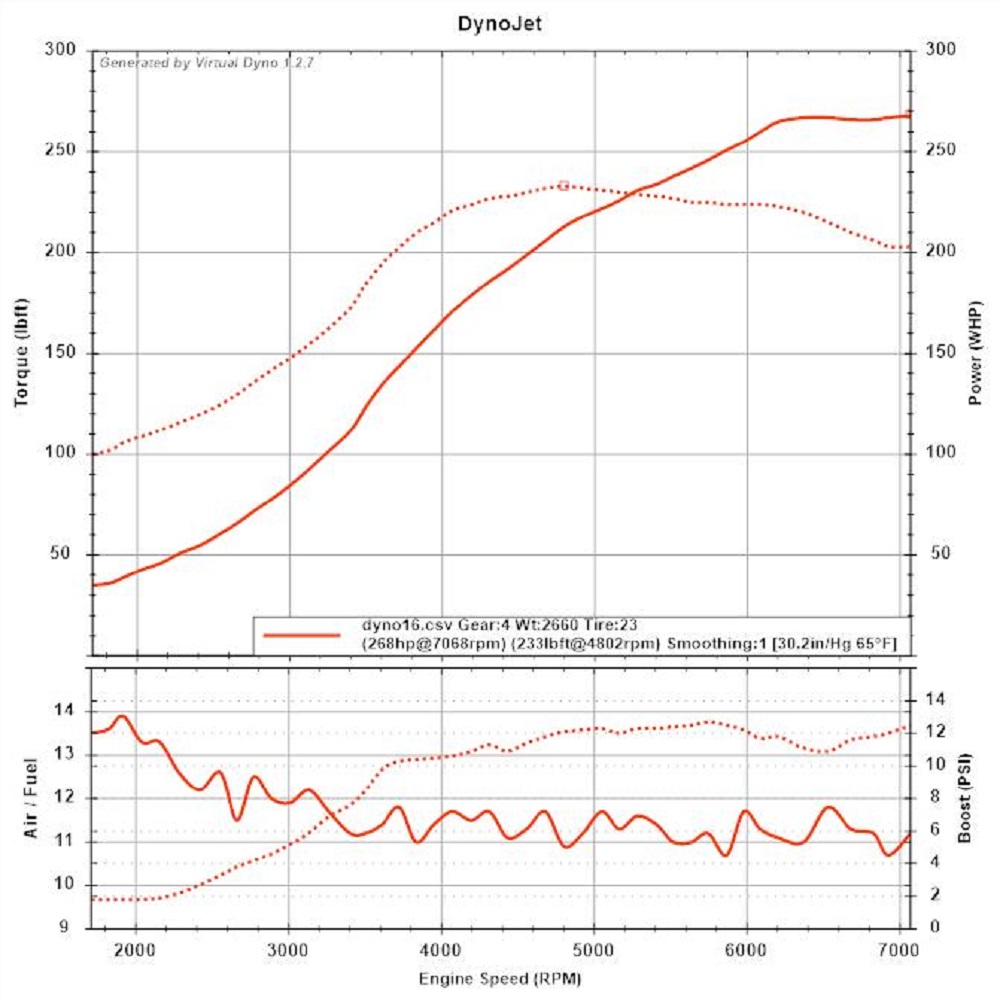

And here is the actual dynojet dyno sheet of my car at 12.5 psi.

The dyno operators at this shop like to use STD correction factor because it gives larger numbers, and not realizing this I was worried about my torque being over 251 lb-ft when I was aiming for between 230 and 240 lb-ft... so my subsequent runs were at 12.0 psi and 11.5 psi.

I think I will probably end up turning boost back up to 12.0 for the drag strip on Sunday, and for daily driving aim for around 11.5 psi. Then when I swap to the snow tires and hard top I will swap to my lightest spring for the wastegate and run spring pressure since traction will be an issue

More comparisons to come!

Keith

Here is the virtual dyno of my car at 12.5 psi.

And here is the actual dynojet dyno sheet of my car at 12.5 psi.

The dyno operators at this shop like to use STD correction factor because it gives larger numbers, and not realizing this I was worried about my torque being over 251 lb-ft when I was aiming for between 230 and 240 lb-ft... so my subsequent runs were at 12.0 psi and 11.5 psi.

I think I will probably end up turning boost back up to 12.0 for the drag strip on Sunday, and for daily driving aim for around 11.5 psi. Then when I swap to the snow tires and hard top I will swap to my lightest spring for the wastegate and run spring pressure since traction will be an issue

More comparisons to come!

