Oil return line size question

#1

Drilling my oil pan is one of the last things i have left to do on my turbo setup. Ive noticed that most kits you buy all come with a rather large drain line and fitting as well as a large tap. I have a bunch of 3/8 fittings I was going to use for the drain line as well as a 3/8 size hole for going into the oil pan. since I am only running 4an from the port on the block to the sr20 t25 turbo (also running water lines) would this drain be big enough or should I upsize it?

Thanks

Thanks

#7

on the actual turbo I believe its about 1/2 inch but i guess if you are only pumping in oil through a line that is (---) wide or so then why do you need a drain thats (--------) wide? just making sure there isnt a special reason. otherwise ill be off to the parts store again.

Garrett says (http://www.turbobygarrett.com/turbob...mization.pdf):

In general, the larger the oil drain, the better. However, a -10AN is typically sufficient for proper oil drainage, but try not to have an inner diameter smaller than the drain hole in the housing as this will likely cause the oil to back up in the center housing.

-10 is 5/8. 3/8 is way too small.

--Ian

#8

Junior Member

iTrader: (6)

Join Date: Jun 2011

Location: Bonita springs florida

Posts: 348

Total Cats: -107

I was going to start my own thread, but this is on topic so I hope you all dont mind that i highjack this thread with a few questions of my own.

I have a 1.8 that im going turbo on little by little. I thouhgt getting the pan plummed would be a good weekend project.

What i have done in the past on other turbo cars, and what i thought would be the best is to drill and weld a -10 male to male fitting into the pan and run a -10 line with a 45deg swivel female to line on the pan side then restrict it down to whater size fitting i need up at the turbo.

But reading around I have found people saying its a pita to remove the pan on the miata with the motor in? not even possable? I would like to avoid removing the motor again as i just got it in a few months ago when i did the 1.8 swap and new clutch.

Also thoughts on braidid line vs silicone? Yes the braided will do better for heat protection. But wont the rubber on the inside break down just as fast from the oil? and so being covered in ss will only discise ware from being seen and make it harder to know condition of the line?

Then i read many people drill and tap and not weld? if i go this route what size tap would i need for a -10 fitting? or would that not have any advantage over a barb fittiong with a clamp since it wont be welded anyway the weak point will be at the pan?

I have a 1.8 that im going turbo on little by little. I thouhgt getting the pan plummed would be a good weekend project.

What i have done in the past on other turbo cars, and what i thought would be the best is to drill and weld a -10 male to male fitting into the pan and run a -10 line with a 45deg swivel female to line on the pan side then restrict it down to whater size fitting i need up at the turbo.

But reading around I have found people saying its a pita to remove the pan on the miata with the motor in? not even possable? I would like to avoid removing the motor again as i just got it in a few months ago when i did the 1.8 swap and new clutch.

Also thoughts on braidid line vs silicone? Yes the braided will do better for heat protection. But wont the rubber on the inside break down just as fast from the oil? and so being covered in ss will only discise ware from being seen and make it harder to know condition of the line?

Then i read many people drill and tap and not weld? if i go this route what size tap would i need for a -10 fitting? or would that not have any advantage over a barb fittiong with a clamp since it wont be welded anyway the weak point will be at the pan?

#9

The aluminum male AN fitting sticking out of the oil pan sucks taking the engine in and out. You need to put a cap on it and be very careful that you dont hit it on something and ruin it. It takes very little force to mess up the threads on an aluminum AN fitting. Any braided line line with rubber that is rated for oil contact will be fine, so will ptfe lined. Silicone will also be ok, its rated to a higher temperature than nylon braided line but not as high as stainless braided line (typically). I have silicone for my coolant lines, they are in fire sleeve though.

#10

But reading around I have found people saying its a pita to remove the pan on the miata with the motor in? not even possable? I would like to avoid removing the motor again as i just got it in a few months ago when i did the 1.8 swap and new clutch.

Also thoughts on braidid line vs silicone? Yes the braided will do better for heat protection. But wont the rubber on the inside break down just as fast from the oil? and so being covered in ss will only discise ware from being seen and make it harder to know condition of the line?

Then i read many people drill and tap and not weld? if i go this route what size tap would i need for a -10 fitting? or would that not have any advantage over a barb fittiong with a clamp since it wont be welded anyway the weak point will be at the pan?

