Buying a welder

#43

Have you tried out this machine yet? I get people asking me about the Everlast brand pretty often (I'm a welder and a CWI), but I have zero experience with them. They honestly look a little "home duty" at first glance, but they seem to have a fairly strong following on many forums. I'm not sure if that's just because of lower cost.

#44

Have you tried out this machine yet? I get people asking me about the Everlast brand pretty often (I'm a welder and a CWI), but I have zero experience with them. They honestly look a little "home duty" at first glance, but they seem to have a fairly strong following on many forums. I'm not sure if that's just because of lower cost.or Everlast editing posts

#45

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

Have you tried out this machine yet? I get people asking me about the Everlast brand pretty often (I'm a welder and a CWI), but I have zero experience with them. They honestly look a little "home duty" at first glance, but they seem to have a fairly strong following on many forums. I'm not sure if that's just because of lower cost.

As far as welds, it does fine. I haven't done any major welding with it yet. I am picking some 1/2" plate up tomorrow for a table.

Oh, and i wish the readout would change to show what you are setting the other dials at when you turned them. Instead it just shows the main amps. I also used the plasma cutter on it and that works awesome even with a small compressor. Overall i'm impressed, it's more machine than i need really. This inverter tech is going to take a while for me to get used to. I normally weld on a 30 year old tig machine at work.

#46

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

What tungsten are you using?

Dont bother with the standard tungsten on these machines! I use the purple tipped e3 hybrid tungsten and they are great on all metals with the inverter machine.

I was having serious contamination issues with aluminum and pure tungsten.

Once you figure out the settings, it will work extremely well and once you get the torch time you will get pretty good. Though you have to do some regular welding or you will start to loose it. LOL

M

Dont bother with the standard tungsten on these machines! I use the purple tipped e3 hybrid tungsten and they are great on all metals with the inverter machine.

I was having serious contamination issues with aluminum and pure tungsten.

Once you figure out the settings, it will work extremely well and once you get the torch time you will get pretty good. Though you have to do some regular welding or you will start to loose it. LOL

M

#47

You like the hybrid/rare eath tungsten on inverter machines? I've been having good luck thoriated on everything except if you run more than about 80amps A/C through a 3/32 tungsten it seems to like to crack in half randomly. We have some rare earth purple stuff at school. I'll grab a piece of it and try it out, it has replace the pure tungsten in the school electrode organizer.

#50

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

What tungsten are you using?

Dont bother with the standard tungsten on these machines! I use the purple tipped e3 hybrid tungsten and they are great on all metals with the inverter machine.

I was having serious contamination issues with aluminum and pure tungsten.

Once you figure out the settings, it will work extremely well and once you get the torch time you will get pretty good. Though you have to do some regular welding or you will start to loose it. LOL

M

Dont bother with the standard tungsten on these machines! I use the purple tipped e3 hybrid tungsten and they are great on all metals with the inverter machine.

I was having serious contamination issues with aluminum and pure tungsten.

Once you figure out the settings, it will work extremely well and once you get the torch time you will get pretty good. Though you have to do some regular welding or you will start to loose it. LOL

M

Well i tried the green stuff, the pure. That didn't work very well on some aluminum i had to do. Now i am onto the grey 2% ceriated stuff (which i found works best for me in the past) and even that's a little funky.

I'm getting a weird "dancing" arc on start. Which in turn produces some contamination, and nubs the tip of the tungsten over time. Maybe i should try 1/16 tungsten too. I'll have to buy some collets and purple tungsten to try out.

I've got this stainless manifold to build here really soon, that's sure going to test my abilities with this welder. I still think this torch is funny, i may have to change a few things out on it, it just doesn't seem like it's sealing very well.

Are you running an extention cord on yours? I need to buy one.