Keith

Last edited by Twodoor; 09-13-2014 at 07:49 PM.

#143

Senior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2014

Location: Meridian, Mississippi

Posts: 628

Total Cats: 44

You always hear the supercharger enthusiasts talking about low end torque production...

Here is my car when it had the M45 in "stock" configuration (unported, stock pulleys, 5.5 psi) compared to the GT2860R at 12.5 psi.

I am not illustrating peak power... look at the low end! From just off idle to redline the GT2860R made more torque than the M45! This is on the same car, on the same dyno with both graphs SAE corrected.

Keith

Here is my car when it had the M45 in "stock" configuration (unported, stock pulleys, 5.5 psi) compared to the GT2860R at 12.5 psi.

I am not illustrating peak power... look at the low end! From just off idle to redline the GT2860R made more torque than the M45! This is on the same car, on the same dyno with both graphs SAE corrected.

Keith

#146

Senior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2014

Location: Meridian, Mississippi

Posts: 628

Total Cats: 44

Drag strip results!

Out of 5 runs I only got one clean pass, and that one was with slow shifting to get a clean run. First run I missed 5th, (passed reverse detent, had to come back and go up). Second pass missed 3rd. Third pass (these were back to back passes) I smoked the **** out of the clutch. Waited an hour for the clutch to cool off and recover a bit, then did my final two runs. Fourth run missed 3rd and 5th, but not as bad. Fifth and final run was clean, but I got a clean run by doing really slow 4th to 5th shift.

60' . . . . . . . . . . . 2.143

330' . . . . . . . . . . 5.8922

1/8th ET . . . . . . . 8.8682

1/8th MPH . . . . . 85.09

1/4 ET . . . . . . . . 13.5783

1/4 MPH . . . . . . 106.86

Keith

<edit>Looked at data logs from last two runs, and I was taking over a full second to do the 4 to 5 shift. If I try to do the 4 to 5 quickly I slam it over into the "nothing forward, Revers back" slot. If I can get a 3.636:1 ring and pinion I will be able to stay in 4th up to trap speeds in the 110 mph region. Also, the clutch I have is marginal at best for the power levels I am making... thanks again Stephanie!</edit>

Out of 5 runs I only got one clean pass, and that one was with slow shifting to get a clean run. First run I missed 5th, (passed reverse detent, had to come back and go up). Second pass missed 3rd. Third pass (these were back to back passes) I smoked the **** out of the clutch. Waited an hour for the clutch to cool off and recover a bit, then did my final two runs. Fourth run missed 3rd and 5th, but not as bad. Fifth and final run was clean, but I got a clean run by doing really slow 4th to 5th shift.

60' . . . . . . . . . . . 2.143

330' . . . . . . . . . . 5.8922

1/8th ET . . . . . . . 8.8682

1/8th MPH . . . . . 85.09

1/4 ET . . . . . . . . 13.5783

1/4 MPH . . . . . . 106.86

Keith

<edit>Looked at data logs from last two runs, and I was taking over a full second to do the 4 to 5 shift. If I try to do the 4 to 5 quickly I slam it over into the "nothing forward, Revers back" slot. If I can get a 3.636:1 ring and pinion I will be able to stay in 4th up to trap speeds in the 110 mph region. Also, the clutch I have is marginal at best for the power levels I am making... thanks again Stephanie!</edit>

Last edited by Twodoor; 09-14-2014 at 11:08 PM.

#147

Senior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2014

Location: Meridian, Mississippi

Posts: 628

Total Cats: 44

Well, my new (to me) wheels and tires will be arriving on Wednesday (15 x 9 6UL's with 225/45/15 RS3's) so after my Dentist appointment in the AM I will be doing my Xida coil overs! I assume I should have an alignment done with the new shoes on the car after the suspension?

Only other things to report are that the clutch sucks, and I need two separate Ethanol maps... noticed I was running uber rich after my last fill up... it is fall now so we have E70 instead of E85.

Keith

Only other things to report are that the clutch sucks, and I need two separate Ethanol maps... noticed I was running uber rich after my last fill up... it is fall now so we have E70 instead of E85.

Keith

#150

Senior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2014

Location: Meridian, Mississippi

Posts: 628

Total Cats: 44

Well, the suspension and 15 x 9 6UL's are on the car now!

