First Look- Manley H beam connecting rods

#1

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

First Look

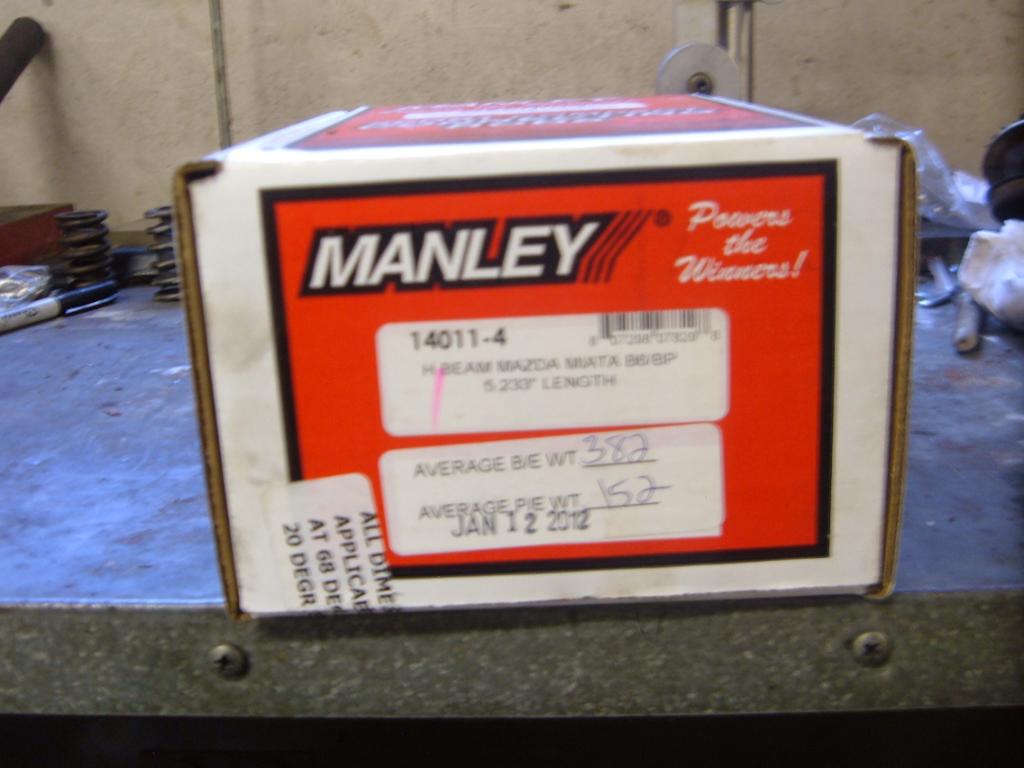

Manley H Beam Rods

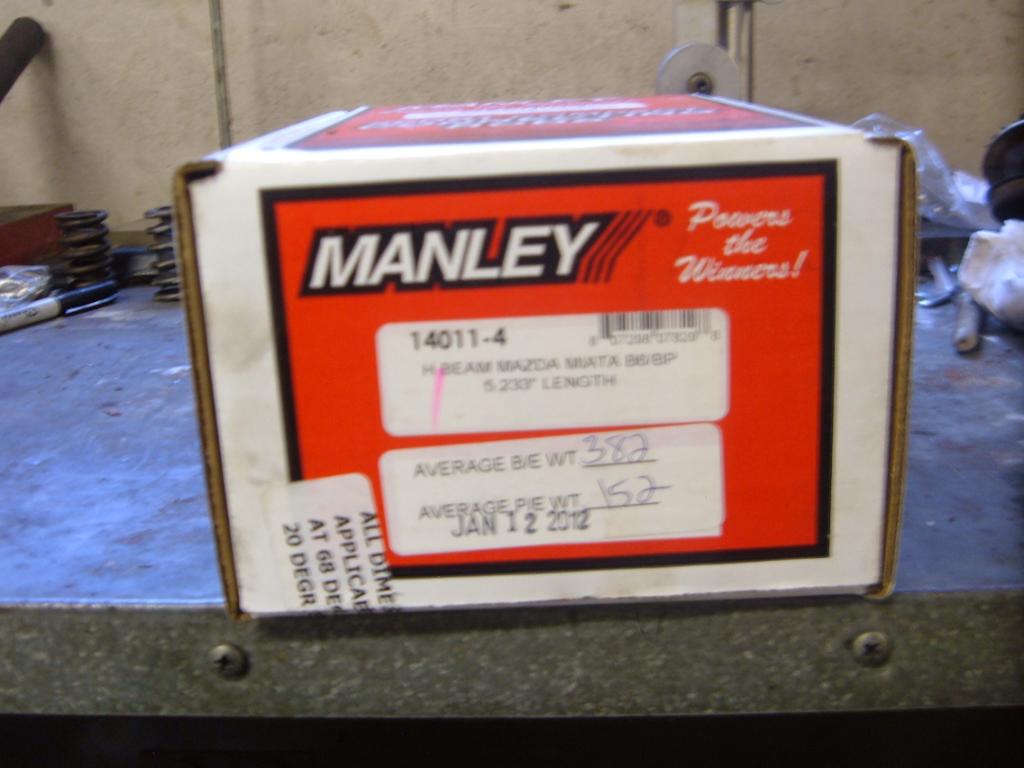

P/N 14011-4

Mazda 1.8l BP

A customer had shipped to me a set of rods for his build.

