Tips for TIG Welding Thin Walled Stainless...Please!

#1

Junior Member

Thread Starter

iTrader: (2)

Join Date: Jul 2011

Location: Grand Rapids, MI

Posts: 213

Total Cats: 48

For all you welders out there –

I have been TIG welding for a few years now, mainly just fabricating exhausts, intercooler tubing, manifolds etc. for my cars. I am getting better at it but the one thing that still eludes me is the ability to make very clean, very “pretty” welds on thin walled stainless. They always turn out more or less gray. If I do a tack weld and let it cool fully in the postflow, it comes out nice and silver. Here are some things I have done so far:

I always backpurge when I do stainless.

I have PTA-17 torch with a shorty gas lens setup (from a PTA-9 torch) with a #8 cup, 1/16” 2% thoriated tungsten, argon flow set to about 15 cfh.

I also tried the standard size gas lens setup with a #12 cup without any noticeable improvement.

I use .040” 308L filler rod on 16 Ga tubing.

I am pretty sure there are no leaks in my torch head but how would you check?

I have learned to pulse the pedal and I try to move relatively quickly

I grind the tungsten to a long, sharp point and always re-grind it if I accidentally touch the weld puddle

I try not to remove the hot filler rod end from the shielding gas as I weld.

I always make sure the pipes fit together very well before welding

I make sure the parts are bright clean metal and clean them with acetone before welding.

…all of that and I still get gray welds. Some things I am suspicious of:

Do I not have enough backpurge? I am fairly certain I do, since I don’t get any sugaring.

Do I not have enough argon flow for the gas lens/ #8 nozzle?

Is my bench grinder contaminating my tungsten? Do they make specific grinding wheels for this purpose?

Do you need a trailing shield to really make awesome welds on tubing?

Should I be striking an arc on copper first, to clean the electrode (I think I remember reading this somewhere…)

Do I need to use less power, or move faster? I have been using 60-65 amps while pulsing the pedal.

Should I be using .040 tungsten?

Thanks in advance. Hopefully ARTech will chime in, because his welds are *******! Of course I will understand if he doesn’t want to share secrets.

I have been TIG welding for a few years now, mainly just fabricating exhausts, intercooler tubing, manifolds etc. for my cars. I am getting better at it but the one thing that still eludes me is the ability to make very clean, very “pretty” welds on thin walled stainless. They always turn out more or less gray. If I do a tack weld and let it cool fully in the postflow, it comes out nice and silver. Here are some things I have done so far:

I always backpurge when I do stainless.

I have PTA-17 torch with a shorty gas lens setup (from a PTA-9 torch) with a #8 cup, 1/16” 2% thoriated tungsten, argon flow set to about 15 cfh.

I also tried the standard size gas lens setup with a #12 cup without any noticeable improvement.

I use .040” 308L filler rod on 16 Ga tubing.

I am pretty sure there are no leaks in my torch head but how would you check?

I have learned to pulse the pedal and I try to move relatively quickly

I grind the tungsten to a long, sharp point and always re-grind it if I accidentally touch the weld puddle

I try not to remove the hot filler rod end from the shielding gas as I weld.

I always make sure the pipes fit together very well before welding

I make sure the parts are bright clean metal and clean them with acetone before welding.

…all of that and I still get gray welds. Some things I am suspicious of:

Do I not have enough backpurge? I am fairly certain I do, since I don’t get any sugaring.

Do I not have enough argon flow for the gas lens/ #8 nozzle?

Is my bench grinder contaminating my tungsten? Do they make specific grinding wheels for this purpose?

Do you need a trailing shield to really make awesome welds on tubing?

Should I be striking an arc on copper first, to clean the electrode (I think I remember reading this somewhere…)

Do I need to use less power, or move faster? I have been using 60-65 amps while pulsing the pedal.

Should I be using .040 tungsten?

Thanks in advance. Hopefully ARTech will chime in, because his welds are *******! Of course I will understand if he doesn’t want to share secrets.

#2

It sounds like you might just need to move faster. You could probably go a little cooler than 60 amps, maybe around 50, but you should be getting some extra cooling with the backpurging.

What kind of machine are you using? If your machine has a pulse setting this would help a lot, especially if your machine has the ability for you to adjust the peak and background amperage in addition to the frequency. If you can turn the background down that will take a lot of heat out of the part.

How long do you postflow? I wouldnt go less than 5 sec, some even suggest going even as long as 15 but thats typically for much greater amperage.

