Broken Bolt Removal- Mixed methods

#1

Senior Member

Thread Starter

iTrader: (1)

Join Date: Mar 2012

Location: Pensacola Fla.

Posts: 588

Total Cats: 203

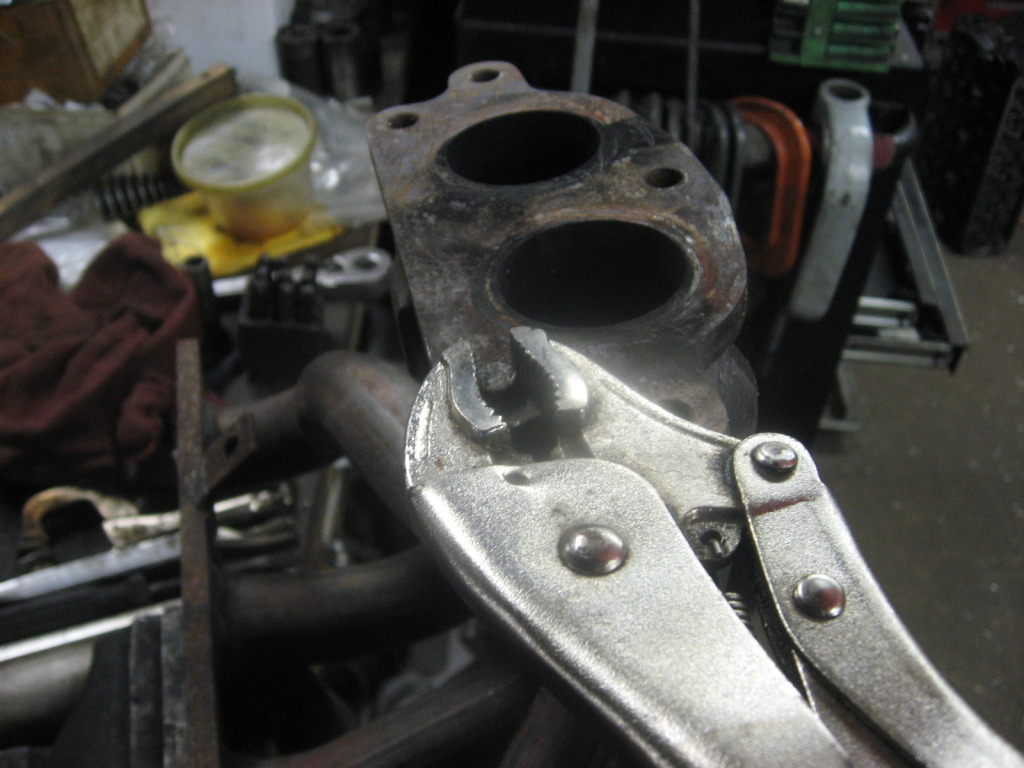

I have a broken bolt in a Honda exhaust header.

It is broken off about 1/8" above the flange.

Just enough to get a bite on it with some vise grips.

