To SSM Ahead of Schedule

#84

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Just got back from the shop, hacking up the intercooler. These tank ends are cast for sure and I think you can see the turbulators good in this picture. Not amazing, but pretty damn good for 90 bucks.

Got everything lined up kind of.

Have some nasty gaps to fill.

Not the prettiest welds, but they hold water, should be structural enough. Not too bad considering we only had 1/16" filler rod (1/8 or 3/16 would have been nice), the gaps were huge, it was cast out of god knows what, and my ground seemed to be a bit iffy.

Got everything lined up kind of.

Have some nasty gaps to fill.

Not the prettiest welds, but they hold water, should be structural enough. Not too bad considering we only had 1/16" filler rod (1/8 or 3/16 would have been nice), the gaps were huge, it was cast out of god knows what, and my ground seemed to be a bit iffy.

#85

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Got a crapload done this weekend. Got the fender bolts fixed and the liners pulled. Bought a non-r-package trunk and cut it to fit the wing supports. Got the intercooler lined up and the brackets welded on that. Then I started pulling the EGR bits out of the enginebay and all of a sudden the engine was out of the engine bay. Haha, well it wasnt that quick I took my time and **** and struggled with the damn driveshaft bolts and PPF bolts.

Obligatory standing in engine bay pic

Quickly cleaned it up and cleaned up the little bit of surface rust.

And are engine mounts supposed to look like this?

And in other big news, my engine at Trackspeed Engineering is finally in the crate, almost 9 months after I first ordered it. I hope it was worth the wait.

Obligatory standing in engine bay pic

Quickly cleaned it up and cleaned up the little bit of surface rust.

And are engine mounts supposed to look like this?

And in other big news, my engine at Trackspeed Engineering is finally in the crate, almost 9 months after I first ordered it. I hope it was worth the wait.

#86

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Pricing out the 2nd to last big purchase of this off season. The exhaust. Looking like its going to come out to almost 600 for the post turbo section. ~160 of that is v band clamps lololololololol. Because I'm putting in breaks after the downpipe and after the two front mufflers so I can either run a turn down there or neck down to 3" for the quiet muffler that goes all the way back. It should be quiet running two different sized dynomax bullets up front and then the biggest case for reasonable price borla XR-1 muffler. With my skill at choosing exhaust bits, it'll make sound, sound like a race car when racing, and sound like ******* when driving around.

#87

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Well ordered all the exhaust bits. Ended up getting talked into the borla XS pro by my roomate. Which was like 50 bucks cheaper than the XR-1. A bit heavier, should and should sound better. This muffler will come off at national events but stays on for locals, at least thats the plan.

#88

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Did more work this weekend. Got the gauges installed. Powering them off the power window plug like a boss. Pulled out the blower motor to follow a some bad information that the 94-95s just had a patch harness from the 90-93 ecu location and that after removing 4 feet or wire I'd be able to put the stand alone behind the dash. No such luck, wasted a bunch of time. Removed more of the airbag system, pretty sure now I've got everything pulled out besides the wiring. Removed some random bolts in the engine bay that dont seem to do anything. Installed the new he man springs, spent a few hours de-rusting the crappy torrington bearings on the Xidas. Why these didnt come supplied covered with grease I'll never know, I covered them with mobile 1 red grease that I had kicking around would have rather used the green marine grade, but oh well. I havent set the car on the ground yet so I know all the ride heights are going to be wack as hell. My dad cut out the splitter and I did some measuring, should finish that up at school besides the mounts on the chassis side, which I have to wait till the car is on the ground and the ride height set to do. Random words no one will read. Mounted the intercooler though. Got the tranny sparkling clean and pull the alt and oil pressure sender off the old engine for use on the new engine. The clutch that was in this car had plenty of life left on the disk but the FW and PP were both toasted, guess it didnt like 4k clutch dump launches with 90hp.

Left to do

Mate engine and tranny and clutch

Setup front and rear coolant reroutes

Install engine

Finish wiring engine

Install front sway bar

Come up with some sort of base map, hoping that TSE has something to save me the work

Break in engine

Mate splitter to car

Make air dam

Make turbo manifold (hopefully dont warp flanges)

Make turbo back

Send manifold, turbine housing and down pipe to swain for White Lightning coating

Plumb turbo oil and water (hope oil return line works)

Run IC tubes (do some funky **** because **** the radiator)

Cut hood to clear IC tubes

Get on dyno

Borrow roller, try pulling front fenders for 275s, also try and pull the rears another 1/2"

All this needs to be done for April 19th at the latest, would prefer April 7th but swain has a 2 week turn around time. And I know the earliest I can have the manifold and stuff done is like the 20th of March, though a week later is more realistic. If the engine goes in flawless and gets broken in right away though I might pull off the miracle and get everything tacked up the 17th. Or I could throw the engine in quick, don't wire, do the manifold and get it out, that seems like a better idea.

