another overboosting thread

#21

wga disconnected would mean wastegate has zero influence on the outcome... ie he would get 7 psi if he removed wga completely or was running 1,000 psi actuator.

iirc guys with proper hardware setups would see like, 2 psi or something with wga disconnected- to me theres obvious hardware issue here. again, i would try porting wg first, and/or get downpipe changed so wastegate gasses have a shorter tube to flow thru before being reunited. i had this exact same issue on v1 of my setup.

iirc guys with proper hardware setups would see like, 2 psi or something with wga disconnected- to me theres obvious hardware issue here. again, i would try porting wg first, and/or get downpipe changed so wastegate gasses have a shorter tube to flow thru before being reunited. i had this exact same issue on v1 of my setup.

You're suggesting the more labor intensive/money intensive method 1st and I'm suggesting the 20-40 dollar wga can swap.

So again, I don't get it.

(maybe I'm wrong, but my past experiences disagree)

#22

so, there are 2 opinions: the wastegate needs to be ported or there is a flow issue with the separated gases pipe AND the can has too stiff of a spring.

what 18psi says is logical. IF with the actuator disconnected all I can make is 7 psi, than with a good can, I should be able to make the same.

However, my initial description (max psi with actuation disconnected was 7 psi) was only partially true. That is because i only did 1st gear pulls. Following the discussion here, I went and did some testing on the car, as follows:

I disconnected the actuator. I then set the red line to 6,500, and ran the car to red line. Then, I set the redline to 6,800 and finally to 7,000 so that I can get more data points. Every time I ran the car to red line in 1st and 2nd gear and noted the max psi at redline for 1st gear as well as 2nd gear. I did a couple of runs for each condition. The outside temperature was about 30-35F. The data:

1. red line at 6,500 rpm:

- first gear - maximum boost was 5 psi

- second gear - max boost - 12 psi

2. red line at 6,800 rpm:

- first gear - max boost 6 psi

- second gear - max boost 13 psi

3. red line at 7,000 rpm:

- first gear - max boost 7 psi

- second gear - max boost 14-15 psi

So, here it is. I am getting rather annoyed. I really don't want to screw up the engine but then I can't really set the red line at 5,000 rpm either, or keep my eye on the boost gauge every time I press on the gas.

what 18psi says is logical. IF with the actuator disconnected all I can make is 7 psi, than with a good can, I should be able to make the same.

However, my initial description (max psi with actuation disconnected was 7 psi) was only partially true. That is because i only did 1st gear pulls. Following the discussion here, I went and did some testing on the car, as follows:

I disconnected the actuator. I then set the red line to 6,500, and ran the car to red line. Then, I set the redline to 6,800 and finally to 7,000 so that I can get more data points. Every time I ran the car to red line in 1st and 2nd gear and noted the max psi at redline for 1st gear as well as 2nd gear. I did a couple of runs for each condition. The outside temperature was about 30-35F. The data:

1. red line at 6,500 rpm:

- first gear - maximum boost was 5 psi

- second gear - max boost - 12 psi

2. red line at 6,800 rpm:

- first gear - max boost 6 psi

- second gear - max boost 13 psi

3. red line at 7,000 rpm:

- first gear - max boost 7 psi

- second gear - max boost 14-15 psi

So, here it is. I am getting rather annoyed. I really don't want to screw up the engine but then I can't really set the red line at 5,000 rpm either, or keep my eye on the boost gauge every time I press on the gas.

#24

it's really skyrocketing in the last 500 rpms...mine did the same thing when i had boost creep issue (internal wastegate, long wastegate tube). it was fine till around 5k, then BAM, boost like crazy. let me grab a datalog.

