Intake Manifold Design Question

#22

The flow entrance orientation is more effective at mitigating flow imbalance then curvature of plenum. Air has a hard time laminarly integrating into a 90 degree to normal flow orientation as it is, make it do it fast, and you end up with turbulence, poor flow, bad performance. So if you can pull the entrant position back and orientate with 15* or more you get great airflow distribution.

This is all kind of mute though compared to proper runner crossection, length, and taper. Even the bellmouth radius could only at very best attribute 1.5% to the flow numbers. Although improper runner entry such as a jagged edge could give -9%.

This is why manifolds are always trades. Cross section, length, and taper all directly interact with operation range. If even any two are incompatibly combined (large cross section and long runner) then you get the worst effects of both. So the systems have to be very knowledgably combined, and even then tested for proper performance.

This is all kind of mute though compared to proper runner crossection, length, and taper. Even the bellmouth radius could only at very best attribute 1.5% to the flow numbers. Although improper runner entry such as a jagged edge could give -9%.

This is why manifolds are always trades. Cross section, length, and taper all directly interact with operation range. If even any two are incompatibly combined (large cross section and long runner) then you get the worst effects of both. So the systems have to be very knowledgably combined, and even then tested for proper performance.

#23

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,027

Total Cats: 6,593

That's pretty much what I'm talking about. It'd be nice to know what the scale of the color gradient is, but there is clearly a semi-linear variance in pressure across the ports.

VW Beetle, 1932:

Continental O-520 (aircraft), 1963:

VW Beetle, 1971:

Subaru WRX STi, 2008:

76 years and counting. Boxer engines are just damn near impossible to design a short-runner plenum intake for. But is this a good thing or a bad thing? Here's one that seems to break all the rules:

No plenum and virtually no runners. Yet this has been the standard in hi-performance carburetion for 40 years, and the design is still used to this day.

VW Beetle, 1932:

Continental O-520 (aircraft), 1963:

VW Beetle, 1971:

Subaru WRX STi, 2008:

76 years and counting. Boxer engines are just damn near impossible to design a short-runner plenum intake for. But is this a good thing or a bad thing? Here's one that seems to break all the rules:

No plenum and virtually no runners. Yet this has been the standard in hi-performance carburetion for 40 years, and the design is still used to this day.

#24

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,027

Total Cats: 6,593

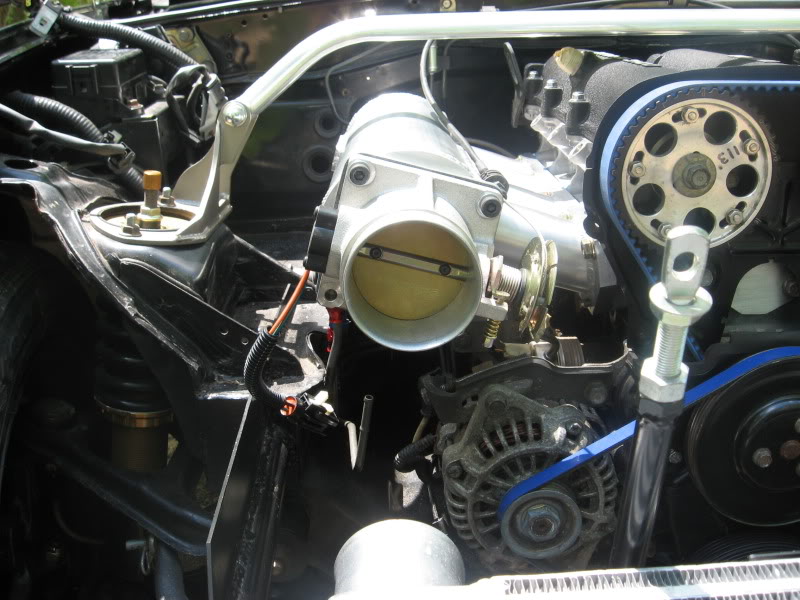

The thing I'm trying to grasp:

A plenum between the throttle body and the intake ports is apparently beneficial insofar as that it is the most efficient means of moving air into the engine, yes? Why? And what are the advantages (if any) to a long tubular intake manifold design such as the one pictured on the Toyota above?

