Dyno Tuning Practices

#1

Elite Member

Thread Starter

iTrader: (17)

Join Date: Aug 2007

Location: Knoxville, TN

Posts: 2,949

Total Cats: 182

I haven't seen this covered before and google didn't turn up anything relevant. I'm curious how you "correctly" dyno tune timing on a car. I'm sure there has to be an extensive writeup somewhere on the vast reaches of the internet, if someone has a link that would be awesome.

When dyno tuning for timing at WOT does the dyno operator use the brake on the dyno to hold the motor at a speed (and MAP) to tune each spark cell individually (which seems like it would be very stressful on the car and time consuming)? Or are you just making pulls, adjusting timing accordingly where you see increases or decreases in tq? Can it be done both ways? Is there some easier way that I didn't think about?

When dyno tuning for timing at WOT does the dyno operator use the brake on the dyno to hold the motor at a speed (and MAP) to tune each spark cell individually (which seems like it would be very stressful on the car and time consuming)? Or are you just making pulls, adjusting timing accordingly where you see increases or decreases in tq? Can it be done both ways? Is there some easier way that I didn't think about?

#2

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

Advance spark angle until output levels off, reduce angle if detonation occurs, pick load cells strategically. The gneral curve shape is logical and you want to pick a few kpa rows and rpm columns and interpolate the rest. I'm posting on a BB so ill post more when I get home.

#4

So why not increase steps between MAP breakpoints to that which you're willing to dyno tune? The problem with the method you describe is that you won't hit the cells head on, and it's a mess when you have lots of fine steps and you then have to interpolate.

This is why my map has 800 RPM and 25 kPa steps.

This is why my map has 800 RPM and 25 kPa steps.

#5

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

If you hold wheel speed at target RPM, you'll "hit the cells head on". I filled-in the gaps by hand rather than using interpolation.

Make sure that when power levels off, you go back to the spark angle where you saw the last increase, then add some safety by reducing spark angle or tune on a lower octane fuel than you'll run after the tune.

Make sure that when power levels off, you go back to the spark angle where you saw the last increase, then add some safety by reducing spark angle or tune on a lower octane fuel than you'll run after the tune.

#6

Elite Member

Thread Starter

iTrader: (17)

Join Date: Aug 2007

Location: Knoxville, TN

Posts: 2,949

Total Cats: 182

I've got a couple more questions if you don't mind...

What gear to you use to tune in? Obviously 1:1 is going to give you the highest number, but it seems like the same tune would be achievable in a shorter gear right?

Also, even using the interpolation method there's no way to get around pegging the car at 7000rpms and running it all the way up to 20psi (or whatever you're running) to get those upper right cells tuned? I guess that's a stupid and obvious question, I just wanted to see the "yes, that's how you do it" before I go off slanging rods errywhur.

Thanks so much for the help. The more I look over other people's spark maps, the more nervous I get about the huge discrepancies. Looking forward to getting a real tune.

What gear to you use to tune in? Obviously 1:1 is going to give you the highest number, but it seems like the same tune would be achievable in a shorter gear right?

Also, even using the interpolation method there's no way to get around pegging the car at 7000rpms and running it all the way up to 20psi (or whatever you're running) to get those upper right cells tuned? I guess that's a stupid and obvious question, I just wanted to see the "yes, that's how you do it" before I go off slanging rods errywhur.

Thanks so much for the help. The more I look over other people's spark maps, the more nervous I get about the huge discrepancies. Looking forward to getting a real tune.

#7

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

I edited this today because I've adjusted my procedure recently.

Yes, yes, yes. I recommend you interpolate with your brain, not the computer, when you're on the dyno. I use 5th because it's 1:1 and I have a 6-speed. The 1:1 gears mean less strain on the little gears in the trans, and loading the car up on the brake is hard work on the trans which will go over 300*f. I'm more concerned with the trans blowing on the dyno than the engine or overheating.