RAGE!

No engine yet. It just arrived at the shipping terminal. I should have it by this weekend but ******* hell this has been a nightmare. I will NEVER again have an engine built or machine work done anywhere but local. Remember I justified this because it was pretty cheap and it would be a time an aggravation saver? ******* 9 months and many gray hairs (yes I'm going gray young) later I could have bored the cylinder walls with a rust spoon by hand and had an engine already.

Left to do

Mate engine and tranny and clutch

Setup front and rear coolant reroutes

Install engine

Finish wiring engine

Install front sway bar

Come up with some sort of base map, hoping that TSE has something to save me the work

Break in engine

Mate splitter to car

Make air dam

Make turbo manifold (hopefully dont warp flanges)

Make turbo back

Send manifold, turbine housing and down pipe to swain for White Lightning coating

Plumb turbo oil and water (hope oil return line works)

Run IC tubes (do some funky **** because **** the radiator)

Cut hood to clear IC tubes

Get on dyno

Borrow roller, try pulling front fenders for 275s, also try and pull the rears another 1/2"

All this needs to be done for April 19th at the latest, would prefer April 7th but swain has a 2 week turn around time. And I know the earliest I can have the manifold and stuff done is like the 20th of March, though a week later is more realistic. If the engine goes in flawless and gets broken in right away though I might pull off the miracle and get everything tacked up the 17th. Or I could throw the engine in quick, don't wire, do the manifold and get it out, that seems like a better idea.

RAGE!

No engine yet. It just arrived at the shipping terminal. I should have it by this weekend but ******* hell this has been a nightmare. I will NEVER again have an engine built or machine work done anywhere but local. Remember I justified this because it was pretty cheap and it would be a time an aggravation saver? ******* 9 months and many gray hairs (yes I'm going gray young) later I could have bored the cylinder walls with a rust spoon by hand and had an engine already.

Last edited by Leafy; 03-11-2013 at 04:34 PM.

#92

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Splitter has one layer of gel coat on it. And its a terrible layer. After much abuse my HF spray gun finally gave up the ghost. I just threw it away, got way more than 10 bucks worth of use out of it. I'm sure it would have lasted much longer if I wasn't spraying gel coat with it, and put any sort of effort into cleaning it when I finished using it.

#93

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

Got the new engine friday. Painted it.

Just making sure everything is alright under here, and I had to take it off the remove the front coolant neck anyways.

Look at that sexy clutch that I put on wrong without an alignment tool because they sent me the wrong one.

Look at that sexy clutch that I put on right after I realized I had another miata clutch with 80 miles on it in a box that had a clutch alignment tool in it. And you can also see the beni coolant re-rout setup, they fucked up the thread for the coolant sensor, it was not m12x1.5 so I retapped over whatever corky tapped it to. Worked well.

Check that seductive billet throwout bearing.

Man getting the tranny on was a pain, did it once on saturday used the bolts to pull it all the way in. Sunday morning I pulled it off again because I was worried on how thought it went on and I thought I pushed the pilot bearing out of the flywheel. I was wrong, it was fine.

Threw the engine in after lunch yesterday went in pretty easily actually.

Started laying out the turbo setup after dinner. It took a while and I would have started before dinner but I had to buy my parents a new printer so I could print out my drawings.

Turbo hit block.

Now turbo no hit block, turbo hit water pump inlet.

And thats where I stopped for the night. So I have a new location that moves it outward, backward, and upwards from that spot that should make everything fit better including the downpipe. If only this compressor housing wasnt so big.

Just making sure everything is alright under here, and I had to take it off the remove the front coolant neck anyways.

Look at that sexy clutch that I put on wrong without an alignment tool because they sent me the wrong one.

Look at that sexy clutch that I put on right after I realized I had another miata clutch with 80 miles on it in a box that had a clutch alignment tool in it. And you can also see the beni coolant re-rout setup, they fucked up the thread for the coolant sensor, it was not m12x1.5 so I retapped over whatever corky tapped it to. Worked well.