Also thoughts on braidid line vs silicone? Yes the braided will do better for heat protection. But wont the rubber on the inside break down just as fast from the oil? and so being covered in ss will only discise ware from being seen and make it harder to know condition of the line?

Then i read many people drill and tap and not weld? if i go this route what size tap would i need for a -10 fitting? or would that not have any advantage over a barb fittiong with a clamp since it wont be welded anyway the weak point will be at the pan?

If you're doing it in the car, drilling and tapping for NPT threads at the front near where the AC compressor would be is about the best you can do. It's workable, but less than ideal.

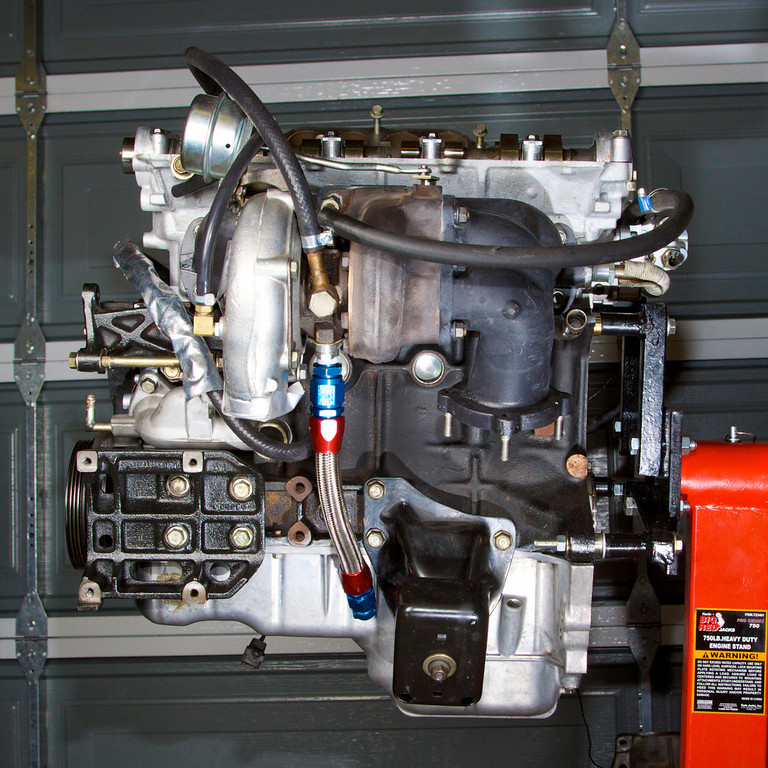

If you take the motor out, you can put it in the middle, which gives a better slope, like this:

I don't have an opinion on the merits of drill/tap vs weld. I don't own a welder or know how to use one, so I drilled/tapped. I've got a 45 degree NPT-NPT fitting with an NPT-AN adapter in it and a straight hose end.

As for oil breaking down the rubber liner of a braided stainless hose -- that's why you buy the hose that's rated for oil.

--Ian

#13

When I installed my original turbo (a FM 1/Bell 4.2) i did the drill and tap and installed the 5/8" hose barb (3/8" NPT thread into the oil pan) with the included rubber hose. After one of the silicone coolant lines failed, I replaced both coolant lines and the oil drain lines with steel braided lines with -AN fittings. Replaced the fitting in the oil pan with a -10 fitting also. To assemble the AN fittings, get a set of Koul Tools (yes that is the spelling) hose end tools and you will be a hose fitting expert in no time.

#14

as other have said, the rule of thumb is to make the return as big as you can, but there is no need to make it bigger than the turbo's hole is...so, in my case, it wasn't worth going bigger than 5/8 because the hole in the turbo is 5/8...which most are, i believe.

anyways, i decided to go 5/8 all the way down to the pan.

now, try to make the oil's journey as easy as possible, don't do hard bends, or a give it a reason for the line to end up collapsing or kinking.

this is my setup.

anyways, i decided to go 5/8 all the way down to the pan.

now, try to make the oil's journey as easy as possible, don't do hard bends, or a give it a reason for the line to end up collapsing or kinking.

this is my setup.

Thread

Thread Starter

Forum

Replies

Last Post

StratoBlue1109

Miata parts for sale/trade

21

09-30-2018 01:09 PM

stoves

Suspension, Brakes, Drivetrain

5

04-21-2016 03:00 PM

JesseTheNoob

DIY Turbo Discussion

15

09-30-2015 02:44 PM