#51

I personally like zirconiated for all around performance. Works well with aluminum too. I've also never understood using tungsten any smaller than 1/8". You can sharpen it down to just as fine a point as anything smaller and it will hold up to much higher amperages. I think it's also easier to sharpen and doesn't break as often as the smaller stuff. What advantages of 1/16" tungsten am I missing?

#54

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

I'd also like to add, about the welder picture above ^ i'm extremely happy i paid a little more for the multi-process. The plasma cutter is sooooooo much more handy than i ever thought. It just cuts anything you want like butter. If anyone is thinking about getting a tig, make sure you get multi-process.

#56

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

Cuts schedule 40 and 10 stainless like butter with the machine not even turned up. I just have a little 1/2hp 5 gallon air compressor too. If i can find some scrap 1/4" or 3/16" stuff i can try that too.

I've cut a bit of sheet metal, but that's a given. I've cut a little bit of 1/8" mild steel angle iron.

Just have to make sure to turn the pulse off when in cut mode.

I've cut a bit of sheet metal, but that's a given. I've cut a little bit of 1/8" mild steel angle iron.

Just have to make sure to turn the pulse off when in cut mode.

#57

I know nothing about TIG. I have welded stick and currently own two MIGs and a Miller plasma cutter. I am seriously considering a TIG machine.

Also I have a friend who works for Lincoln (in a round about way) and they told me they thought the Eastwood units are rebadged Lincoln's. Not 100% sure of this, but what do you guys think of these? Which unit would you recommend and why.

Eastwood -TIG Welder | TIG Welders | TIG Welding Equipment & Accessories

Thanks!

Also I have a friend who works for Lincoln (in a round about way) and they told me they thought the Eastwood units are rebadged Lincoln's. Not 100% sure of this, but what do you guys think of these? Which unit would you recommend and why.

Eastwood -TIG Welder | TIG Welders | TIG Welding Equipment & Accessories

Thanks!

Last edited by Amellrotts; 08-24-2013 at 08:43 AM. Reason: cuz Imma dummy......

#60

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

I actually used an Eastwood tig someone had in their garage. Just ran a few welds on some mild steel... I'll tell you right now, it's no where near as capable as mine. Though, i paid a bit more to get more features. But mine welds just as good, and nicely as the Esab's, and Millers.

The Eastwood unit will work fine for garage use (didn't even try anything in AC)and buzzing metal together, but i wouldn't expect to use it for any heavy fabrication or making things look good.

I'm no toxic fab... Really, i am still learning this machine. It's pretty advanced, right up there with the digital Esab machine.

