YABEB - Yet Another Bottem End Build

#1

Senior Member

Thread Starter

iTrader: (1)

Join Date: Sep 2011

Location: Lambertville, NJ

Posts: 1,215

Total Cats: 74

So, after planning for this for three years, I finally started the build on my bottom end. Of course I have some questions:

Most importantly: I'm installing a VVT crank in a NB1 block. What type thrust bearing do I need? Or to put it differently is the difference with the block or with the crank? Or did I screw up and they're both different and this combination is not allowed?

Secondly: Ebay China-rods. crank clearance looks good on all 4 (ACL race bearings). But the wristpin clearance seems low to me. I'm right at 0.0004" +/- 0.0001", essentially between 3/10 of a 1/1000 and 5/10 of a 1/1000. They feel snug. They actually feel more snug in the rods than in the pistons (Supertechs). One I had to open up a bit with a hone, because it was maybe 1/10000- if that.

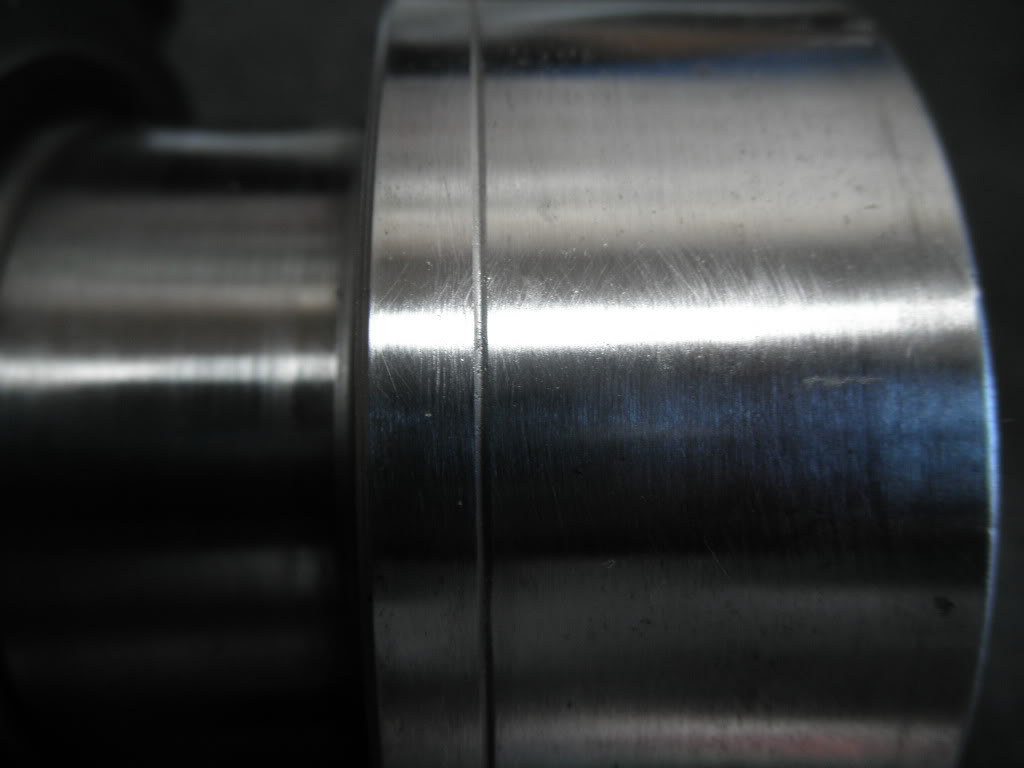

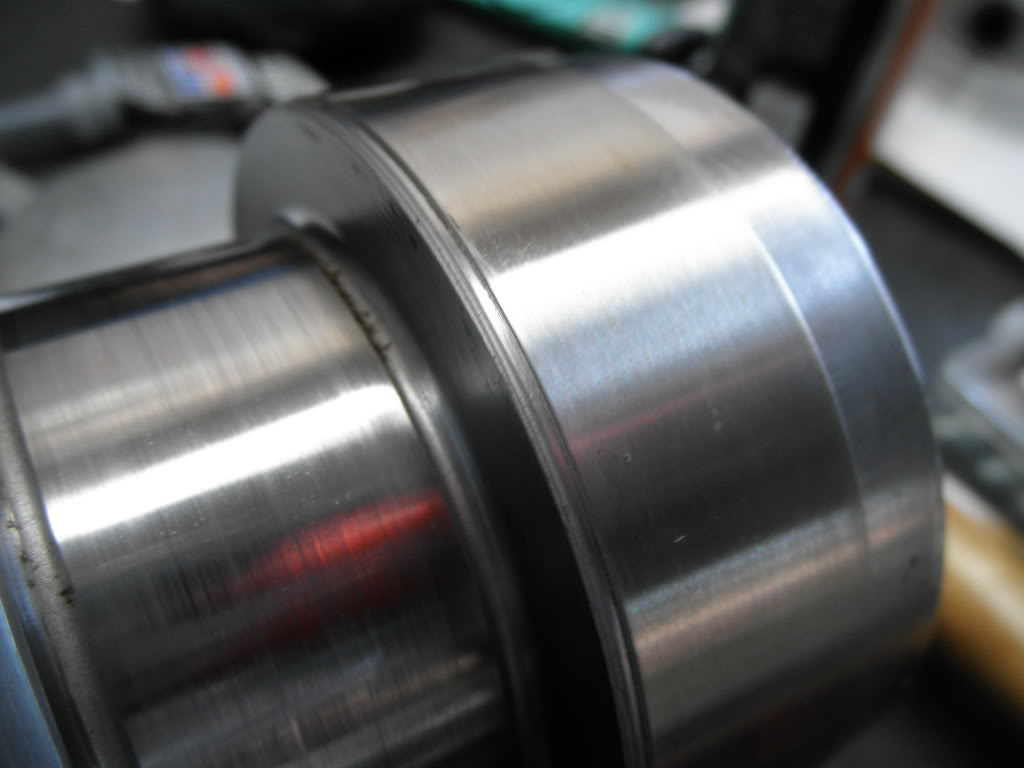