Balancing the engine is being done.

This was a sealed box, I cut the seal.

I open the box, and I see this.

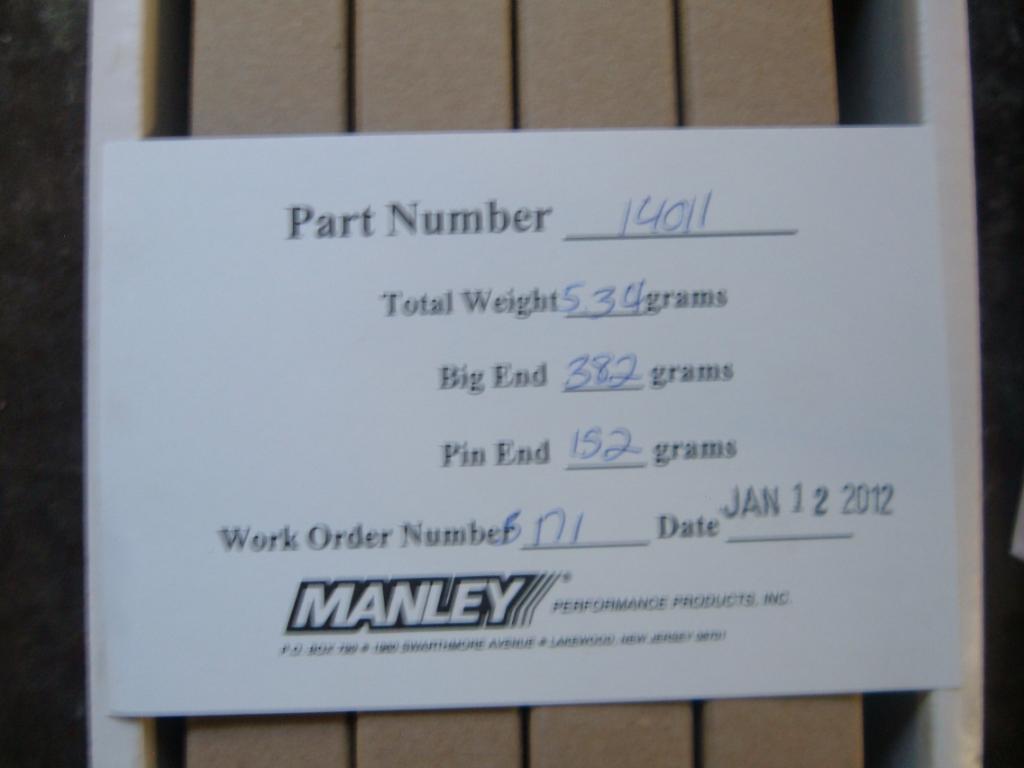

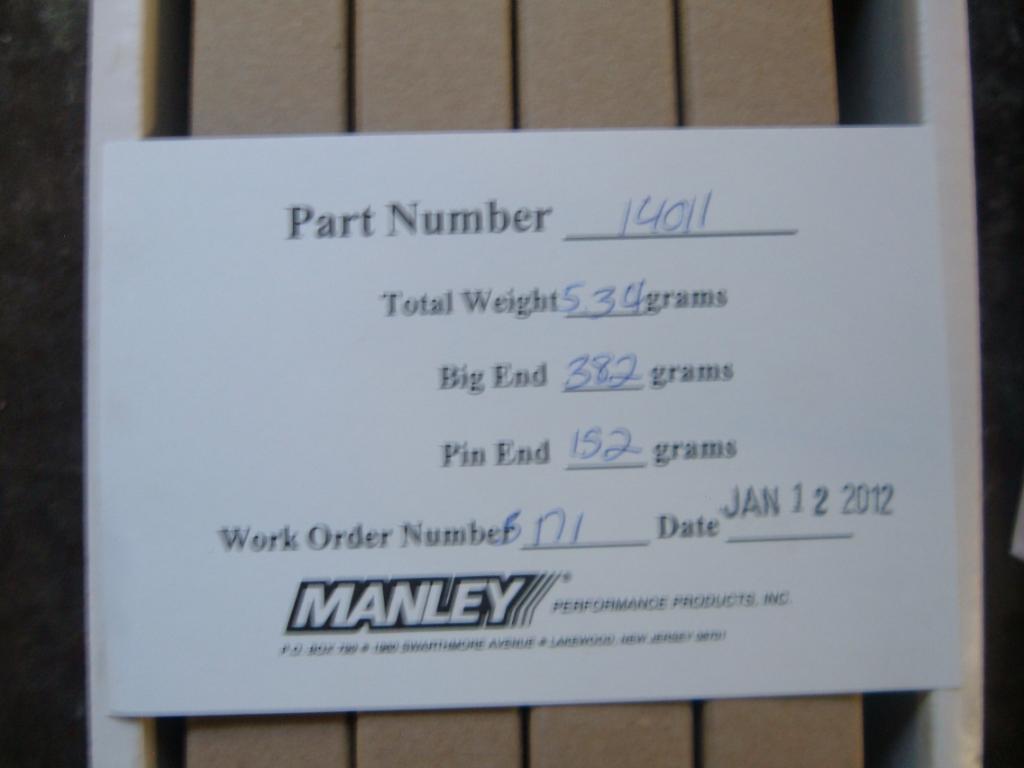

It already has my small end weights..

And the overall or big end weights noted on the box.

