3d printed intake for N/A NA miatas

#61

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I am hoping the newest version can can be rotated to face directly back at the driver and be used an an intake source for a turbo car. Obviously that depends on IC piping but my plan is to make it extremely flexible.

#66

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

From my research it looks like it is difficult to layup ontop of ABS plastic and get a good bond. Also, you would need to print the plastic significantly thinner than the current 3mm wall thickness, which is problematic. Right now the duct just barely rubs the hood support structure so there is basically no extra room to make the part thicker.

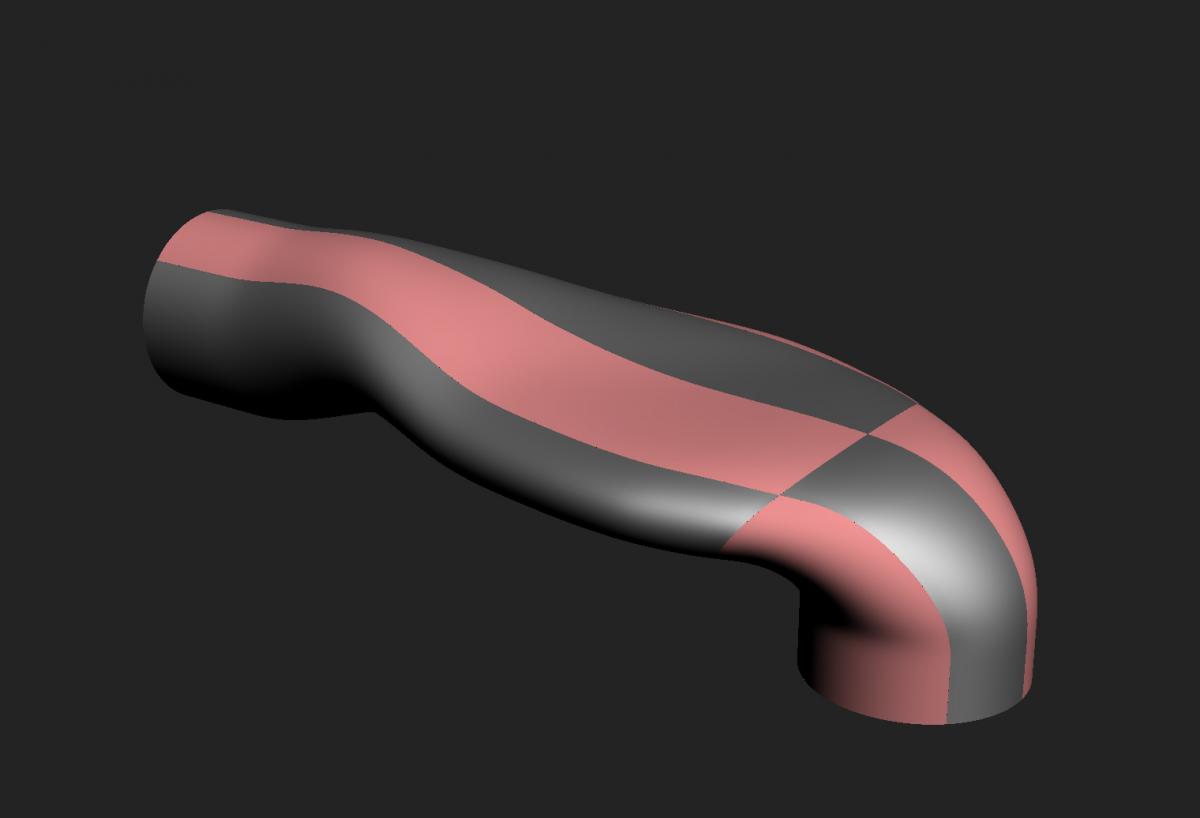

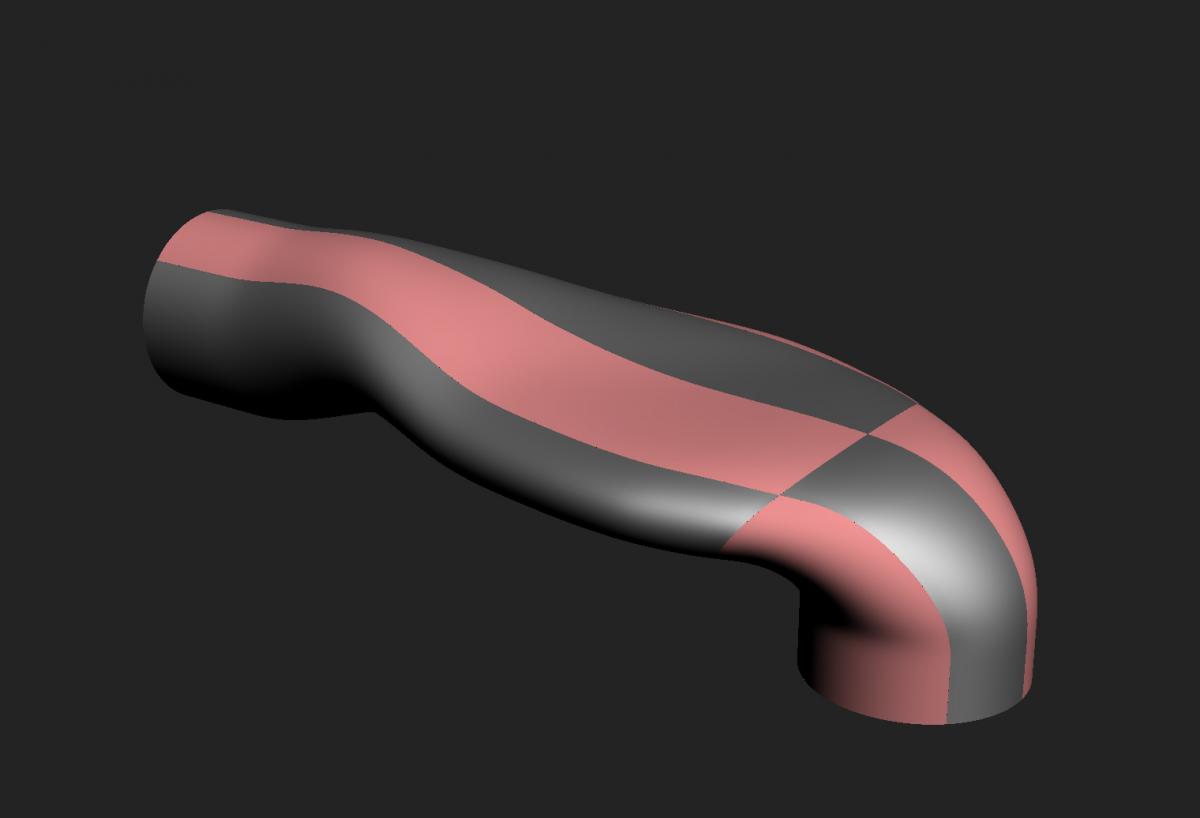

For the new design I am working on a version that is snapped together in 12 pieces The idea is that you can layup carbon fiber sleeves overtop, then un-snap the pieces and remove them:

For the new design I am working on a version that is snapped together in 12 pieces The idea is that you can layup carbon fiber sleeves overtop, then un-snap the pieces and remove them:

Last edited by asmasm; 03-17-2014 at 06:14 PM.

#67

So do y'all think the ABS as it stands will tolerate being used on a daily driver? I will wrap it in thermal insulating tape for heat protection, or is this something that will end up with a stress fracture and me on the of the road at 2am fixing it with gorilla tape and cursing asmasm's name? (not that I'd really wish you harm, I just get frustrated when I'm stranded at 1am.)