A plenum between the throttle body and the intake ports is apparently beneficial insofar as that it is the most efficient means of moving air into the engine, yes? Why? And what are the advantages (if any) to a long tubular intake manifold design such as the one pictured on the Toyota above?

#25

Elite Member

Thread Starter

iTrader: (7)

Join Date: Apr 2006

Location: VaBch, VA

Posts: 6,451

Total Cats: 322

Hmm... I'm glad I asked the question. I've been reworking my build list and trying to make a super-accurate cost-sheet of exactly what it's gonna take me to replicate "The Machine". Cali 91 octane is going to hurt as I approach the efficiency limits of the 2560, which I no doubt will. I need all the flow help I can get, and an IM seems required if I've got a prayer of 300whp on stock internals. Realistically, as long as I'm in California, I think I should aim in the 280whp range. The temptation to throw in a few more degrees of timing and one more psi just to hit my numbers might be too much.

I just found this manifold... it is a front-mount TB, but the TB is offset on the face, evidently, presumably to help equalize flow into the runners? And the cylinder looks like it's made from diamond-plate... cool!

I just found this manifold... it is a front-mount TB, but the TB is offset on the face, evidently, presumably to help equalize flow into the runners? And the cylinder looks like it's made from diamond-plate... cool!

#26

Elite Member

Thread Starter

iTrader: (7)

Join Date: Apr 2006

Location: VaBch, VA

Posts: 6,451

Total Cats: 322

I hope Emilio sees this thread. I was at 949 a few weeks back when Oscar brought over his Rotrex car, and we were talking about all sorts of IM stuff. Packaging constraints seem to be the achilles heel in the '99+ cars. If I remember right, he said the 90-93 IM's were the best, properly tuned and very efficient. The VICS system totally destroyed any chance the 99+ IM's would have of being a "good" design, starting with the double-jog just past the TB to get into the plenum, the runners aren't the right length, etc...

I have no packaging constraints and no EGR worries... so I'm motivated solely by what works.

More interesting IM's:

I have no packaging constraints and no EGR worries... so I'm motivated solely by what works.

More interesting IM's:

#27

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,494

Total Cats: 4,080

It's possible the length of the runners makes up for the need of a plenum. Ideally the "standard" is 80% volume of displacement for N/A and 120-150% for FI.

But aren't the boxer motors notorious for crazy high torque bursts and **** for top-end past 3K?

like this:

162rwtq loss from 3600 to 6800RPM.

#30

The thing I'm trying to grasp:

A plenum between the throttle body and the intake ports is apparently beneficial insofar as that it is the most efficient means of moving air into the engine, yes? Why? And what are the advantages (if any) to a long tubular intake manifold design such as the one pictured on the Toyota above?

A plenum between the throttle body and the intake ports is apparently beneficial insofar as that it is the most efficient means of moving air into the engine, yes? Why? And what are the advantages (if any) to a long tubular intake manifold design such as the one pictured on the Toyota above?

I'm the air as the cylinder is opening. Immidiately upon cracking the intake valve I feel negative pressure from good exhaust tuning (hopefully). A small pressure wave begins extending up the port in the head. The piston begins comming down the port. This induces a further pressure drop, and a continum of "low pressure". These waves move up the port as the speed of sound. First pressure wave hits the plenum. ********* NOTICE****** no air from the plenum has actually even moved yet!!!! When the wave hits the plenum the depression causes the molecules to flood into the low pressure pocket, this wave spreads through the plenum, but is significantly decreased in magnitude as operable surface area for inflow expands dramatically with every tick of radius because its a sphere now. The air moves down the tube until the valve closes. The valve in the neighboring cylinder begins to open.