Now that I'm at a real keyboard,

Road tuning:

Then, set your "IAT Related Ignition" and pull 1* of spark, per 5*f IAT>100*f. This will help stop detonation in the summer.

I usually pick a total of 10-15 target load cells for load tuning because that's all you really need, no one is tuning 140 cells. You can guess pretty accurately where to go from after one cell is set at MBT and most of this forum has done the hard work for you. I'm tuning NA cars in about 30-minutes now after the car is strapped down, an FI can probably be done in about an hour.

Look around here and find a spark table for a set-up similar to yours and go from there. I recently tuned Johnwag's car by ear, as in the dyno was broken and not displaying torque output properly so I listened to the motor getting stronger and stronger with spark advance until it made no change in sound, this was MBT. My awesomeness was vetted when I saw the spark table I made was a near identical copy to DIY Autotune and 949's 1.8/header/intake tune. I had Machismo load that tune on his car and there were similar results. There is less chance of this on a turbo car, but you can get a good spark tale and go from there.

Finally, I want you guys getting your feet wet to do this yourself rather than pay someone. You're running MS, which is here for the hobbyist. We've explained this process to you because we want you to come full circle. I fix more tunes than anything else, even expensive ones. You can do this, it will be fun, and you can say with pride that you built it and tuned it.

Yes, yes, yes. I recommend you interpolate with your brain, not the computer, when you're on the dyno. I use 5th because it's 1:1 and I have a 6-speed. The 1:1 gears mean less strain on the little gears in the trans, and loading the car up on the brake is hard work on the trans which will go over 300*f. I'm more concerned with the trans blowing on the dyno than the engine or overheating.

Now that I'm at a real keyboard,

Road tuning:

- AFR better be damn good, or you're wasting time and money, lots of it. Enrichments also need to be spot on, this is where I spent the most time in my car and where it helps to have a buddy.

- VE Analyze Live is increadibly good. I've used several auto-tune tools and they are all miserable pieces of ****; VEAL is insanely good, closely approaching perfect. When people disagree with you, it's because inference and logic are intersecting with ignorance.

- Pop in your detontation headphones from Mr. Cieslieskinatronicon

- Pick an RPM column, lock wheel speed there.

- Now use throttle position to see your output level (using trace in TS or MT)

- add a few degrees of spark

- hit the same load cell and see if output goes up

- add a few degrees of spark

- hit the same load cell and see if output increases

- wash, rinse repeat

- If you hear detonation, back off a minimum of 1* based upon intensity

- when power stops increasing, go back to the spark angle that made the most output and leave it (welcome to MBT)

- Now, pick your degree of safety, I pulled 3-degrees out because I tuned on 93 octane and that's what I run at the track.

- now pick another cell in the same RPM column and repeat. (I usually pick 4-5 MAP cells per column)

- Do this up to 5000rpm, then see below

- This is the easy part of dyno tuning

- adjust entire rows in steps until you hit MBT or det (described below)

- increase spark below 5000, then over

- you want the "McDonald's arch" shape on a stock compression motor (4500-5000rpm trough), you'll hit MBT and have a more linear shape with a low comp motor

- Now load the dyno up at 4000 for 10-seconds, make the turbo glow yellow, then release the dyno brake and complete the ramp run while listening for det. If you think this is scary, put a camera on your turbo next time you go to the track. It will bglow yellow all day.

Then, set your "IAT Related Ignition" and pull 1* of spark, per 5*f IAT>100*f. This will help stop detonation in the summer.

I usually pick a total of 10-15 target load cells for load tuning because that's all you really need, no one is tuning 140 cells. You can guess pretty accurately where to go from after one cell is set at MBT and most of this forum has done the hard work for you. I'm tuning NA cars in about 30-minutes now after the car is strapped down, an FI can probably be done in about an hour.