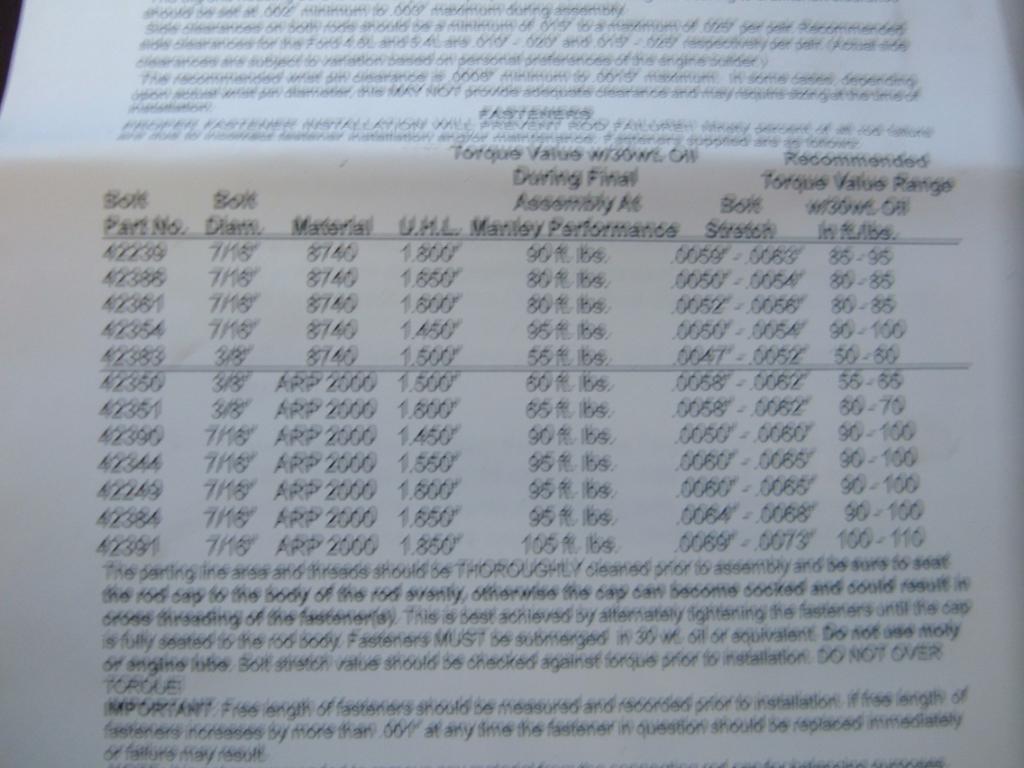

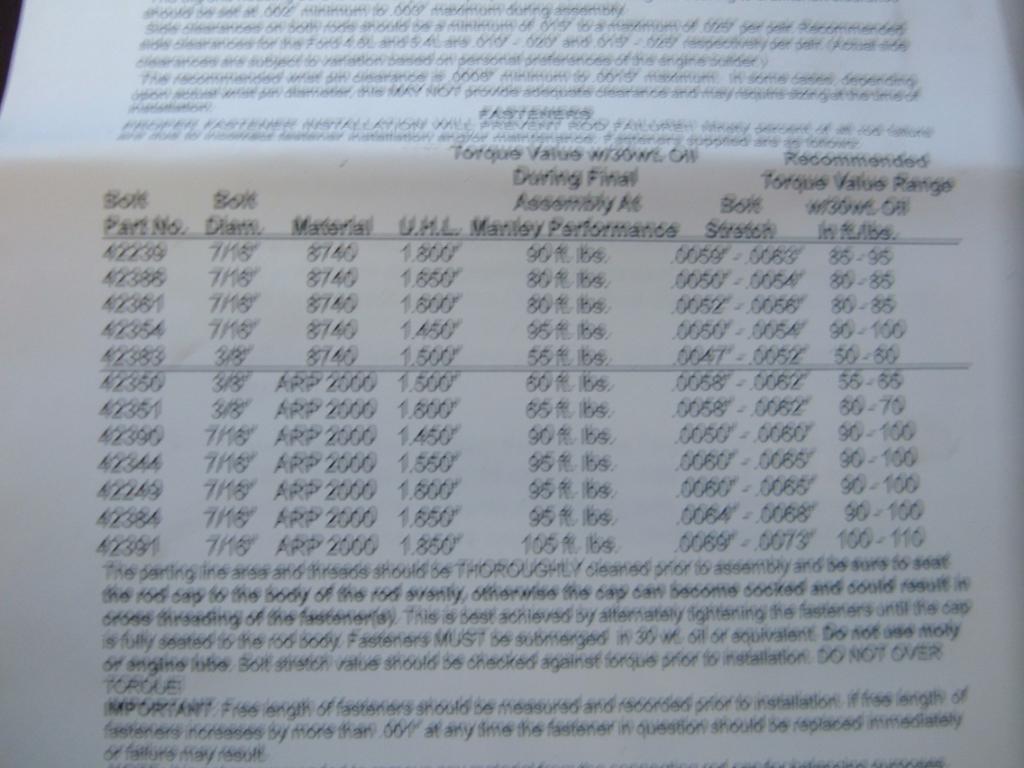

Also there is a spec sheet.

Along with tech info sheet and fastener torque specs.

First thing to do is number the rods.

A hammer and number stamp set is needed.

Place the rod in a rod vise to hold it stable and not mar it up.

Now to stamp the rod in to spots, one above the parting line and again below, with the same number.

Repeat for all rods. Since the boxes have info on them, I use a sharpie and number the box it came out of.

