Who does Fabrication/Machining for a living ?

#1

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2008

Location: Cromwell CT

Posts: 1,146

Total Cats: 56

Im proud to say my day job is a CNC Machinist for a great company in CT, Just wondering how many of us do fabrication or machining for a living and what sort of equipment do you operate?

I run Swiss style sliding headstock CNC lathes, super fast super high precision. my tolerance's are usually +/- .00025 . Most of what i run are 8 axis. We machine alot of 2024,303,416,15-5ph and MP35N

this is like what i run (demo)

I run Swiss style sliding headstock CNC lathes, super fast super high precision. my tolerance's are usually +/- .00025 . Most of what i run are 8 axis. We machine alot of 2024,303,416,15-5ph and MP35N

this is like what i run (demo)

#3

Elite Member

iTrader: (12)

Join Date: Nov 2009

Location: Harpers Ferry WV

Posts: 1,516

Total Cats: 20

I work as a machinist for R&D at NASA Goddard our shop is small no CNC equipment its all old school by hand. We do mostly small stuff and one off development pieces. We have two manual causing 14" lathes and a standard size bridgeport.

#4

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,190

Total Cats: 1,135

I used to. Cnc and manual gear cutting mostly. Also ran a cnc mill and giant drill press. I'm drunk and can't remember the name. Picked up lathe and programming skills along the way.

Look up allied systems inc, I made all the gears for their whiches.

Look up allied systems inc, I made all the gears for their whiches.

#5

Having done tool and die work part time, coupled with chassis work full time for a while, never again. I'll stick with engineering for the time being. Tool and die was too monotonous for me (a lot of bulk orders for surgical companies), and I will NEVER run or work in a fab shop again. Too many ******* customers that want everything done/changed for free.

#6

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2008

Location: Cromwell CT

Posts: 1,146

Total Cats: 56

Having done tool and die work part time, coupled with chassis work full time for a while, never again. I'll stick with engineering for the time being. Tool and die was too monotonous for me (a lot of bulk orders for surgical companies), and I will NEVER run or work in a fab shop again. Too many ******* customers that want everything done/changed for free.

#7

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

I do.

I work in a machine shop with 3 CnC machines, a devlieg, CnC lathe, other assorted machines bridgeport, grinders, ect. and a fabricating shop in the back where i work.

I sometimes operate the CnC's, but it's boring as hell.