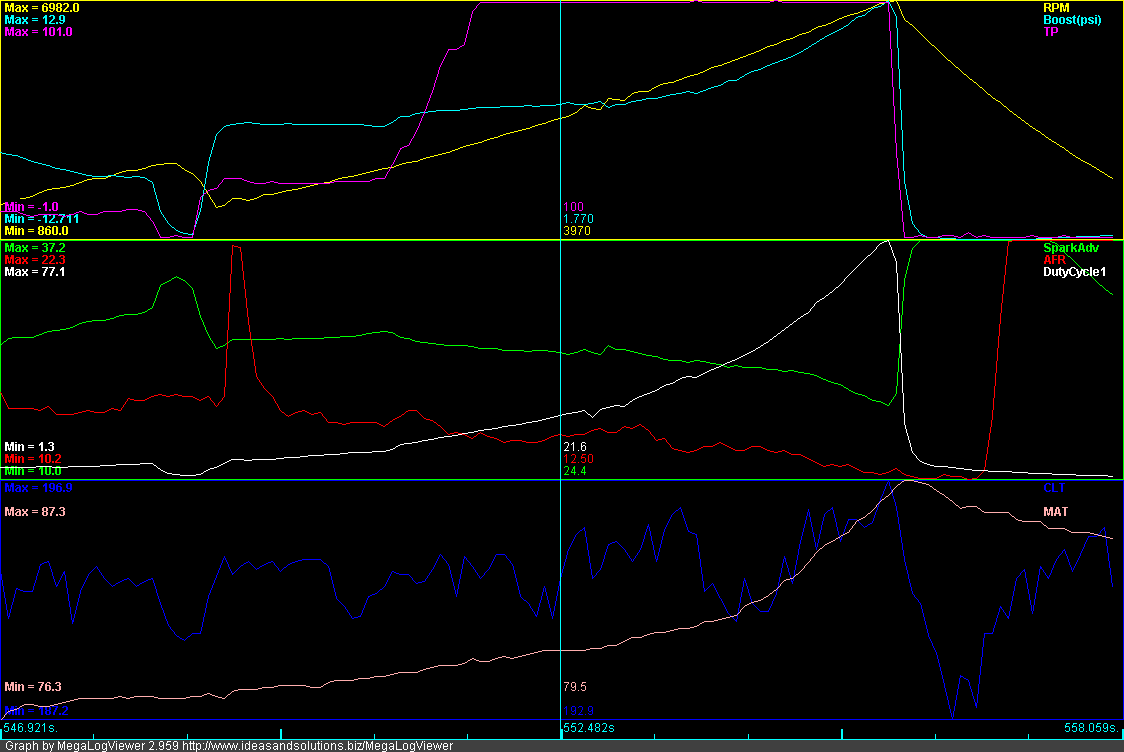

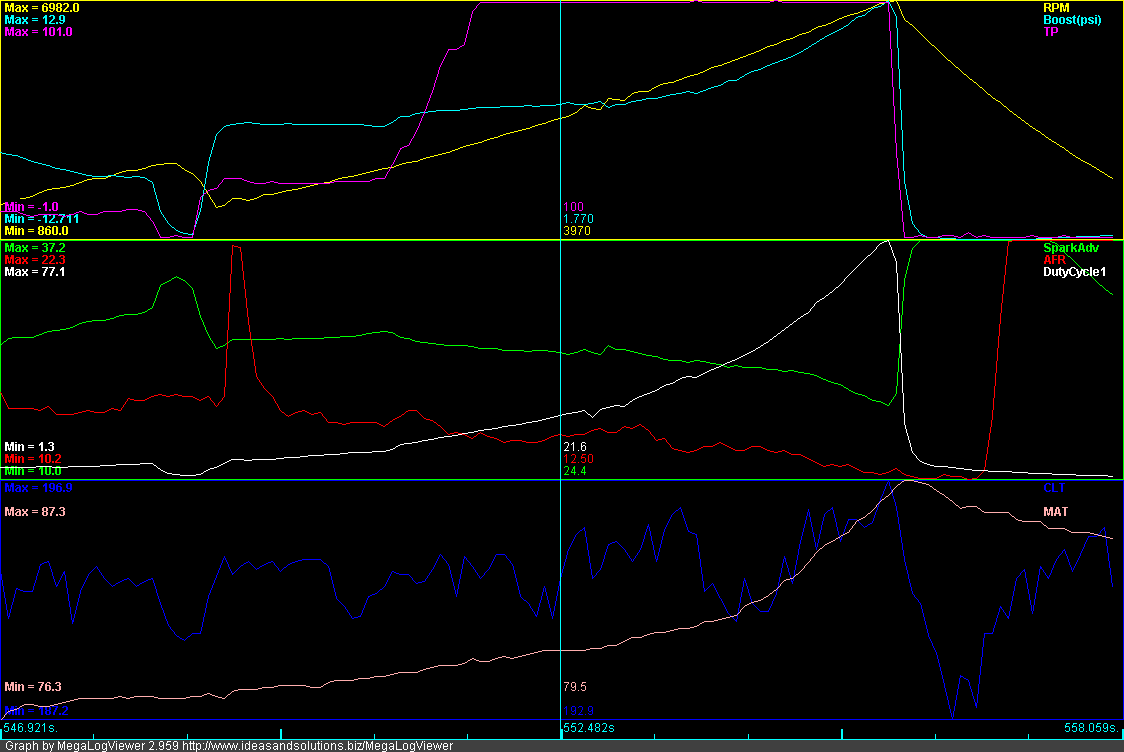

open flapper/WGA disconnected

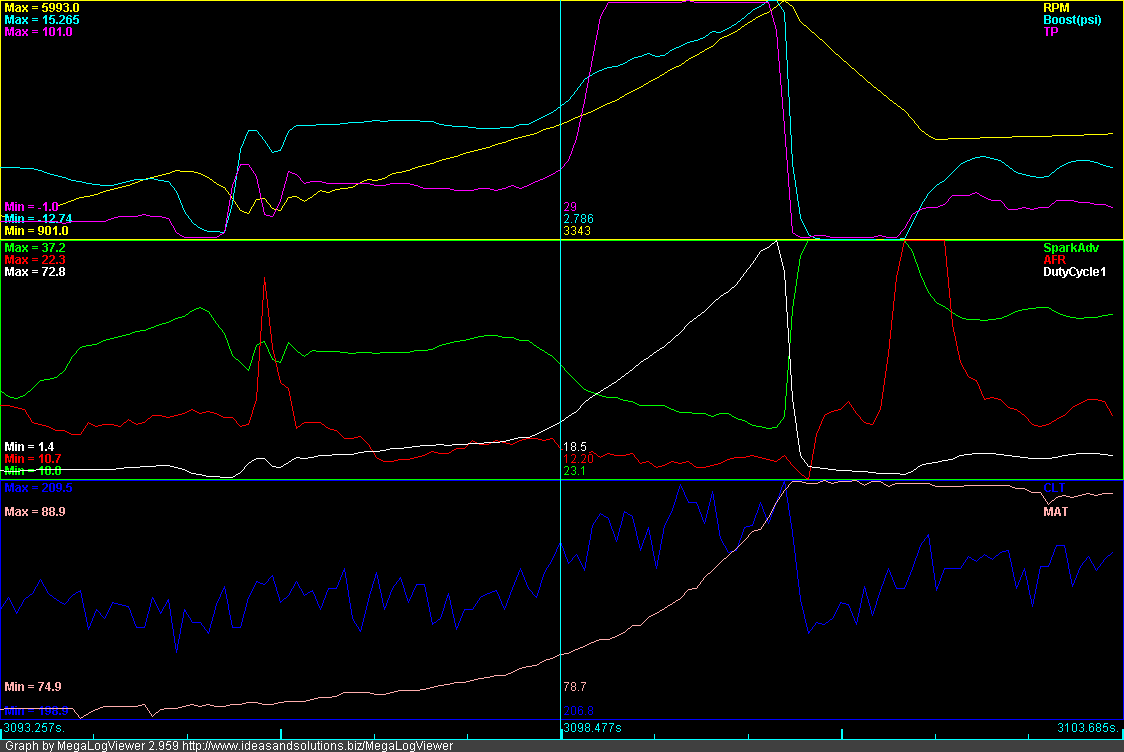

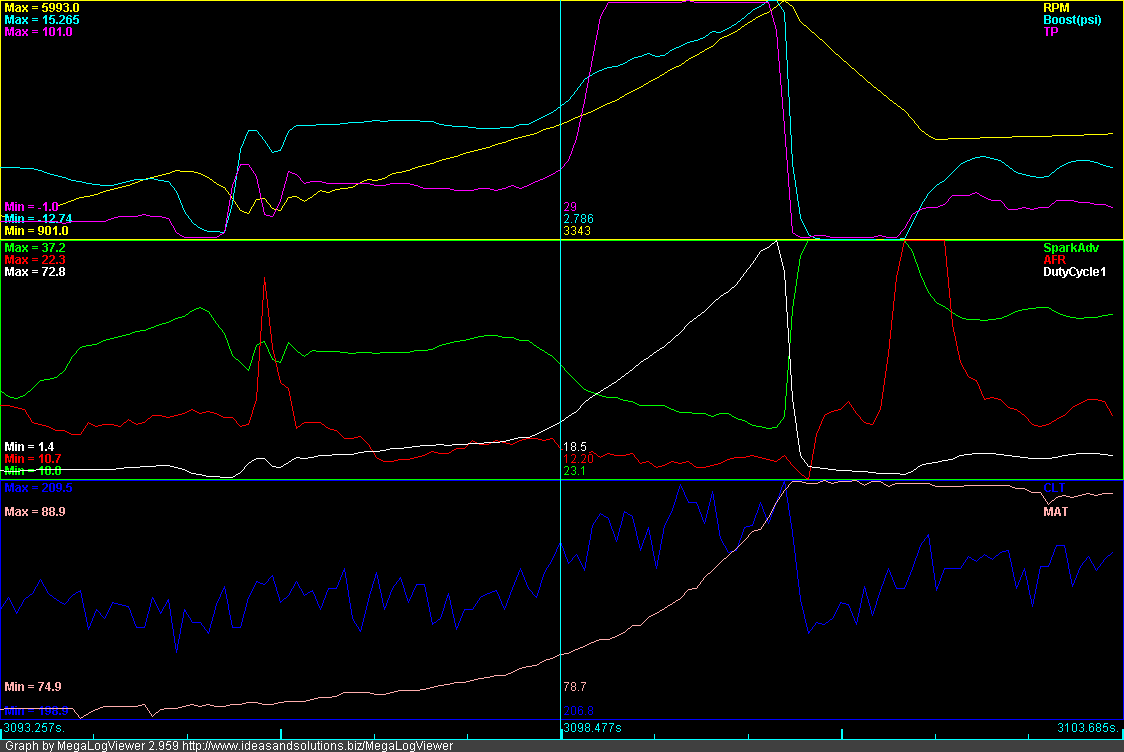

WGA attached, no boost controller, as little of preload as possible (and after getting wastegate ported). it was advertised 6psi actuator

I ended up just going EWG at this point...and of course it's fine now. But after talkign to ARTech, i was the only guy who had any sort of boost creep issues with his parts, but i also had a way longer wastegate tube than anyone else. we agreed that it probably most likely due to that. IWG + long wastegate tube no good, it just creates too much of a restriction and the flow is not inclined to take that route, even with the resistance of the turbine wheel.

open flapper/WGA disconnected