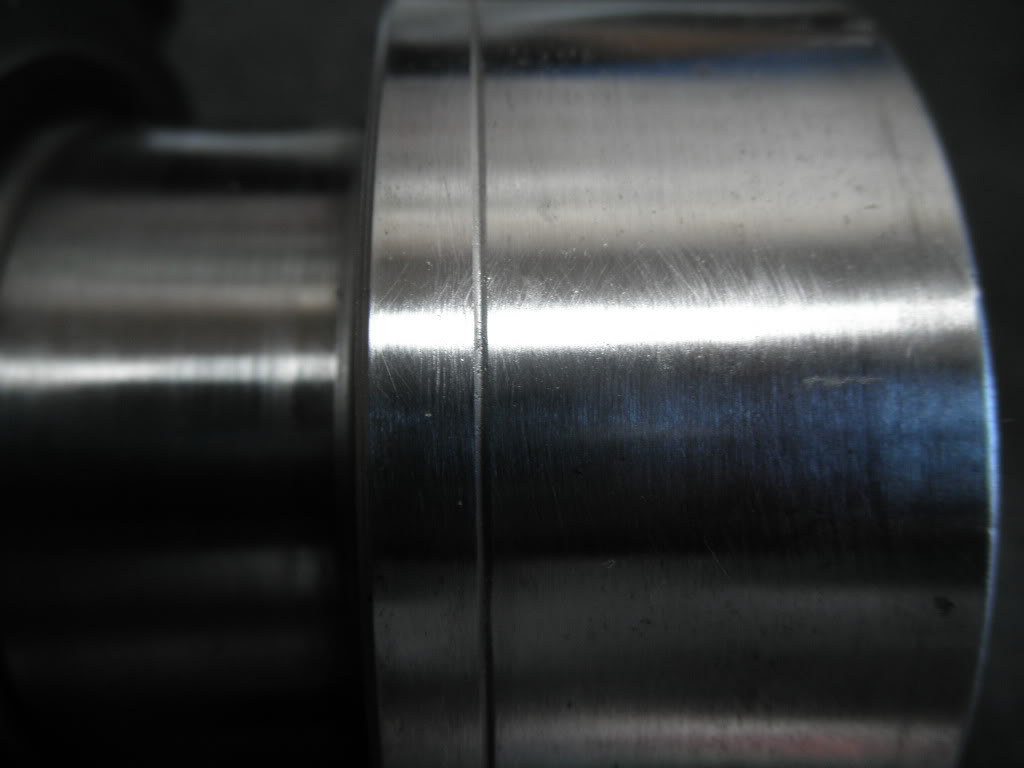

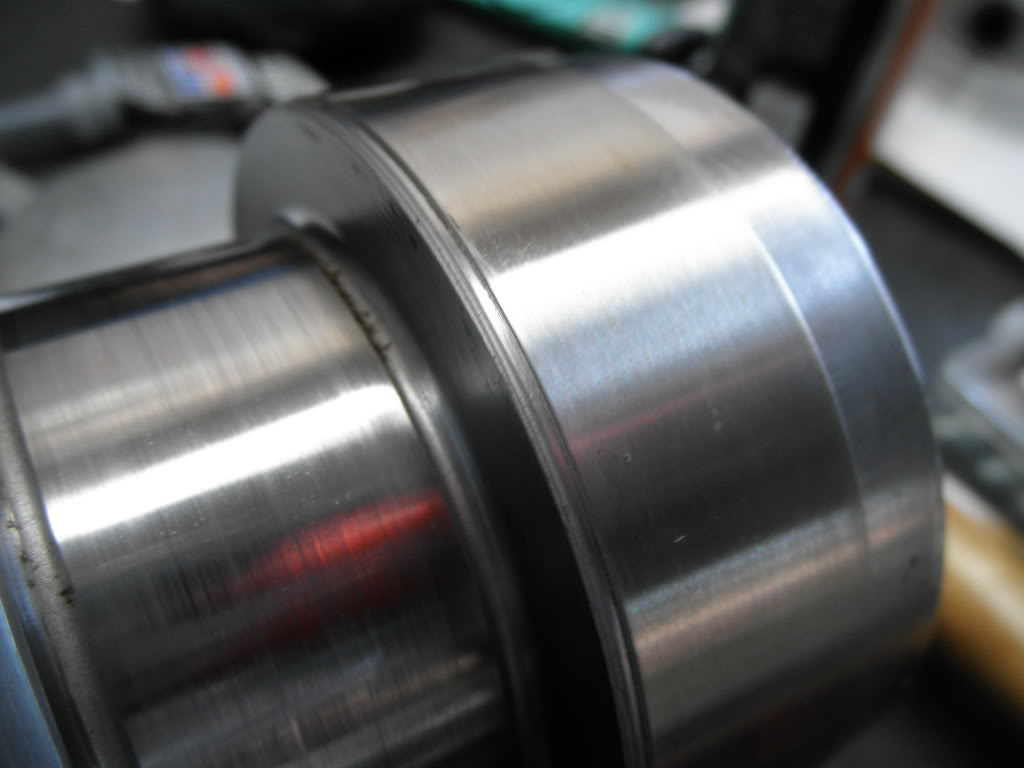

Last but not least, my front and rear main seal surfaces look a bit 'used'. The dips can easily be felt with a fingernail. Shut I cut them down and sleeve, or am I OK? Pictures attached.

Most importantly: I'm installing a VVT crank in a NB1 block. What type thrust bearing do I need? Or to put it differently is the difference with the block or with the crank? Or did I screw up and they're both different and this combination is not allowed?

Secondly: Ebay China-rods. crank clearance looks good on all 4 (ACL race bearings). But the wristpin clearance seems low to me. I'm right at 0.0004" +/- 0.0001", essentially between 3/10 of a 1/1000 and 5/10 of a 1/1000. They feel snug. They actually feel more snug in the rods than in the pistons (Supertechs). One I had to open up a bit with a hone, because it was maybe 1/10000- if that.

Last but not least, my front and rear main seal surfaces look a bit 'used'. The dips can easily be felt with a fingernail. Shut I cut them down and sleeve, or am I OK? Pictures attached.

#2

Elite Member

iTrader: (15)

Join Date: Jan 2007

Location: Murfreesboro,TN

Posts: 2,043

Total Cats: 265

On the thrust bearing you'll have to measure the saddle width on the block to see if you need the old narrow bearing or the new wide bearing. The NB1 block is when the thrust bearing issues were discovered (though some '97's have been seen with the same issue), so depending on when the motor was assembled, it could be ither.

#9

SadFab CEO

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

I look up the skf catalog and google the part number. Ive bought them on ebay and your local skf dealer (bearing house, autozone) can order them for you. They're usually $30-50.

Ill dig up some part numbers in a bit if I have time.

Ill dig up some part numbers in a bit if I have time.

#11

SadFab CEO

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

Posting all info for others, hopefully this **** formats. Rockauto has these under: engine> crankshaft repair sleeve.