NOW THIS IS THE PART WHERE A BIG PLENUM HELPS.

Since the next valve is open and the wave is still compacting in the next runner then this means air is basically flowing in the wrong direction, and there is a low pressure area in front of the runner your trying to fill. The next pressure wave starts from the valve and flows up just like the last except when it reaches the plenum instead of a hearty hello and a red carpet, he gets a couple of disorderly molecules moving the wrong direction.

The larger you make the plenum the smaller the changes in pressure differential across the manifold, and the better the filling for each port. The goal is to get each port 100% of the pressure coming out of the throttle every revolution so you get the best mass flow.

There is an upper limit just like for capacitors. At some point you just stop getting returns, and the plenum should be as small as humanly posisble if it is throttled volume because transient response will suffer inhumanely from large plenums. The S2000 for instance uses one of the smallest plenums for its engine size PERIOD, but is shaped to ensure equal cylinder filling, and so that each pulse does not interfere with the filling of the next cylinder. You can have both, you just need a super computer to do the calculations.

#31

Elite Member

Thread Starter

iTrader: (7)

Join Date: Apr 2006

Location: VaBch, VA

Posts: 6,451

Total Cats: 322

Check this guy out... never seen this website before.

FE DOHC

His manifold is DIY using the OEM flange, and welding runners and the plenum directly to that (Braineak style). The plenum just looks like some sheet-metal bent and cut.

It also looks like they've offset the TB towards the middle/bottom of the front face of the plenum, while the runners are on the top-half. This looks to be a similar engineering design to one I posted earlier. The air doesn't necessarily have a direct path down the plenum into the runners... the air has to lean a little if you catch my drift.

FE DOHC

His manifold is DIY using the OEM flange, and welding runners and the plenum directly to that (Braineak style). The plenum just looks like some sheet-metal bent and cut.

It also looks like they've offset the TB towards the middle/bottom of the front face of the plenum, while the runners are on the top-half. This looks to be a similar engineering design to one I posted earlier. The air doesn't necessarily have a direct path down the plenum into the runners... the air has to lean a little if you catch my drift.

#32

with a 2 piece design like that cobra manifold you actually build an ITB turbo application you would just run your velocity stack in to the box. Of course that would be a really lot of work but do able and would also create more power in higher rpms. with a 99-00 head you could probably build power up to about 8000rpms

