My 99 miata tur...I mean Eaton M90 build

#21

TB after the blower is an awful idea. The blower will constantly be creating boost between the blower and the TB, and the bypass valve will always be closed unless you plumb the vacuum lines up in a very non-conventional way. You need to have a TB before the blower, having a secondary one after the blower would be fine, but you need the primary before the blower.

#25

Elite Member

iTrader: (1)

Join Date: Jun 2006

Location: Warrington/Birmingham

Posts: 2,642

Total Cats: 42

Without the bypass you'll find blower temps increase dramatically when you're not in boost.

To the point where rotors expand and touch the casing. It's not pretty.

#27

Elite Member

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

I'll try and find a proper technical drawing for the input shaft.

As for the material, you got me there... I'm guessing hard(ish) steel?

What did you use for your input shaft?

#29

You dont NEED a bypass. There are more aftermarket blower setups with the throttling plate before the blower and no bypass than those with it on cars right now. Its not the right way to do it, but its the way that it was done for the first 40 years of hot rodding cars with blowers off of diesel trucks.

#32

Hard is important, but there is torsion on the shaft....hehehe....that you need to account for, you dont want it being too brittle.

I cant remember what I used off the top of my head at the moment, total brain fart. I can help you determine what material, its what I do. Ill let you know tomorrow.

#33

Thanks that drawing should be useful.

Hard is important, but there is torsion on the shaft....hehehe....that you need to account for, you dont want it being too brittle.

I cant remember what I used off the top of my head at the moment, total brain fart. I can help you determine what material, its what I do. Ill let you know tomorrow.

Hard is important, but there is torsion on the shaft....hehehe....that you need to account for, you dont want it being too brittle.

I cant remember what I used off the top of my head at the moment, total brain fart. I can help you determine what material, its what I do. Ill let you know tomorrow.

You could also use a SAE4130 which can be through hardened but you won't get the surface hardness like SAE8620. Depends on your expectation of shaft life.

I fixed a truck pinion years ago by turning/grinding the journal and adding a 52100 hardened sleeve on it. Froze the pinion + put the sleeve in an oven and it gave enough clearance to assemble. After everything cooled down and was fused together I OD ground the journal back to spec. Saved me $400 but at the time but I had access to the equipment.

#34

Elite Member

iTrader: (2)

Join Date: Jun 2009

Location: Istanbul, Turkey

Posts: 3,214

Total Cats: 1,687

SAE8620 is a case hardened material which should be suitable. Softer/tougher core + harder surface. You would need to allow for the carburizing + quench/temper and allow for grind stock on the bearing journals.

You could also use a SAE4130 which can be through hardened but you won't get the surface hardness like SAE8620. Depends on your expectation of shaft life.

I fixed a truck pinion years ago by turning/grinding the journal and adding a 52100 hardened sleeve on it. Froze the pinion + put the sleeve in an oven and it gave enough clearance to assemble. After everything cooled down and was fused together I OD ground the journal back to spec. Saved me $400 but at the time but I had access to the equipment.

You could also use a SAE4130 which can be through hardened but you won't get the surface hardness like SAE8620. Depends on your expectation of shaft life.

I fixed a truck pinion years ago by turning/grinding the journal and adding a 52100 hardened sleeve on it. Froze the pinion + put the sleeve in an oven and it gave enough clearance to assemble. After everything cooled down and was fused together I OD ground the journal back to spec. Saved me $400 but at the time but I had access to the equipment.

#35

SAE8620 is a case hardened material which should be suitable. Softer/tougher core + harder surface. You would need to allow for the carburizing + quench/temper and allow for grind stock on the bearing journals.

You could also use a SAE4130 which can be through hardened but you won't get the surface hardness like SAE8620. Depends on your expectation of shaft life.

I fixed a truck pinion years ago by turning/grinding the journal and adding a 52100 hardened sleeve on it. Froze the pinion + put the sleeve in an oven and it gave enough clearance to assemble. After everything cooled down and was fused together I OD ground the journal back to spec. Saved me $400 but at the time but I had access to the equipment.

You could also use a SAE4130 which can be through hardened but you won't get the surface hardness like SAE8620. Depends on your expectation of shaft life.

I fixed a truck pinion years ago by turning/grinding the journal and adding a 52100 hardened sleeve on it. Froze the pinion + put the sleeve in an oven and it gave enough clearance to assemble. After everything cooled down and was fused together I OD ground the journal back to spec. Saved me $400 but at the time but I had access to the equipment.

yea either of these materials would work. I would rather go with the 8620 over the 4130, but really both would work in this application.

#36

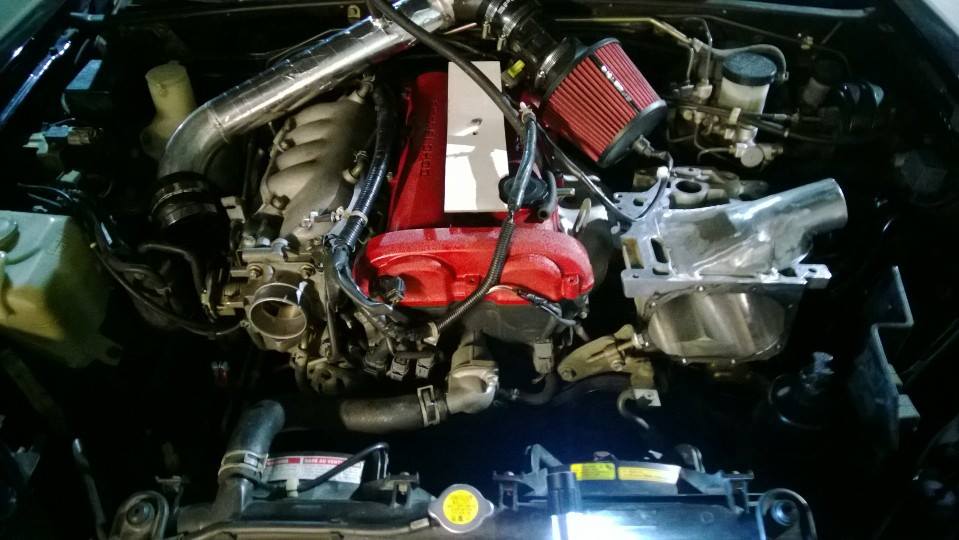

quick pic of my work

Im making the pressure outlet and intake now, ill be running a miata TB on the intake side of the SC, with a gutted TB on the intake manifold, unless anyone says otherwise.

Ill me machining the housing to get rid of some extra weight, and Ill be adding a pipe to the bypass valve, its all in process, please feel free to ask any questions

Im making the pressure outlet and intake now, ill be running a miata TB on the intake side of the SC, with a gutted TB on the intake manifold, unless anyone says otherwise.

Ill me machining the housing to get rid of some extra weight, and Ill be adding a pipe to the bypass valve, its all in process, please feel free to ask any questions

Thread

Thread Starter

Forum

Replies

Last Post

elesjuan

Build Threads

9

11-14-2018 12:18 PM

SuperSneakySecretSquirrel

Meet and Greet

5

09-06-2015 08:30 PM