The Miata Bushing MEGAthread: Heirarchy, DIY delrin dimensions, info and discussion

#241

SadFab CEO

Thread Starter

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

I don't know what happened with the links, here they are:

https://www.miataturbo.net/suspensio...rection-74732/

https://www.miataturbo.net/suspensio...takeoff-75495/

Let me throw this in here, too.

https://www.miataturbo.net/suspensio...ive-pro-80290/

https://www.miataturbo.net/suspensio...rection-74732/

https://www.miataturbo.net/suspensio...takeoff-75495/

Let me throw this in here, too.

https://www.miataturbo.net/suspensio...ive-pro-80290/

Very clear, thank you.

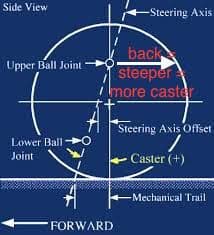

I am coming from a Macpherson strut car, where I used to run alot of caster 6deg+. Having alot of caster allows you to run less static camber because of camber gain. This, in-turn, has better contact patch under braking and can increase your ultimate turning grip.

I guess I need to do more research on set-ups but I was thinking getting camber is easier than caster. I will be running a extended lower ball joint already and if I needed more static camber I could always make offset FUCA bushings (I may have to run a spacer for wheel clearance, no biggy).

I guess I curious about a setup like this:

Offset FUCA (adds camber)

Extended Lower balljoint (adds Camber)

Offset FLCA-R (adds caster, slightly decreases camber)

Poly FLCA-F

I'm not sure where that would leave you as far as alignment specs but Ill be doing some more research. Seems like to much caster can lead to corner jacking and bump steer issues possibly.

I am coming from a Macpherson strut car, where I used to run alot of caster 6deg+. Having alot of caster allows you to run less static camber because of camber gain. This, in-turn, has better contact patch under braking and can increase your ultimate turning grip.

I guess I need to do more research on set-ups but I was thinking getting camber is easier than caster. I will be running a extended lower ball joint already and if I needed more static camber I could always make offset FUCA bushings (I may have to run a spacer for wheel clearance, no biggy).

I guess I curious about a setup like this:

Offset FUCA (adds camber)

Extended Lower balljoint (adds Camber)

Offset FLCA-R (adds caster, slightly decreases camber)

Poly FLCA-F

I'm not sure where that would leave you as far as alignment specs but Ill be doing some more research. Seems like to much caster can lead to corner jacking and bump steer issues possibly.

Yup, another reason I wont do it. Especially on that offset pictured, the thin side is already kinda thin, grooving that could possibly make the bushing collapse. It was one of those, 3 is better than nothing things.

#242

Elite Member

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

FUCA-

1.There is no inner thrust face period. The bolt passed through a tube in the subframe, which is around the same diameter as the steel sleeve. So you would have to add a washer to make a thrust face for the flanges that would face each other.

2.. There is little relative load on this arm, 1 thrust face is fine.

3. Assuming you did #1, you would have to machine the sleeve length specific to each car. Alternatively, you could make sure that the sleeve bore lengths are within a few thou of each other, and that the gap between them is the same, minus flange thickness, as the mounting point width. And that whole stack-up cant exceed a few thou. Delrin is not squishy, so in order for the rear facing or front facing thrust surfaces to both take a their full load, you would have to fit them to each arm so there is probably around a 0.002" gap. There is too much variation in arms and subframes, and they are definitely not within 0.002" in any dimension. If not, one thrust surface will makes contact first, and the arm will have to bend the amount of the difference between sleeve length and flange gap on the other bushing before it make contact, and even then they are very unequally loaded. Never mind the fact that would make things kind of tight and a pita to install for the end user, for almost no benefit. This is true of all locations, and one of the benefits of running poly in each lower is that it mitigate this on the arms that carry the majority of the loads on the car (the LCAs).

1.There is no inner thrust face period. The bolt passed through a tube in the subframe, which is around the same diameter as the steel sleeve. So you would have to add a washer to make a thrust face for the flanges that would face each other.

2.. There is little relative load on this arm, 1 thrust face is fine.

3. Assuming you did #1, you would have to machine the sleeve length specific to each car. Alternatively, you could make sure that the sleeve bore lengths are within a few thou of each other, and that the gap between them is the same, minus flange thickness, as the mounting point width. And that whole stack-up cant exceed a few thou. Delrin is not squishy, so in order for the rear facing or front facing thrust surfaces to both take a their full load, you would have to fit them to each arm so there is probably around a 0.002" gap. There is too much variation in arms and subframes, and they are definitely not within 0.002" in any dimension. If not, one thrust surface will makes contact first, and the arm will have to bend the amount of the difference between sleeve length and flange gap on the other bushing before it make contact, and even then they are very unequally loaded. Never mind the fact that would make things kind of tight and a pita to install for the end user, for almost no benefit. This is true of all locations, and one of the benefits of running poly in each lower is that it mitigate this on the arms that carry the majority of the loads on the car (the LCAs).

Pertinent statements are highlighted in bold above.

Regardless of design, ideally there should be no gap in the stack. (Stack: FUCA front bushing sleeve + tube in subframe + FUCA rear bushing sleeve)

Also, sleeves should not protrude from either end of the delrin bushings. Otherwise, the entire FUCA would slide fore and aft on the sleeves, and the sliding distance would be equal to the total sleeve protrusion from the delrin bushings.

Let's suppose sleeves are protruding 0.5 mm on either side on both bushings. This would mean a total travel distance of 1 mm.

Given the spindle height, a 1 mm travel will alter caster angle by 2.69 degrees - a 2 mm travel distance creates 5.38 degree caster variance.

So, there has to be a very precise fit for the FUCA bushings on either side of the subframe tube.

I really can not figure out what difference a 1 piece or 2 piece design makes in the light of the facts I tried to explain above.

If there is any gap in the stack at all, one surface will make contact first, like you said.

It's not like you can pull your one piece bushings into place by torquing the big bolt nut, because both bushings have lips on them. Can't move.

Bolt ends/washers etc make sure sleeves can not move in beyond flush with delrin surface.

All of these add up to one inevitable fact: Sleeves must have very precise dimensions.

And, once you have very precise sleeves, it really makes no difference whether you have 1 or 2 piece bushings, or if you are using washers on both ends of the subframe tubing.

All you need to do is subtract the thickness of the washers from the sleeve length and make them exactly that long.

Like I said, I am having the worst time comprehending your approach.

What the hell am I missing here?

-----------

Completely unrelated:

I am chrome plating my sleeves for the smoothest possible articulation, so there.

Thank you, and sorry for dragging this thing this far.

Last edited by Godless Commie; 03-17-2017 at 05:16 PM.

#243

Now, if one were to move the FUCA towards the front by splitting that 11 mm difference like, say, 8 mm front and 3 mm rear, that would angle the upright towards the front at the top, yielding more caster.

I can never get the prescribed 5.5 degrees, best I can get is around 3 degrees or so.

Would such a modification be helpful, or am I missing something here?

I can never get the prescribed 5.5 degrees, best I can get is around 3 degrees or so.

Would such a modification be helpful, or am I missing something here?

#247

Caster is the angle between the steering axis and the vertical axis. In a caster, they are parallel, ergo zero caster.

What you're describing is trail (usually measured as a distance between intersection points with the ground), not caster. Also, moving the FUCA forward would potentially decrease trail, not necessarily increase it.

What you're describing is trail (usually measured as a distance between intersection points with the ground), not caster. Also, moving the FUCA forward would potentially decrease trail, not necessarily increase it.