#34

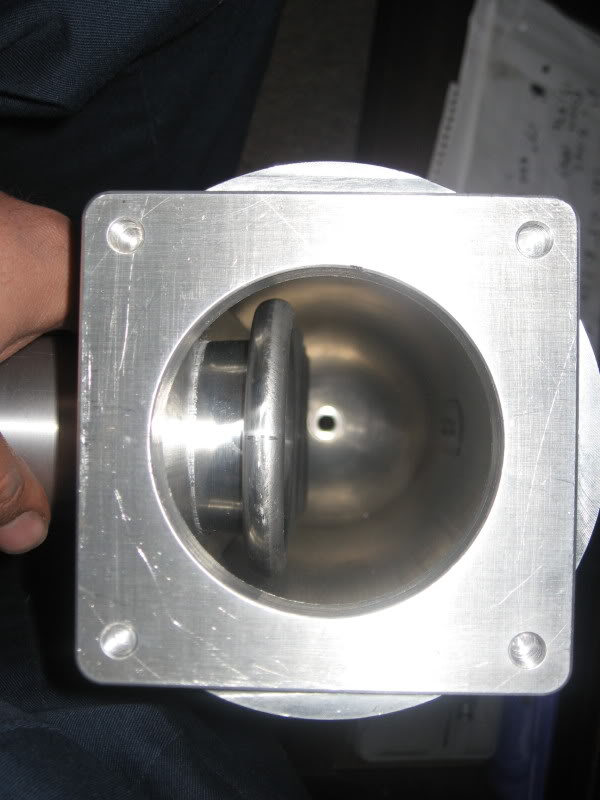

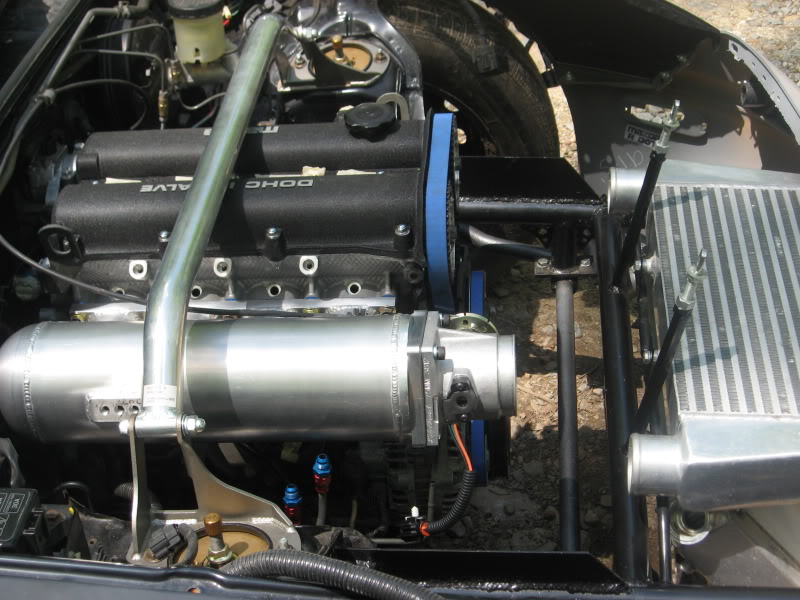

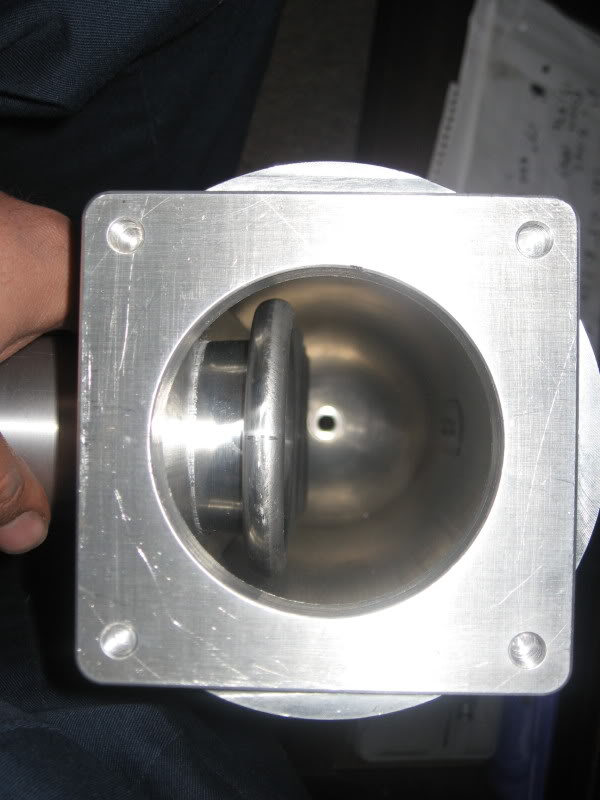

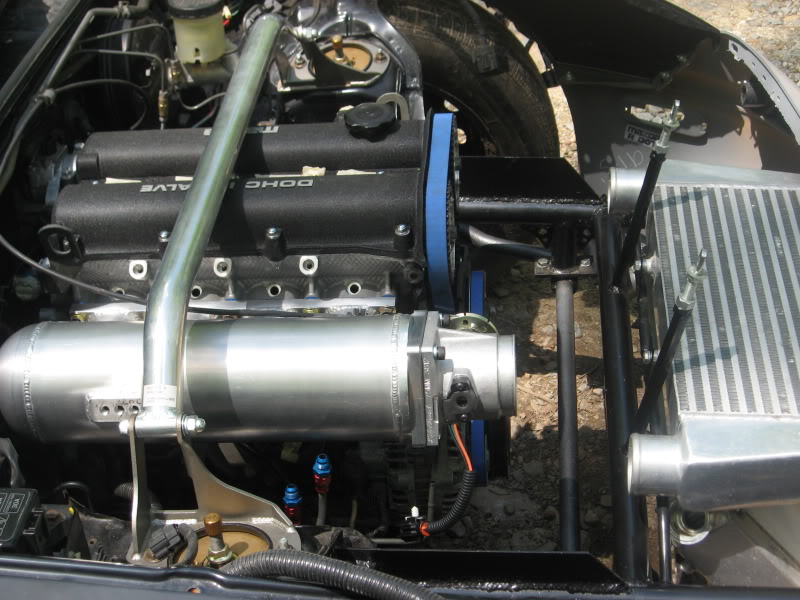

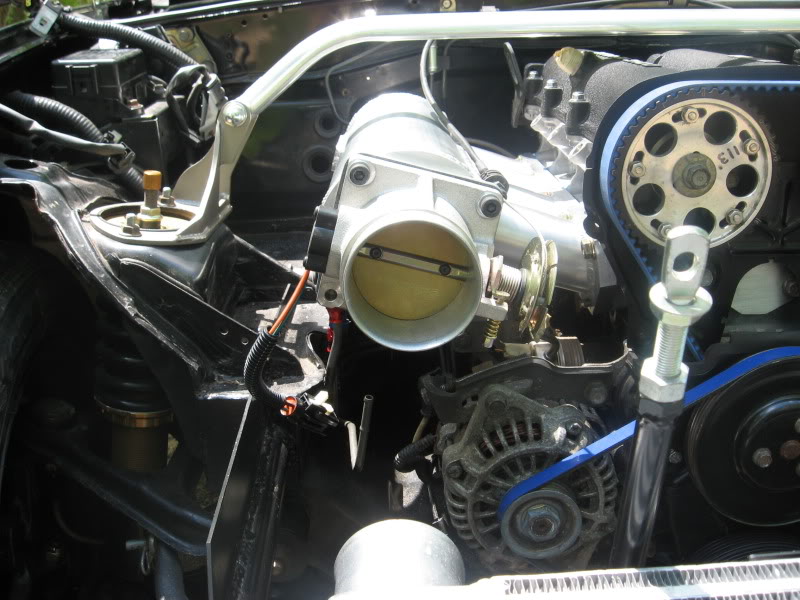

here is the manifold that i just finished for my car, 99 head

manifold is frequency tuned( dynamic flow effect) between 6500- 9200 rpm, my engine will be reving to 9000-9200

i can post all the numbers for 3rd and 4th harmonic, wasnt physicly possible to build a manifold to capture 2nd harmonic and fit in my engine bay

manifold is frequency tuned( dynamic flow effect) between 6500- 9200 rpm, my engine will be reving to 9000-9200

i can post all the numbers for 3rd and 4th harmonic, wasnt physicly possible to build a manifold to capture 2nd harmonic and fit in my engine bay

#40

Elite Member

Thread Starter

iTrader: (7)

Join Date: Apr 2006

Location: VaBch, VA

Posts: 6,451

Total Cats: 322

So, here's question that would take me 2hrs to search, but I'm sure somebody knows off the top of their head.

Are all 1.6 heads the same?

Do all 1.8 heads have the same intake manifold flange and fuel rail attachment points?

What are the important dimensions of the ports? Spacing? Diameter?

What other OEM cars use compatible flanges based on spacing?

Are all 1.6 heads the same?

Do all 1.8 heads have the same intake manifold flange and fuel rail attachment points?

What are the important dimensions of the ports? Spacing? Diameter?

What other OEM cars use compatible flanges based on spacing?