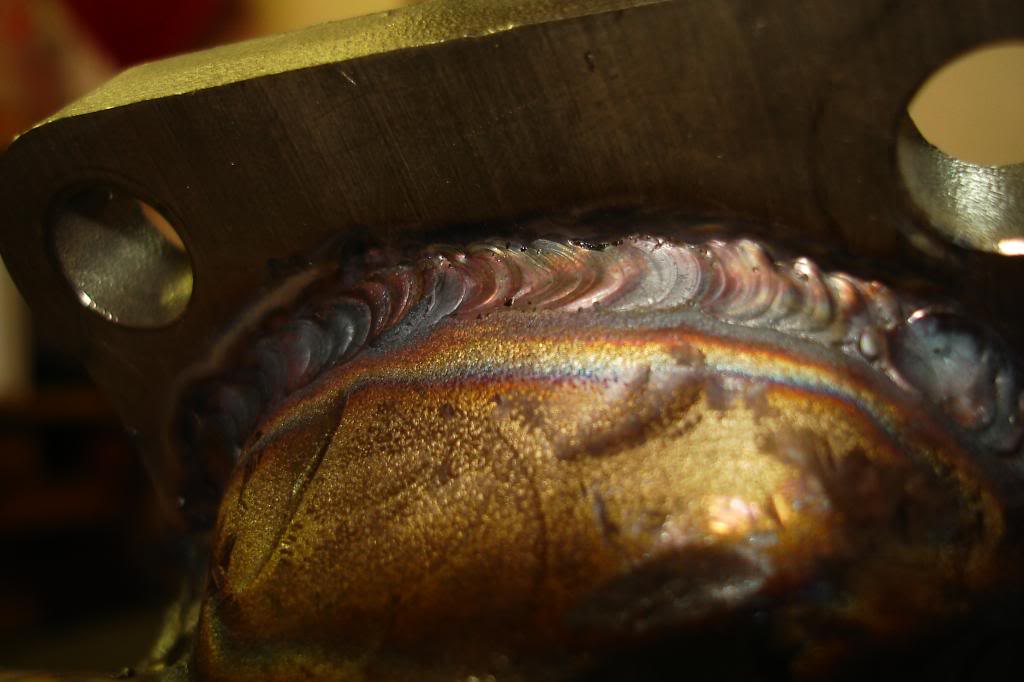

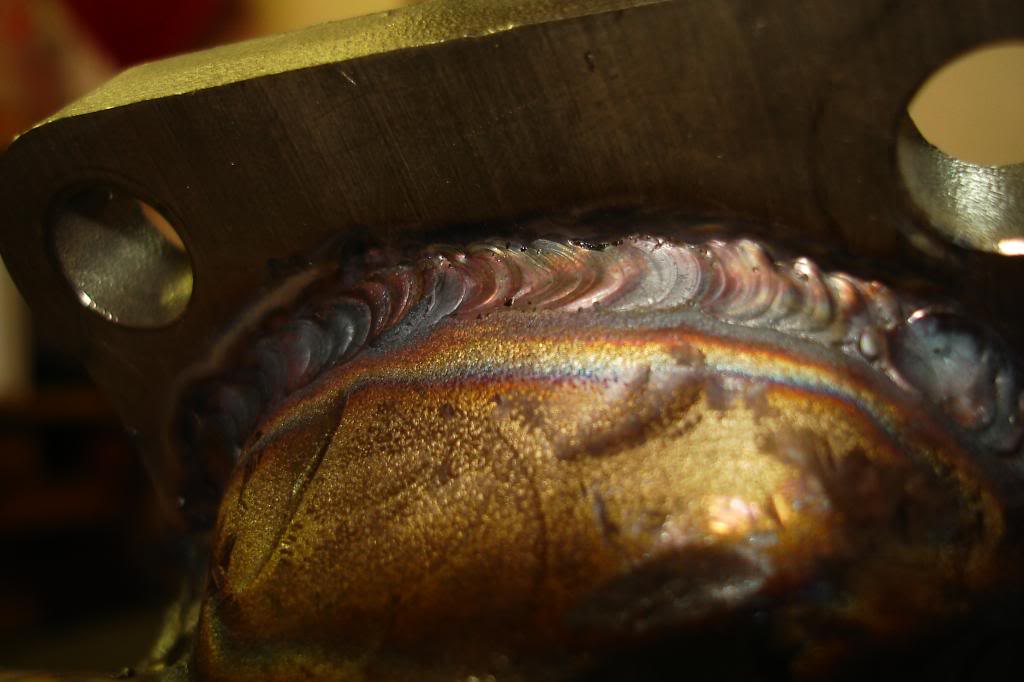

It goes pretty good. May raise the heat and turn the lowside pulse down a little. Could give me a little more color in the welds, instead of the icky gray look. Also, it's 316, i've made 304 look a bit better. The 316 stays pretty gray. (grey-gray???)

The Eastwood unit will work fine for garage use (didn't even try anything in AC)and buzzing metal together, but i wouldn't expect to use it for any heavy fabrication or making things look good.

I'm no toxic fab... Really, i am still learning this machine. It's pretty advanced, right up there with the digital Esab machine.

It goes pretty good. May raise the heat and turn the lowside pulse down a little. Could give me a little more color in the welds, instead of the icky gray look. Also, it's 316, i've made 304 look a bit better. The 316 stays pretty gray. (grey-gray???)