WGA attached, no boost controller, as little of preload as possible (and after getting wastegate ported). it was advertised 6psi actuator

I ended up just going EWG at this point...and of course it's fine now. But after talkign to ARTech, i was the only guy who had any sort of boost creep issues with his parts, but i also had a way longer wastegate tube than anyone else. we agreed that it probably most likely due to that. IWG + long wastegate tube no good, it just creates too much of a restriction and the flow is not inclined to take that route, even with the resistance of the turbine wheel.

#27

so, i was told by begi that the turbine exhaust was ported. unfortunately, with my lack of experience, i didn't know what to look for before i put it on the car, so i don't actually know the physical size of the port. removing it is a huge pain, as on that manifold, one of the lower bolts is very difficult to reach, tighten/untighten...

at this point, in case the cast mani cannot be easily adapted for an ewg, i am thinking the following, suboptimal route (in this order):

1. adapt a mbc before the can, so that i can maximize boost up to say, 8-9 psi.

2. replace the can with one that is rated at 10 psi (softer spring)

3. given it is winter now and temps are 25-40 F, maybe (just maybe) I would not have a problem in the summer. So, for now, if I choke my exhaust a bit (i don't have a cat and I have 3 inch all the way back) with a restrictor plate with say an internal diameter of 2-2.5 inch, MAYBE, it would be enough to drop the psi at 10-11. I can take out the restrictor plate in the summer. The downside to this would be less power now, but basically the same power that I am making in summer time. i know this defeats the purpose of more power, but the real purpose was to have a RELIABLE higher horsepower miata, not a blown engine.