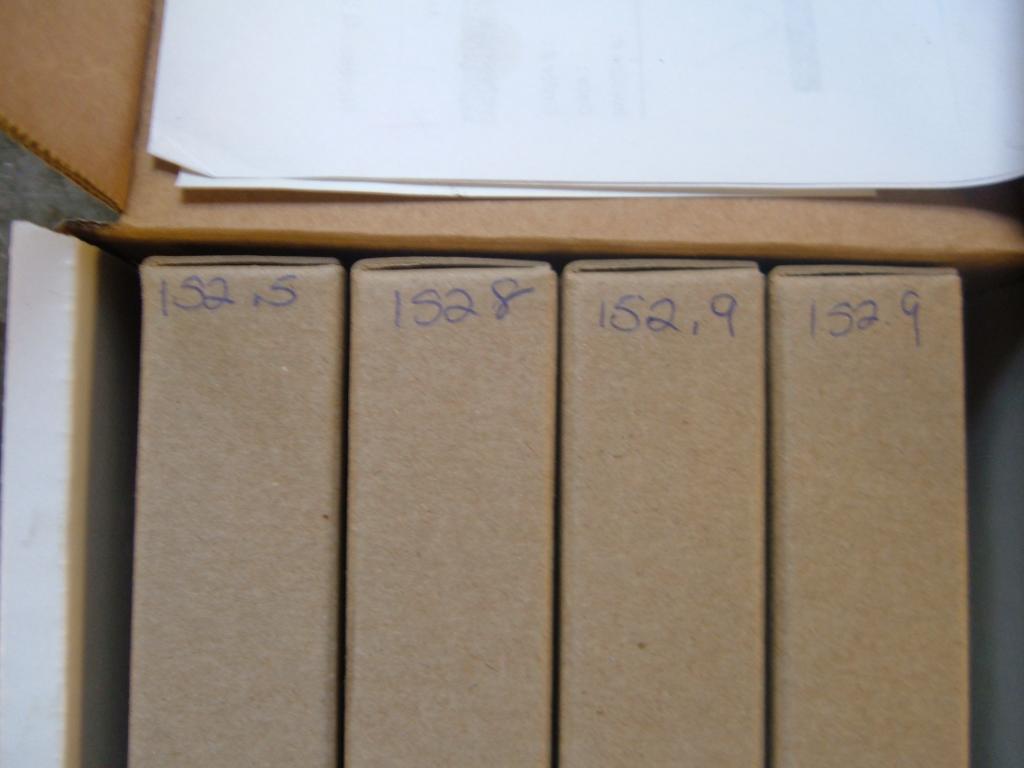

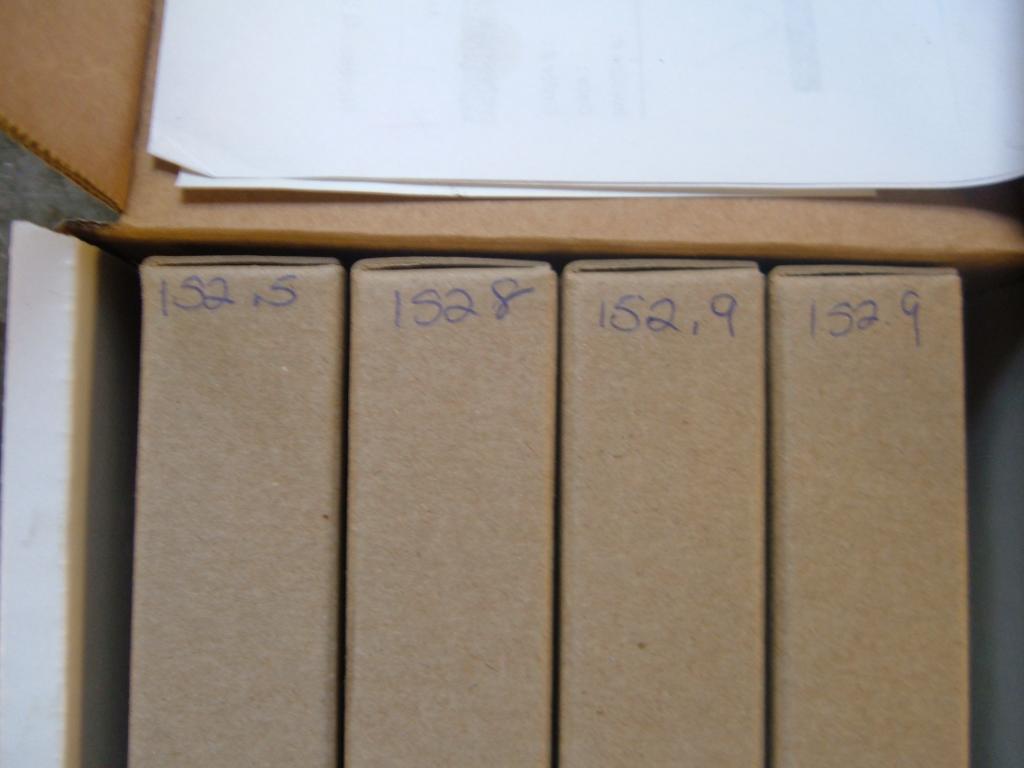

Now starting with the small end, or wrist pin end, I weigh all 4 rods in this set, and to check the factory recorded specs on the box.

Factory Mine

#1 152.5 153.0

#2 152.8 152.7

#3 152.9 152.9

#4 152.9 153.0

So I have one rod (#3) that weighed the same as the factory spec, and two rods (#2 & #4) that were off by .1g

Number 1 rod is off by .5g by what the factory claimed, but over all the difference between high and low is .3g. Thatís good for out the box.

I am going to start with the heaviest small end and get it closer to 152.7g

I start with rod #1, 153.0g,

I know I do not to do more than buff it.

I scale it again, this has to be done quickly before the scale shuts off and I have to start all over.

I over shot my weight, The new belt cut quicker than I had expected. Small end is at 151.6g now.

