Torque Wrench Inconsistency, Beam Type vs Click Type

#1

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

So.... I have a Autozone Click type 1/2" Drive torque wrench that I've had forever, and used to torque my head bolts on my miata many times. I take good care of it, only use it for head bolts and flywheel bolts, things like that.

But recently I believe I lifted the head when I cracked a piston, and after having the head and deck checked and both were perfectly flat, this made me question if maybe my torque wrench was off.

Did a bit of research and ended up buying a Craftsmen 1/2" Beam type torque wrench. This one: Craftsman 1/2-in. Dr. Beam Style Torque Wrench, 0-150 ft. lbs. - Tools - Wrenches - All Open Stock Wrenches Brand new.

It is said to be withing 4% accurate. Older ones of the same brand were said to be withing 2% accurate...

Anyways, I began torquing my head bolts, and I got them all to 40 ft*lbs as indicated by my beam type torque wrench, and then decided to whip out the 1/2" Click type and see if it agreed.

IT DOES NOT!!!

Click type is showing 56! That's 16 higher/40% difference!

So then took them to 50 ft*lbs with the beam type and checked again. Click type now shows 68 ft*lbs! Or 18 higher or 36% difference!

Now my gut says the beam type is right, but damn that's a huge difference. So tomorrow I'm going to buy a new click type and check to see if it agrees with my beam type before I continue torquing the bolts.

Will post back what I find. But for now, I can say, be careful using cheap torque wrenches!

But recently I believe I lifted the head when I cracked a piston, and after having the head and deck checked and both were perfectly flat, this made me question if maybe my torque wrench was off.

Did a bit of research and ended up buying a Craftsmen 1/2" Beam type torque wrench. This one: Craftsman 1/2-in. Dr. Beam Style Torque Wrench, 0-150 ft. lbs. - Tools - Wrenches - All Open Stock Wrenches Brand new.

It is said to be withing 4% accurate. Older ones of the same brand were said to be withing 2% accurate...

Anyways, I began torquing my head bolts, and I got them all to 40 ft*lbs as indicated by my beam type torque wrench, and then decided to whip out the 1/2" Click type and see if it agreed.

IT DOES NOT!!!

Click type is showing 56! That's 16 higher/40% difference!

So then took them to 50 ft*lbs with the beam type and checked again. Click type now shows 68 ft*lbs! Or 18 higher or 36% difference!

Now my gut says the beam type is right, but damn that's a huge difference. So tomorrow I'm going to buy a new click type and check to see if it agrees with my beam type before I continue torquing the bolts.

Will post back what I find. But for now, I can say, be careful using cheap torque wrenches!

#6

Its not surprising the craftsman torque wrench is reading screwy, one of those magazines tested a bunch of torque wrenches and an HF that sat at lug nut torque in a toss around tool box for years blew a new crapsman out of the water. I bet you could find a tool truck and get your craftsman recalibrated though, but based on that article I wouldnt expect it to stay that way for long.

#8

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

We have a fancy digital meter to unofficially 'requalifiy' torque wrenches here. My superduper cheap HF is pretty damn accurate and repeatable. About as good and the bigdollar Snapon Digital buzzers here. Just be sure to unwind the spring when you're done.

I still borrowed the snapon wrench when I built my engine though...

I still borrowed the snapon wrench when I built my engine though...

#9

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

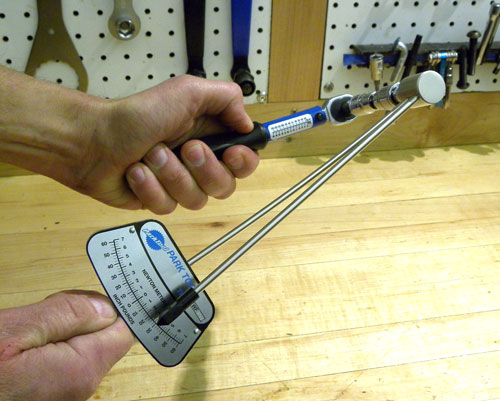

But I wanted to be sure so I tested it.