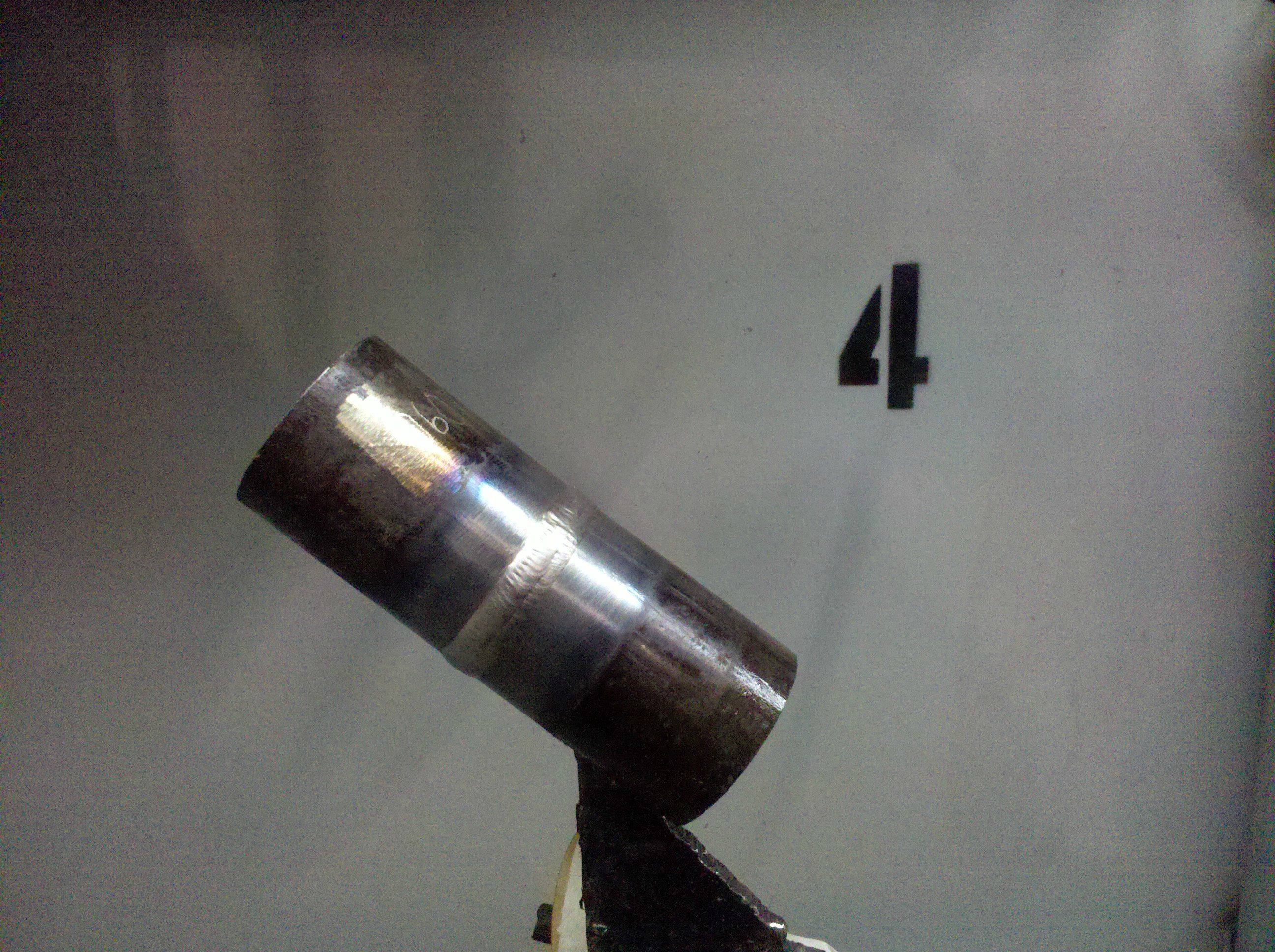

Our newest.

I've posted some of the BS i've made in here. But this is where i work.

It is what i would consider a "clean" shop. We do a lot of high end stuff for the army, automotive, and medical field.

I work in a machine shop with 3 CnC machines, a devlieg, CnC lathe, other assorted machines bridgeport, grinders, ect. and a fabricating shop in the back where i work.

I sometimes operate the CnC's, but it's boring as hell.

Our newest.

I've posted some of the BS i've made in here. But this is where i work.

It is what i would consider a "clean" shop. We do a lot of high end stuff for the army, automotive, and medical field.

Last edited by Erat; 04-24-2013 at 07:34 AM.

#8

I used to work in a machine shop, first as a an operator, and then as a setup guy. Pretty great stuff, they had all sorts of machines, including a 9 axis cnc lathe. The stuff made there was crazy, from missile parts to government secret stuff hid behind a screen labeled some acronym. We even made parts for jetlev, yeah that water powered jet pack, I have one of the pressure nozzles here in my collection of scrap parts. Unfortunately I hated being a worker ant employees in the eyes of the multi million dollar company decimal engineering. I also worked at Pettit racing for a while, doing lots of work on rx7s, and making all of the products that were sold, ie, charge tubing, welding and finishing intercoolers, machining his Greddy replica elbows, battery trays, blah blah. Lots of random stuff. But again, being an employee was just that. I'm a lot more happy now just doing as many custom fab jobs as I can handle. It's easier, more profitable, and allows me the creative design freedom you usually can't have working for someone.

#9

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

^ You're living my overall goal. Being "just the worker" is already getting old. Having ideas in my head and knowing how i'm going to go about something only to have my boss shoot it down and come up with a completely bogus way of doing things is annoying. But i'm young, and i'll stick it out for as long as i can tolerate. Doing custom work, repair work, having my own business is my goal.

