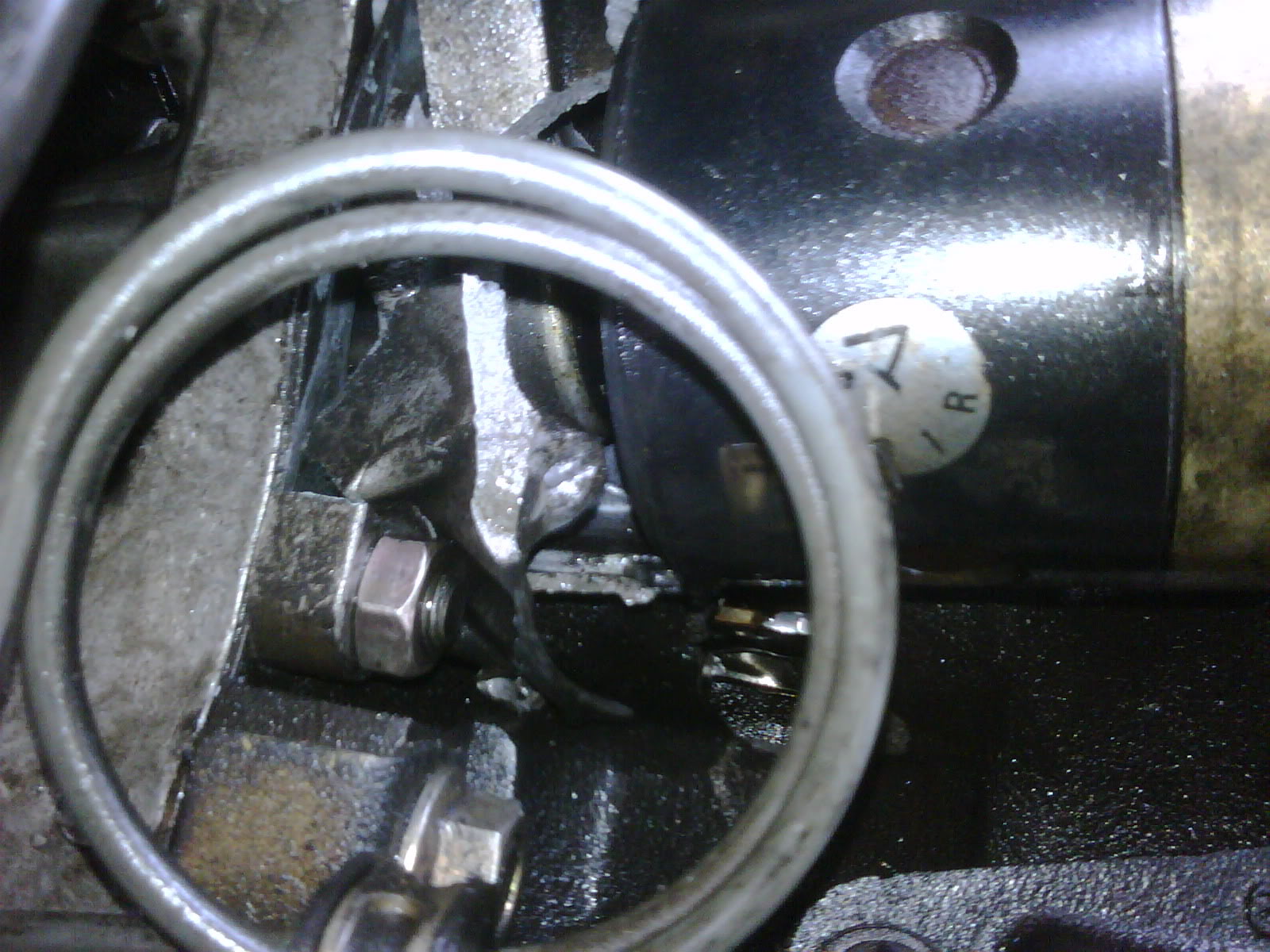

