Timk Makes Up for Talent With an EFR

#62

Senior Member

Thread Starter

Join Date: Dec 2004

Location: Brisbane, Australia

Posts: 1,278

Total Cats: 37

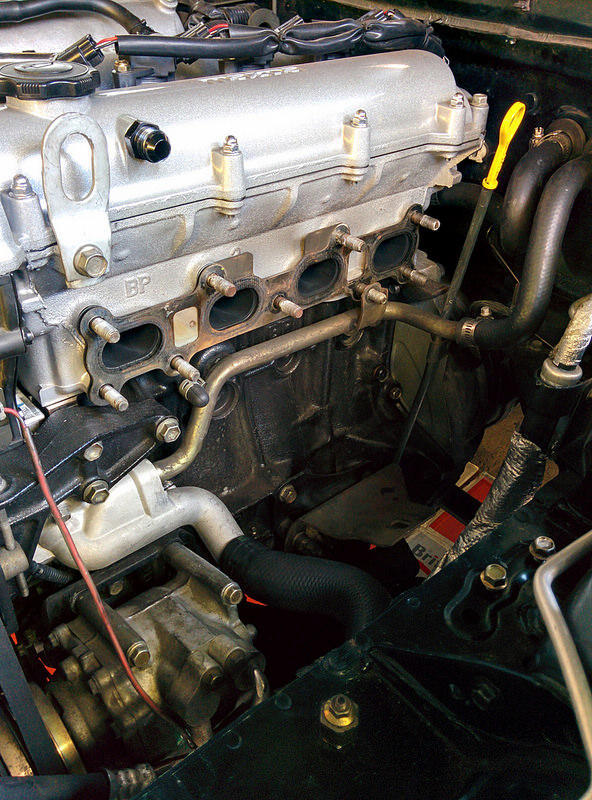

The car is in at MX-5 Plus at the moment getting a few things done. I've had them replace the harmonic balancer with a new one and fit the Protege 36-1 wheel:

It all bolts up perfectly and works fine with the standard crank sensor, obviously you need to reconfigure triggering settings in the ECU to reflect the change.

It all bolts up perfectly and works fine with the standard crank sensor, obviously you need to reconfigure triggering settings in the ECU to reflect the change.

#63

Senior Member

Thread Starter

Join Date: Dec 2004

Location: Brisbane, Australia

Posts: 1,278

Total Cats: 37

A few changes have been made; MX-5 Plus swapped out my turbo and cleaned up the air intake piping, I'll have to take some photos as Dave did a really good job. As the subframe had to be removed they also fitted my new front shocks and swapped in a depowered steering rack. I'm a big fan of how manual steering loads up on corners!