I used to work exclusively with 14, 16 and 18ga 304ss sheet. I used a pta-17 torch with a large lens and a #10 cup and 1/16th" 2% thoriated tungsten with 15cfh argon and 5 sec postflow. For filler we had .035 316L and 1/16 308L. I never did anything special with trailing cups (even when welding 2-4 foot long seems/joints), copper, dedicated grinder wheel, pack purge(due to sheet) etc and never had any problems with graying. It sounds like you are just fighting heat. If youre welding stainless tube try to find some aluminum tube with a similar inside diameter to your stainless material's outside diameter. Cut the aluminum tube in half and place your halves as close as you can to the area you are welding on both sides of the weld. This will suck a lot of heat out of your working area.

What kind of machine are you using? If your machine has a pulse setting this would help a lot, especially if your machine has the ability for you to adjust the peak and background amperage in addition to the frequency. If you can turn the background down that will take a lot of heat out of the part.

How long do you postflow? I wouldnt go less than 5 sec, some even suggest going even as long as 15 but thats typically for much greater amperage.

I used to work exclusively with 14, 16 and 18ga 304ss sheet. I used a pta-17 torch with a large lens and a #10 cup and 1/16th" 2% thoriated tungsten with 15cfh argon and 5 sec postflow. For filler we had .035 316L and 1/16 308L. I never did anything special with trailing cups (even when welding 2-4 foot long seems/joints), copper, dedicated grinder wheel, pack purge(due to sheet) etc and never had any problems with graying. It sounds like you are just fighting heat. If youre welding stainless tube try to find some aluminum tube with a similar inside diameter to your stainless material's outside diameter. Cut the aluminum tube in half and place your halves as close as you can to the area you are welding on both sides of the weld. This will suck a lot of heat out of your working area.

#3

I would use a bigger cup and bump up the gas flow a little bit, that gave my welds a much nicer color.

The best advice I can give you is to post this same exact question WITH PICTURES on the Honda tech welding and fabrication forum. It is an amazing resource, and has the most amazing welders in one place. If 9bells gives you tips, listen to him.

The best advice I can give you is to post this same exact question WITH PICTURES on the Honda tech welding and fabrication forum. It is an amazing resource, and has the most amazing welders in one place. If 9bells gives you tips, listen to him.

#4

Might try posting on the Miller forum as well... http://www.millerwelds.com/resources...nities/mboard/

#7

Junior Member

Thread Starter

iTrader: (2)

Join Date: Jul 2011

Location: Grand Rapids, MI

Posts: 213

Total Cats: 48

Wow guys thanks for the help! Sorry I know this thread is sorta useless without pics, I will get some pics of the crappy welds next time I take the DP off the car (I usually only take pictures of the good welds!)

Baxt3r: I did some more welding yesterday and tried the lower amperage - it definitely seemed to help.

I am using a Lincoln Precision TIG 225. It has an adjustable pulse setting (duration only, background current is not adjustable) but I rarely use it. I find it difficult to use the pulse setting and simultaneously time my filler rod application - do you use the pulse to create a rhythm, i.e. one pulse per "coin" in the roll of coins? Or do you allow it to pulse several times in one spot before applying filler and moving on? It also doesn't make much sense to me how that could help keep the weld cool since it seems to me like you have to move slower, and the longer you stay in one spot the larger the HAZ no?

I postflow between 10 and 15 seconds usually, depending on the amperage - it's pretty easy to watch the weld puddle and see if it changes color instantly when the postflow stops, at which point I turn it up some more.

I am thinking my #8 cup is a little on the small side, I will get a 10.

Good idea with the aluminum heat sinks - I notice that when I am welding pipe to a flange or something thicker, the welds always look better because of the heatsink effect of the more massive piece. That reaffirms the theory that I am fighting extra heat.

Reverend Greg -

I get my gas from the welding supply place - AirGas i think it is. I am pretty sure I don't have any leaks but how would I check? Soapy water? My secondary regulator reads in L/min and I usually just crack it open to about 4 L/min which is about 8 CFH. When i am done the inside of the pipe usually looks as if it were welded from the inside - a silver weld bead look (no sugar). What is a purge dam?

jasonb - I already do flip the part and continuously weld opposite sides. And my weld beads are generally no longer than 1" at a time, since it is hard to do any more than that on a pipe! Isn't a blue color bad? Shouldn't it be silver/light gold with some hints of blue and pink?

Baxt3r: I did some more welding yesterday and tried the lower amperage - it definitely seemed to help.

