Fuel Pump PWM Control

#1

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Breaking this out from the other fuel pump thread. Here is my setup on the bench.

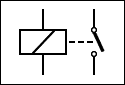

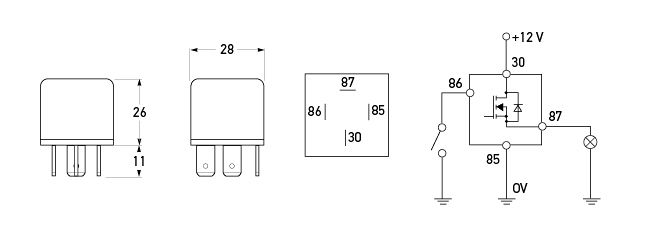

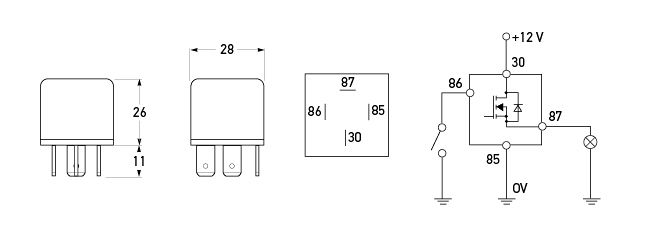

Here is the circuit diagram for the relay

And my chicken scratch circuit

Lets keep this thread open for help setting it up, and sharing tuning ideas. I hope to have my setup in the car in the next few weeks.

Here is the circuit diagram for the relay

And my chicken scratch circuit

Lets keep this thread open for help setting it up, and sharing tuning ideas. I hope to have my setup in the car in the next few weeks.

#3

Senior Member

iTrader: (1)

Join Date: Dec 2010

Location: Farmington Hills, MI

Posts: 1,218

Total Cats: 175

Are you going to run this with a regulator, or totally closed-loop without a regulator? If closed loop, it seems like anything below would cause a target pressure below regulator pressure would just mean nothing goes through the return. If set above, then the duty cycle will climb to 100% because it never reaches target. So open loop seems the way to go with a regulator, that way you can tune in to always provide enough duty cycle to keep the pressure just above regulator pressure.

I was considering this route, but my current plans are to put my flex fuel sensor on the return, in which it would rarely get fuel. However now I'm considering running the flex fuel sensor on the feed line, and PWM'ing it open loop. I'll be running this on an E85 LS1 swap with 630cc EV14's.

I was considering this route, but my current plans are to put my flex fuel sensor on the return, in which it would rarely get fuel. However now I'm considering running the flex fuel sensor on the feed line, and PWM'ing it open loop. I'll be running this on an E85 LS1 swap with 630cc EV14's.

#4

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Definitely not closed loop. Tuning would have to be way too perfect.

Plan is to run lower DC at vacuum, ramp up to higher DC in boost. I have a big AFPR so im not worried about overpowering the FPR.

The return line should always get fuel, you would have to perfectly tune DC to keep any from flowing.

Plan is to run lower DC at vacuum, ramp up to higher DC in boost. I have a big AFPR so im not worried about overpowering the FPR.

The return line should always get fuel, you would have to perfectly tune DC to keep any from flowing.

#5

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,100

My expectation is that there will be X%DC which is the minimum duty cycle required to maintain adequate fuel pressure, and there will be Y%DC which is the duty cycle that starts to overpower the factory regulator. My expectation is that there will be a pretty wide range of "correct" duty cycles which will give adequate pressure without blowing the FPR open. Not an issue for you, but I see this as a great option for people who need a big pump but don't necessarily need the adjustability of an aftermarket FPR.

#6

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

I'm really hoping those values are the same for each pump. I can't test it. But you should get a fuel pressure sensor and log where it overwhelms, and where it doesnt.

I think this value will also change with load/RPM.

I think this value will also change with load/RPM.