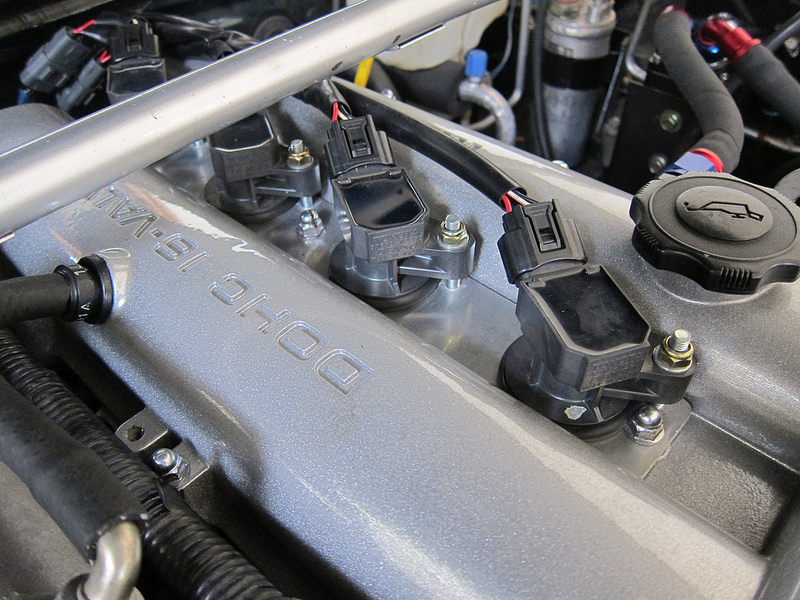

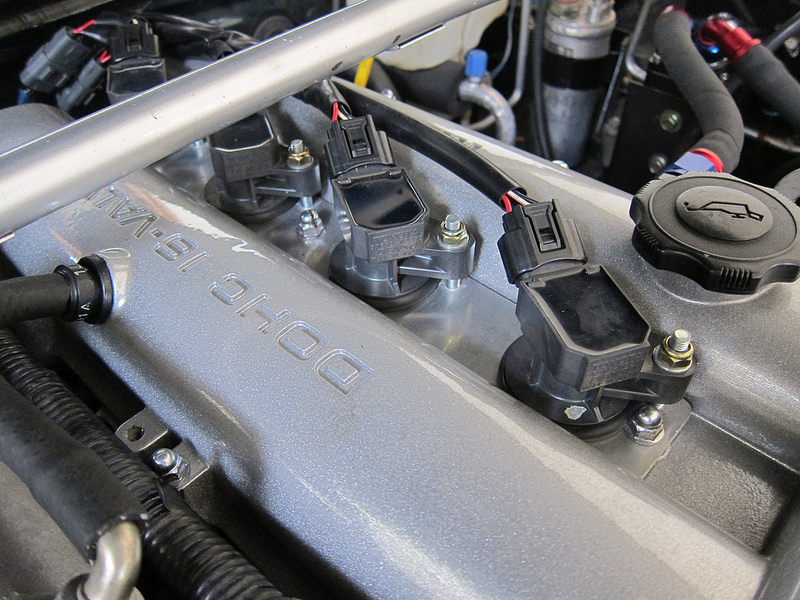

I've swapped in my coil loom for the Toyota coils:

Also fitted the 949 Racing swaybar endlinks:

Here's one I prepared earlier:

The standard endlink is about 103mm hole to hole, I set these to 95mm and things seemed to be fairly flat with the car sitting on the ground.

I've swapped in my coil loom for the Toyota coils:

Also fitted the 949 Racing swaybar endlinks:

Here's one I prepared earlier:

The standard endlink is about 103mm hole to hole, I set these to 95mm and things seemed to be fairly flat with the car sitting on the ground.

#64

Senior Member

Thread Starter

Join Date: Dec 2004

Location: Brisbane, Australia

Posts: 1,278

Total Cats: 37

Space is pretty tight but here's the new turbo setup, it's a BNR turbo designed to work with the standard SE/MSM manifold and dump pipe and is based on an EVO3 TD05-16G:

Dave's fabrication work on the intake:

Dave's fabrication work on the intake:

#65

very clean, professional install

did your flex pipe solve your exhaust stud issues?

I have had to drill and safety wire mine

our bottom ends are very similar

my signature tells you my dyno numbers

with as much investment as you have in your motor, why not a TSE competition oil pump?

ditto on the Proxies over the Kumho's

did your flex pipe solve your exhaust stud issues?

I have had to drill and safety wire mine

our bottom ends are very similar

my signature tells you my dyno numbers

with as much investment as you have in your motor, why not a TSE competition oil pump?

ditto on the Proxies over the Kumho's

#66

Senior Member

Thread Starter

Join Date: Dec 2004

Location: Brisbane, Australia

Posts: 1,278

Total Cats: 37

Thanks Roy. I haven't done a track day since the flex pipe so I'm not sure. I didn't want to do a track day before getting a tune, and it was pointless to get the tune done before the turbo went in. Shouldn't be long now!