Check that seductive billet throwout bearing.

Man getting the tranny on was a pain, did it once on saturday used the bolts to pull it all the way in. Sunday morning I pulled it off again because I was worried on how thought it went on and I thought I pushed the pilot bearing out of the flywheel. I was wrong, it was fine.

Threw the engine in after lunch yesterday went in pretty easily actually.

Started laying out the turbo setup after dinner. It took a while and I would have started before dinner but I had to buy my parents a new printer so I could print out my drawings.

Turbo hit block.

Now turbo no hit block, turbo hit water pump inlet.

And thats where I stopped for the night. So I have a new location that moves it outward, backward, and upwards from that spot that should make everything fit better including the downpipe. If only this compressor housing wasnt so big.

#94

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

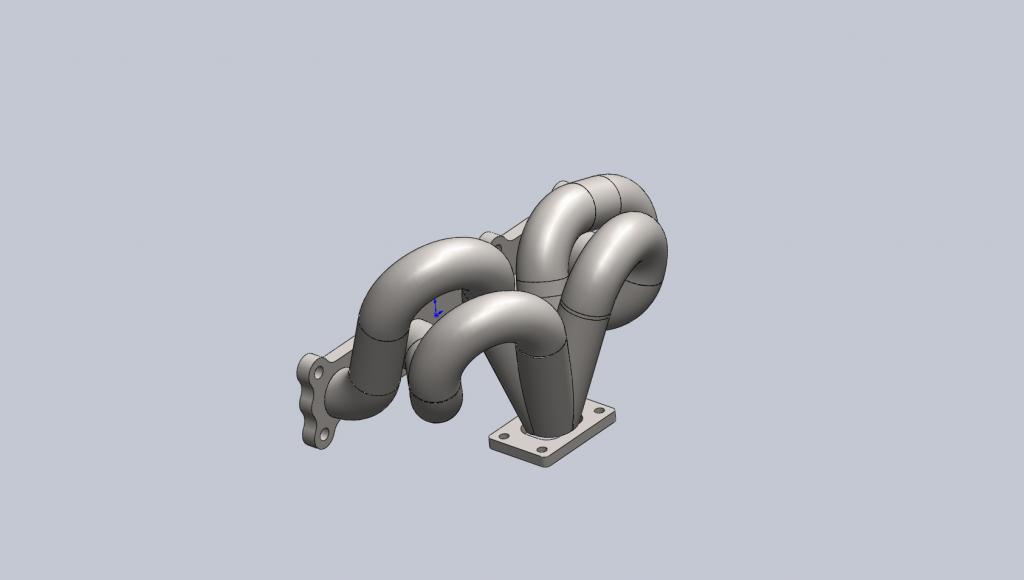

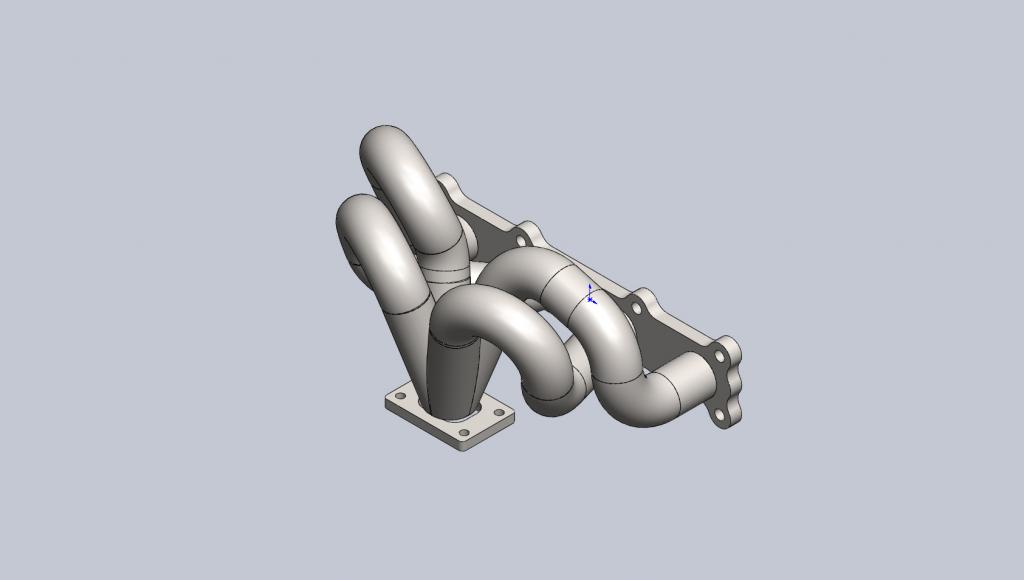

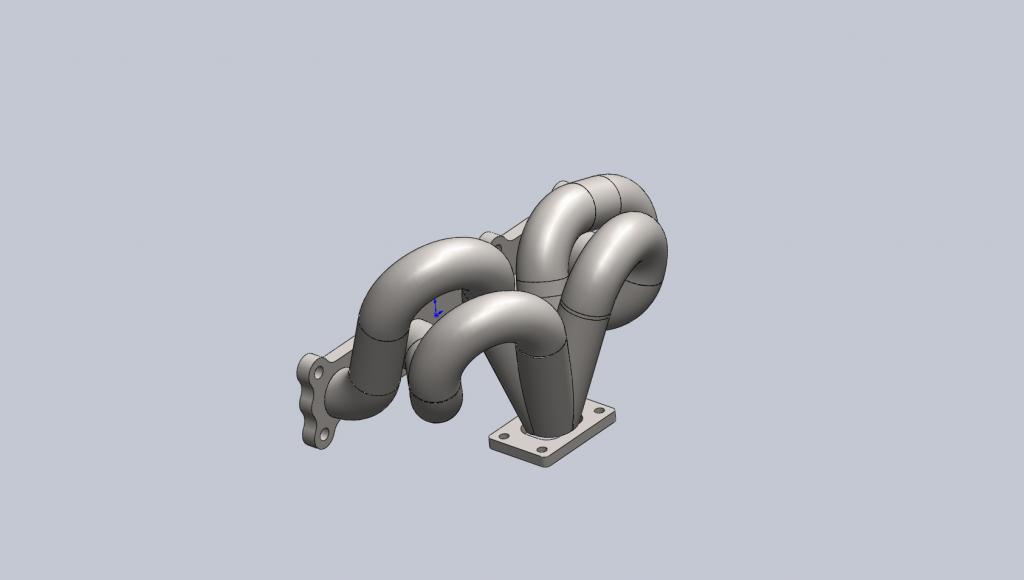

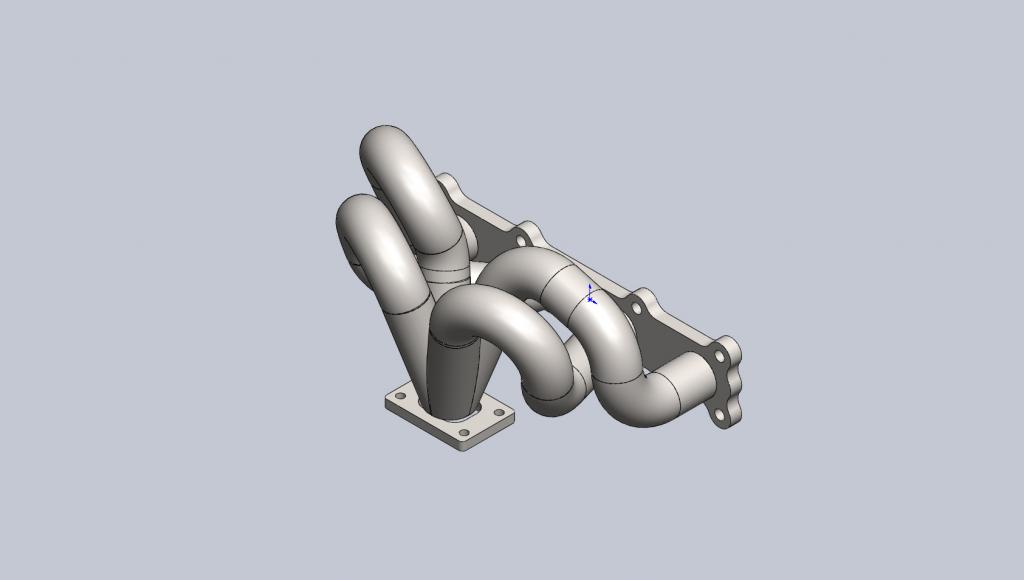

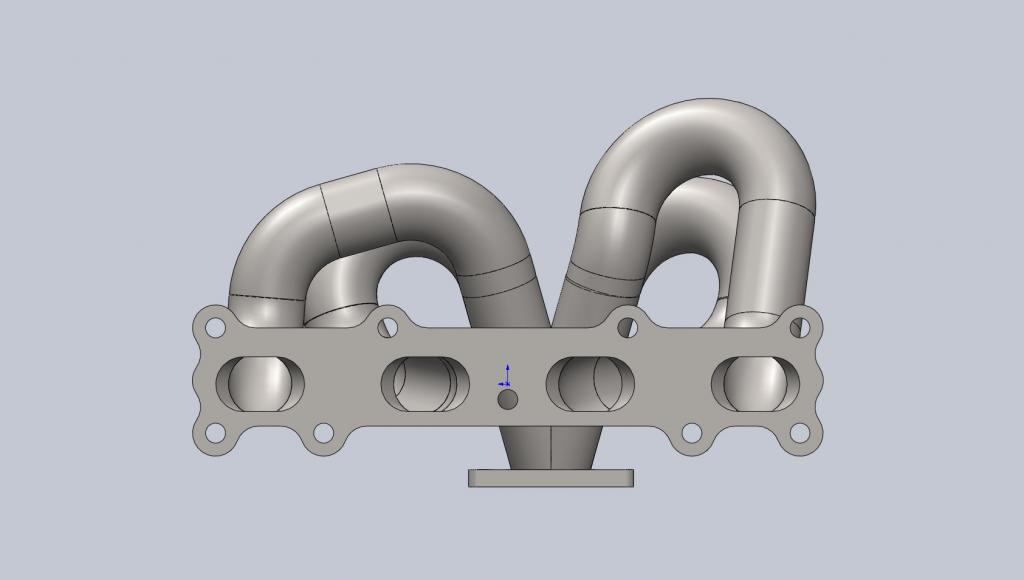

Well now turbo no hit block, turbo no hit water pump inlet, turbo no hit frame, manifold no hit valve cover.