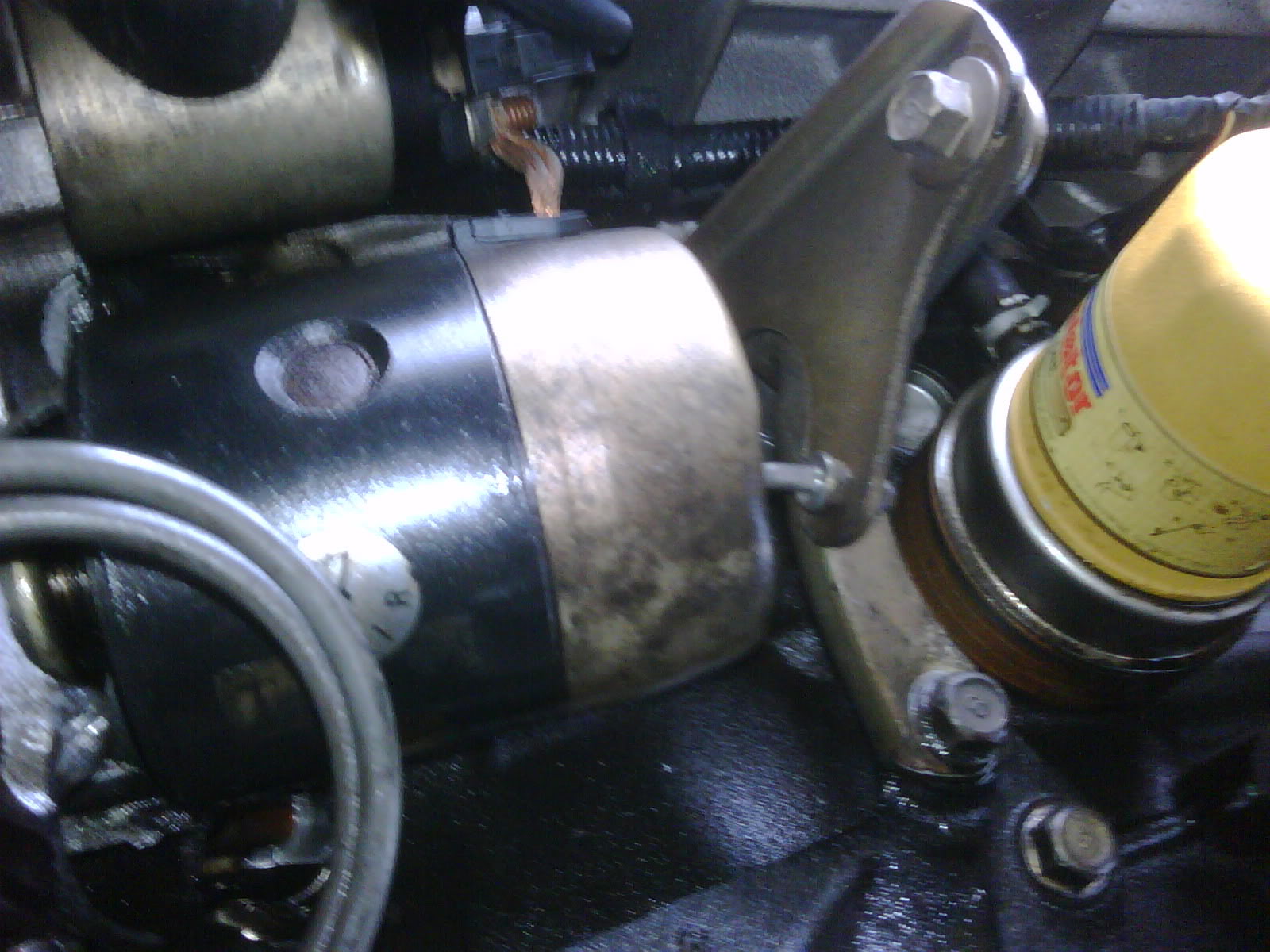