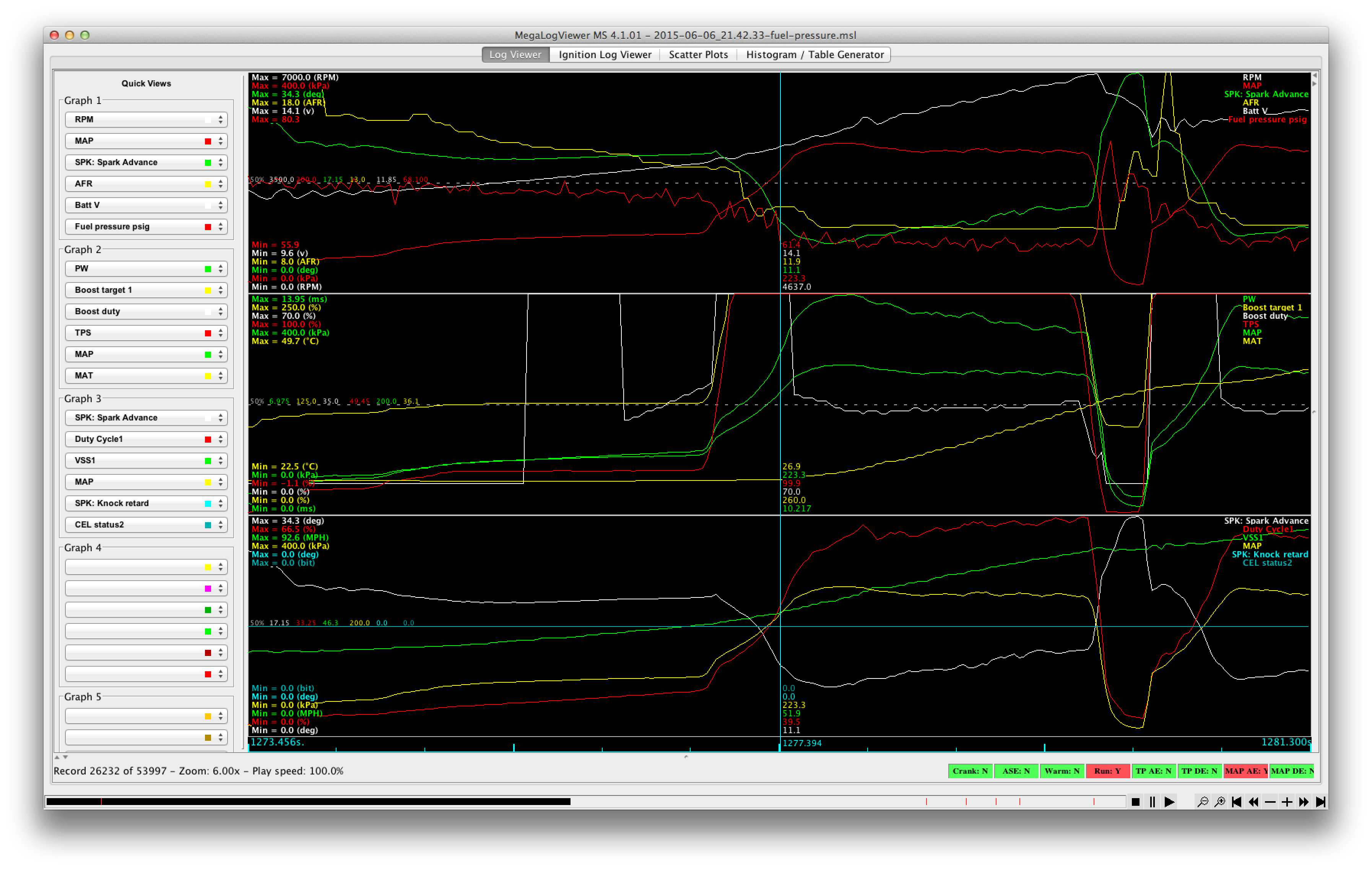

#8

Looking at the data I took before I installed a regulator, with the stock NB regulator and a Walbro on my 99 it took 4600 RPM and 220 kpa MAP (at a DC of 40% on my id1000s) to bring the fuel pressure down to the nominal regulator set point.

--Ian

#11

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Alright just tried out PWM control with the Walbro450. Fuel pressure is not stable at all if I am below the FPR setting. jumps back and forth 2-3psi. I'll get data this week.

This wouldn't work without an FPR. But with an FPR it works great. Right now I have it set to be 50% at idle and low rpm vacuum. 75% in high rpm vaccum. And 100% in boost for now.

This wouldn't work without an FPR. But with an FPR it works great. Right now I have it set to be 50% at idle and low rpm vacuum. 75% in high rpm vaccum. And 100% in boost for now.

#18

Senior Member

iTrader: (1)

Join Date: Dec 2010

Location: Farmington Hills, MI

Posts: 1,218

Total Cats: 175

Cool. I've got a 1N5819 planned for my fuel pump. Do you happen to know of a diode that's rated for over 30A peak? I'm trying to find one for a cooling fan that maxes out in the 35A range.