My Money Pit - part 2 (next time do it right the first time)

#84

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

http://www.youtube.com/watch?v=8VPloV9a-mE

EDIT: OOps 289rwhp

http://www.youtube.com/watch?v=mI9dclLeMqA

Anyway, my circa '92 mount(s) are busted.

I like 1/8 between pipes/trans that move together. As much as possible between the things that don't like the steering. I'm a little nervous with a thumbs width (~5/8") between turbine & steering rod on the current setup i'm building.

#87

Senior Member

Thread Starter

iTrader: (4)

Join Date: Nov 2009

Location: Toronto, ON

Posts: 1,446

Total Cats: 6

This safety wiring business isn't as easy as it looks, damnit. Does the wire between the two nuts have to be rigid to be effective?

I'm just waiting on the new coolant lines to arrive, get a new oil feed line with a 90* fitting and I'll be ready to start it up again. Still unsure if I should go with a new IC and piping or not. Mine does not live up to the rest of the system. I will probably just live with it for now and upgrade later.

I'm just waiting on the new coolant lines to arrive, get a new oil feed line with a 90* fitting and I'll be ready to start it up again. Still unsure if I should go with a new IC and piping or not. Mine does not live up to the rest of the system. I will probably just live with it for now and upgrade later.

Last edited by dgmorr; 03-22-2011 at 09:10 PM.

#90

Senior Member

Thread Starter

iTrader: (4)

Join Date: Nov 2009

Location: Toronto, ON

Posts: 1,446

Total Cats: 6

Nothing really. Just one sub-optimal bend, chipping black paint on steel pipes, hose clamp for the Forge style bov. I was going to have Weirtech make me something nice. All aluminum, new Mishimoto ricer gold IC, minimal silicone connectors, Tial bov, you fancy huh.

http://www.mishimoto.com/mishimoto-m...-all-gold.html

I'll see how it holds up after the first event and decide. I'm surprised the charge pipes fit in the same position even though the turbo is not in the same spot. Either I'm doing it wrong, or <blank>.

Current IC setup, made by Stein. I don't have my own pics of it.

http://www.mishimoto.com/mishimoto-m...-all-gold.html

I'll see how it holds up after the first event and decide. I'm surprised the charge pipes fit in the same position even though the turbo is not in the same spot. Either I'm doing it wrong, or <blank>.

Current IC setup, made by Stein. I don't have my own pics of it.

#91

Senior Member

Thread Starter

iTrader: (4)

Join Date: Nov 2009

Location: Toronto, ON

Posts: 1,446

Total Cats: 6

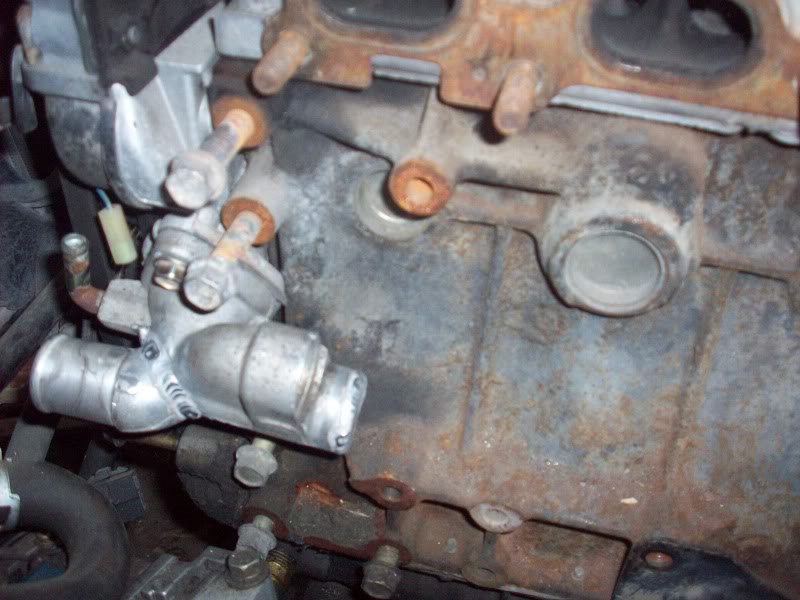

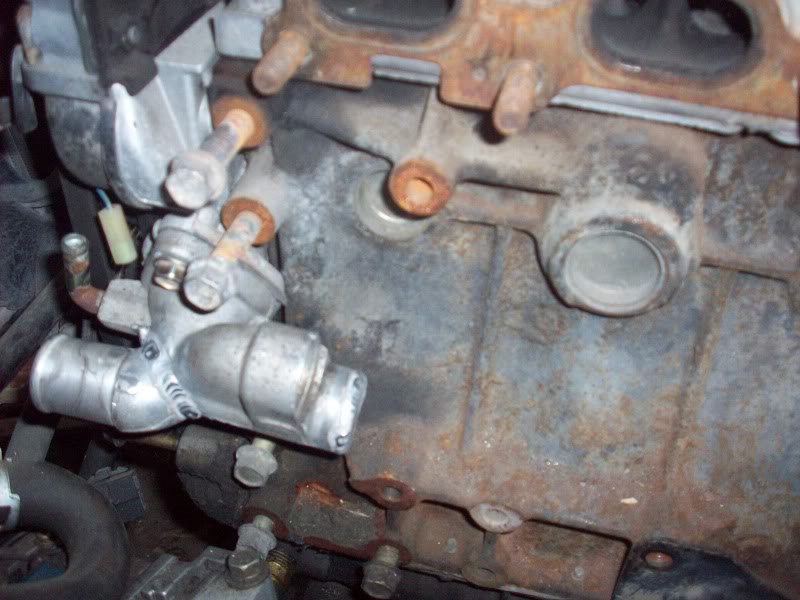

I guess I could have got the car running by now, but I've been dragging my feet on getting a new oil feed line with a 90* off the turbo. Finally went and got it today and some heater hose.