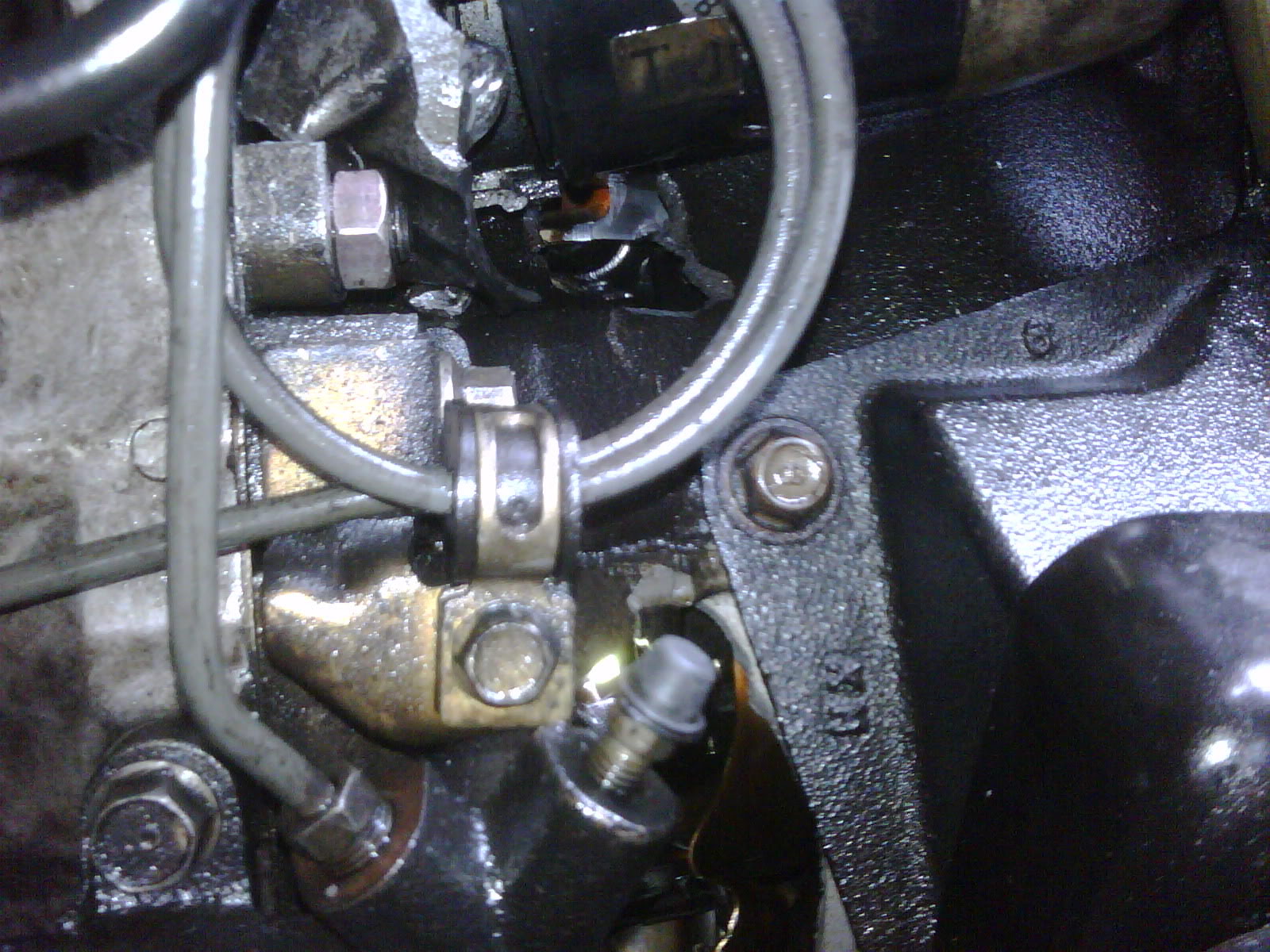