#68

Senior Member

Thread Starter

Join Date: Dec 2004

Location: Brisbane, Australia

Posts: 1,278

Total Cats: 37

Last week I took a road trip to Hervey Bay to see Bradley Smith at Turning Point and get the car tuned. Here is the car ready to go:

He's using a Dynapack 4000 dyno (the sticker lies), being a hub dyno it is very safe and the readouts are consistent:

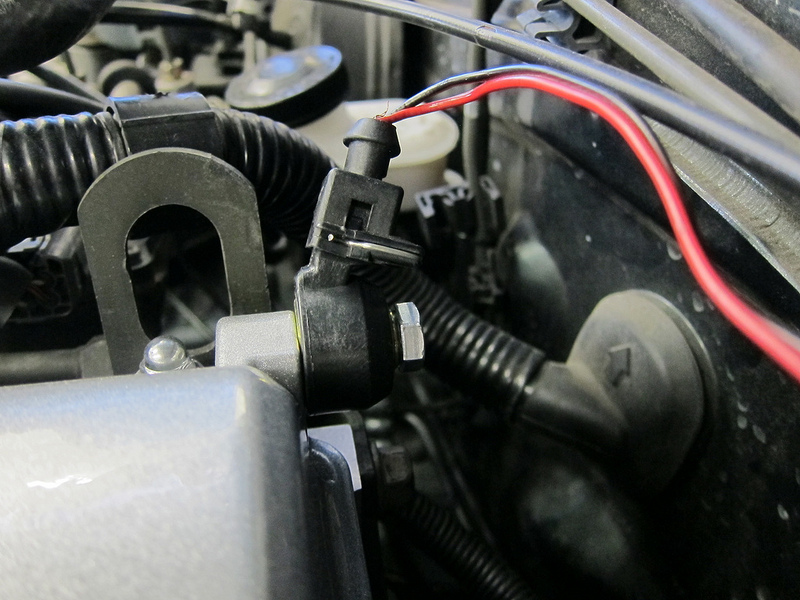

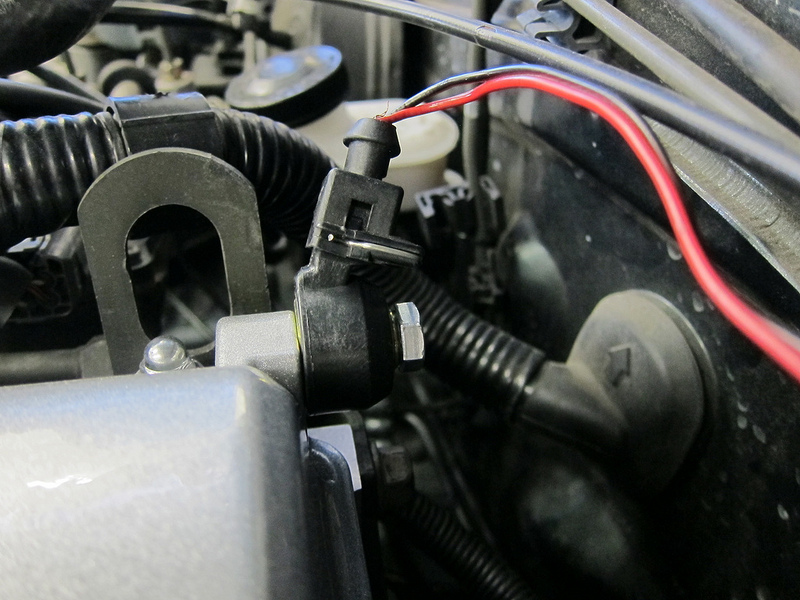

A secondary knock sensor was fitted to the head for safety:

Before jumping in, Bradley went over my Adaptronic map to ensure the air correction and injector opening times (dead times) were correct. He also checked the fuel pressure and base timing.