4. if #3 doesn't do it, I can move to modifying the downpipe by shortening the separated gases pipe.

in conclusion, i am willing to give up 10-20 hp to have a reliable car. remember, this is an early NA (1990) so I am working with an 1.6. I knew from the get go that i will not make as much power as an 1.8. also, i am not enthused about replacing the mani and the dp to adapt an ewg. the downside to this approach is that i have no idea if it's gonna work, and i may end up in the same situation a month down the road.

thoughts?

#29

Senior Member

iTrader: (10)

Join Date: Aug 2007

Location: Fredericton, NB

Posts: 1,186

Total Cats: 4

I had the same issue with my chinabob2870 and SG downpipe and 3" exhaust.

I could still make 15psi with the wastegate wired open by 3rd gear.

Ended up porting the IWG. I now make the 7psi flat and 10psi with the wastegate tightened up a lot.

I could still make 15psi with the wastegate wired open by 3rd gear.

Ended up porting the IWG. I now make the 7psi flat and 10psi with the wastegate tightened up a lot.

#30

1. more porting??

2. do you have the long separated gases pipe or the short one?

3. what can do you have? straight arm? i am sure mine doesn't open the wg all the way, since i barely attach it (no pressure on the diaphragm) and I am making more boost that with the actuator disconnected.

4. when you say "wired open" do you mean you actually blocked it in the open position with a wire or something, or you just disconnected the actuator arm. I was wondering if the damn flapper somehow "flaps" due to turbulence when i just disconnect the actuator arm and allow it to move freely.

thanks

Florin

#31

maybe a half *** job was done on your porting- really wouldnt know unless you take a look. i sent mine to begi, and the job they did wasn't near as good as what they posted on their website. if i had ported more would it have made enough difference?? who knows. you could probably easily port it more....thats probably your best option at the moment, since it is really no cost, just some work to remove it

#32

Senior Member

iTrader: (10)

Join Date: Aug 2007

Location: Fredericton, NB

Posts: 1,186

Total Cats: 4

Answers:

1. more porting??

-Mine was not ported at all.... now its heavily ported to say the least...so much so that I took out too much and had to weld in some metal so there wasn't a hole when the flapper was shut. I took out A LOT.

2. do you have the long separated gases pipe or the short one?

-the Wastegate gasses rejoin the downpipe just before the flexpipe (just before the wideband). About 2 feet later I would say.

3. what can do you have? straight arm? i am sure mine doesn't open the wg all the way, since i barely attach it (no pressure on the diaphragm) and I am making more boost that with the actuator disconnected.

-I have a straight arm...the same one that came with the turbo...ebay special I'm sure. with the separated gases downpipe, mine doesn't open all the way either without hitting the side... It very hard to attach the downpipe in a fashion that still let it move semi-freely. I would say it opens about 2/3rds way now.

4. when you say "wired open" do you mean you actually blocked it in the open position with a wire or something, or you just disconnected the actuator arm. I was wondering if the damn flapper somehow "flaps" due to turbulence when i just disconnect the actuator arm and allow it to move freely.

-When I wired it open...I disconnected the Wastegate arm and wired it open. Ran an old piece of copper welding wire from the WG arm and looped it around the manifold to physically hold it open as a test.

1. more porting??

-Mine was not ported at all.... now its heavily ported to say the least...so much so that I took out too much and had to weld in some metal so there wasn't a hole when the flapper was shut. I took out A LOT.

2. do you have the long separated gases pipe or the short one?

-the Wastegate gasses rejoin the downpipe just before the flexpipe (just before the wideband). About 2 feet later I would say.

3. what can do you have? straight arm? i am sure mine doesn't open the wg all the way, since i barely attach it (no pressure on the diaphragm) and I am making more boost that with the actuator disconnected.

-I have a straight arm...the same one that came with the turbo...ebay special I'm sure. with the separated gases downpipe, mine doesn't open all the way either without hitting the side... It very hard to attach the downpipe in a fashion that still let it move semi-freely. I would say it opens about 2/3rds way now.

4. when you say "wired open" do you mean you actually blocked it in the open position with a wire or something, or you just disconnected the actuator arm. I was wondering if the damn flapper somehow "flaps" due to turbulence when i just disconnect the actuator arm and allow it to move freely.

-When I wired it open...I disconnected the Wastegate arm and wired it open. Ran an old piece of copper welding wire from the WG arm and looped it around the manifold to physically hold it open as a test.