#68

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

So far so good on my car. I have driven around town, an hour and a half each way to an auto-x, and up to VIR for a few hours of driving like a total ******* on a skidpad. I have also driven through rain, and the skidpad was soaking wet with no issues.

Last edited by asmasm; 03-17-2014 at 08:41 PM.

#69

Good deal. Will the new design work with a MAF? I'm building in stages and don't have a standalone yet, but cooler air is still good.

Would it be possible to go through the hole on the passenger side of the car, or does the top neck/cap of the radiator prevent that? Perhaps that side would be too short anyhow.

This is just an idea, but I saw you talking about using this as a mold and then dissolving the plastic to leave the composite form. Could you reduce the overall dimensions to account for the final product, and then use a kevlar bi-axial sleeve to create the final form? The sleeves I've read about are very versital, I think a 3" sleeve would be able to accommodate all of the contours, and it layers well. Kevlar can with stand something to the tune of 320 degrees continuous without failure, and even past failure it doesn't completely disintegrate. I'm pretty sure degradation is linear. Just a thought. This is all assuming the ABS shows weakness at some point.

Would it be possible to go through the hole on the passenger side of the car, or does the top neck/cap of the radiator prevent that? Perhaps that side would be too short anyhow.

This is just an idea, but I saw you talking about using this as a mold and then dissolving the plastic to leave the composite form. Could you reduce the overall dimensions to account for the final product, and then use a kevlar bi-axial sleeve to create the final form? The sleeves I've read about are very versital, I think a 3" sleeve would be able to accommodate all of the contours, and it layers well. Kevlar can with stand something to the tune of 320 degrees continuous without failure, and even past failure it doesn't completely disintegrate. I'm pretty sure degradation is linear. Just a thought. This is all assuming the ABS shows weakness at some point.

Last edited by jj1000; 03-18-2014 at 11:46 AM.

#74

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

The new one hasn't even been test fit yet. I should have one arriving tomorrow to do the initial fit but I am guessing it will need a second iteration. The first design took ~7 passes of tweaks with 4 different printings. It will be compatible with the MAF but only when using this exact elbow:

Edit: that elbow ended up being garbage. I am now just using a silicone intakes 2.75 to 2.75 45 degree.

The leg length is important here. The 2.75" to 2.5" reducing elbow silicone intakes sells has legs that are too short.

I am holding off on opening up the newest design to everyone until I know it isn't going to cause a problem with getting a composite version released. Personally, I really want a fiberglass or carbon version for peace of mind. If my plan for a plug that breaks up into pieces works out I will release the design since I can make it for myself.

Edit:

I am going to order some epoxy resin from fiberglast and test the bonding strength to ABS.

Edit: that elbow ended up being garbage. I am now just using a silicone intakes 2.75 to 2.75 45 degree.

The leg length is important here. The 2.75" to 2.5" reducing elbow silicone intakes sells has legs that are too short.

I am holding off on opening up the newest design to everyone until I know it isn't going to cause a problem with getting a composite version released. Personally, I really want a fiberglass or carbon version for peace of mind. If my plan for a plug that breaks up into pieces works out I will release the design since I can make it for myself.

Edit:

I am going to order some epoxy resin from fiberglast and test the bonding strength to ABS.

Last edited by asmasm; 03-21-2014 at 04:48 PM.

#75

Try Uscomposites for resin. It's a good product and priced right.

Epoxy : Epoxy Resins and Hardeners

No, I don't work there. Been using their stuff for years and never had a single issue.

Epoxy : Epoxy Resins and Hardeners

No, I don't work there. Been using their stuff for years and never had a single issue.

#76

Try Uscomposites for resin. It's a good product and priced right.

Epoxy :-Epoxy Resins and Hardeners

No, I don't work there. Been using their stuff for years and never had a single issue.

Epoxy :-Epoxy Resins and Hardeners

No, I don't work there. Been using their stuff for years and never had a single issue.