I am using a Lincoln Precision TIG 225. It has an adjustable pulse setting (duration only, background current is not adjustable) but I rarely use it. I find it difficult to use the pulse setting and simultaneously time my filler rod application - do you use the pulse to create a rhythm, i.e. one pulse per "coin" in the roll of coins? Or do you allow it to pulse several times in one spot before applying filler and moving on? It also doesn't make much sense to me how that could help keep the weld cool since it seems to me like you have to move slower, and the longer you stay in one spot the larger the HAZ no?

I postflow between 10 and 15 seconds usually, depending on the amperage - it's pretty easy to watch the weld puddle and see if it changes color instantly when the postflow stops, at which point I turn it up some more.

I am thinking my #8 cup is a little on the small side, I will get a 10.

Good idea with the aluminum heat sinks - I notice that when I am welding pipe to a flange or something thicker, the welds always look better because of the heatsink effect of the more massive piece. That reaffirms the theory that I am fighting extra heat.

Reverend Greg -

I get my gas from the welding supply place - AirGas i think it is. I am pretty sure I don't have any leaks but how would I check? Soapy water? My secondary regulator reads in L/min and I usually just crack it open to about 4 L/min which is about 8 CFH. When i am done the inside of the pipe usually looks as if it were welded from the inside - a silver weld bead look (no sugar). What is a purge dam?

jasonb - I already do flip the part and continuously weld opposite sides. And my weld beads are generally no longer than 1" at a time, since it is hard to do any more than that on a pipe! Isn't a blue color bad? Shouldn't it be silver/light gold with some hints of blue and pink?

#8

Junior Member

Thread Starter

iTrader: (2)