Look around here and find a spark table for a set-up similar to yours and go from there. I recently tuned Johnwag's car by ear, as in the dyno was broken and not displaying torque output properly so I listened to the motor getting stronger and stronger with spark advance until it made no change in sound, this was MBT. My awesomeness was vetted when I saw the spark table I made was a near identical copy to DIY Autotune and 949's 1.8/header/intake tune. I had Machismo load that tune on his car and there were similar results. There is less chance of this on a turbo car, but you can get a good spark tale and go from there.

Finally, I want you guys getting your feet wet to do this yourself rather than pay someone. You're running MS, which is here for the hobbyist. We've explained this process to you because we want you to come full circle. I fix more tunes than anything else, even expensive ones. You can do this, it will be fun, and you can say with pride that you built it and tuned it.

Last edited by hustler; 09-07-2011 at 08:17 PM.

#8

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

http://www.innovatemotorsports.com/resources/myths.php

Read this if you haven't. I recently experienced this, and talked about it in another thread. I have low enough static comp that I can advance spark well beyond MBT for at least 6* and get either no change or less output, and still not achieve detonation. This can benefit you at high, motorcycle RPM but from what I understand we turn too low of an RPM to benefit from this extreme spark advance.

FYI:

Savington and I both confirmed max torque at 11.5:1 and neither one of us make black smoke out the pipe or fire (i get a pop occasionally). I think this article is referring to people running fire-puking rich. The multitude of Evo's and STI's which frequently puke fire at the racetrack confirm this notion.

Read this if you haven't. I recently experienced this, and talked about it in another thread. I have low enough static comp that I can advance spark well beyond MBT for at least 6* and get either no change or less output, and still not achieve detonation. This can benefit you at high, motorcycle RPM but from what I understand we turn too low of an RPM to benefit from this extreme spark advance.

FYI:

To combat knock they make the mixture richer. All that happens really then is that the mixture burns slower and therefore hits the peak pressure closer to the right point. This of course reaffirms the belief that the richer mixture creates more power. In reality the flame front speed was adjusted to get the right peak pressure point.

#9

Elite Member

Thread Starter

iTrader: (17)

Join Date: Aug 2007

Location: Knoxville, TN

Posts: 2,949

Total Cats: 182

I love hearing that detonation is occurring that far after MBT, it's certainly nice to think that there is a decent buffer between max power and detonation, I was under the impression that the margin of error was much smaller.