It is really close to all those things though. Much further from the block though and now its not trying to intersect the water pump inlet. Did get much closer to the frame with the wastegate canister. I'll be able to mock this up in a couple hours.

Anyone know the threading for the hole on a 1.6 thermofan switch on the thermo cover? I've heard M16x1.5, M14x1.5, and 1/2 BSPP, and I tried a 3/8 45*flare fitting while I was in the store and that thread was pretty close too.

It is really close to all those things though. Much further from the block though and now its not trying to intersect the water pump inlet. Did get much closer to the frame with the wastegate canister. I'll be able to mock this up in a couple hours.

Anyone know the threading for the hole on a 1.6 thermofan switch on the thermo cover? I've heard M16x1.5, M14x1.5, and 1/2 BSPP, and I tried a 3/8 45*flare fitting while I was in the store and that thread was pretty close too.

#95

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

FFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFFUUUUUUUUUUUUUUUU UUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUUU UUUUUUUUUUUU

I cant reasonably make the 3.5" downpipe fit. So I wasted a lot of tonight. Going to just have to go with a 3 inch. Turbo clears everything now. But I'm going to have to do some interesting coolant routing. Not a deal breaker. But god damn I wont be turbo for the first race of the season.

I think I could fit the 3.5 If I cut the tabs off the tranny and hammered the **** out of the trans tunnel. But one of those things is not class legal.

Also, my cops will be up fro sale at some point. I'm going to clean up the harness and sell em. Mainly because of the wholesale amount of material I'd have to remove from the vvt valve cover to make them fit. I'll be running 01 coils for the time being and when I start to have spark problems I'll switch to truck coils with custom wires.

I cant reasonably make the 3.5" downpipe fit. So I wasted a lot of tonight. Going to just have to go with a 3 inch. Turbo clears everything now. But I'm going to have to do some interesting coolant routing. Not a deal breaker. But god damn I wont be turbo for the first race of the season.

I think I could fit the 3.5 If I cut the tabs off the tranny and hammered the **** out of the trans tunnel. But one of those things is not class legal.

Also, my cops will be up fro sale at some point. I'm going to clean up the harness and sell em. Mainly because of the wholesale amount of material I'd have to remove from the vvt valve cover to make them fit. I'll be running 01 coils for the time being and when I start to have spark problems I'll switch to truck coils with custom wires.