Here is the new tire next to my old summer tire.

And here it is next to my winter setup.

The new wheel and tire package at 32 lbs each is only half a pound heavier per corner than the stock 15 x 6 wheels with 195/50/15's.

With the current generation Xida coilovers with the lower spring mount just high enough to put a tinny bit of pre-tension on the springs (just enough to seat the springs), the car sits at 3.5" at the pinch welds front and back.... and you can't get it off a lift without re-lifting it and putting some 2 x 4's under the tires I did the measuring after I got it off the lift BTW.

I did the measuring after I got it off the lift BTW.

Since the car was 6" at the pinch welds on stock suspension that means I currently have a 2.5" drop. I think I will raise it up about 1" to 1.5" from where it is now and then take it in for an alignment to Flyin Miata's "street car" settings.

Later,

Keith

Here is the new tire next to my old summer tire.

And here it is next to my winter setup.

The new wheel and tire package at 32 lbs each is only half a pound heavier per corner than the stock 15 x 6 wheels with 195/50/15's.

With the current generation Xida coilovers with the lower spring mount just high enough to put a tinny bit of pre-tension on the springs (just enough to seat the springs), the car sits at 3.5" at the pinch welds front and back.... and you can't get it off a lift without re-lifting it and putting some 2 x 4's under the tires

I did the measuring after I got it off the lift BTW.

I did the measuring after I got it off the lift BTW.Since the car was 6" at the pinch welds on stock suspension that means I currently have a 2.5" drop. I think I will raise it up about 1" to 1.5" from where it is now and then take it in for an alignment to Flyin Miata's "street car" settings.

Later,

Keith

#152

Senior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2014

Location: Meridian, Mississippi

Posts: 628

Total Cats: 44

After trying to call BEGi about my still missing parts (correct intake pipe, maf delete pipe, mounting bolts for radiator cover, mounting bolt for oil / water distribution block, and last but not least the correct heat shield for my kit) I figured out why I fucked up BEGi's name on my video's! I keep calling it Bell Engineering Group inc. instead of (as shown on their web site and any invoices /paperwork you get from them) Bell Experimental Group inc.

When the phone answering machine picked up it was Stephanie's voice saying "Bell Engineering blah blah blah... and I am pretty sure that is how she answers the phone in person as well.

The really fucked up thing is their mailing address is "Bell Engineering" so I can't even blame Stephanie for not knowing the name of the company she works for...

Keith

When the phone answering machine picked up it was Stephanie's voice saying "Bell Engineering blah blah blah... and I am pretty sure that is how she answers the phone in person as well.

The really fucked up thing is their mailing address is "Bell Engineering" so I can't even blame Stephanie for not knowing the name of the company she works for...

Keith

#153

Senior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2014

Location: Meridian, Mississippi

Posts: 628

Total Cats: 44

Keith

#154

I put a cheap (free to me, thanks Ben!) MBC on the car and aimed for 12 psi. God do I hate boost creep! Without boost creep I would be hitting 11.5 to 12 psi by 4000 RPM... as it is, I have to get the wastegate to start opening early, and I am only hitting 10 psi by 4000 RPM, and then creeping from there up to my peak boost.

Here is the spool data:

2000 1.5 psi

2500 3.1 psi

3000 5.1 psi

3500 8.6 psi

4000 10.3 psi

4500 11.2 psi

5000 11.9 psi

5500 12.2 psi

6000 12.1 psi

6500 11.0 psi

7000 12.5 psi

Keith

Here is the spool data:

2000 1.5 psi

2500 3.1 psi

3000 5.1 psi

3500 8.6 psi

4000 10.3 psi

4500 11.2 psi

5000 11.9 psi

5500 12.2 psi

6000 12.1 psi

6500 11.0 psi

7000 12.5 psi

Keith

How did you route it? I assume boost source>mbc>lower port of EWG leaving upper port open to atmosphere?

Thanks, I am building a similar setup

#155

Senior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2014

Location: Meridian, Mississippi

Posts: 628

Total Cats: 44

I swapped out the free one from Ben for a Halman MBC for ease of adjustment, and had identical spool up and stability as the free one. Since mine has creep issues I am sourced right at the compressor housing to the Halman, and from the Halman to the bottom port on the EWG. If I didn't have creep issues I would source from the intercooler pipe just before the throttle body.

Later,

Keith

#156

Senior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2014

Location: Meridian, Mississippi

Posts: 628

Total Cats: 44

Boost creep from hell!

