Casting blem on crank, should I be concerned?

#1

Junior Member

Thread Starter

iTrader: (6)

Join Date: Mar 2010

Location: Morgan Hill, CA

Posts: 382

Total Cats: 27

Tearing down a 91 long nose engine to prep it to drop in a 90 project car with my 14year old son.

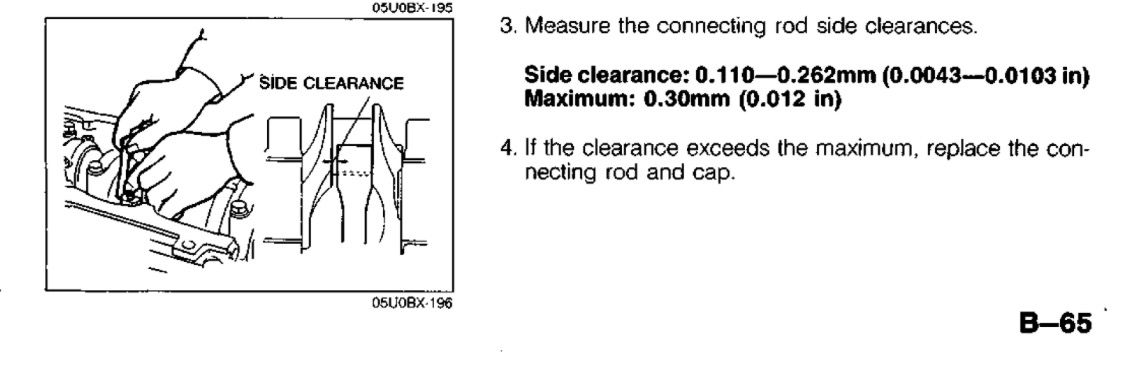

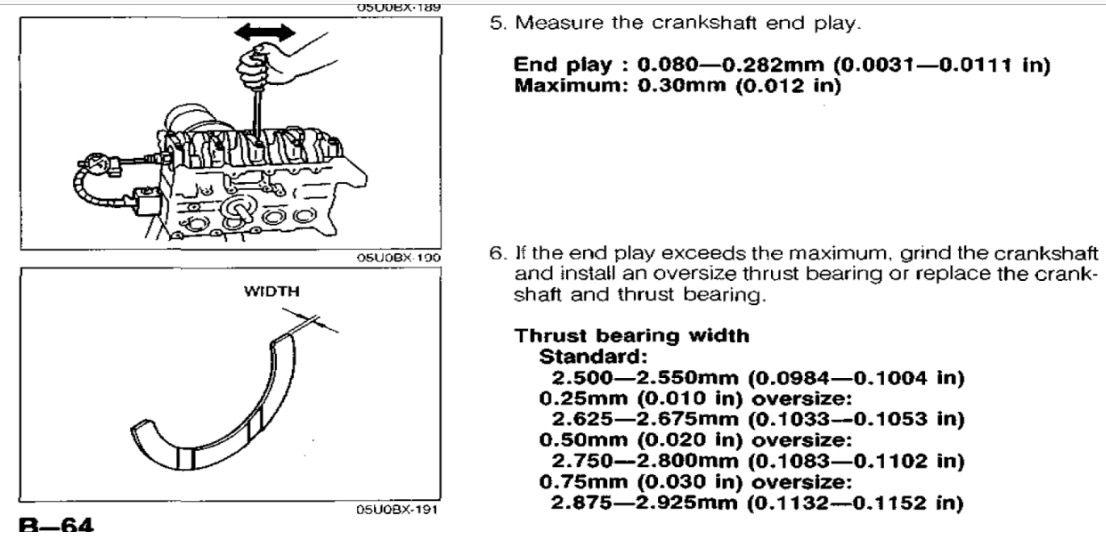

Engine is supposed to have low miles but sitting in a shed for many years. So far it has looked good coming apart but when we to pull the piston and rods out to put in new rings I noticed that the play between the rod cap and crank on cylinder 2 was slightly over max allowable (0.012"). When I took the rod assemblies out I noticed this on the crank:

<br >

<br > <br >

<br >

The manual says to replace the rod and cap but should I really replace the crank?