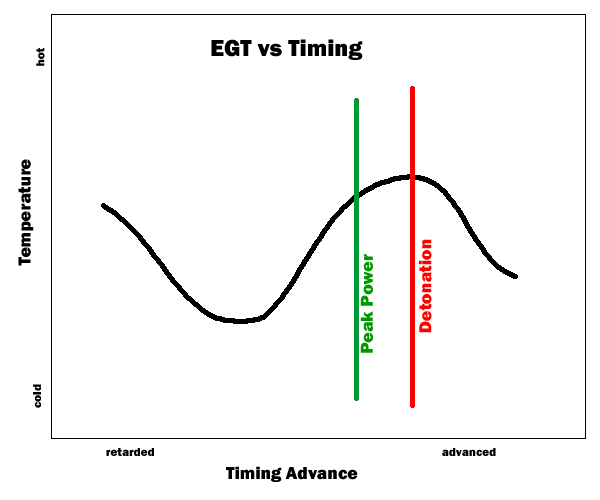

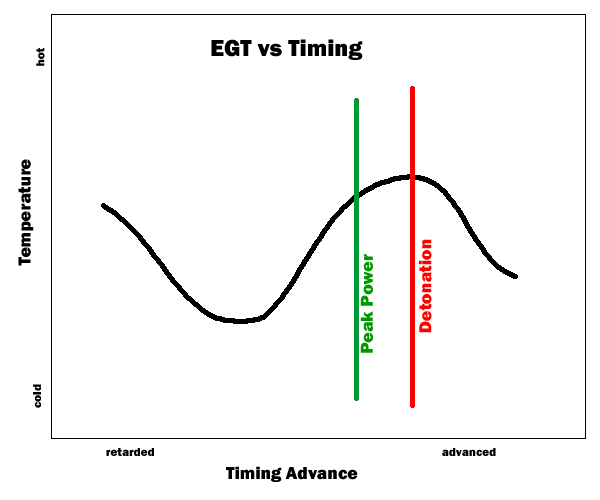

This is going a slightly different direction, but still in reference to timing. I've been reading up on EGT's as a function of timing and there seems to be surprisingly little information. I found an old post on NASIOC (ancient by internet standards, ca 2004), and just wanted to make sure I understood it correctly.

The post (http://forums.nasioc.com/forums/show...23&postcount=3) seemed to indicate that a plot of EGT vs Timing advance would look something like:

This lead me to think that with a EGT gauge you could simply tune to cold temperatures to arrive at a very safe spark map. Is that reasonable to assume? It would be nice to see plot with actual data to see exactly what that relationship looked like and how much timing is between the "cold" and "hot" peaks.

This is going a slightly different direction, but still in reference to timing. I've been reading up on EGT's as a function of timing and there seems to be surprisingly little information. I found an old post on NASIOC (ancient by internet standards, ca 2004), and just wanted to make sure I understood it correctly.

The post (http://forums.nasioc.com/forums/show...23&postcount=3) seemed to indicate that a plot of EGT vs Timing advance would look something like:

This lead me to think that with a EGT gauge you could simply tune to cold temperatures to arrive at a very safe spark map. Is that reasonable to assume? It would be nice to see plot with actual data to see exactly what that relationship looked like and how much timing is between the "cold" and "hot" peaks.

#10

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

This is going a slightly different direction, but still in reference to timing. I've been reading up on EGT's as a function of timing and there seems to be surprisingly little information. ... This lead me to think that with a EGT gauge you could simply tune to cold temperatures to arrive at a very safe spark map. Is that reasonable to assume? It would be nice to see plot with actual data to see exactly what that relationship looked like and how much timing is between the "cold" and "hot" peaks.

Trey's posts are all 100% spot on, except road tuning. I don't do road tuning anymore - IMO it's a waste of time. What takes me 3-4 hours on the road can be done more accurately in 30 minutes on the dyno. Set the spark conservative, then start at the column just off of idle, lock the wheel speed, and dial in each cell from as low as you can go until as high as you feel comfortable. Wear the det cans while you're doing this, and don't go above 100kpa under 2000rpm. I do 2 columns/30 second break up to 4000rpm, then 1 column/30 second break up to redline. Stop at ~6000rpm and extrapolate to redline, and use WOT pulls to confirm. In the higher RPM higher load cells, I usually sweep the throttle through instead of sitting on each cell - it's a little less accurate but a little faster and easier on the cooling system. Again, wear the det cans while you're doing this. Dyno tuning the fuel map like this should take you around 40 minutes, and it will be absolutely flawless when you're done. You'll also be able to hit cells that are hard to road tune, like the high load/low RPM cells and the high RPM/low load cells.

Alternatively, you can do it like Jason does, using the columns for RPM fueling and then adjusting the 2D MAP vs. RPM trim that AEMs are equipped with (does MS do this?). Dial the fuel in at ~70kpa, then pick 3000rpm and dial in the 2D map. Once it's done, spotcheck to make sure everything looks good. (I've never actually done this but I'm going to try it when our dyno arrives.)

Spark is just like Trey said - using TPS vs. MAP to gauge output is actually fairly ingenious. It allows you to repeatably look at the output without it being affected by the slow decay caused by rising internal temperatures.

Once you're done, you can torture test it if you're feeling confident. I know Trey sets the ramp run options to hold 4000rpm for 10 seconds, then terminate at redline (usually you hold at ~2k for 2 seconds to stabilize and load the motor up, then terminate at redline). He holds the motor at ~4k at full boost for 10 seconds to simulate a high-gear road course pull, then lets the motor run to redline at WOT to check for detonation. Street guys may think we're nuts, but the abuse your motor sees on a road course is hard to simulate anywhere else. Trey's regiment gets damn close.

