3d printed intake for N/A NA miatas

#221

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

Can someone smarter than me tell me why my napkin math for hz to RPM doesn't match what I find online? I am messing around with Helmholtz resonator dimensions and I am currently converting between RPM and Hz like this:

Hz=RPM/2

-----60

Sources online just use RPM/60 which doesn't take into account that there are two crankshaft rotations for every time the intake valve opens. Also, would halving a doubling the resonance frequency have a significant effect? For example, half of the peaks at 35hz will fall in line with 70hz.

Hz=RPM/2

-----60

Sources online just use RPM/60 which doesn't take into account that there are two crankshaft rotations for every time the intake valve opens. Also, would halving a doubling the resonance frequency have a significant effect? For example, half of the peaks at 35hz will fall in line with 70hz.

#223

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

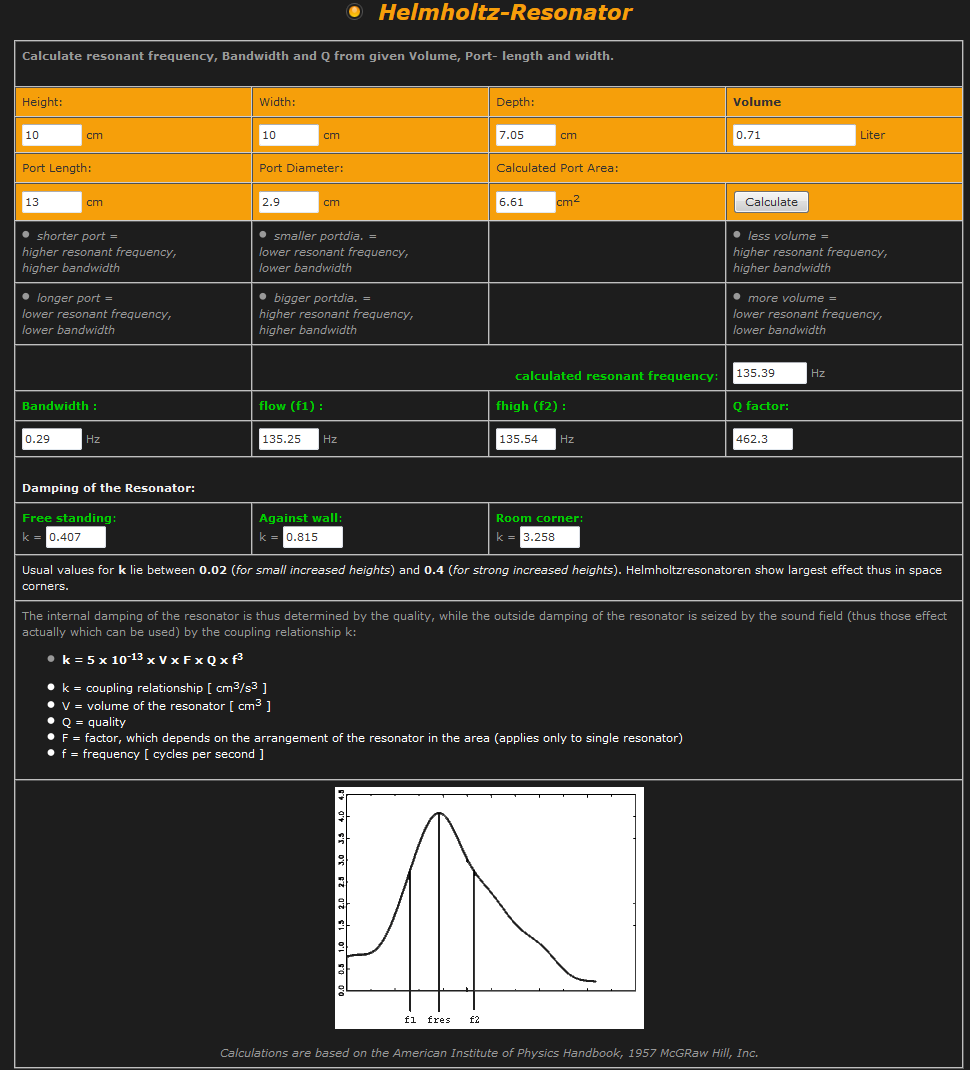

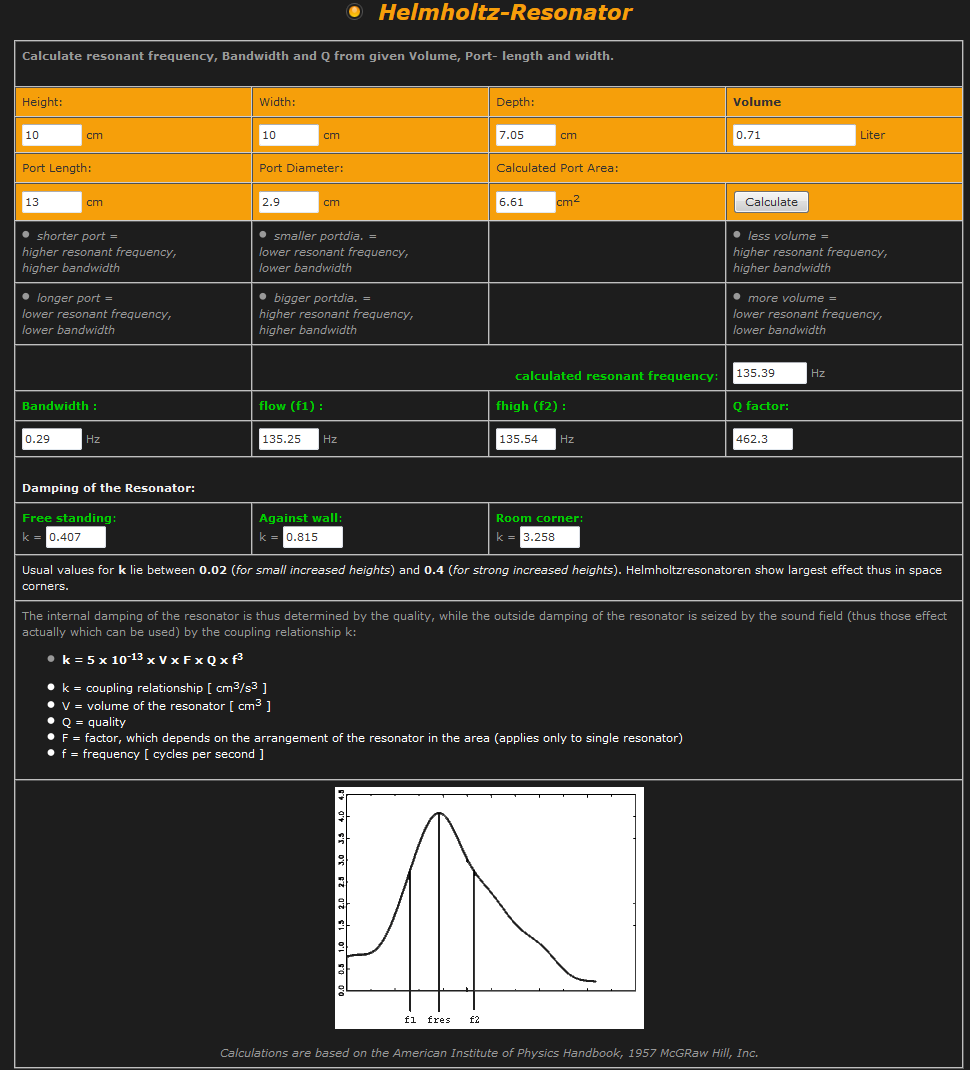

If anyone is curious, these are the rough numbers for the stock na8 helmholtz resonator:

I measured the chamber volume by how many grams of water it took to fill. For the neck I took dimensions but with all the curves it won't be as accurate.

It looks like they targeted a twice the ideal frequency in order to make the peak wider.

I measured the chamber volume by how many grams of water it took to fill. For the neck I took dimensions but with all the curves it won't be as accurate.

It looks like they targeted a twice the ideal frequency in order to make the peak wider.

#230

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I am making big changes to my work schedule, in part so I have more time for this. My composites oven is wired and ready, and I have finally solved the issues I have had with ABS plugs self destructing. I also registered an LLC, and have done a bunch of work to reduce kit costs as far as possible. One example- For people who need an IACV fitting the best option is a silicone intakes port system but it costs $15. I am having a small steel press bender machined so I can make washers with the correct curve:

That will allow me to install a fitting for $3.40 which means kits that kits with an IACV connection will be $11.60 cheaper.

That will allow me to install a fitting for $3.40 which means kits that kits with an IACV connection will be $11.60 cheaper.

Last edited by asmasm; 03-15-2015 at 09:51 PM.