MX-5 Miata Forum

Engine is supposed to have low miles but sitting in a shed for many years. So far it has looked good coming apart but when we to pull the piston and rods out to put in new rings I noticed that the play between the rod cap and crank on cylinder 2 was slightly over max allowable (0.012"). When I took the rod assemblies out I noticed this on the crank:

<br >

<br > <br >

<br >The manual says to replace the rod and cap but should I really replace the crank?

MX-5 Miata Forum

#2

Junior Member

Thread Starter

iTrader: (6)

Join Date: Mar 2010

Location: Morgan Hill, CA

Posts: 382

Total Cats: 27

Any thoughts? I'm looking at buying another crank and a full set of ACL race bearings for $150 + shipping so I'd love some feedback on if that is money well spent or should just try to fix this.

#4

I'd run that crank. Journals look pristine from the pic (no scratching from debris). I wouldn't worry about that defect on the side. If you imagine pushing the rod against the side of the crank, that metal that's missing is only probably a 3-5% reduction in area. Given the extremely low loading in that direction, that will never matter.

Carry on.

Carry on.

#6

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,027

Total Cats: 6,592

Interesting problem...

On the one hand, if the pits are smooth and the journal is otherwise within spec, I'd just have them polished.

OTOH. I've never seen anything quite like this before, so who am I to say that they're not going to wind up being stress risers that eventually lead to a crack?

I'm with Giz0r on this one. Take the crank to someone who deals with cranks for a living, have them clean and inspect it, and go from there.

On the one hand, if the pits are smooth and the journal is otherwise within spec, I'd just have them polished.

OTOH. I've never seen anything quite like this before, so who am I to say that they're not going to wind up being stress risers that eventually lead to a crack?

I'm with Giz0r on this one. Take the crank to someone who deals with cranks for a living, have them clean and inspect it, and go from there.

#7

Interesting problem...

On the one hand, if the pits are smooth and the journal is otherwise within spec, I'd just have them polished.

OTOH. I've never seen anything quite like this before, so who am I to say that they're not going to wind up being stress risers that eventually lead to a crack?

I'm with Giz0r on this one. Take the crank to someone who deals with cranks for a living, have them clean and inspect it, and go from there.

On the one hand, if the pits are smooth and the journal is otherwise within spec, I'd just have them polished.

OTOH. I've never seen anything quite like this before, so who am I to say that they're not going to wind up being stress risers that eventually lead to a crack?

I'm with Giz0r on this one. Take the crank to someone who deals with cranks for a living, have them clean and inspect it, and go from there.

#11

Junior Member

Thread Starter

iTrader: (6)

Join Date: Mar 2010

Location: Morgan Hill, CA

Posts: 382

Total Cats: 27

I'd run that crank. Journals look pristine from the pic (no scratching from debris). I wouldn't worry about that defect on the side. If you imagine pushing the rod against the side of the crank, that metal that's missing is only probably a 3-5% reduction in area. Given the extremely low loading in that direction, that will never matter.

Carry on.

Carry on.

<br >

<br > When I run my finger over this spot on the side I get a little "catch" so I'm wonder if this is contributing to the tolerance issue. All the other rod play clearances are well within spec.

#12

Junior Member

Thread Starter

iTrader: (6)