I think it's Dave Coleman and the Lemons Miata guys that spin the motor up to 7k in 5th at full boost, then use the dyno to drag it back down to 4000rpm, then let it pull back up to 7000rpm? Makes my skin crawl, but I bet that thing never, ever pings.

#13

For example. Imagine if you had super fine MAP steps, and you're now tuning mechanical boost which is approximately 150 kPa. You have 130, 140, 150, 160 ... rows in you map (I exaggerate a bit to show the concept).

You do an RPM sweep, and as RPM climbs it goes 148 150 152 155 158 due to some boost creep.

Above 150 kPa the 160 kPa row also affects the resultant timing. So you need to adjust both 150 and 160 kPa, while maintaining some downward slope. Messy.

And to add to that, as you change timing, boost/MAP tends to change a bit because EGT's change. Which means on your next pull, the engine won't walk through the same MAP rows...

Whereas, if you had coarser jumps, say 125, 150, 175 kPa, in the above case, the 125 an 175 kPa rows would hardly affect the resulting timing, making it much easier.

So, you have to ask. Are you really capable of tuning 140, 150, and 160 kPa rows on the dyno? Do you have the time and the money? Does the engine really need such fine tuning slices that if you only tuned 150 and 175 kPa, that at 162.5 kPa the timing will be off?

#14

Additionally, tuning one cell at a time, by holding RPM with the dyno, is an expensive (dyno time) method. If you do an RPM sweep, the dyno shows all RPM's at once. If you then say, advance by 2* and overlay the 2 most recent plots, you can quickly see which RPMs benefited from the timing increase, so you increase those and roll back the timing on the others.

#15

Not mentioned here are the AIT and CLT retard functions and the monkey wrench they throw into the works. That is, as AIT and CLT temps climb while tuning, or during a pull, and their timing retard kicks in, it adds an uncontrolled variable into the mix.

Theoretically they are used to prevent ping due to high CLT and AIT. The margin between MBT and ping shrinks at high temperatures. So the basic spark table is tuned for MBT, and then the CLT and IAT maintain margin against ping. Making all this correct for a knock limited (e.g. high compression) motor is difficult.

This is why I think the theoretical right way to do it is to set them to zero and tune on a cool day (or use race gas) , then come back on a hot day with pump gas and tune the AIT curves if you get ping.

Theoretically they are used to prevent ping due to high CLT and AIT. The margin between MBT and ping shrinks at high temperatures. So the basic spark table is tuned for MBT, and then the CLT and IAT maintain margin against ping. Making all this correct for a knock limited (e.g. high compression) motor is difficult.

This is why I think the theoretical right way to do it is to set them to zero and tune on a cool day (or use race gas) , then come back on a hot day with pump gas and tune the AIT curves if you get ping.

#17

This also brings me to a proposal I had before for tuning off-boost cells. Off boost timing is far less sensitive than on boost timing (i.e. knock is far away, 3* error has less effect on torque output), but if you are very far off street driveability will suffer.

For a given MAP and RPM combo, MBT is when torque/MAP is maximized.

I wisht there were dyno software that could do this:

You make the dyno it hold RPM.

You start datalogging wherein you begin with very light throttle and slowly increase it.

The dyno will then plot MAP on the x-axis, and then torque divided by MAP on the Y axis.

You then adjust timing in the various MAP values and watch the effect on output.

The reason for the division is to "normalize" the readings, because at low MAP the torque output is low and so smaller percentage changes at lower MAP values are harder to see on a torque plot than at higher MAP values.

I'm a bit surprised there is no dyno software that does this.

For a given MAP and RPM combo, MBT is when torque/MAP is maximized.