Well, before I swapped to the Tial BOV my boost creep for the 4.4 psi spring in my external wastegate had my boost peaking at 7.1 psi. Now after swapping in the Tial BOV and intake pipe without a flange for the BOV recirce line I am now peaking at 10.5 psi! My boost curve looks like I have a Rotrex supercharger rather than a turbocharger! Here is the spool data for comparison:

Leaky BOV Tial BOV

2000 1.5 1.5

2500 2.6 3.2

3000 4.3 4.9

3500 5.0 5.5

4000 5.2 5.8

4500 6.1 6.6

5000 6.4 7.1

5500 6.4 8.0

6000 6.5 8.7

6500 6.2 8.9

7000 7.1 10.5

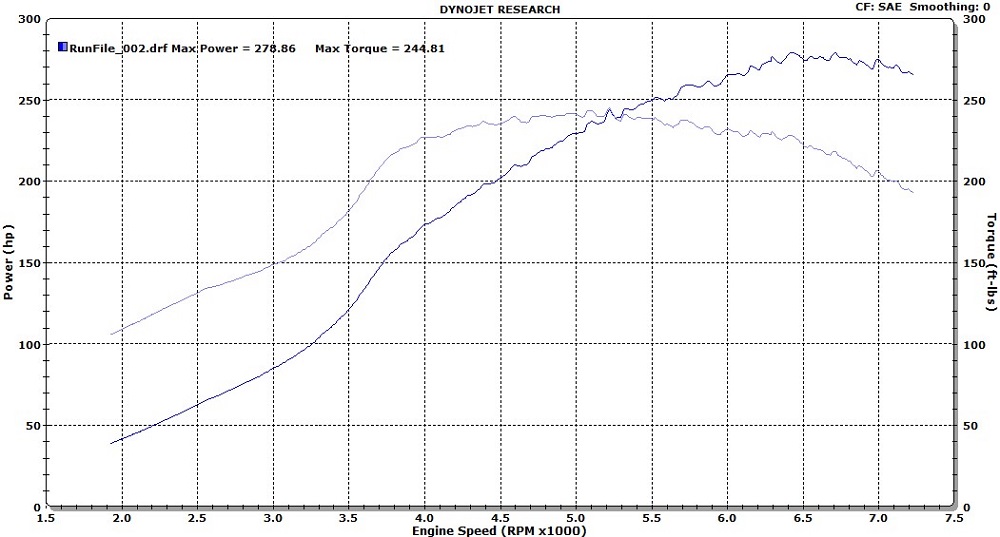

Here is the virtual dyno sheet for the low boost wastegate spring with the Tial BOV.

Later,

Keith

Well, before I swapped to the Tial BOV my boost creep for the 4.4 psi spring in my external wastegate had my boost peaking at 7.1 psi. Now after swapping in the Tial BOV and intake pipe without a flange for the BOV recirce line I am now peaking at 10.5 psi! My boost curve looks like I have a Rotrex supercharger rather than a turbocharger! Here is the spool data for comparison:

Leaky BOV Tial BOV

2000 1.5 1.5

2500 2.6 3.2

3000 4.3 4.9

3500 5.0 5.5

4000 5.2 5.8

4500 6.1 6.6

5000 6.4 7.1

5500 6.4 8.0

6000 6.5 8.7

6500 6.2 8.9

7000 7.1 10.5

Here is the virtual dyno sheet for the low boost wastegate spring with the Tial BOV.

Later,

Keith

#157

Senior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2014

Location: Meridian, Mississippi

Posts: 628

Total Cats: 44

I e-mailed Stephanie again today asking about my heat shield. She said they have looked at the pictures I sent, and think that the best solution is for me to mark up the one I have now showing what changes need to be made, and send it back to them so they can modify it. What I am hearing in my head is that they don't have a pattern to make the correct heat shield for my turbo setup, and that you don't want to randomly try different things over and over trying to get it right...

The "don't have a pattern" and "can't get it right to save out lives" is that mode of operation they have been in since I started trying to get the correct parts. The intake tube I have now is still a 2.5" tube where it mounts up to the 3" inlet on my turbo. It also has a weird molded in divot for clearance... but there is nothing anywhere near the divot that needs to be clearenced. I got tired of trying on that item and just gave up. A 2.5" tube that flared out to 3" at the connection may not have been ideal but it would have worked better than the one they sent me. If I remove the AC and PS from my car I will make my own 3" intake that actually fits correctly. I have a feeling I have to do the same thing with the heat shield.