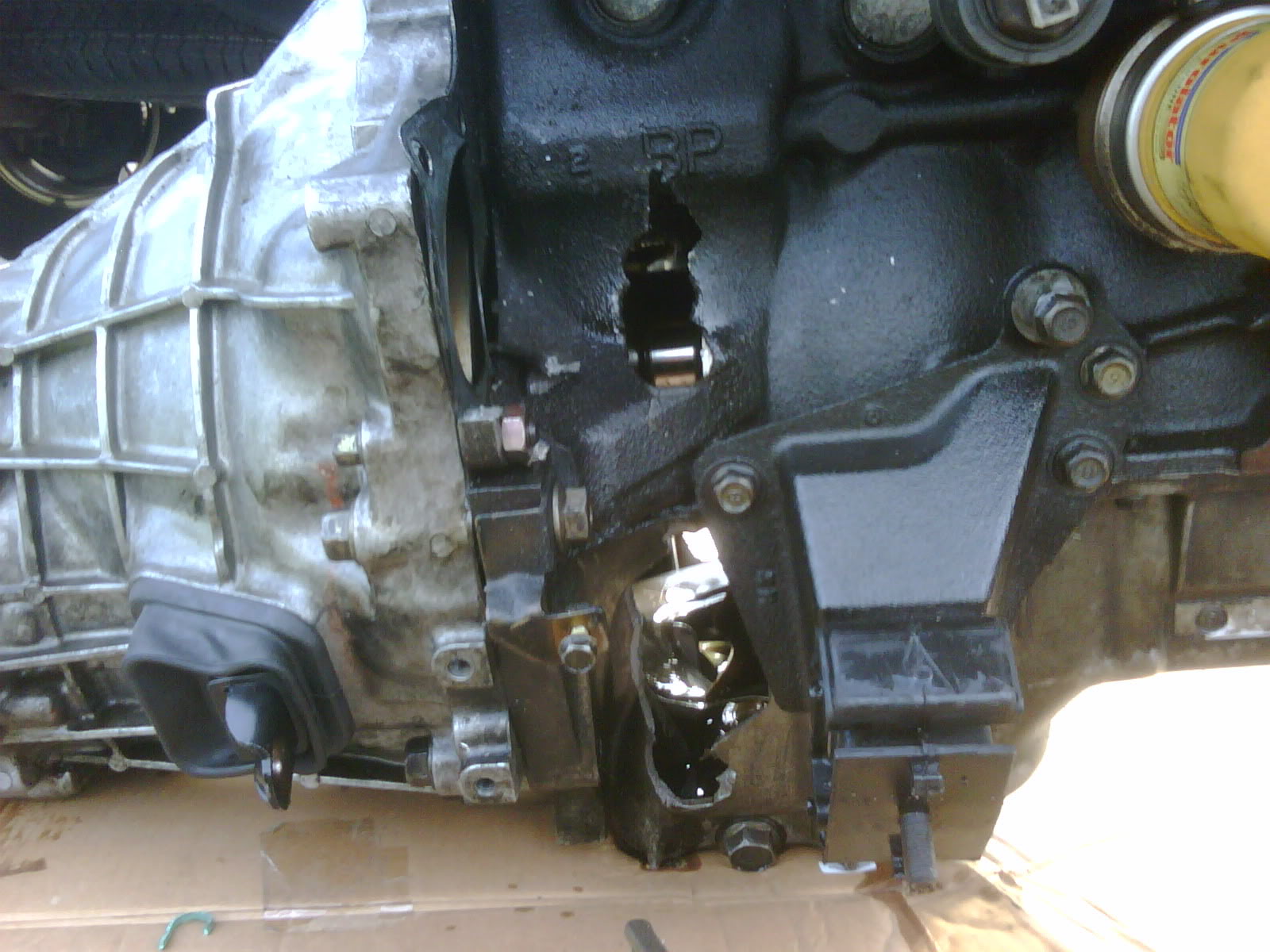

rod stretching carnage.