I wisht there were dyno software that could do this:

You make the dyno it hold RPM.

You start datalogging wherein you begin with very light throttle and slowly increase it.

The dyno will then plot MAP on the x-axis, and then torque divided by MAP on the Y axis.

You then adjust timing in the various MAP values and watch the effect on output.

The reason for the division is to "normalize" the readings, because at low MAP the torque output is low and so smaller percentage changes at lower MAP values are harder to see on a torque plot than at higher MAP values.

I'm a bit surprised there is no dyno software that does this.

#18

And....

Here's a feature that would be good for MS3.

Have a 2D table for VE vs RPM.

Another 2D table for VE vs MAP.

Have an option, that the fuel pulse is multiplied by the inverse of the AFR target table.

And of course, the 3D VE table.

You start with the 3D table all flat.

You put in some kind of VE curve into the 2D VE vs RPM table, that resembles an NA motor's torque curve.

The fuel pulses are modified by your AFR target table, so that the additional richness you want in the midrange in-boost, and say, extra leanness you want in cruise, does not need to be entered into the 3D table.

This way after you tune the 2D RPM and 2D MAP tables, you're 90% of the way there in fueling. Easy peasy. The only additional tuning you need to do in the 3D table is for when actual VE deviates from the theoretical, due to 2nd order effects such as entering your turbo's sweet spot, etc.

VE vs MAP btw changes only a bit, not as stark as VE vs RPM. VE vs MAP would address say, atmo-referenced vs. mani-referenced FPR's. Or better yet, have a wizard with a checkbox that correctly applies an injector pulse correction factor based on atmo vs mani referenced injectors....

In my AEM I use Excel to calculate the atmo referenced injector correction into the "boost comp" curve. I also use Excel to preload additional richness from my AFR target table into the 3D VE table...

Here's a feature that would be good for MS3.

Have a 2D table for VE vs RPM.

Another 2D table for VE vs MAP.

Have an option, that the fuel pulse is multiplied by the inverse of the AFR target table.

And of course, the 3D VE table.

You start with the 3D table all flat.

You put in some kind of VE curve into the 2D VE vs RPM table, that resembles an NA motor's torque curve.

The fuel pulses are modified by your AFR target table, so that the additional richness you want in the midrange in-boost, and say, extra leanness you want in cruise, does not need to be entered into the 3D table.

This way after you tune the 2D RPM and 2D MAP tables, you're 90% of the way there in fueling. Easy peasy. The only additional tuning you need to do in the 3D table is for when actual VE deviates from the theoretical, due to 2nd order effects such as entering your turbo's sweet spot, etc.

VE vs MAP btw changes only a bit, not as stark as VE vs RPM. VE vs MAP would address say, atmo-referenced vs. mani-referenced FPR's. Or better yet, have a wizard with a checkbox that correctly applies an injector pulse correction factor based on atmo vs mani referenced injectors....

In my AEM I use Excel to calculate the atmo referenced injector correction into the "boost comp" curve. I also use Excel to preload additional richness from my AFR target table into the 3D VE table...

#19

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

Again, I'm literally picking 7-10 RPM columns and if you're spending more than 1-hour on the dyno for simple spark table tuning, I think you should consider tuning fewer load cells.

Additionally, tuning one cell at a time, by holding RPM with the dyno, is an expensive (dyno time) method. If you do an RPM sweep, the dyno shows all RPM's at once. If you then say, advance by 2* and overlay the 2 most recent plots, you can quickly see which RPMs benefited from the timing increase, so you increase those and roll back the timing on the others.

Once you're done, you can torture test it if you're feeling confident. I know Trey sets the ramp run options to hold 4000rpm for 10 seconds, then terminate at redline (usually you hold at ~2k for 2 seconds to stabilize and load the motor up, then terminate at redline). He holds the motor at ~4k at full boost for 10 seconds to simulate a high-gear road course pull, then lets the motor run to redline at WOT to check for detonation. Street guys may think we're nuts, but the abuse your motor sees on a road course is hard to simulate anywhere else. Trey's regiment gets damn close.