I grabbed an old head bolt, welded it to a piece of steel, clamped it my work bench. Then got some free weights and para-cord and applied a given force on a known fulcrum and checked the beam type wrench.

I tested the beam type at two different torques, one at 35 and again at 58 ft*lbs. Both test the calculated and indicated torque on the beam type wrench were withing 1 ft*lb!

So now I trust the beam type, and I just torqued the head to 65 ft*lbs with it.

#10

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Well with the head bolts, I used the ARP torque lube they come with, and every time I torqued them to some number, they started turning again as soon as I went over that number according to the beam type torque wrench. So the friction was very low on these bolts. I could torque to 40, and by 41-42 they were turning again with the beam, but not with the click type!

#12

Do you loosen the torque wrench between uses?

Every second your torque wrench spends "set", the spring inside loses some grunt.

It's not really a huge deal to have it set for a few minutes at a time, but if you (like me) set your torque wrench to your lug-spec and then leave it for a year at a time, it will become weaker, and will click at a lower torque.

The result is, you get a new, calibrated torque wrench and set something to 50, but your old, weakened torque wrench needs to be set to ~68 to think it's at 50.

I have been planning on picking up a new torque wrench soon for more delicate work, since I leave my main one set to ~85 to do wheels (I figure it's probably putting them actually at around 72 or so.)

Every second your torque wrench spends "set", the spring inside loses some grunt.

It's not really a huge deal to have it set for a few minutes at a time, but if you (like me) set your torque wrench to your lug-spec and then leave it for a year at a time, it will become weaker, and will click at a lower torque.

The result is, you get a new, calibrated torque wrench and set something to 50, but your old, weakened torque wrench needs to be set to ~68 to think it's at 50.

I have been planning on picking up a new torque wrench soon for more delicate work, since I leave my main one set to ~85 to do wheels (I figure it's probably putting them actually at around 72 or so.)

#13

The Wrench Should Always Be “Unloaded” Before Storage

If you’re using a mechanical click-type wrench, this one turns out to be absolutely true. A click-type torque wrench presses a ball into a detent that’s held in place by a spring. The wrench is normally adjusted by twisting the handle on the wrench. Twisting it in compresses the spring and requires more torque to pop the ball out of the detent. This is how it measures torque.

A click-type wrench is popular and dependable. You set the amount of torque you want by twisting the handle of the wrench. This compresses a spring in the handle which increases the amount of torque required before a steel ball will pop out of its detent inside the wrench, giving you the familiar “click” to let you know you’ve reached your desired torque setting.

But if the spring is stored with the wrench “loaded” or set for a high torque rating, the pressure on the spring can cause it to weaken over time. To protect the wrench it should always be returned to the lowest setting before storing it back into your toolbox. For big wrenches (measuring in ft-lbs increments) the lowest setting is usually 20 ft-lbs. If, for some reason, you have a click-type torque wrench that goes all the way down to zero, leave the wrench set to 10 or 20 pounds. You always want to keep a minimum amount of pressure on the spring so that the ball can’t fall all the way out of the detent.

For other styles of torque wrenches, this isn’t an issue. The newest digital torque wrenches use an electronic strain gauge to measure torque, so when the wrench is not in use the only thing you may need to do is remove the batteries so that there is no chance of corrosion ruining your expensive digital wrench.

If you’re using a mechanical click-type wrench, this one turns out to be absolutely true. A click-type torque wrench presses a ball into a detent that’s held in place by a spring. The wrench is normally adjusted by twisting the handle on the wrench. Twisting it in compresses the spring and requires more torque to pop the ball out of the detent. This is how it measures torque.

A click-type wrench is popular and dependable. You set the amount of torque you want by twisting the handle of the wrench. This compresses a spring in the handle which increases the amount of torque required before a steel ball will pop out of its detent inside the wrench, giving you the familiar “click” to let you know you’ve reached your desired torque setting.

But if the spring is stored with the wrench “loaded” or set for a high torque rating, the pressure on the spring can cause it to weaken over time. To protect the wrench it should always be returned to the lowest setting before storing it back into your toolbox. For big wrenches (measuring in ft-lbs increments) the lowest setting is usually 20 ft-lbs. If, for some reason, you have a click-type torque wrench that goes all the way down to zero, leave the wrench set to 10 or 20 pounds. You always want to keep a minimum amount of pressure on the spring so that the ball can’t fall all the way out of the detent.