First of all the fuel map was set up so open loop matched the closed loop lambda targets. The dyno made it possible to hit pretty much any load cell at any RPM. The car was then tuned for Mean Best Torque up to 4,000 RPM. Above this range seemed to be full throttle tuning first of all making sure the fuel lambda ranges were safe, then playing with timing. A slow ramp up rate of 250 rpm/sec was used to confirm that the engine would be free of knock under any conditions.

We had a few issues throughout the day:

I also had an oil consumption problem on the dyno, completely filling my 500ml catch can! Bradley said he wasn't able to leave much timing in when in boost, this could be related. I haven't had the car back on the dyno to confirm, but just this week Jason at Automotive Plus tested the PCV valve and it seemed to be leaking pretty drastically. We have since replaced the PCV valve and added a one-way valve from a brake booster line just in case.

The car is certainly lively to drive now!

Cheers

He's using a Dynapack 4000 dyno (the sticker lies), being a hub dyno it is very safe and the readouts are consistent:

A secondary knock sensor was fitted to the head for safety:

Before jumping in, Bradley went over my Adaptronic map to ensure the air correction and injector opening times (dead times) were correct. He also checked the fuel pressure and base timing.

First of all the fuel map was set up so open loop matched the closed loop lambda targets. The dyno made it possible to hit pretty much any load cell at any RPM. The car was then tuned for Mean Best Torque up to 4,000 RPM. Above this range seemed to be full throttle tuning first of all making sure the fuel lambda ranges were safe, then playing with timing. A slow ramp up rate of 250 rpm/sec was used to confirm that the engine would be free of knock under any conditions.

We had a few issues throughout the day:

- The wastegate wasn't preloaded enough and was causing intermittent spool issues, we were able to space it with some washers.

- The feed for the bleed valve for the turbo was on the same vac line as the MAP sensor for the ECU, so it was throwing the readings off. We added a fitting to the charge pipe near the turbo to hook the bleed valve up to.

- The turbo bypass valve was leaking, fortunately I had stiffer springs in the car to swap in.

I also had an oil consumption problem on the dyno, completely filling my 500ml catch can! Bradley said he wasn't able to leave much timing in when in boost, this could be related. I haven't had the car back on the dyno to confirm, but just this week Jason at Automotive Plus tested the PCV valve and it seemed to be leaking pretty drastically. We have since replaced the PCV valve and added a one-way valve from a brake booster line just in case.

The car is certainly lively to drive now!

Cheers

#70

Senior Member

Thread Starter

Join Date: Dec 2004

Location: Brisbane, Australia

Posts: 1,278

Total Cats: 37

I took the car out to an MX-5 Club track day last Monday, it was great fun once I sorted out my thermal management!

We had a few sessions of the Clubman circuit, then Sprint, then Sportsman followed by National. I wasn't able to sort out my car issues until the Sprint circuit but still got some decent track time.

The new version of the Adaptronic firmware has a 'hot RPM limit' for when the car gets over a set coolant temperature. My car was hitting this temperature (105C) then setting my rev limit to 5,000RPM. I upped the setting to 109C and put the heater on, this seemed to keep things under control. It's surprising things are getting this hot as I am just running wastegate boost (0.6 bar). I think it is a great feature as I potentially may not have noticed the temps creeping up otherwise!

Here's a squirt around the National layout:

I'm a noob when it comes to this layout so don't look at my lines too closely!