I think it's Dave Coleman and the Lemons Miata guys that spin the motor up to 7k in 5th at full boost, then use the dyno to drag it back down to 4000rpm, then let it pull back up to 7000rpm? Makes my skin crawl, but I bet that thing never, ever pings.

I think it's Dave Coleman and the Lemons Miata guys that spin the motor up to 7k in 5th at full boost, then use the dyno to drag it back down to 4000rpm, then let it pull back up to 7000rpm? Makes my skin crawl, but I bet that thing never, ever pings.

FYI: I'm switching to Dave Coleman's method because I think its easier on the trans.

Threads like this one are what set up apart from the rest.

#20

The reverse RPM method is also good for making the engine hit higher MAP rows in lower RPMs which it may not hit with a regular RPM (upward) sweep. There was a time I hit 10 psi up a very steep hill at 3000 RPM and my engine pinged. I'd never hit this on the dyno before, and I recalled this reverse RPM thing and would have allowed me to tune that combo of RPM and MAP.

Another thing to remember is that MBT *changes* as the piston crowns heat up, which may not be reflected in the coolant and air temps. One trick I was told is to do 3 sweeps in succession, (if on a dynojet) and watch how much the torque drops between the 2nd and 3rd pulls. Retard the timing, and if the drop reduces, you are past MBT for the 3rd pull, because MBT may now be more retarded due to piston temps.

So with the Dave Coleman method one might tune off of the 2nd, upward half of the (down-up) sweep where the pistons are hotter.

This BTW is my other beef with the hold-it cell by cell tuning method Hustler describes. It's the inconsistency - at another cell you may end up holding it 3 seconds longer than the previous time, so the piston temps will be different.

Bottom line is that you want to dwell the engine in a manner that simulates the usage of the car. One may argue that a dyno that simulates the car's weight and aero drag, that allows you to do a 3-4-5 shift would be an accurate facsimile (but it would need a 100 mph radiator dyno fan lol).

Speaking of "dwelling" the engine - the fact that RPMs climb more slowly in higher gears on the road ... the longer *time*the engine sustains full boost is what makes temperatures climb. I don't like to say "the load is higher in 5th gear", because "load" is also used to mean "manifold pressure". It's semantics, but one could also say "the load is the same, because the car's mass is the same" (when say, comparing 1st and 2nd gear, where aero loads are far less significant)

Another thing to remember is that MBT *changes* as the piston crowns heat up, which may not be reflected in the coolant and air temps. One trick I was told is to do 3 sweeps in succession, (if on a dynojet) and watch how much the torque drops between the 2nd and 3rd pulls. Retard the timing, and if the drop reduces, you are past MBT for the 3rd pull, because MBT may now be more retarded due to piston temps.

So with the Dave Coleman method one might tune off of the 2nd, upward half of the (down-up) sweep where the pistons are hotter.

This BTW is my other beef with the hold-it cell by cell tuning method Hustler describes. It's the inconsistency - at another cell you may end up holding it 3 seconds longer than the previous time, so the piston temps will be different.

Bottom line is that you want to dwell the engine in a manner that simulates the usage of the car. One may argue that a dyno that simulates the car's weight and aero drag, that allows you to do a 3-4-5 shift would be an accurate facsimile (but it would need a 100 mph radiator dyno fan lol).

Speaking of "dwelling" the engine - the fact that RPMs climb more slowly in higher gears on the road ... the longer *time*the engine sustains full boost is what makes temperatures climb. I don't like to say "the load is higher in 5th gear", because "load" is also used to mean "manifold pressure". It's semantics, but one could also say "the load is the same, because the car's mass is the same" (when say, comparing 1st and 2nd gear, where aero loads are far less significant)

Last edited by JasonC SBB; 03-22-2011 at 12:31 PM.