#99

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

If I was fae I'd have made it fit by cutting a few unused tabs off the tranny and beating the ever living **** out of the trans tunnel. Though it does look like it will reduce the weight of my downpipe by almost a pound doing 3" instead of 3.5" and I do end up getting more muffler packing volume in the bullet mufflers in the trans tunnel.

#100

Elite Member

Thread Starter

iTrader: (1)

Join Date: Jun 2012

Location: NH

Posts: 9,479

Total Cats: 104

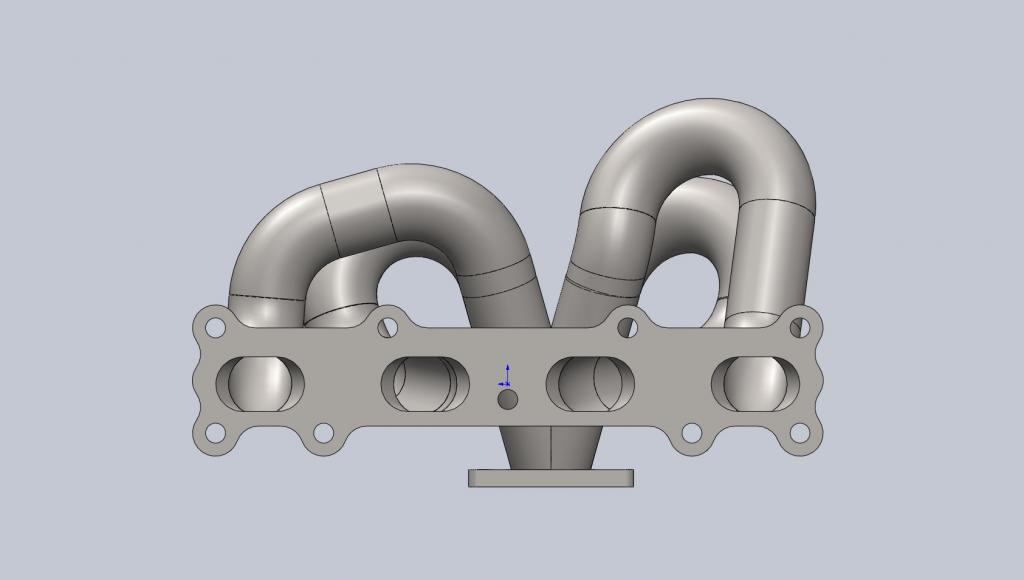

Got an immense amount of work done this weekend. I have the wiring ~1/3 of the way done. I painted the valve cover and I have the turbo manifold most of the way done as well as the downpipe. I've got to Finish weld the collector to the turbo flange, and drill and weld for the EGT bungs in, and finish weld the downpipe then I'll be able to send it out to swain to get white lightning. The manifold went together surprisingly fast, some of the welds ended up kind of ugly and none of them look particularly beautiful for some reason. I think it was because I was trying out the cerated tungsten instead of the thoriated. It'll be functional and most of them you wont be able to see and the coating will cover the rest. After measruing everything up the wideband is actually going to go right after the end of the down pipe since that puts it the AEM recommended 36 inches from the exhaust port for a turbo car. I figured out that I'm going to need slim fans to clear my coolant hoses so I ordered two 12" slim fans from silicon intakes.

You can see my sweet *** welding table.

Yeah I know I made a special plate for this but I left it in worcester and I was impatient.

Still to do

Finish wiring

Install stock exhaust

Install VICS manifold

Finish temporary coolant routing

Install sway bar

Set ride height

Add coolant and oil

Break in engine

Install splitter

Roll front fenders

Race the first weekend without turbo

Put freshly coated turbo bits back in the car

Make oil lines

Do turbo coolant routing

Make exhaust after turbo

Make IC piping

Tune for turbo

Race in Jersey and beat Jake Namer and dont break anything

You can see my sweet *** welding table.

Yeah I know I made a special plate for this but I left it in worcester and I was impatient.

Still to do

Finish wiring

Install stock exhaust

Install VICS manifold

Finish temporary coolant routing

Install sway bar

Set ride height

Add coolant and oil

Break in engine

Install splitter

Roll front fenders

Race the first weekend without turbo

Put freshly coated turbo bits back in the car

Make oil lines

Do turbo coolant routing

Make exhaust after turbo

Make IC piping

Tune for turbo

Race in Jersey and beat Jake Namer and dont break anything