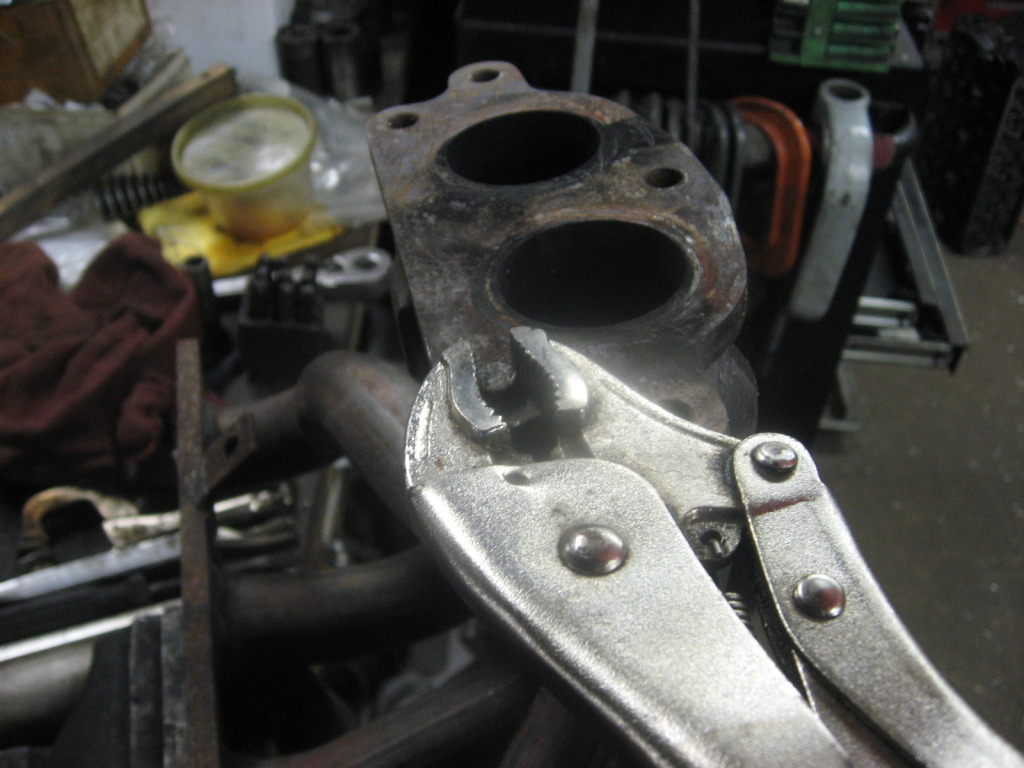

First thing I am going to do is heat it up with a torch.

Make the area around the broken bolt glow.

At this point , work quickly, lock the vice grips in place, and wiggle, DO NOT try to superman the broken bolt out on the first try.

Soak in WD-40, wax, engine oil.

It will smoke and stink, and watch for flare ups.

I was able to get about a 1/4 turn befor it locked up again and the vise grips kept slipping off.

Time to try something else.....

Get a nut that just fits around the broken bolt.

I used my old stick welder and welded the nut to the broken bolt.

Get a wrench on there, and keep working the bolt back and forth.

I was able to apply more force applied to the broken bolt and get it out.

Now with the broken bolt out, I can see why it broke.

A couple threads had gaulled, and sripped some.

I will let the header cool, then install a Heli-coil.

It is broken off about 1/8" above the flange.

Just enough to get a bite on it with some vise grips.

First thing I am going to do is heat it up with a torch.

Make the area around the broken bolt glow.

At this point , work quickly, lock the vice grips in place, and wiggle, DO NOT try to superman the broken bolt out on the first try.

Soak in WD-40, wax, engine oil.

It will smoke and stink, and watch for flare ups.

I was able to get about a 1/4 turn befor it locked up again and the vise grips kept slipping off.

Time to try something else.....

Get a nut that just fits around the broken bolt.

I used my old stick welder and welded the nut to the broken bolt.

Get a wrench on there, and keep working the bolt back and forth.

I was able to apply more force applied to the broken bolt and get it out.

Now with the broken bolt out, I can see why it broke.

A couple threads had gaulled, and sripped some.

I will let the header cool, then install a Heli-coil.

#5

Which is the best method for bolt removal? Please share it in details. Thanks in advance.

____________________

removing broken bolts

____________________

removing broken bolts

#6

i have great luck with just drilling a hole in the bolt, about 1/4"-1/2" deep . spray with some penetrable lube, then hammer an allen wrench into it. sounds rough but, it works. allen sockets make it easier. remember, big enough wrench for the job but, smaller hole is better. leave some wall thickness....have your fun here...

#9

Great information thank you, I just have one thing to say and please correct me if I am wrong. But when you heat an area of metal this hot, and than quickly cool it back down. It makes the metal stronger, but it is more brittle. I feel like people should be cautious on what parts they heat up on the car. replacing the part because of a broken bolt can put a damper on a project, But better safe than sorry...

Spencer

Spencer

#10

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

Dang, i was hoping for something cool.

Like a bolt broken off like a quarter of an inch down inside.

I wanted to see you build up a pad on top of it with 309 stainless. Built up far enough to get a vice grip on it and and twist it out (or whatever method from there).

That was one of my the tests for my final in my tool and die class just before i graduated. I think i took pictures of it, someday i'll dig them up.

Like a bolt broken off like a quarter of an inch down inside.

I wanted to see you build up a pad on top of it with 309 stainless. Built up far enough to get a vice grip on it and and twist it out (or whatever method from there).

That was one of my the tests for my final in my tool and die class just before i graduated. I think i took pictures of it, someday i'll dig them up.

#13

Why does everyone make reference to stainless?? It is NOT a structural metal for the most part. It is high carbon steel at best, with corrosion inhibitors. Most of the stainless blends do not bond well with regular steel. It also has a huge thermal expansion coefficient.

#16

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

Because you're a knucklehead and turned it into a metallurgy debate i now must respond, creating a further downward spiral.

READ: 309

When it bonds with mild steel (what it's also good for) it has high tensel and rotational stregth. Good for turning a bolt out. If you were to use mild steel filler on the bolt to turn it out it would just bend twist and break off.

Credits - I went to school for this.

- I've never had to do this in a real world seniro. It's uncommon, and is easier to drill and tap. Though much larger diameter bolts (1"+) this is common and effective.

READ: 309

When it bonds with mild steel (what it's also good for) it has high tensel and rotational stregth. Good for turning a bolt out. If you were to use mild steel filler on the bolt to turn it out it would just bend twist and break off.

Credits - I went to school for this.

- I've never had to do this in a real world seniro. It's uncommon, and is easier to drill and tap. Though much larger diameter bolts (1"+) this is common and effective.