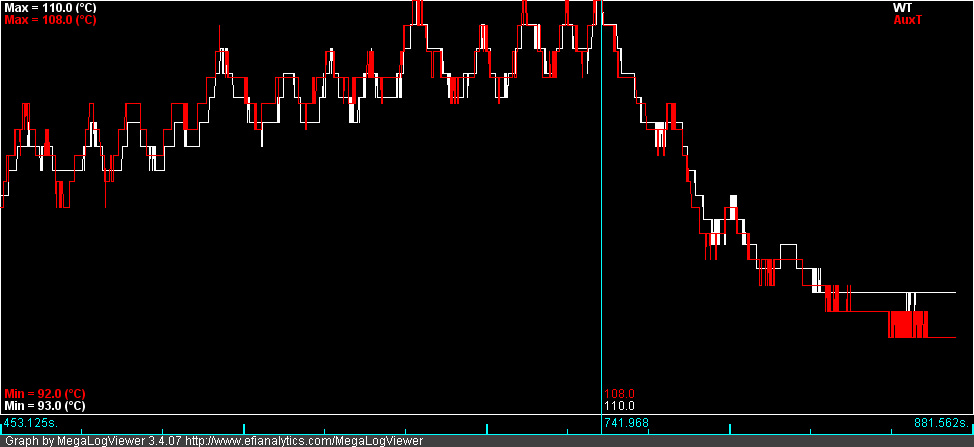

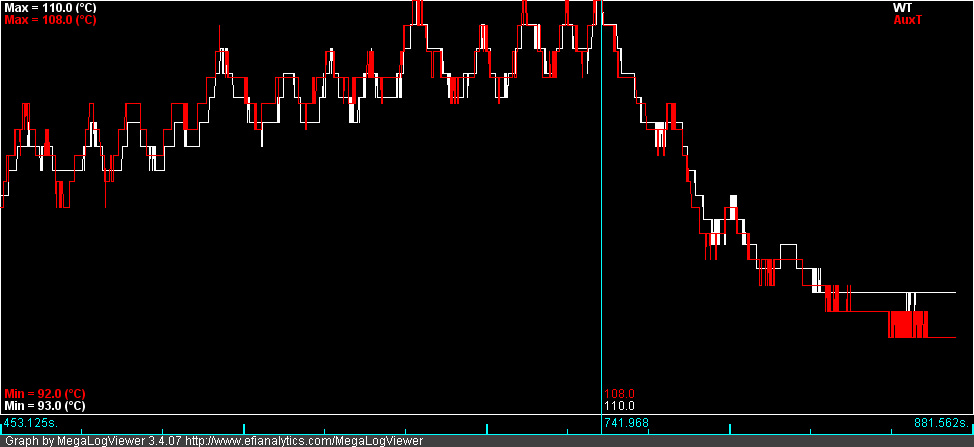

One interesting metric I observed is the temps between the front and back of the head. I have a Maruha thermostat housing spacer with an extra thermistor fitted, and the maximum delta between the front and back of the head was only 2 degrees C:

Cheers

We had a few sessions of the Clubman circuit, then Sprint, then Sportsman followed by National. I wasn't able to sort out my car issues until the Sprint circuit but still got some decent track time.

The new version of the Adaptronic firmware has a 'hot RPM limit' for when the car gets over a set coolant temperature. My car was hitting this temperature (105C) then setting my rev limit to 5,000RPM. I upped the setting to 109C and put the heater on, this seemed to keep things under control. It's surprising things are getting this hot as I am just running wastegate boost (0.6 bar). I think it is a great feature as I potentially may not have noticed the temps creeping up otherwise!

Here's a squirt around the National layout:

I'm a noob when it comes to this layout so don't look at my lines too closely!

One interesting metric I observed is the temps between the front and back of the head. I have a Maruha thermostat housing spacer with an extra thermistor fitted, and the maximum delta between the front and back of the head was only 2 degrees C:

Cheers

#71

Senior Member

Thread Starter

Join Date: Dec 2004

Location: Brisbane, Australia

Posts: 1,278

Total Cats: 37

I've been pretty busy with other stuff so the car has been neglected of late. After the last track day the dump pipe became loose which created an exhaust leak, so I gave the car to Jason at Automotive Plus and he is testing some Inconel studs and Resbond threadlocker. We are sticking with the deformed nuts due to the limited space, and the fact that the issue was always the studs backing out, not the nuts coming off the studs.

