ITT we discuss why not to turbo your daily bent rod

#382

Senior Member

Thread Starter

iTrader: (1)

Join Date: Apr 2011

Location: Columbia, SC

Posts: 1,332

Total Cats: 87

Rutland Black Hi-temp stove cement.

Serious as a heart attack.

Ace hardware usually has it.

Amazon.com - Rutland Stove Gasket Cement Black 10.3 Oz Cartridge - Wall Surface Repair Products

Serious as a heart attack.

Ace hardware usually has it.

Amazon.com - Rutland Stove Gasket Cement Black 10.3 Oz Cartridge - Wall Surface Repair Products

#384

Senior Member

Thread Starter

iTrader: (1)

Join Date: Apr 2011

Location: Columbia, SC

Posts: 1,332

Total Cats: 87

Toying with the idea of building a motor this time next year.

Right here, with just my lazy googling, I am at $1546.50. This is with 0 machine work, and I'm sure I am missing parts. I was just curious a rough idea. I have never had anything machined, but I'm guessing $500 would cover it? I'm at $2000. $3000 I can have it all done by Andrew and it shows up at my door. Decisionssss. Like I said,planning contemplating at least a year out.

Ebay Forged H-beams with ARP Hardware

$232

Supertech 84mm 8.6:1 Pistons + Rings (P4-MA84-N4)

$460.99 + Shipping

Notes: Also considering 11:1, maybe. Probably not.

Main, Connecting Rod, and Thrust Bearings

$39.71 + $26.91 + $10.52 + Shipping

ARP Headstud kit (218-4701)

$119

$103.38

Boundary Oil Pump (Maybe? new OEM is $299...)

$399.99 + shipping

Ebay timing belt / waterpump kit

$59.95

Ebay Full Gasket Kit

$47.05

Right here, with just my lazy googling, I am at $1546.50. This is with 0 machine work, and I'm sure I am missing parts. I was just curious a rough idea. I have never had anything machined, but I'm guessing $500 would cover it? I'm at $2000. $3000 I can have it all done by Andrew and it shows up at my door. Decisionssss. Like I said,

Ebay Forged H-beams with ARP Hardware

$232

Supertech 84mm 8.6:1 Pistons + Rings (P4-MA84-N4)

$460.99 + Shipping

Notes: Also considering 11:1, maybe. Probably not.

Main, Connecting Rod, and Thrust Bearings

$39.71 + $26.91 + $10.52 + Shipping

ARP Headstud kit (218-4701)

$119

$103.38

Boundary Oil Pump (Maybe? new OEM is $299...)

$399.99 + shipping

Ebay timing belt / waterpump kit

$59.95

Ebay Full Gasket Kit

$47.05

#385

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Use weisco rings with the supertechs.

And get an MLS head gasket if you dont have one already.

Also cleaning and resealing oil pan.

New seals everywhere (because why not)

New intake and exhaust manifold gaskets.

Welding a fitting on to oil pan if you havent already.

And get an MLS head gasket if you dont have one already.

Also cleaning and resealing oil pan.

New seals everywhere (because why not)

New intake and exhaust manifold gaskets.

Welding a fitting on to oil pan if you havent already.

#387

Do not do cheap ebay gasket kit. I did that when I did my 1.8 rebuild and I have since replaced almost every main seal that is intended to keep oil inside the engine. Those crappy seals just do not last. I have had front and rear main leaks, cam seal leaks, and valve cover gasket leaks. The Ebay MLS headgasket has worked fine. I didn't use the ebay CAS oring, oil pump o-ring or valve stem seals and have not had a single issue with those seals.

There is nothing more aggravating than spending all that effort to rebuild and end up with an oil leak 6-12months later.

There is nothing more aggravating than spending all that effort to rebuild and end up with an oil leak 6-12months later.

#388

Toying with the idea of building a motor this time next year.