What do you guys typically do to run this heater hose back to the firewall? This hose has a big minimum bend radius and will collapse if I make it neat and tight. I could delete the heater core, but i'd still have to loop this to the back of the head. I have a flipped mixing manifold, so the outlet faces forward. I could get a 90* off the mixing manifold but I want a better idea of how to get it back. Should I just put the stock water pipe in place under the exhaust manifold? I wish I had Abe cut the water neck off and weld it towards the front to keep the water pipe outlet in the stock location. Looking for some creativity here.

I'm also waiting for the water lines to come, damn USPS.

What do you guys typically do to run this heater hose back to the firewall? This hose has a big minimum bend radius and will collapse if I make it neat and tight. I could delete the heater core, but i'd still have to loop this to the back of the head. I have a flipped mixing manifold, so the outlet faces forward. I could get a 90* off the mixing manifold but I want a better idea of how to get it back. Should I just put the stock water pipe in place under the exhaust manifold? I wish I had Abe cut the water neck off and weld it towards the front to keep the water pipe outlet in the stock location. Looking for some creativity here.

I'm also waiting for the water lines to come, damn USPS.

#94

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

I asked Abe what he does for a solution. He showed me yours and also gave me this link to an adapter. Might work out for a cleaner solution for you.

http://cgi.ebay.com/ebaymotors/Inlin...Q5fAccessories

http://cgi.ebay.com/ebaymotors/Inlin...Q5fAccessories

#95

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

Nothing really. Just one sub-optimal bend, chipping black paint on steel pipes, hose clamp for the Forge style bov. I was going to have Weirtech make me something nice. All aluminum, new Mishimoto ricer gold IC, minimal silicone connectors, Tial bov, you fancy huh.

http://www.mishimoto.com/mishimoto-m...-all-gold.html

I'll see how it holds up after the first event and decide. I'm surprised the charge pipes fit in the same position even though the turbo is not in the same spot. Either I'm doing it wrong, or <blank>.

Current IC setup, made by Stein. I don't have my own pics of it.

http://www.mishimoto.com/mishimoto-m...-all-gold.html

I'll see how it holds up after the first event and decide. I'm surprised the charge pipes fit in the same position even though the turbo is not in the same spot. Either I'm doing it wrong, or <blank>.

Current IC setup, made by Stein. I don't have my own pics of it.

word on the street is that aaron was going to stop fabbing and just do flanges....

if you want, i can build you some IC piping too...

bring your car down and i can do it same day. Just give me a week or 2 notice so i can have the day not busy with other projects or racing.

-Matt

#96

Senior Member

Thread Starter

iTrader: (4)

Join Date: Nov 2009

Location: Toronto, ON

Posts: 1,446

Total Cats: 6

I asked Abe what he does for a solution. He showed me yours and also gave me this link to an adapter. Might work out for a cleaner solution for you.

http://cgi.ebay.com/ebaymotors/Inlin...Q5fAccessories

http://cgi.ebay.com/ebaymotors/Inlin...Q5fAccessories

My mixing manifold right now has a 3/4" NPT barbed fitting coming off the end. I'll look for a male NPT plug and see if I can seal it up. JayL sent me pics of how he did his and it looks great.

I've seen someone with the mixing manifold in the factory orientation, but the rad hose end was welded towards the front allowing the water pipe to plug in like normal. It looked like a simple solution that I should have asked for.

word on the street is that aaron was going to stop fabbing and just do flanges....

if you want, i can build you some IC piping too...

bring your car down and i can do it same day. Just give me a week or 2 notice so i can have the day not busy with other projects or racing.

-Matt

if you want, i can build you some IC piping too...

bring your car down and i can do it same day. Just give me a week or 2 notice so i can have the day not busy with other projects or racing.

-Matt

Last edited by dgmorr; 03-25-2011 at 09:49 PM.

#99

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,189

Total Cats: 1,135

Show us please

#100

Curly, the fitting is a 3/4NPT to 3/4" barb adapter.

It was just a DIY solution I suggested since I wasn't sure if you wanted to pay to have one modified. Probably should have asked. I just received your core Saturday and modified it to point the lower rad hose towards the front of the car. If you want, I'll ship you this one.

For future reference (or as a temp solution while the new mixing manifold gets there) you can slide a spring over the hose to keep it from collapsing. Not a bad idea to do it on the oil drain hose either since it will need make a sharp turn towards the oil pan. BTW, that drain fitting looks pretty small, what size is it?

It was just a DIY solution I suggested since I wasn't sure if you wanted to pay to have one modified. Probably should have asked. I just received your core Saturday and modified it to point the lower rad hose towards the front of the car. If you want, I'll ship you this one.

For future reference (or as a temp solution while the new mixing manifold gets there) you can slide a spring over the hose to keep it from collapsing. Not a bad idea to do it on the oil drain hose either since it will need make a sharp turn towards the oil pan. BTW, that drain fitting looks pretty small, what size is it?