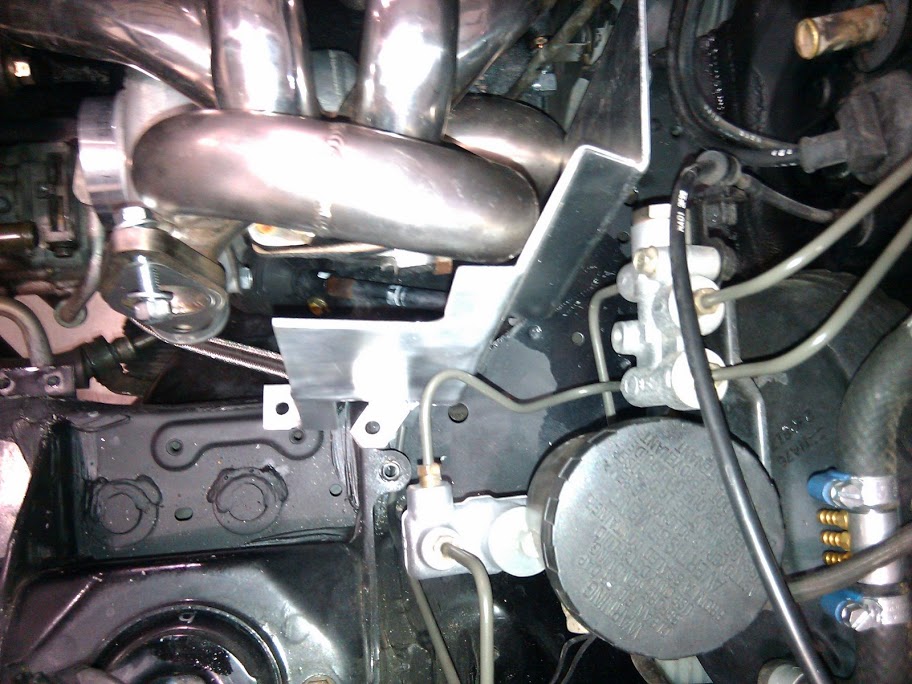

The fact that this setup has horrible boost creep means I will have to re-do the down pipe, (it doesn't fit right anyway, Ben commented on my exhaust leaks when he rode in my car). I will get ride of the retarded slip fit wastegate return line and just go with a dump tube to try and reduce my boost creep issues, and get rid of some of the exhaust leaks in the process.

Disgustedly yours,

Keith

The "don't have a pattern" and "can't get it right to save out lives" is that mode of operation they have been in since I started trying to get the correct parts. The intake tube I have now is still a 2.5" tube where it mounts up to the 3" inlet on my turbo. It also has a weird molded in divot for clearance... but there is nothing anywhere near the divot that needs to be clearenced. I got tired of trying on that item and just gave up. A 2.5" tube that flared out to 3" at the connection may not have been ideal but it would have worked better than the one they sent me. If I remove the AC and PS from my car I will make my own 3" intake that actually fits correctly. I have a feeling I have to do the same thing with the heat shield.

The fact that this setup has horrible boost creep means I will have to re-do the down pipe, (it doesn't fit right anyway, Ben commented on my exhaust leaks when he rode in my car). I will get ride of the retarded slip fit wastegate return line and just go with a dump tube to try and reduce my boost creep issues, and get rid of some of the exhaust leaks in the process.

Disgustedly yours,

Keith

#159

Senior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2014

Location: Meridian, Mississippi

Posts: 628

Total Cats: 44

I need to pull the current down pipe, cut it and rotate the top part about 3 degrees to get it to line up with the turbo outlet correctly, and have it welded back together. While they are doing that they can cut the inlet for the wastegate return off, and patch the hole.

The wastegate return line being a slip fit is the dumbest design I can imagine. They make flex sections for pipes that small, so why not use one so you could use a real non-leaky V-Band flange?

Everything Corky publishes about the divorced wastegate setups says he has it return to the main exhaust stream 15" to 20" down stream. Mine dumps back into the main exhaust stream about 2" from the turbine outlet. How he thought this was a good idea I will never know.

Keith

<edit>I just got a brilliant idea! I can get another 3" V-band clamp, and have it installed where I cut the down pipe so I can rotate it as needed to line up to the turbine outlet rather than welding it together and hoping I got it right.</edit>