Join Date: Mar 2010

Location: Morgan Hill, CA

Posts: 382

Total Cats: 27

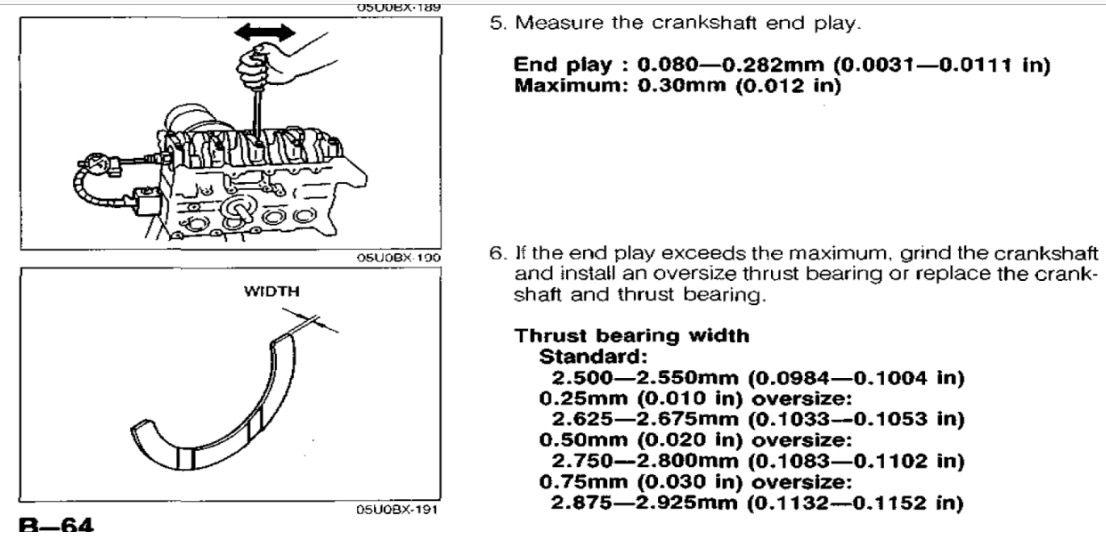

This is probably the way to go. The question is if I pull the crank to bring it in to the shop do I have to replace all the main bearings as a matter course or can I reuse since the end play is right in the middle of the spec?

<br >

<br >

<br >

<br >

<br >

<br > <br >

<br >

#13

If the mains are fine you don't have to replace them.

I'd buy a caliper and check the big end of the rod in question to the other 3, see if they all measure the same. Then do same to each journal on the crank where the rods contact the side. That will tell you what part(s) are worn. Maybe that one rod is a touch loose, or that journal is a bit wider machined than the others, or both. You or a machinist can check this. If you're building it yourself and taking measurements, you can measure this too and know yourself.

I'd buy a caliper and check the big end of the rod in question to the other 3, see if they all measure the same. Then do same to each journal on the crank where the rods contact the side. That will tell you what part(s) are worn. Maybe that one rod is a touch loose, or that journal is a bit wider machined than the others, or both. You or a machinist can check this. If you're building it yourself and taking measurements, you can measure this too and know yourself.

#15

Junior Member

Thread Starter

iTrader: (6)

Join Date: Mar 2010

Location: Morgan Hill, CA

Posts: 382

Total Cats: 27

First, I stupid because after checking all the rods (they were all exactly the same when measured on my cheap digital calipers down to the ten thousands of an inch) I fitted the same cap up to the 4 journals and found that it was journal 3 not 2 with the blem that had the most play.

Ok, so took the engine down to the local motor shop and he said he didn't think I had anything to worry about with the slightly wider play in the one journal and the engine must have had low miles based on the wear on the rings and the over all look of the engine.

I brought the cams down just to have him take a look and he said they looked fine but then he fitted the exhaust side cam into the head and it rocked slightly. He said it wasn't out much and I could probably get away with it or he could fix it. I figured it would be better to fix that problem than worry any more about the crank.

Ok, so took the engine down to the local motor shop and he said he didn't think I had anything to worry about with the slightly wider play in the one journal and the engine must have had low miles based on the wear on the rings and the over all look of the engine.

I brought the cams down just to have him take a look and he said they looked fine but then he fitted the exhaust side cam into the head and it rocked slightly. He said it wasn't out much and I could probably get away with it or he could fix it. I figured it would be better to fix that problem than worry any more about the crank.

Thread

Thread Starter

Forum

Replies

Last Post

gtiracer06

Cars for sale/trade

6

04-02-2016 02:04 PM