#33

maybe a half *** job was done on your porting- really wouldnt know unless you take a look. i sent mine to begi, and the job they did wasn't near as good as what they posted on their website. if i had ported more would it have made enough difference?? who knows. you could probably easily port it more....thats probably your best option at the moment, since it is really no cost, just some work to remove it

can you do porting at home with a dremel, or should i send it back to them? porting it myself could work, i suppose, but aren't there issues with angles, etc? meaning, you just make that hole larger or the shape/angles, etc matter as well?

#34

-Mine was not ported at all.... now its heavily ported to say the least..

Sorry for the stupid question. How exactly did you port it?

- with the separated gases downpipe, mine doesn't open all the way either without hitting the side... It very hard to attach the downpipe in a fashion that still let it move semi-freely. I would say it opens about 2/3rds way now.

Same in my case. I think, however, that I solved this. if it hits the flange of the dp, you can slightly bend the arm of the flapper upwards and in my case, that solved any interference.

Sorry for the stupid question. How exactly did you port it?

- with the separated gases downpipe, mine doesn't open all the way either without hitting the side... It very hard to attach the downpipe in a fashion that still let it move semi-freely. I would say it opens about 2/3rds way now.

Same in my case. I think, however, that I solved this. if it hits the flange of the dp, you can slightly bend the arm of the flapper upwards and in my case, that solved any interference.

#35

Senior Member

iTrader: (10)

Join Date: Aug 2007

Location: Fredericton, NB

Posts: 1,186

Total Cats: 4

-Mine was not ported at all.... now its heavily ported to say the least..

Sorry for the stupid question. How exactly did you port it?

- with the separated gases downpipe, mine doesn't open all the way either without hitting the side... It very hard to attach the downpipe in a fashion that still let it move semi-freely. I would say it opens about 2/3rds way now.

Same in my case. I think, however, that I solved this. if it hits the flange of the dp, you can slightly bend the arm of the flapper upwards and in my case, that solved any interference.

Sorry for the stupid question. How exactly did you port it?

- with the separated gases downpipe, mine doesn't open all the way either without hitting the side... It very hard to attach the downpipe in a fashion that still let it move semi-freely. I would say it opens about 2/3rds way now.

Same in my case. I think, however, that I solved this. if it hits the flange of the dp, you can slightly bend the arm of the flapper upwards and in my case, that solved any interference.

http://www.bellengineering.net/artic...rticles_id=273

Where it said don't alter that side of the casting...listen...I found out the hard way...

I used a die grinder bit on the end of of a Dewalt Electric Drill how all the porting (Pretty rough but it worked).

#36

I finally broke down and replaced my setup with an EWG setup from BEGi. Now it works like a charm with absolutely no overboosting. It hits 12 (or 14 psi, depending on the mbc) every single time. I love EWG...

Thank you for all your advice. The EWG was definitely troublesome (sending turbo, dp, etc for modifications) and somewhat pricier than just porting the IWG, but it just works, so I am happy.

Thank you for all your advice. The EWG was definitely troublesome (sending turbo, dp, etc for modifications) and somewhat pricier than just porting the IWG, but it just works, so I am happy.

#38

Going with an EWG setup was an executive decision. I didn't really try to make the IWG work. Perhaps more porting plus minus shorter separated gas pipe would have worked. But the uncertainty of the outcome and the work involved peruaded me to just take the tried and true EWG approach. HappyI did so.

#40

If i tried the IWG and it did NOT work, then I would have had to add that cost to what I paid for the EWG.

Sorry, using same turbo, same everything. Even same log manifold that was adapted for EWG and same dp modified to take the EWG tube (not venting to atmo, as I heard that get obnoxious soon).

You know, I don't have experience with a good performing IWG. Mine sucked and caused only overboosting (not sure about the effects of that, but know that now my car makes blue smoke, and it didn't before), down time for my car and a lot of wasted time in phone calls, etc, etc. The EWG works SO WELL that i will have a hard time in the future to even consider an IWG on a different turbo system.

as you can tell, i LOVE EWG

just my opinion...

Thread

Thread Starter

Forum

Replies

Last Post

Zaphod

MEGAsquirt

47

10-26-2018 11:00 PM

stoves

Suspension, Brakes, Drivetrain

5

04-21-2016 03:00 PM