Right here, with just my lazy googling, I am at $1546.50. This is with 0 machine work, and I'm sure I am missing parts. I was just curious a rough idea. I have never had anything machined, but I'm guessing $500 would cover it? I'm at $2000. $3000 I can have it all done by Andrew and it shows up at my door. Decisionssss. Like I said,planning contemplating at least a year out.

Ebay Forged H-beams with ARP Hardware

$232

Supertech 84mm 8.6:1 Pistons + Rings (P4-MA84-N4)

$460.99 + Shipping

Notes: Also considering 11:1, maybe. Probably not.

Main, Connecting Rod, and Thrust Bearings

$39.71 + $26.91 + $10.52 + Shipping

ARP Headstud kit (218-4701)

$119

ARP Main Stud Kit (218-5401)

$103.38

Boundary Oil Pump (Maybe? new OEM is $299...)

$399.99 + shipping

Ebay timing belt / waterpump kit

$59.95

Ebay Full Gasket Kit

$47.05

Right here, with just my lazy googling, I am at $1546.50. This is with 0 machine work, and I'm sure I am missing parts. I was just curious a rough idea. I have never had anything machined, but I'm guessing $500 would cover it? I'm at $2000. $3000 I can have it all done by Andrew and it shows up at my door. Decisionssss. Like I said,

Ebay Forged H-beams with ARP Hardware

$232

Supertech 84mm 8.6:1 Pistons + Rings (P4-MA84-N4)

$460.99 + Shipping

Notes: Also considering 11:1, maybe. Probably not.

Main, Connecting Rod, and Thrust Bearings

$39.71 + $26.91 + $10.52 + Shipping

ARP Headstud kit (218-4701)

$119

ARP Main Stud Kit (218-5401)

$103.38

Boundary Oil Pump (Maybe? new OEM is $299...)

$399.99 + shipping

Ebay timing belt / waterpump kit

$59.95

Ebay Full Gasket Kit

$47.05

I'd change that to Weisco pistons, ebay rods, stock main bolts (unless you are prepared to have the mains line honed for the studs) stock oil pump, mazda gaskets, ARP head bolts are optional. If you don't have a good calibrated torque wrench, I'd buy that instead of head studs.

#390

Why what? Why use stock bolts? Because they are plenty strong enough unless he's trying to spin it to the moon. ARPs are going to put more clamping force when torqued vs the stock bolts, so that means you have to line hone the caps with the studs installed to get the bores back in line. AKA machine shop work, more money in bottom end.

#391

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

Do not do cheap ebay gasket kit. I did that when I did my 1.8 rebuild and I have since replaced almost every main seal that is intended to keep oil inside the engine. Those crappy seals just do not last. I have had front and rear main leaks, cam seal leaks, and valve cover gasket leaks. The Ebay MLS headgasket has worked fine. I didn't use the ebay CAS oring, oil pump o-ring or valve stem seals and have not had a single issue with those seals.

There is nothing more aggravating than spending all that effort to rebuild and end up with an oil leak 6-12months later.

There is nothing more aggravating than spending all that effort to rebuild and end up with an oil leak 6-12months later.

#392

Senior Member

Thread Starter

iTrader: (1)

Join Date: Apr 2011

Location: Columbia, SC

Posts: 1,332

Total Cats: 87

Why what? Why use stock bolts? Because they are plenty strong enough unless he's trying to spin it to the moon. ARPs are going to put more clamping force when torqued vs the stock bolts, so that means you have to line hone the caps with the studs installed to get the bores back in line. AKA machine shop work, more money in bottom end.

What's your goal for the engine?

I'd change that to Weisco pistons, ebay rods, stock main bolts (unless you are prepared to have the mains line honed for the studs) stock oil pump, mazda gaskets, ARP head bolts are optional. If you don't have a good calibrated torque wrench, I'd buy that instead of head studs.

I'd change that to Weisco pistons, ebay rods, stock main bolts (unless you are prepared to have the mains line honed for the studs) stock oil pump, mazda gaskets, ARP head bolts are optional. If you don't have a good calibrated torque wrench, I'd buy that instead of head studs.