I work the other 3 small ends and now have them at

1) 151.6g

2) 151.6g

3) 151.7g

4) 151.7g

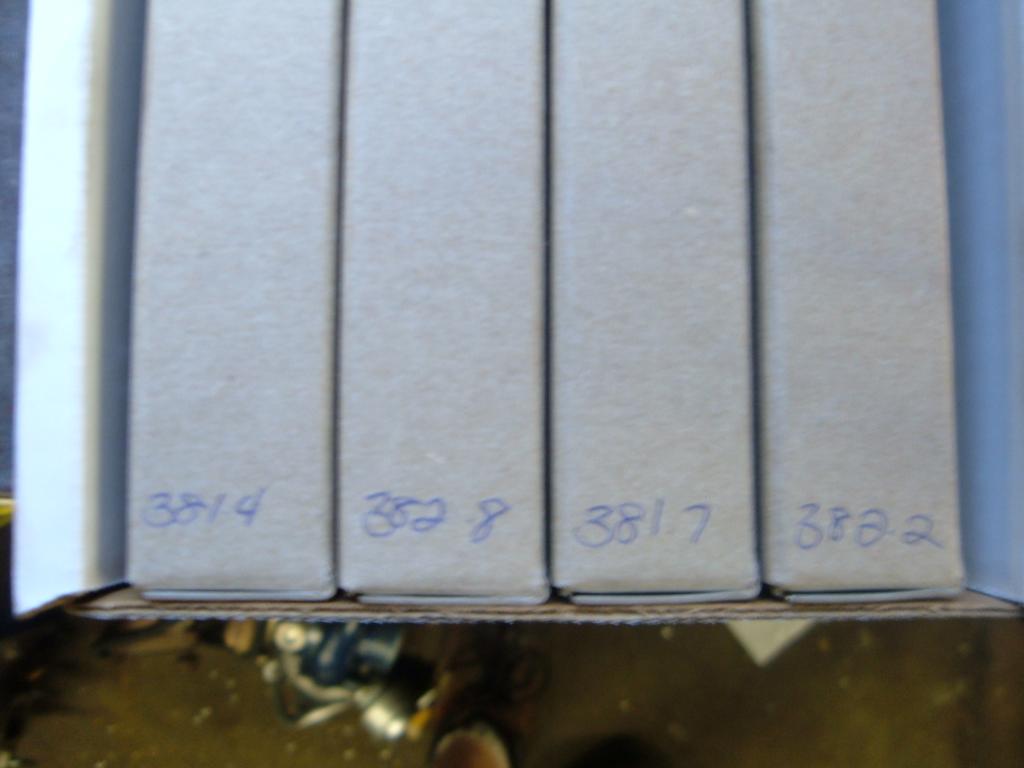

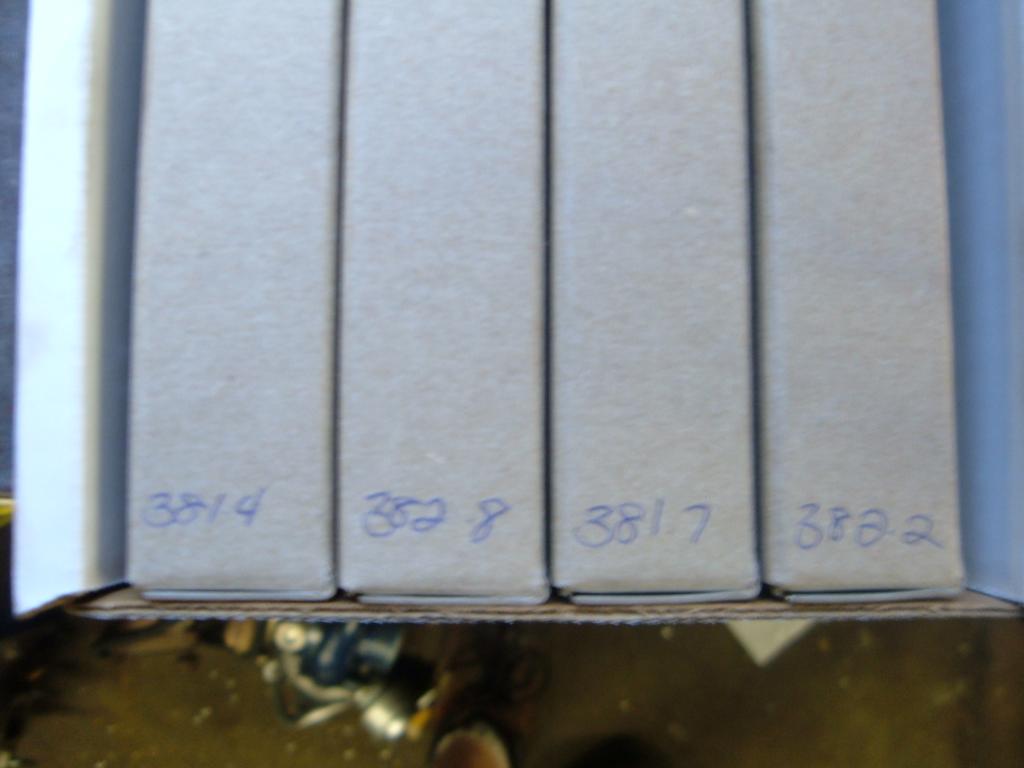

Now with all the small ends with in a tight range, time to work the big end.

Some shops will weigh the big end like I have done the small end also. I go to an overall weight now.

The over all weights I start with are

1) 534.0

2) 535.6

3) 535.0

4) 535.1

These weights were taken after the small end has been done.

Target weight is Rod #1 of 534.0g

Rod #1

Rod#2

Rod #3

Rod #4

The rods were not too bad out of the box, with the small ends having a range of .4g and the big ends having a range of 1.4g

I would have thought Manley would have the big end weight a bit closer, 1g or less.

Manley H Beam Rods

P/N 14011-4

Mazda 1.8l BP

A customer had shipped to me a set of rods for his build.

Balancing the engine is being done.

This was a sealed box, I cut the seal.

I open the box, and I see this.

It already has my small end weights..