#10

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2008

Location: Cromwell CT

Posts: 1,146

Total Cats: 56

I agree, but at the same time I truly enjoy my job stability, the goal with a big company is to make your self as close as possible to indispensable. I like not having to worry about medical benefits , and we have insane profit sharing and retirement. Not to mention great pay and sick time.

I always wanted my own business, but I decided I like steady income and stable healthcare over creativity and freedom. I have access to great resources to do my projects "G-jobs " so I'm content with being a worker bee

I always wanted my own business, but I decided I like steady income and stable healthcare over creativity and freedom. I have access to great resources to do my projects "G-jobs " so I'm content with being a worker bee

#13

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,190

Total Cats: 1,135

Our biggest winch could (and did) pull a freight car up a cliff, they weren't high speed gear boxes taking racing abuse. I understand you're partially joking (I think), but I actually discussed this with my boss. We made up to a quality 6 or 8 I think, he said auto transmission gears should be one or two steps better than what we could do. I mentioned Quaife had gear sets for $3.5k or whatever the price is and he said that was a very reasonable price.

Quality Gear Manufacturing Standards - ISO 9001, AGMA Standards - American Gear, Inc.

Quality Gear Manufacturing Standards - ISO 9001, AGMA Standards - American Gear, Inc.

#14

^ You're living my overall goal. Being "just the worker" is already getting old. Having ideas in my head and knowing how i'm going to go about something only to have my boss shoot it down and come up with a completely bogus way of doing things is annoying. But i'm young, and i'll stick it out for as long as i can tolerate. Doing custom work, repair work, having my own business is my goal.

#15

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

I just need to be given a chance. I know it sounds petty, but on a daily basis i'm told how exactly to do so many things down to the very last minute detail. It's exhausting.

Even if 80% of the work is reading off a print.

I'm 22, but every day i think about it more and more. I need to just start off doing small side jobs for people and take it from there.

Even if 80% of the work is reading off a print.

I'm 22, but every day i think about it more and more. I need to just start off doing small side jobs for people and take it from there.

#18

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

Made these at work.

That's 1.5" material. They didn't tell me what turbo was being strapped to it. But it's clearly an outlet flange (silly design for wastegate flapper relief IMO). Not even sure if a pipe is welded or just bolted on to it. I do know it's for a turbo diesel.

Not my design. Just thought you guys would enjoy the look.

That's 1.5" material. They didn't tell me what turbo was being strapped to it. But it's clearly an outlet flange (silly design for wastegate flapper relief IMO). Not even sure if a pipe is welded or just bolted on to it. I do know it's for a turbo diesel.

Not my design. Just thought you guys would enjoy the look.

#19

Im doing fab work full time now.

Just moved into an industrial unit 5 weeks ago, its a pretty good size, about 1600^2 feet.

Started off doing odd jobs for friends, now my average customer comes from around 2 hours away.

Im not raking it in I still dont have a hoist-trying to find a 240v one is difficult- but I have plenty of work to pay the bills and thats good enough for me at this stage, and work is only getting busier.

I figure if you are passionate about what you do, dont take the ****, and ALWAYS make sure the customer is satisfied you will always be able to pay your bills working for yourself, in any industry.

Dann

PS: not sure if the US has that saying, but not taking the **** is "To take the **** is an expression meaning to mock, tease, ridicule or scoff. Take the Mickey etc variations"

So in other words, do a good honest job with no BS.

Just moved into an industrial unit 5 weeks ago, its a pretty good size, about 1600^2 feet.

Started off doing odd jobs for friends, now my average customer comes from around 2 hours away.

Im not raking it in I still dont have a hoist-trying to find a 240v one is difficult- but I have plenty of work to pay the bills and thats good enough for me at this stage, and work is only getting busier.

I figure if you are passionate about what you do, dont take the ****, and ALWAYS make sure the customer is satisfied you will always be able to pay your bills working for yourself, in any industry.

Dann

PS: not sure if the US has that saying, but not taking the **** is "To take the **** is an expression meaning to mock, tease, ridicule or scoff. Take the Mickey etc variations"

So in other words, do a good honest job with no BS.