I've also gathered bits to test the radiator efficiency:

I had to tap the thread in the coolant sensor block to suit the OE thermistor (12mm x 1.5mm), props to Lokiel for loan of the tools. The hose pictured is the bottom radiator hose which I will cut to fit the sensor block inline. I already have a thermistor fitted very close to the radiator inlet, so with this extra sensor I will be able to see the inlet/outlet deltas with good accuracy.

Cheers

I've also gathered bits to test the radiator efficiency:

I had to tap the thread in the coolant sensor block to suit the OE thermistor (12mm x 1.5mm), props to Lokiel for loan of the tools. The hose pictured is the bottom radiator hose which I will cut to fit the sensor block inline. I already have a thermistor fitted very close to the radiator inlet, so with this extra sensor I will be able to see the inlet/outlet deltas with good accuracy.

Cheers

#75

Senior Member

Thread Starter

Join Date: Dec 2004

Location: Brisbane, Australia

Posts: 1,278

Total Cats: 37

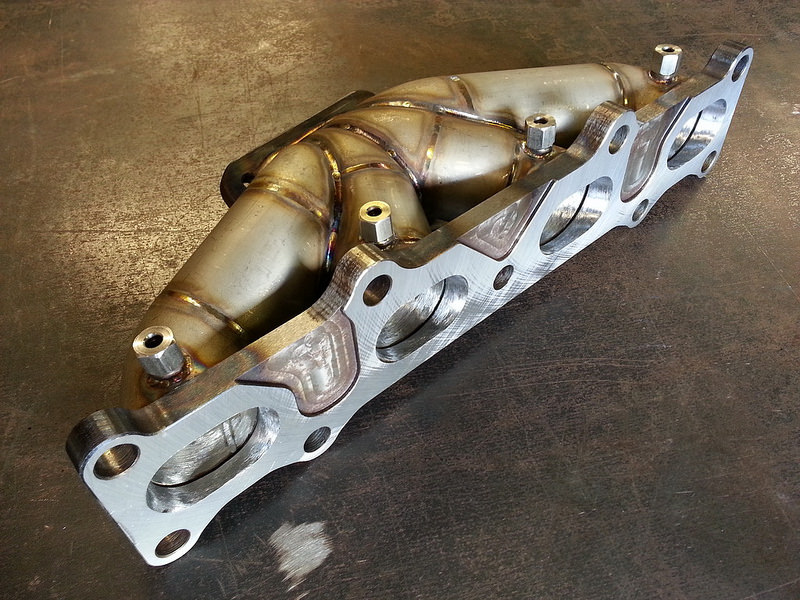

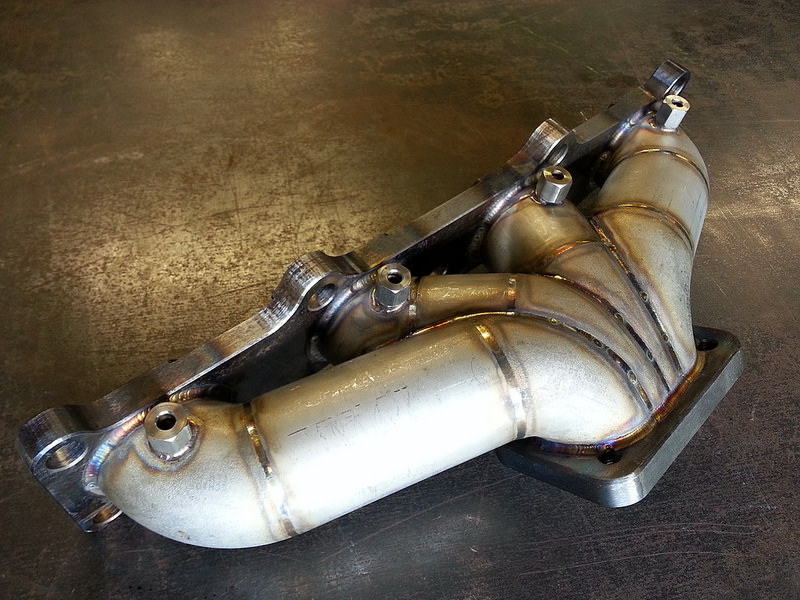

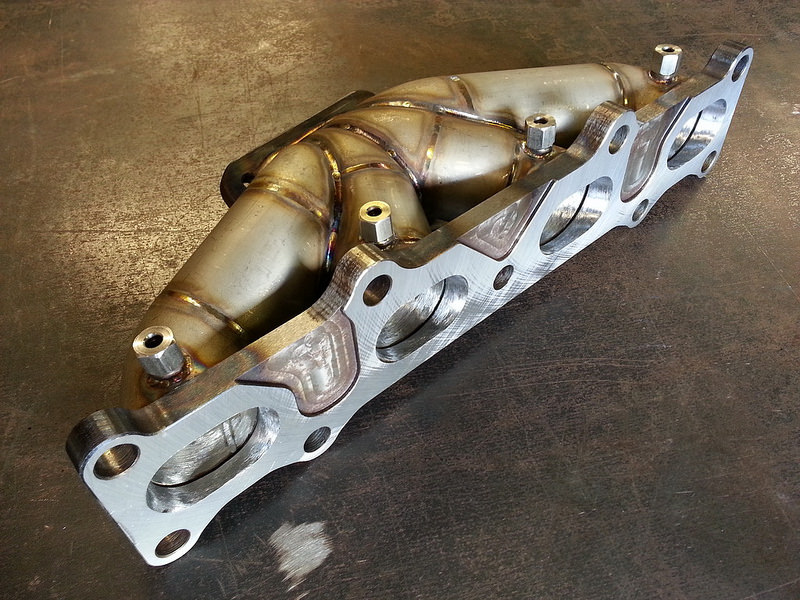

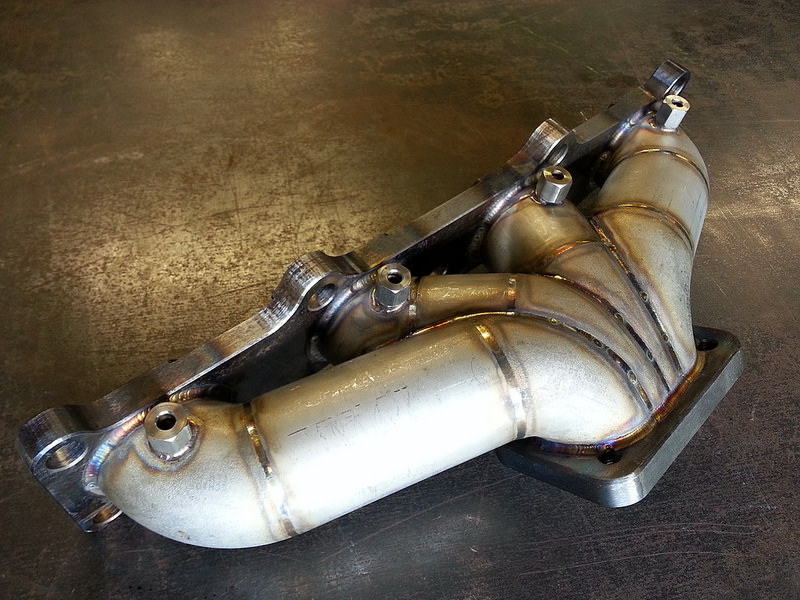

Manifold is done. I apologise in advance for posting such explicit material:

The holes for the EGT bungs were done on a milling machine so they are all evenly spaced and perfectly flat!

Cheers

The holes for the EGT bungs were done on a milling machine so they are all evenly spaced and perfectly flat!

