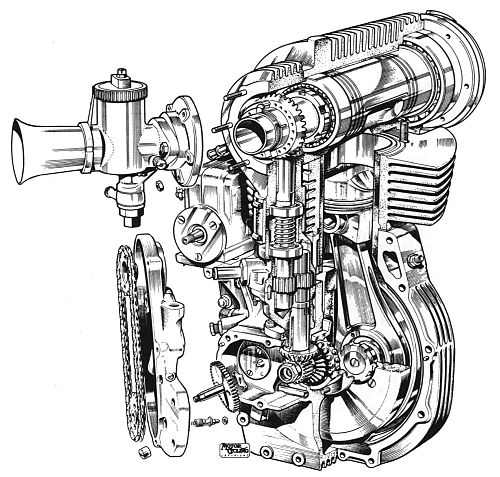

Inside Koenigsegg Cam-less engine

#43

But if you can control each valve individually you want to, so you want 16 circuits. You can do the one valve opening later than the other like the old ccvc engines for more fuel economy for example. And of course having this technology and not using as the throttling device would be silly.

#45

You could also do like the skyactiv engines and go into Atkinson cycle at low loads for FE then to Otto cycle for power at high loads. Though, how many will bother to tune this into their car without software that makes it easy?

#48

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,050

Total Cats: 6,608

I'm surprised nobody has mentioned the obvious, which is that with electro-pneumatic valve control, you can also eliminate the throttle.

#49

But if you can control each valve individually you want to, so you want 16 circuits. You can do the one valve opening later than the other like the old ccvc engines for more fuel economy for example. And of course having this technology and not using as the throttling device would be silly.

There's some data to suggest that being able to control each valve individually has value. For a system as radical as this, I'd think they'd not want to ignore "easy" gains.

I'm surprised nobody has mentioned the obvious, which is that with electro-pneumatic valve control, you can also eliminate the throttle.

I'm surprised nobody has mentioned the obvious, which is that with electro-pneumatic valve control, you can also eliminate the throttle.

#52

no the k20a3 opens 1 valve more than the other at lower rpm/load for better swirl/combustion/etc....its that (intake) camp specifically that has this and then opens both same amount when "vtak kicks in bro". lol

The more potent k20a2 on the other hand does it completely differently, so I dunno how effective it is.

The more potent k20a2 on the other hand does it completely differently, so I dunno how effective it is.

#53

Elite Member

iTrader: (1)

Join Date: May 2009

Location: Jacksonville, FL

Posts: 5,155

Total Cats: 406

pffft K20A3. Get that **** outta here  That **** was done on the D first.

That **** was done on the D first.

OBD2 D15B had 3 different ways to run the intake valves. One valve opening normally with the other just cracking to induce swirl, both valves opening normally, and high cam "vtec" with more lift and duration. All on one camshaft. It was hilarious looking, all sorts of lobes on that cam.

Edit: Found a pic:

Also, **** i-VTEC, its all about that "Advancted VTEC", assuming it ever sees the light of day:

But anyway.

I had a similar idea in highschool more or less. Except I was thinking of like an electrical actuator, so it would have control of lift as well, not just duration and timing. Variable lift isnt much of a sacrifice, sure its not ideal to use a super short, high lift profile at low speed, but the benefits would outweigh it. Plus if the engine isnt being designed for performance, you could make the lift small so it was well suited.

My idea way back when would be the ultimate of everything. Infinitely variable lift, duration, and timing of the cams, so it could make the best power possible at any rpm.

That **** was done on the D first.

That **** was done on the D first. OBD2 D15B had 3 different ways to run the intake valves. One valve opening normally with the other just cracking to induce swirl, both valves opening normally, and high cam "vtec" with more lift and duration. All on one camshaft. It was hilarious looking, all sorts of lobes on that cam.

Edit: Found a pic:

Also, **** i-VTEC, its all about that "Advancted VTEC", assuming it ever sees the light of day:

But anyway.

I had a similar idea in highschool more or less. Except I was thinking of like an electrical actuator, so it would have control of lift as well, not just duration and timing. Variable lift isnt much of a sacrifice, sure its not ideal to use a super short, high lift profile at low speed, but the benefits would outweigh it. Plus if the engine isnt being designed for performance, you could make the lift small so it was well suited.

My idea way back when would be the ultimate of everything. Infinitely variable lift, duration, and timing of the cams, so it could make the best power possible at any rpm.

Last edited by Full_Tilt_Boogie; 02-24-2013 at 03:34 AM.

#57

Elite Member

iTrader: (1)

Join Date: May 2009

Location: Jacksonville, FL

Posts: 5,155

Total Cats: 406

Ive seen that as well, but I dont think it worked very well.

This actually has been used for high performance, but because of boring racing rules meant to level the field and snuff out innovation, it hasnt seen any real use. But its definitely been worked on. This article is about a similar system designed for F1 use:

http://home.people.net.au/~mrbdesign...utoTechBRV.pdf

This actually has been used for high performance, but because of boring racing rules meant to level the field and snuff out innovation, it hasnt seen any real use. But its definitely been worked on. This article is about a similar system designed for F1 use:

http://home.people.net.au/~mrbdesign...utoTechBRV.pdf

#58

There's some data to suggest that being able to control each valve individually has value. For a system as radical as this, I'd think they'd not want to ignore "easy" gains.

I'm surprised nobody has mentioned the obvious, which is that with electro-pneumatic valve control, you can also eliminate the throttle.

I'm surprised nobody has mentioned the obvious, which is that with electro-pneumatic valve control, you can also eliminate the throttle.

In my opinion those pneumatic/modular valve control systems work very well.

I tried this multiair technology driving some cars my company owns (we have one 1.4L 170hp and one 0.9L 85hp): the one which really impressed me is a low-size (two cylinders only) 900cc engine turbocharged, 85hp and it's really surprising how a low cc engine can have such a good driveability and low fuel consumption... of course if you push it hard the fuel consumption goes away from declared one as it suffer for low size (even if it still keeps a good mileage per gallon value compared to the other engines), but I'm satisfied of the result of city and freeway standard driving.

Now there's a new upgrade scheduled for 2013 which brings the power to 101HP... we will see how it works!

#60

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,050

Total Cats: 6,608

The company that is developing the actuator is Cargine, not Koenigsegg. Check out their website.

Cargine | Free Valve Technology

Cargine | Free Valve Technology

Not that it's being done by someone other than Koenigseggisseggggnignigsegigisegggnigseggniggsegg , but that they appear to be claiming credit for it.