Implementation of the Joe Perez Purge Valve Mod for AC Idle

#1

Elite Member

Thread Starter

iTrader: (4)

Join Date: Mar 2008

Location: Granbury, TX

Posts: 6,301

Total Cats: 696

I implemented the Purge Valve mod on my MSPNP last week. The basic idea is to apply power to the Purge Valve when the AC compressor is engaged. This causes a vacuum leak to increase engine speed. Because this happens right away, it helps prevent RPM drop while the normal closed loop idle controls catch up. In other words, no stalls. This is pretty important to me at the moment. June 2011 was, apparently, the hottest June on record since 1980. Average high temperature in my area was ~100°F with many days much hotter.

This modification can be done entirely inside the MS. The wires that are needed already exist in the stock harness. The ECU output to the AC relay is on the "L/B" line (Pin 1J on 90-93s), and the output to the Purge Valve is on the "Y/R" line (Pin 2X on 90-93s). I added a couple of diodes to my installation for safety, an isolation diode between "L/B" and "Y/R," and a flyback voltage diode from "Y/R" to ECU power on "W/R" (Pin 1B on 90-93s). Schematic is simple:

"L/B" Pin 1J---|<---"Y/R" Pin 2X--->|---"W/R" Pin1B

(where --->|--- is a 1N400X diode)

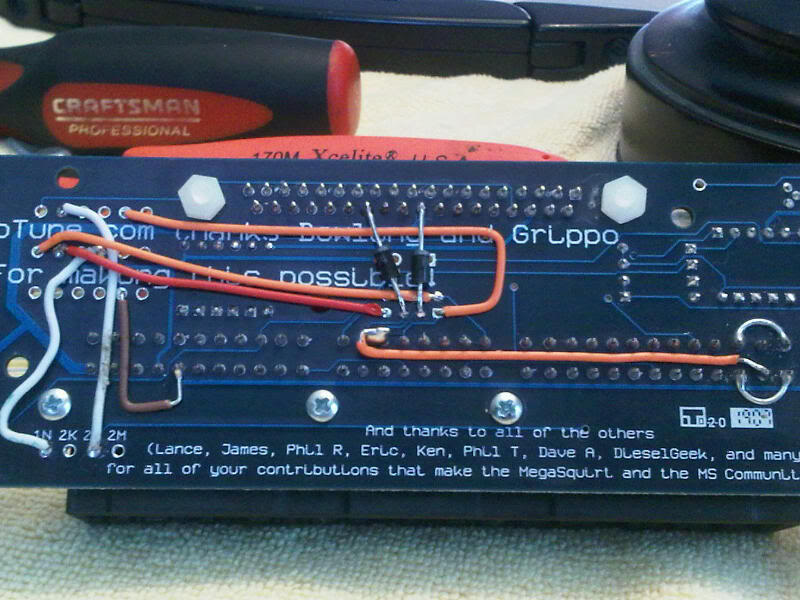

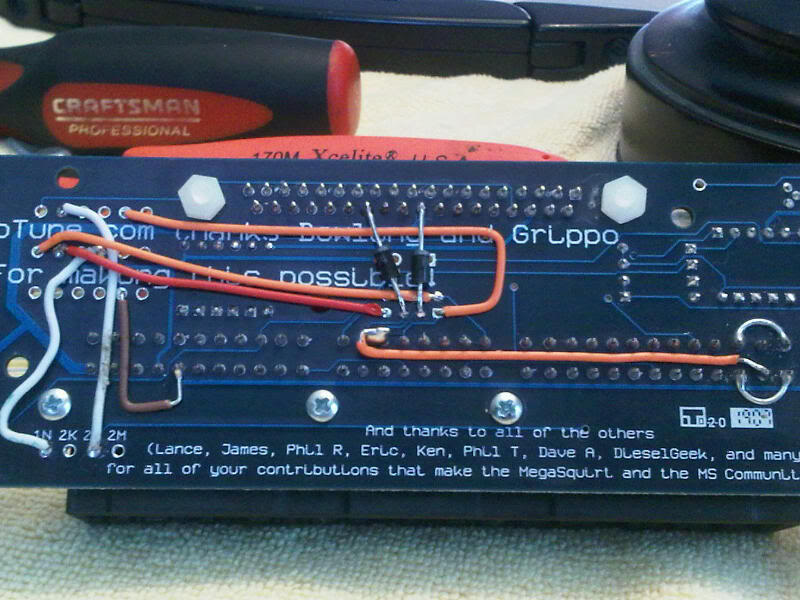

Here's a picture of my MSPNP daughter board mods:

The two diodes go from unused header pins to the 37-pin connector at pins 28 (internally connected to ECU power on Pin 1B) and 31 (connected to Pin 1J as part of an earlier spark table switching mod). In addition, a jumper line was soldered between the unused header pins and Pin 2X.