And the overall or big end weights noted on the box.

Also there is a spec sheet.

Along with tech info sheet and fastener torque specs.

First thing to do is number the rods.

A hammer and number stamp set is needed.

Place the rod in a rod vise to hold it stable and not mar it up.

Now to stamp the rod in to spots, one above the parting line and again below, with the same number.

Repeat for all rods. Since the boxes have info on them, I use a sharpie and number the box it came out of.

Now starting with the small end, or wrist pin end, I weigh all 4 rods in this set, and to check the factory recorded specs on the box.

Factory Mine

#1 152.5 153.0

#2 152.8 152.7

#3 152.9 152.9

#4 152.9 153.0

So I have one rod (#3) that weighed the same as the factory spec, and two rods (#2 & #4) that were off by .1g

Number 1 rod is off by .5g by what the factory claimed, but over all the difference between high and low is .3g. Thatís good for out the box.

I am going to start with the heaviest small end and get it closer to 152.7g

I start with rod #1, 153.0g,

I know I do not to do more than buff it.

I scale it again, this has to be done quickly before the scale shuts off and I have to start all over.

I over shot my weight, The new belt cut quicker than I had expected. Small end is at 151.6g now.

I work the other 3 small ends and now have them at

1) 151.6g

2) 151.6g

3) 151.7g

4) 151.7g

Now with all the small ends with in a tight range, time to work the big end.

Some shops will weigh the big end like I have done the small end also. I go to an overall weight now.

The over all weights I start with are

1) 534.0

2) 535.6

3) 535.0

4) 535.1

These weights were taken after the small end has been done.

Target weight is Rod #1 of 534.0g

Rod #1

Rod#2

Rod #3

Rod #4

The rods were not too bad out of the box, with the small ends having a range of .4g and the big ends having a range of 1.4g

I would have thought Manley would have the big end weight a bit closer, 1g or less.

#3

Elite Member

iTrader: (2)

Join Date: Jan 2007

Location: Los Angeles, CA

Posts: 8,682

Total Cats: 130

So have you seen the belfab/mtuned/ebay rods before? Common for miatas and hondas.

If so, what was your opinion?

Also, how often have you seen busted h beam rods? I have only ever seen one before.

If so, what was your opinion?

Also, how often have you seen busted h beam rods? I have only ever seen one before.

#4

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

fae... yes I have installed over 100 of the china bay H beams over the years, As long as common sense ia applied to use of them they are fine.

As far as use in a 300-500 hp build, I see no issue with them, 4340 chrome moly, same as Eagle uses.

The name really dosnt matter, that cost about another $2.00 per rod....

I can have them made also... want them to say "MiataTurbo.com" on the beam? lol

If going for over 500hp on a 4cyl, I would say go with a rod that has had some R&D and stress testing done on it, and not an off shore clone.

As far as use in a 300-500 hp build, I see no issue with them, 4340 chrome moly, same as Eagle uses.

The name really dosnt matter, that cost about another $2.00 per rod....

I can have them made also... want them to say "MiataTurbo.com" on the beam? lol

If going for over 500hp on a 4cyl, I would say go with a rod that has had some R&D and stress testing done on it, and not an off shore clone.

#6

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

Well Carrillo for the big well known one.

If your money thick, GRP Billit Ti rods are hard to beat.

But now you are getting out of the area of where I work and play.

But for most, Chinabay, Std Eagle, Manley, or the like, will be the ones that 80% out there will ever need.

If your money thick, GRP Billit Ti rods are hard to beat.

But now you are getting out of the area of where I work and play.

But for most, Chinabay, Std Eagle, Manley, or the like, will be the ones that 80% out there will ever need.

#10

Probably two reasons:

1) So that they can be identified if they are removed from the motor again, even if by a sloppy builder.

2) On the same side so that the caps are never put on backward.

I'm surprised they weren't already laser etched honestly. Even the original Chinese Belfab rods years ago were laser etched on one side on both the cap and body. These Manley rods look, and likely are, identical to those original runs.

1) So that they can be identified if they are removed from the motor again, even if by a sloppy builder.

2) On the same side so that the caps are never put on backward.

I'm surprised they weren't already laser etched honestly. Even the original Chinese Belfab rods years ago were laser etched on one side on both the cap and body. These Manley rods look, and likely are, identical to those original runs.

#11

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

What was said below. VVVV Add to that it was the way I was trained 20 years ago. When tearing down a SBC, they are not stamped from the factory, rods or main caps, so My first job was to go through and number them.

I can not tell you how many sets of rods I have had to fix because they were not numbered.

I also number the head casting and cam caps, this way if I have 2 or more of the same head, i am not worried if the caps get mixed up.

I come across allot of aftermarket rods that are not numbered, it matters not what cylinder they are placed in, just that the rod and cap stay together.