Join Date: Jul 2011

Location: Grand Rapids, MI

Posts: 213

Total Cats: 48

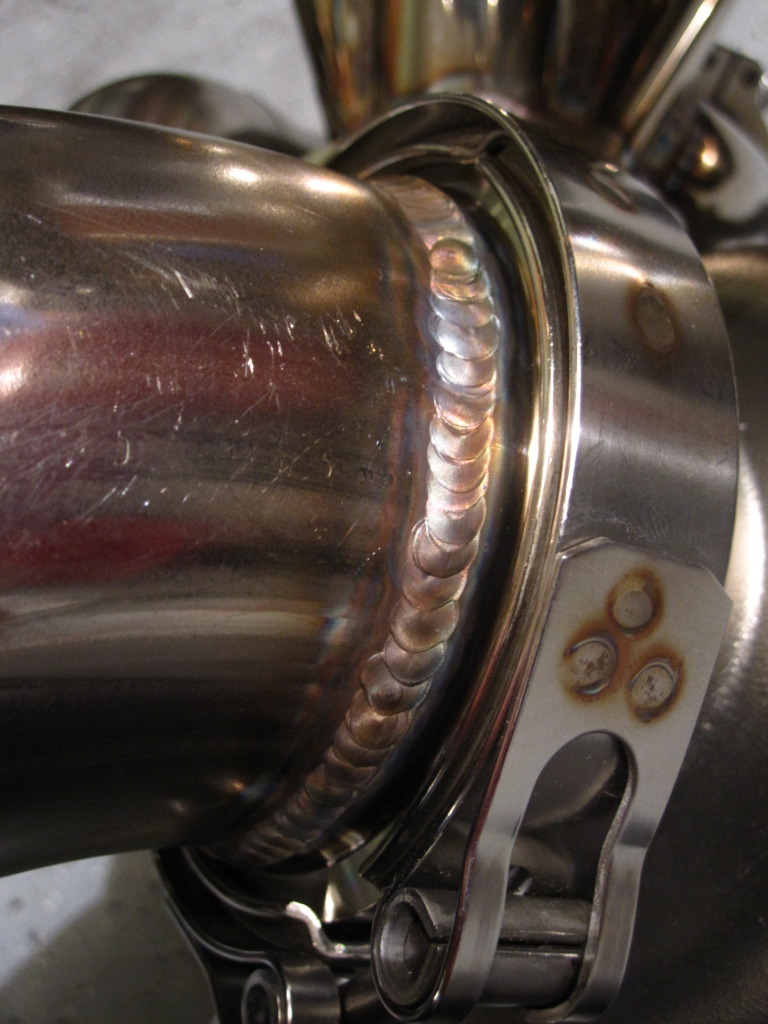

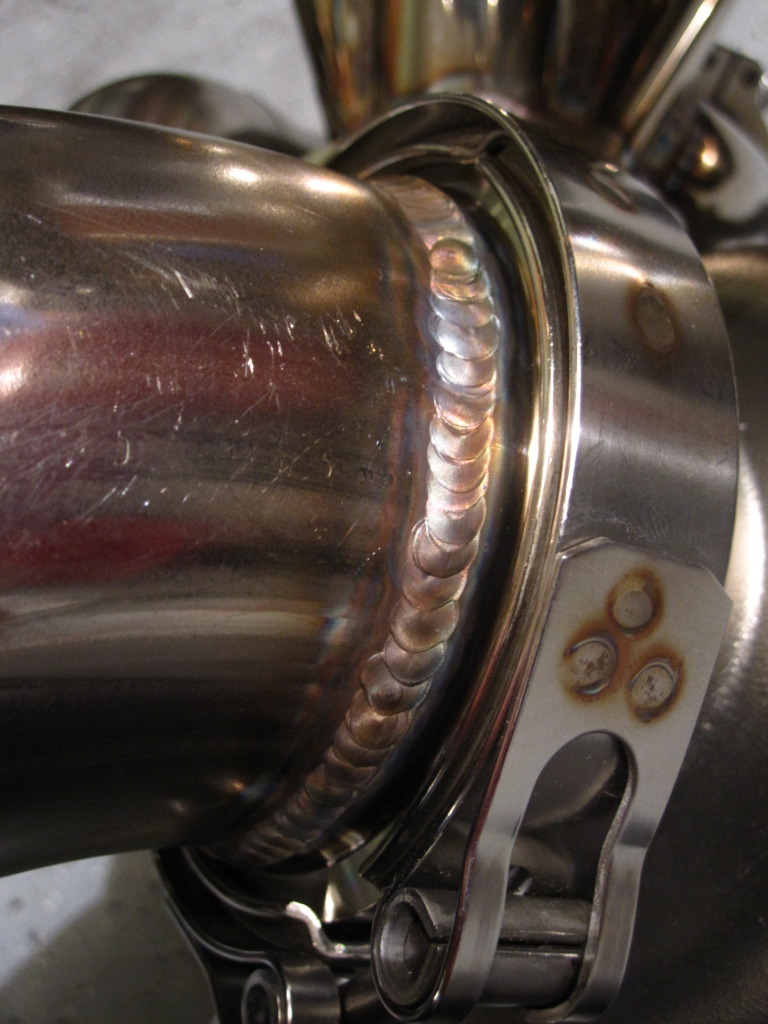

Here are some examples of my better welds - still not what I would consider perfect but I am happy with these. Both of these however were on flanges, which always seem to turn out better for me because of the heatsink effect.

#9

Before working at my current and former jobs I had only used the pulse setting in very low frequencies, probably somewhat similar to what you are describing as your experience with it as well. Since then however, I have learned to turn it up and weld as if the pulse was not turned on. Just get your puddle going as normal and move and dab at your personal rhythm. Once you have a high enough frequency to run a bead at a normal non-pulsed speed then you will start to see greater benefits from using it. When you use it like this you will have to turn your amperage up because youre basically only hitting your peak heat/amperage approximately 50% of the time. When i welded ss sheetmetal, I would turn my machine up to around 70 amps with the pulse setting on the same material that I would usually weld at around 50 amps without it. I used to use a precision tig 185 and would routinely use its pulse setting set to half way(12o'clock) which I can no longer remember what that hertz was. I'll check my machine at work tomorrow to double check what my pulse setting it is on. You will get a tighter looking weld using a higher frequency, your dimes wont be spread out. Heres a weld I did with my normal pulse setting using a rotisserie machine:

#11

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,892

Total Cats: 399

Bump, have you ever figured out your settings? I am reading thru your old posts to get some good info. My welds have never looked good. Lincoln Tig 185 here, basically same setup to what you are doing in the initial post here too.

#13

Junior Member

Thread Starter

iTrader: (2)

Join Date: Jul 2011

Location: Grand Rapids, MI

Posts: 213

Total Cats: 48

I never really did much better than the pictures I posted. I tried the pulse settings, and it was difficult for me to keep control and see what I was doing, so I never had much success with that. What I started doing more often was just working the pedal on-off-on-off to make each coin in the weld bead, which seems to help keep the heat down. I also noticed that my welds always look far better on flanges and heavy gauge parts, because the extra material acts as a heat sink. I think my problem is just that I overheat the thin walled stuff and it doesn't have time to cool by the time I move on and it loses it shielding gas too early

Thread

Thread Starter

Forum

Replies

Last Post

elesjuan

Build Threads

9

11-14-2018 12:18 PM

StratoBlue1109

Miata parts for sale/trade

21

09-30-2018 01:09 PM

FAB

Prefabbed Turbo Kits

216

03-22-2017 04:00 PM