I'll price mazda gaskets.

#393

Senior Member

Thread Starter

iTrader: (1)

Join Date: Apr 2011

Location: Columbia, SC

Posts: 1,332

Total Cats: 87

Does the NB stock knock sensor location see oil? If so, I am 99.9999999% sure that is where my substantial oil leak is coming from. That's going to be fun to get to....

Also, I see everyone flaming anyone wiring their fans in parallel, yet I have been unable to find out how to set this up in Tuner Studio so far. Anyone care to enlighten me?

Also, I see everyone flaming anyone wiring their fans in parallel, yet I have been unable to find out how to set this up in Tuner Studio so far. Anyone care to enlighten me?

#395

Senior Member

Thread Starter

iTrader: (1)

Join Date: Apr 2011

Location: Columbia, SC

Posts: 1,332

Total Cats: 87

Knock sensor does not have oil pressure behind it.

Not sure what you're asking about on the fans and tuner studio. Just how to setup the fans to turn on? Wiring the fans in parallel is a wiring job as the name says. Controlling them can be done however you want in tunerstudio.

Not sure what you're asking about on the fans and tuner studio. Just how to setup the fans to turn on? Wiring the fans in parallel is a wiring job as the name says. Controlling them can be done however you want in tunerstudio.

And I was referring to a checkbox like "turn on a/c fan with radiator fan". As in, a software solution to the requirement for parallel wiring. I know there is one to do the opposite, radiator fan on with a/c.

#397

Retired Mech Design Engr

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 857

A/C fan always comes on with A/C. The other fan can be set with switch to also come on with A/C. Then the A/C fan can also be set to come on / off at the same temps as the main fan. Mission Accomplished.