Front seal:

90-91 1.6, short nose, up to vin 209446: national or SKF #99114

Flanged Outside Diameter (Inch) 1.781

Flanged Outside Diameter (MM)45.240

Installation Depth (Inch)0.812

Installation Depth (MM)20.620

MaterialStainless SteelOuter Diameter (Inch)1.781

Overall Width (Inch)0.500Overall Width (MM)12.700

Part TypeRedi-SleevesShaft Size Max (Inch)1.46

Shaft Size Maximum (Inch)1.460Shaft Size Maximum (MM)37.080

Shaft Size Min (Inch)1.453

Shaft Size Minimum (Inch)1.453

Shaft Size Minimum (MM)36.910

Width (inch)0.375

Width On Shaft (Inch)0.375

Width on Shaft (MM)9.530

Rear seal:

All B6 and BPs: It would appear there is a gap for this size range in the Nat/SKF product range, so Im only finding the rear in Timken #KWK99328

Minimum Shaft Diameter Range3.225

"Maximum Shaft Diameter Range3.231"

Installation Depth1.732"

Width On Shaft0.661

"Overall Width0.85"

Flange Diameter3.587"

And I found some pics of when I used one on my nissan.

Use a sealant between the crank and sleeve. I use RTV.

Front seal:

90-91 1.6, short nose, up to vin 209446: national or SKF #99114

- Redi-Sleeve

- Front

- To Serial Number: 209446

- 1.4 Inch O.D.

- 0.315 Inch Width

- Material: Stainless Steel

- Flange Diameter (In): 1.400 Inch

- Flange Diameter (mm): 35.56mm

- Maximum Shaft Size (In): 1.184 Inch

- Maximum Shaft Size (mm): 30.07mm

- Minimum Shaft Size (In): 1.179 Inch

- Minimum Shaft Size (mm): 29.95mm

Flanged Outside Diameter (Inch) 1.781

Flanged Outside Diameter (MM)45.240

Installation Depth (Inch)0.812

Installation Depth (MM)20.620

MaterialStainless SteelOuter Diameter (Inch)1.781

Overall Width (Inch)0.500Overall Width (MM)12.700

Part TypeRedi-SleevesShaft Size Max (Inch)1.46

Shaft Size Maximum (Inch)1.460Shaft Size Maximum (MM)37.080

Shaft Size Min (Inch)1.453

Shaft Size Minimum (Inch)1.453

Shaft Size Minimum (MM)36.910

Width (inch)0.375

Width On Shaft (Inch)0.375

Width on Shaft (MM)9.530

Rear seal:

All B6 and BPs: It would appear there is a gap for this size range in the Nat/SKF product range, so Im only finding the rear in Timken #KWK99328

Minimum Shaft Diameter Range3.225

"Maximum Shaft Diameter Range3.231"

Installation Depth1.732"

Width On Shaft0.661

"Overall Width0.85"

Flange Diameter3.587"

And I found some pics of when I used one on my nissan.

Use a sealant between the crank and sleeve. I use RTV.

Last edited by hi_im_sean; 10-28-2016 at 03:56 PM.

#12

Senior Member

Thread Starter

iTrader: (1)

Join Date: Sep 2011

Location: Lambertville, NJ

Posts: 1,215

Total Cats: 74

Ordered the sleeves- thanks for the pointer! Have a kitty.

Still: Any pointers on the wristpin clearance? To hone or not to hone? What should my clearance be? Can't plastigage- don't like that part.

Still: Any pointers on the wristpin clearance? To hone or not to hone? What should my clearance be? Can't plastigage- don't like that part.

#13

Senior Member

Thread Starter

iTrader: (1)

Join Date: Sep 2011

Location: Lambertville, NJ

Posts: 1,215

Total Cats: 74

Sorry to bump this, but I want to get the rotating assembly buttoned up on Saturday and still would like to know, if I'm OK with the wristpins as-is. Or is my question so dumb that I don't deserve an answer? Not impossible.....

#14

SadFab CEO

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

My opinion is that they should be fine. But if you're worried, open them another tenthou or 2. You say they spin in the piston easier that the rod, but things are different when its all running and loaded. Im not expert though so....

#15

Also if in a pinch on a crank with wear from a seal, I've just not pressed the seal in to the same spot so the new seal lip touches forward of the old one. Works, but a sleeve is probably better if you got the time to do it.