#232

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

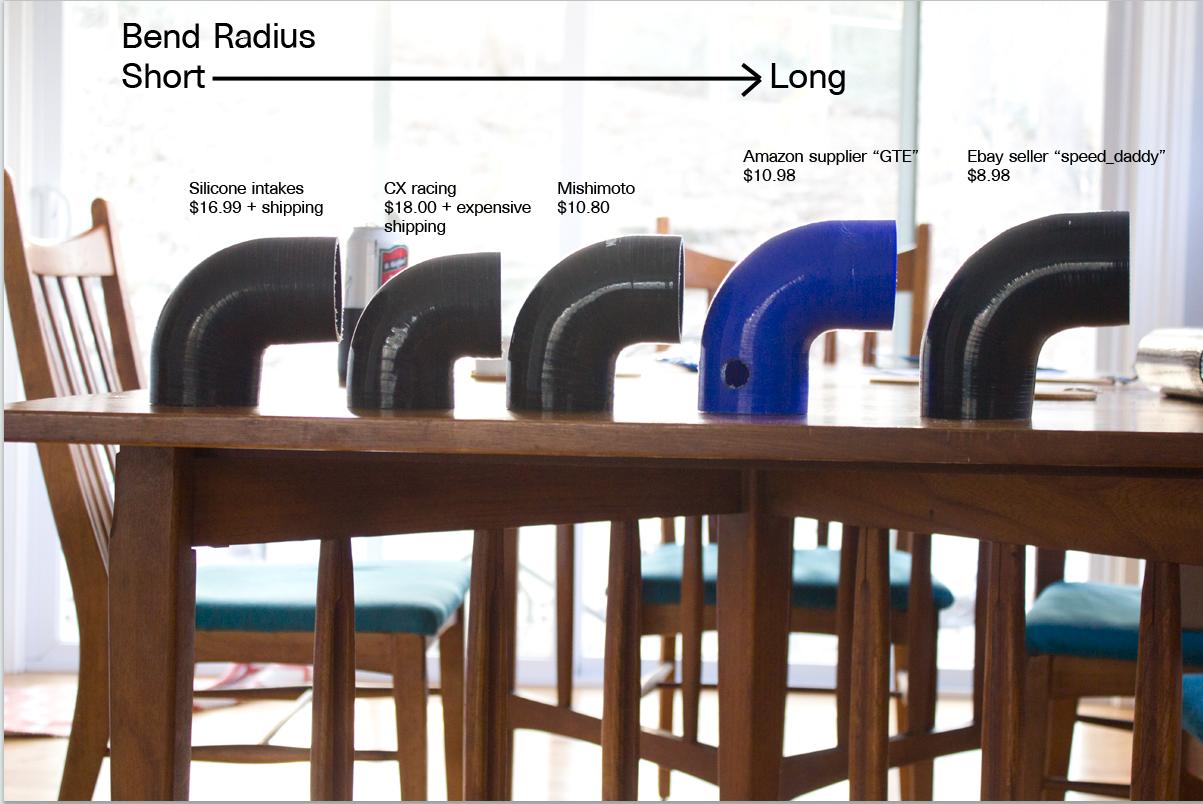

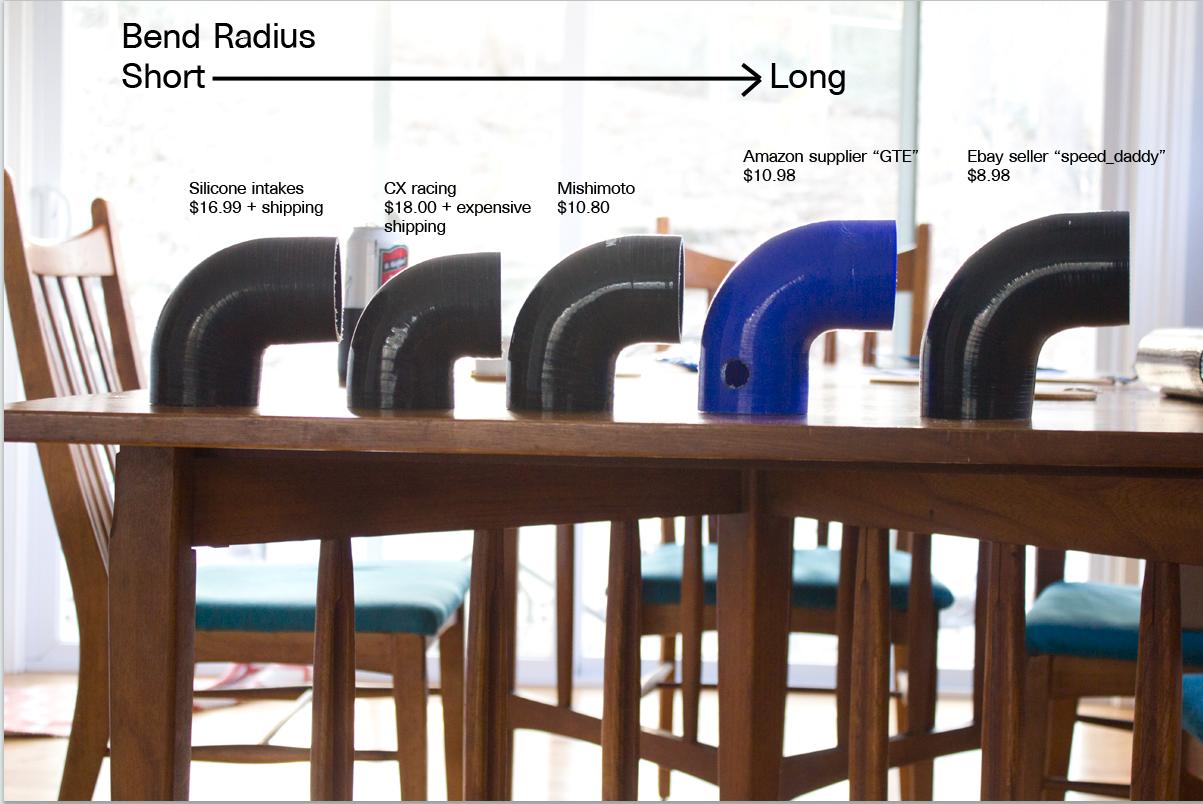

Finding 90 degree elbows with a long bend radius is not easy. If anyone knows of a source please let me know. Silicone intakes sent me a perfect elbow about a year ago but they have more the one supplier and half the time you get one that looks like this.

So far I have ordered about a dozen different 2.5" elbows and these are the standouts:

Also, this is finally close to done.

So far I have ordered about a dozen different 2.5" elbows and these are the standouts:

Also, this is finally close to done.

#234

Finding 90 degree elbows with a long bend radius is not easy. If anyone knows of a source please let me know. Silicone intakes sent me a perfect elbow about a year ago but they have more the one supplier and half the time you get one that looks like this.

So far I have ordered about a dozen different 2.5" elbows and these are the standouts:

Turbohoses Custom Design, Engineering & Manufacturing

http://www.turbohoses.com/technical_assistance.htm

#235

Perhaps one of these?

Silicone 180 Degree U Shape Bending Hose 2 5" Blue | eBay

http://www.ebay.com/itm/VMS-2-5-90-Degree-Silicone-Elbow-Bend-for-Intercooler-Turbo-4-Ply-RED-/121491058529?pt=Motors_Car_Truck_Parts_Accessories &hash=item1c496e6f61&vxp=mtr

http://www.farapp.com/static/prodimg...esinc/3339.gif for the above.

Silicone 180 Degree U Shape Bending Hose 2 5" Blue | eBay

http://www.ebay.com/itm/VMS-2-5-90-Degree-Silicone-Elbow-Bend-for-Intercooler-Turbo-4-Ply-RED-/121491058529?pt=Motors_Car_Truck_Parts_Accessories &hash=item1c496e6f61&vxp=mtr

http://www.farapp.com/static/prodimg...esinc/3339.gif for the above.

#240

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

My plug is now at a pro level of finish. Its hard to believe there are glued together peices of ABS that came out of of a consumer grade printer under there.

Mold production is next. I am going to do a split mold and lay up each piece separately with carbon bending slightly around the flange. In order to trim the parts for a clean join line to insert carefully cut steel shim stock between the part and the mold flange an then sand away the excess material. That should give me the correct dimensions to the tolerance of the shim stock thickness and keep me from ruining each mold.

Mold production is next. I am going to do a split mold and lay up each piece separately with carbon bending slightly around the flange. In order to trim the parts for a clean join line to insert carefully cut steel shim stock between the part and the mold flange an then sand away the excess material. That should give me the correct dimensions to the tolerance of the shim stock thickness and keep me from ruining each mold.

Wet layup with the right resin can easily hold up to the heat, and while covering the part with reflective heat barrier may not seem sexy, it will protect the part and keep the intake air cooler.

Wet layup with the right resin can easily hold up to the heat, and while covering the part with reflective heat barrier may not seem sexy, it will protect the part and keep the intake air cooler.