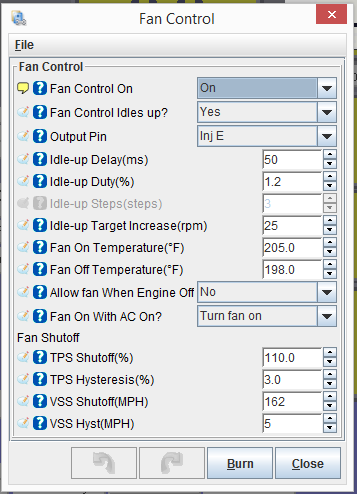

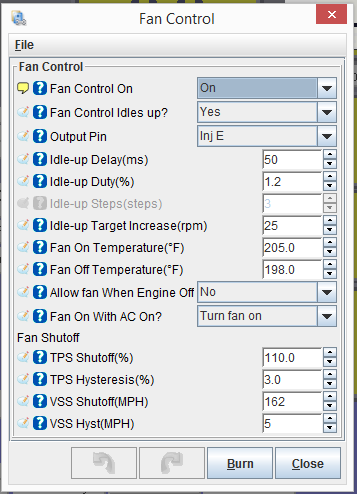

Basic/Load Settings => Fan Control Fan On With AC On? = Turn fan on

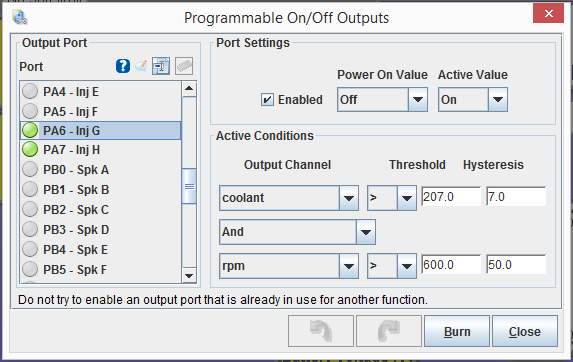

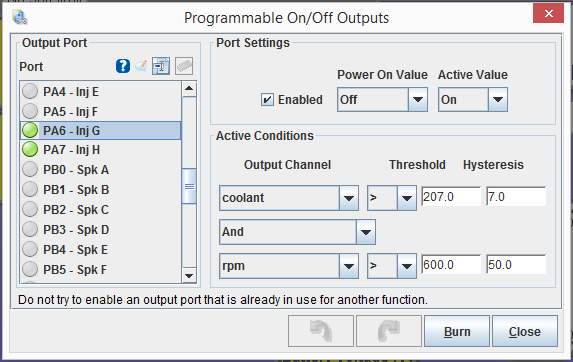

Then, on my Basic MS3, under Advanded Engine / Programmable On/Off Outputs is the A/C fan control, sent to PA6 - Inj G. It is set for coolant > 207, Hysteresis 7

That is actually a 2 degree differential on temps. Main fan 205 / 198 and A/C fan 207 / 200.

Basic/Load Settings => Fan Control Fan On With AC On? = Turn fan on

Then, on my Basic MS3, under Advanded Engine / Programmable On/Off Outputs is the A/C fan control, sent to PA6 - Inj G. It is set for coolant > 207, Hysteresis 7

That is actually a 2 degree differential on temps. Main fan 205 / 198 and A/C fan 207 / 200.

#398

Senior Member

Thread Starter

iTrader: (1)

Join Date: Apr 2011

Location: Columbia, SC

Posts: 1,332

Total Cats: 87

A/C fan always comes on with A/C. The other fan can be set with switch to also come on with A/C. Then the A/C fan can also be set to come on / off at the same temps as the main fan. Mission Accomplished.

Basic/Load Settings => Fan Control Fan On With AC On? = Turn fan on

Then, on my Basic MS3, under Advanded Engine / Programmable On/Off Outputs is the A/C fan control, sent to PA6 - Inj G. It is set for coolant > 207, Hysteresis 7

That is actually a 2 degree differential on temps. Main fan 205 / 198 and A/C fan 207 / 200.

Basic/Load Settings => Fan Control Fan On With AC On? = Turn fan on

Then, on my Basic MS3, under Advanded Engine / Programmable On/Off Outputs is the A/C fan control, sent to PA6 - Inj G. It is set for coolant > 207, Hysteresis 7

That is actually a 2 degree differential on temps. Main fan 205 / 198 and A/C fan 207 / 200.

My car runs super cool (due to the incorrect thermostat I'm running. Long story.) on the interstate on cool days. On warm days it runs ~20deg over the thermostat. But in downtown traffic it has been creeping up into the high 220s low 230s, especially if the a/c is on. I had everything set up for both fans to run with a/c, but my thought is that they may only run with the compressor is on. I'm hoping that maybe this new Programmable i/o setting will help with that. In addition, if I cut a/c off, now I will have both fans helping cool things off faster.

Next step if this doesn't resolve it will be bigger (maybe SPAL) fans. I will be doing some ducting at some point, but probably not soon. In my mind that will be more track-oriented, because as I said, I don't really have much of an issue at cruising speeds once I get the car moving.

EDIT: Thermostat is 170deg. Realized I kept talking about it, but left that tidbit out.

#399

Senior Member

Thread Starter

iTrader: (1)

Join Date: Apr 2011

Location: Columbia, SC

Posts: 1,332

Total Cats: 87

I went to install the exhaust brace I bought from FM, but it does not fit on my MKTurbo exhaust. Not worried about it, as I knew it was a risk going in. Made one instead. Works well, but I can definitely feel exhaust vibrations when decelerating and stuff like that. I have to drive on the interstate for a while tomorrow, so that should be a good test of how bad that is. I may end up adding a piece of rubber on the brace or something. I cannot move the midpipe now. But I have a flex in the downpipe, so I am not very worried about anything breaking.

#400

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Normally the point of the downpipe brace is to support the turbo more. Yours just makes your exhaust vibe your tranny.

Also, bbundy had issues with the clamps like that breaking the pipe. too much stress in one area.

Also, bbundy had issues with the clamps like that breaking the pipe. too much stress in one area.