I can not tell you how many sets of rods I have had to fix because they were not numbered.

I also number the head casting and cam caps, this way if I have 2 or more of the same head, i am not worried if the caps get mixed up.

Probably two reasons:

1) So that they can be identified if they are removed from the motor again, even if by a sloppy builder.

2) On the same side so that the caps are never put on backward.

I'm surprised they weren't already laser etched honestly. Even the original Chinese Belfab rods years ago were laser etched on one side on both the cap and body. These Manley rods look, and likely are, identical to those original runs.

1) So that they can be identified if they are removed from the motor again, even if by a sloppy builder.

2) On the same side so that the caps are never put on backward.

I'm surprised they weren't already laser etched honestly. Even the original Chinese Belfab rods years ago were laser etched on one side on both the cap and body. These Manley rods look, and likely are, identical to those original runs.

#13

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

I have not balanced a set of ebay rods for the Miata.

Out of all the rods I have balanced, I can not recall a set close enough to use right out of the box. Be it Manley, Eagle, ebay, or stock...

Out of all the rods I have balanced, I can not recall a set close enough to use right out of the box. Be it Manley, Eagle, ebay, or stock...

#16

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

I'm trying to get a feel for what you think is too far out.

Using their measurements, they are out 0.3%. Sure, it's always good to double check.

Do you measure it with bearings? Could not the bearings weight 1.4g from one to the other? Are ARP bolts that consistent, or do you sometimes hammer numbers on those too, to make sure they go back into the same hole they were in when you balanced the assy?

How accurate is your crank balancer (or crank balancers in general)? could it balance the throws to 1.4 gram? Do you balance the intermediate throws? What happens if one of the middle throws or counter weights is 1.4grams more than the others?

I'm trying to learn here. Your posts are always informative.

Using their measurements, they are out 0.3%. Sure, it's always good to double check.

Do you measure it with bearings? Could not the bearings weight 1.4g from one to the other? Are ARP bolts that consistent, or do you sometimes hammer numbers on those too, to make sure they go back into the same hole they were in when you balanced the assy?

How accurate is your crank balancer (or crank balancers in general)? could it balance the throws to 1.4 gram? Do you balance the intermediate throws? What happens if one of the middle throws or counter weights is 1.4grams more than the others?

I'm trying to learn here. Your posts are always informative.

#17

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

I go for .2g high to low spec, on both the small end and the overall weight.

Pistons I go for .1g

The few sets of rod bearing I have scaled have been close, less than .1g

Mainly the only time rod bearings are weighed is for "V" engines to make up bob weights.

Now balancing the throws or crank is done on a spin balancer, I do not have one in house.

The shop I use has this one.

Crankshaft Balancers and Balancing Machines - Contact CWT Industries for Machine Ship Equipment

I also like to have the flywheel, pressure plate, and harmonic balancer, this way the pressure plate is indexed to the flywheel and the flywheel to the crank.

This way any out balance can be corrected to bring it in closer to the crank center line.

Some assemblies can see 500lbs of out of balance at 7000 RPM, then with indexing the pressure plate have it down to 350.

Then by the time the crank is brought in, either by removing weigh, or adding heavy metal, will commonly be under 50lbs

Pistons I go for .1g

The few sets of rod bearing I have scaled have been close, less than .1g

Mainly the only time rod bearings are weighed is for "V" engines to make up bob weights.

Now balancing the throws or crank is done on a spin balancer, I do not have one in house.

The shop I use has this one.

Crankshaft Balancers and Balancing Machines - Contact CWT Industries for Machine Ship Equipment

I also like to have the flywheel, pressure plate, and harmonic balancer, this way the pressure plate is indexed to the flywheel and the flywheel to the crank.

This way any out balance can be corrected to bring it in closer to the crank center line.

Some assemblies can see 500lbs of out of balance at 7000 RPM, then with indexing the pressure plate have it down to 350.

Then by the time the crank is brought in, either by removing weigh, or adding heavy metal, will commonly be under 50lbs

#18

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

Wow, ok then.

Can you rebalance my 60deg V6 next time it's apart? I do not trust the guy who did it the first time. Rubber trans mount helped my vibrations 1000x but I'm still scared the guy did a half assed job.

Can you rebalance my 60deg V6 next time it's apart? I do not trust the guy who did it the first time. Rubber trans mount helped my vibrations 1000x but I'm still scared the guy did a half assed job.

#19

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

Sure that will not be an issue.

The only glitch is if the pistons are press fit and not a clip style.

Most all pistons that are press fit, tend to distort, crack or just bust when the wrist pin is pushed out.

The only glitch is if the pistons are press fit and not a clip style.

Most all pistons that are press fit, tend to distort, crack or just bust when the wrist pin is pushed out.