#49

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,175

Total Cats: 1,129

It's common knowledge in the engine building world not to use lock washers or loctite for any bearing or main caps. Technically speaking if you know the physical properties of the nuts and bolts you're tightening and torque them to the correct torque, you will never need any locking devices, liquid or solid.

That said, with rod studs you want to 'set' the studs into the rod. Torque them, loosen them, and then torque them a final time. The first torquing will pull them all the way into the rod, and the final torque will keep them tight.

wes65, these are just general engine building tips, and in no way insult your engine building skills, if you did indeed build this engine. 18psi and 12,000rpm (which I highly doubt your friend did, btw) will kill just about all of our motors eventually.

That said, with rod studs you want to 'set' the studs into the rod. Torque them, loosen them, and then torque them a final time. The first torquing will pull them all the way into the rod, and the final torque will keep them tight.

wes65, these are just general engine building tips, and in no way insult your engine building skills, if you did indeed build this engine. 18psi and 12,000rpm (which I highly doubt your friend did, btw) will kill just about all of our motors eventually.

#50

Senior Member

Thread Starter

iTrader: (7)

Join Date: Aug 2007

Location: Southern Indiana

Posts: 1,369

Total Cats: -1

It's common knowledge in the engine building world not to use lock washers or loctite for any bearing or main caps. Technically speaking if you know the physical properties of the nuts and bolts you're tightening and torque them to the correct torque, you will never need any locking devices, liquid or solid.

That said, with rod studs you want to 'set' the studs into the rod. Torque them, loosen them, and then torque them a final time. The first torquing will pull them all the way into the rod, and the final torque will keep them tight.

wes65, these are just general engine building tips, and in no way insult your engine building skills, if you did indeed build this engine. 18psi and 12,000rpm (which I highly doubt your friend did, btw) will kill just about all of our motors eventually.

That said, with rod studs you want to 'set' the studs into the rod. Torque them, loosen them, and then torque them a final time. The first torquing will pull them all the way into the rod, and the final torque will keep them tight.

wes65, these are just general engine building tips, and in no way insult your engine building skills, if you did indeed build this engine. 18psi and 12,000rpm (which I highly doubt your friend did, btw) will kill just about all of our motors eventually.

held up quite nicely, i think.

held up quite nicely, i think.

#51

Elite Member

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

Like SolarYellow said, I wonder if ARP's would have stopped this. Everything I've seen, people say they aren't needed, but this seems to show otherwise. First cap I've seen fail on a Miata. Sure its happened before though.

#54

Elite Member

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

Even if the bearings were completely flat, wouldn't the caps still be snuggly against each other where the bolts go through. Perhaps the bolt didn't streatch in total length, but the threads may have given way just enough to let the nut become loose. Only way I can see it happening.

#55

Senior Member

Thread Starter

iTrader: (7)

Join Date: Aug 2007

Location: Southern Indiana

Posts: 1,369

Total Cats: -1

Even if the bearings were completely flat, wouldn't the caps still be snuggly against each other where the bolts go through. Perhaps the bolt didn't streatch in total length, but the threads may have given way just enough to let the nut become loose. Only way I can see it happening.

#56

Senior Member

iTrader: (8)

Join Date: Mar 2006

Location: Indianapolis, IN

Posts: 1,105

Total Cats: 229

My hunch is that the bolt stretched just enough for the nut to then be loose enough to back off. Looks like you dominated your starter too.

Are you interested in that 99 head? I'll be in New Albany from Sunday through most of next week and will be stripping the parts car. Give me a shout if you want to check it out.

Are you interested in that 99 head? I'll be in New Albany from Sunday through most of next week and will be stripping the parts car. Give me a shout if you want to check it out.