Cheers

#77

Senior Member

Thread Starter

Join Date: Dec 2004

Location: Brisbane, Australia

Posts: 1,278

Total Cats: 37

I have a few side projects going on, first of all I am trying some LS3 coils. The factory ignition wiring is a bit on the light side so I'm hoping to minimise voltage drop due to inrush current by using some beefy caps:

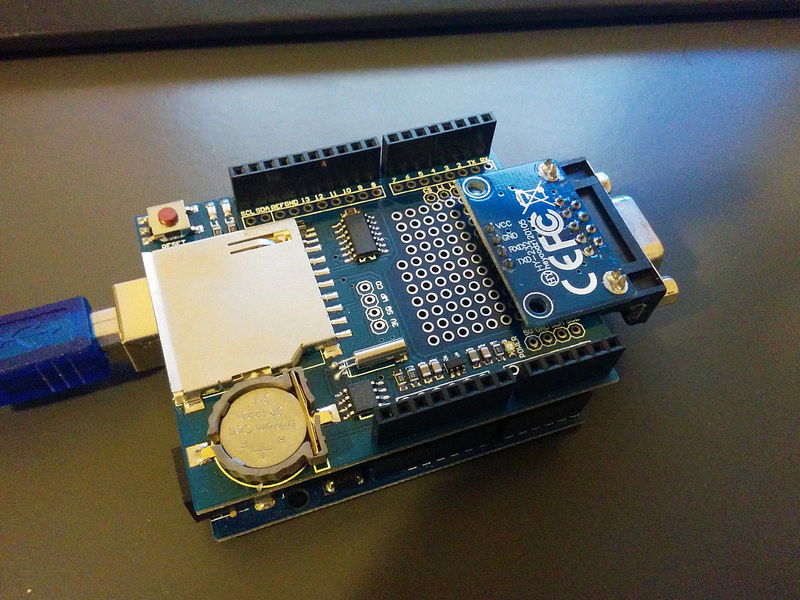

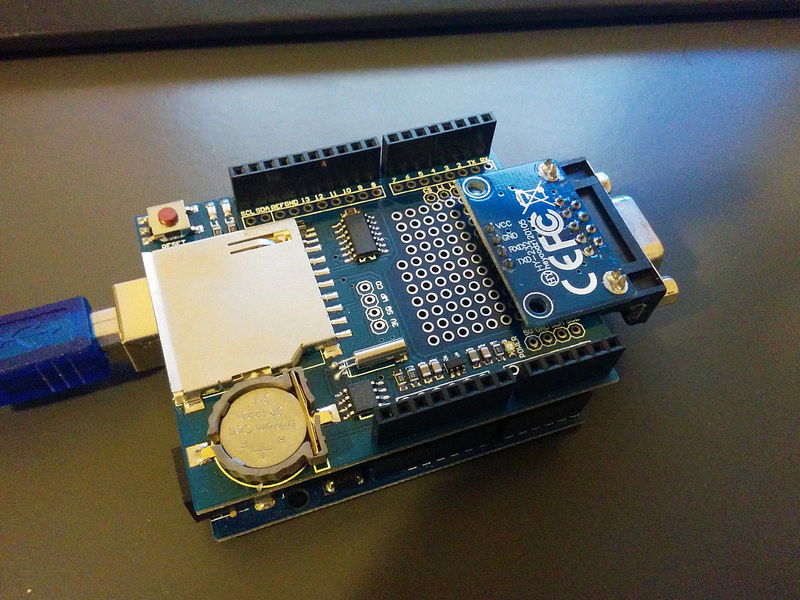

The second project I have been working on is an Adaptronic hardware datalogger. This runs on AVR (Arduino) using a fairly common shield, plus an RS232 line driver board:

I have a fully working prototype, let me know if you have an Adaptronic and are keen to test it!

Cheers

The second project I have been working on is an Adaptronic hardware datalogger. This runs on AVR (Arduino) using a fairly common shield, plus an RS232 line driver board:

I have a fully working prototype, let me know if you have an Adaptronic and are keen to test it!

Cheers