For other styles of torque wrenches, this isn’t an issue. The newest digital torque wrenches use an electronic strain gauge to measure torque, so when the wrench is not in use the only thing you may need to do is remove the batteries so that there is no chance of corrosion ruining your expensive digital wrench.

#15

Elite Member

iTrader: (1)

Join Date: May 2009

Location: Jacksonville, FL

Posts: 5,155

Total Cats: 406

Do you loosen the torque wrench between uses?

Every second your torque wrench spends "set", the spring inside loses some grunt.

It's not really a huge deal to have it set for a few minutes at a time, but if you (like me) set your torque wrench to your lug-spec and then leave it for a year at a time, it will become weaker, and will click at a lower torque.

Every second your torque wrench spends "set", the spring inside loses some grunt.

It's not really a huge deal to have it set for a few minutes at a time, but if you (like me) set your torque wrench to your lug-spec and then leave it for a year at a time, it will become weaker, and will click at a lower torque.

#16

I know fuckall about guns, but I'm assuming you're being sarcastic.

Here's some science. Torque Wrench Testing - Shop Tools - Car Craft Magazine

They left a torque wrench set at 70 and tested it every 30 days, and it continued to drop.

There's a bit of a difference between "will this spring push bullets up towards my gun at a rate that will allow me to fire" vs "will this spring hold this ball in a divot until precisely 70ft-lbs is applied to the handle"

Here's some science. Torque Wrench Testing - Shop Tools - Car Craft Magazine

They left a torque wrench set at 70 and tested it every 30 days, and it continued to drop.

There's a bit of a difference between "will this spring push bullets up towards my gun at a rate that will allow me to fire" vs "will this spring hold this ball in a divot until precisely 70ft-lbs is applied to the handle"

#17

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 477

Do you loosen the torque wrench between uses?

Every second your torque wrench spends "set", the spring inside loses some grunt.

It's not really a huge deal to have it set for a few minutes at a time, but if you (like me) set your torque wrench to your lug-spec and then leave it for a year at a time, it will become weaker, and will click at a lower torque.

The result is, you get a new, calibrated torque wrench and set something to 50, but your old, weakened torque wrench needs to be set to ~68 to think it's at 50.

I have been planning on picking up a new torque wrench soon for more delicate work, since I leave my main one set to ~85 to do wheels (I figure it's probably putting them actually at around 72 or so.)

Every second your torque wrench spends "set", the spring inside loses some grunt.

It's not really a huge deal to have it set for a few minutes at a time, but if you (like me) set your torque wrench to your lug-spec and then leave it for a year at a time, it will become weaker, and will click at a lower torque.

The result is, you get a new, calibrated torque wrench and set something to 50, but your old, weakened torque wrench needs to be set to ~68 to think it's at 50.

I have been planning on picking up a new torque wrench soon for more delicate work, since I leave my main one set to ~85 to do wheels (I figure it's probably putting them actually at around 72 or so.)

What I learned is, beam type is spot-on accurate. I'll use it from now on. Click type will be retired until I can get it calibrated if I ever need to use it again. I really only use torque wrenches for things like head bolts and flywheel bolts, things where a beam type is easy to use, so I may never use the click type again at least on the miata.

#18

2 Props,3 Dildos,& 1 Cat

iTrader: (8)

Join Date: Jun 2005

Location: Fake Virginia

Posts: 19,338

Total Cats: 573

We have a fancy digital meter to unofficially 'requalifiy' torque wrenches here. My superduper cheap HF is pretty damn accurate and repeatable. About as good and the bigdollar Snapon Digital buzzers here. Just be sure to unwind the spring when you're done.

I still borrowed the snapon wrench when I built my engine though...

I still borrowed the snapon wrench when I built my engine though...

I just plain didn't want to think about it.

If you're really concerned, send it for calibration too.

Thread

Thread Starter

Forum

Replies

Last Post