In the engine compartment, the purge valve is disconnected from the charcoal cannister. In my case, the cannister had already been removed to make way for my WI pump. The only other change was to add a small-engine inline fuel filter to filter the air from the purge valve. Here's a picture:

Bottom line on this modification is that it adds ~100-150RPM when activated. Most of the restriction comes from the length of rubber tube between the purge valve and the intake manifold. With different components, you could increase that RPM bump quite a bit, although at some point you would need to start worrying about boost leaks. Unlike the stock ECU, the MS doesn't disengage the AC at high throttle settings. If you're willing to hack the harness a bit, you could wire a TPS switch inline to perform that function.

Anyway, I'm pretty happy with the setup. Between the spark table switching (adds 8° of ignition advance when the AC relay activates) and this purge valve mod, my idle operation with AC on in the extreme TX heat has been pretty decent.

YMMV.

This modification can be done entirely inside the MS. The wires that are needed already exist in the stock harness. The ECU output to the AC relay is on the "L/B" line (Pin 1J on 90-93s), and the output to the Purge Valve is on the "Y/R" line (Pin 2X on 90-93s). I added a couple of diodes to my installation for safety, an isolation diode between "L/B" and "Y/R," and a flyback voltage diode from "Y/R" to ECU power on "W/R" (Pin 1B on 90-93s). Schematic is simple:

"L/B" Pin 1J---|<---"Y/R" Pin 2X--->|---"W/R" Pin1B

(where --->|--- is a 1N400X diode)

Here's a picture of my MSPNP daughter board mods:

The two diodes go from unused header pins to the 37-pin connector at pins 28 (internally connected to ECU power on Pin 1B) and 31 (connected to Pin 1J as part of an earlier spark table switching mod). In addition, a jumper line was soldered between the unused header pins and Pin 2X.

In the engine compartment, the purge valve is disconnected from the charcoal cannister. In my case, the cannister had already been removed to make way for my WI pump. The only other change was to add a small-engine inline fuel filter to filter the air from the purge valve. Here's a picture:

Bottom line on this modification is that it adds ~100-150RPM when activated. Most of the restriction comes from the length of rubber tube between the purge valve and the intake manifold. With different components, you could increase that RPM bump quite a bit, although at some point you would need to start worrying about boost leaks. Unlike the stock ECU, the MS doesn't disengage the AC at high throttle settings. If you're willing to hack the harness a bit, you could wire a TPS switch inline to perform that function.

Anyway, I'm pretty happy with the setup. Between the spark table switching (adds 8° of ignition advance when the AC relay activates) and this purge valve mod, my idle operation with AC on in the extreme TX heat has been pretty decent.

YMMV.

#3

Nice! I wish I had the skills to do all my mods on the board, so much cleaner that way.

I found running 2 air solenoids in parallel worked much better than one. Also gave them a headstart by placing a time delay relay on the compressor. I still have to figure out the correct delay- the choices are almost no delay, in the hope they cancel out, or a longer delay to let the idle go up and the code to settle down before hitting it with the AC load. Jason made a post of how to build the delay circuit on the board.

Gotta find me some of those inline fuel filters, I'm sucking in engine bay air at the moment

I found running 2 air solenoids in parallel worked much better than one. Also gave them a headstart by placing a time delay relay on the compressor. I still have to figure out the correct delay- the choices are almost no delay, in the hope they cancel out, or a longer delay to let the idle go up and the code to settle down before hitting it with the AC load. Jason made a post of how to build the delay circuit on the board.

Gotta find me some of those inline fuel filters, I'm sucking in engine bay air at the moment

Last edited by Greg G; 07-05-2011 at 10:23 PM.

#4

Elite Member

Thread Starter

iTrader: (4)

Join Date: Mar 2008

Location: Granbury, TX

Posts: 6,301

Total Cats: 696

Nice! I wish I had the skills to do all my mods on the board, so much cleaner that way.

I found running 2 air solenoids in parallel worked much better than one. Also gave them a headstart by placing a time delay relay on the compressor. I still have to figure out the correct delay- the choices are almost no delay, in the hope they cancel out, or a longer delay to let the idle go up and the code to settle down before hitting it with the AC load. Jason made a post of how to build the delay circuit on the board.

Gotta find me some of those inline fuel filters, I'm sucking in engine bay air at the moment

I found running 2 air solenoids in parallel worked much better than one. Also gave them a headstart by placing a time delay relay on the compressor. I still have to figure out the correct delay- the choices are almost no delay, in the hope they cancel out, or a longer delay to let the idle go up and the code to settle down before hitting it with the AC load. Jason made a post of how to build the delay circuit on the board.

Gotta find me some of those inline fuel filters, I'm sucking in engine bay air at the moment

With 2 parallel air solenoid valves (which should give a 250-300RPM bump), do you notice much in the way of boost leak?

Try Home Depot for the fuel filters. The filter media is stainless steel mesh.

Thread

Thread Starter

Forum

Replies

Last Post

stoves

Suspension, Brakes, Drivetrain

5

04-21-2016 03:00 PM