Z3 1990 Miata

#25

Slowest Progress Ever

iTrader: (26)

Join Date: Oct 2007

Location: The coal ridden hills of Pennsylvania

Posts: 6,025

Total Cats: 304

This is simple. Drive the car into a garage that has some sort of overhead hoist.

Attach cable to "newly engineered style bar" and try to lift the car off the ground. If it comes off the ground, you win. Try it and find out though...on video...just for proving me wrong purposes.

Attach cable to "newly engineered style bar" and try to lift the car off the ground. If it comes off the ground, you win. Try it and find out though...on video...just for proving me wrong purposes.

#27

If you look at that picture the bar didn't fail, it folded at the seat belt tower due to non triangulated load. If you take hard dog 4 point bar and chop rear legs off, it will do same thing. Btw style bar is 2.25x1/8" tubing, seems like people talking about it never handled one in person, and I agree that with no rear legs that thing will fold easy. As for assumptions, I was neglecting load distribution to front/rear contact point of the car when it flips, and assuming that the bar takes full stress. In real life, quite bit of the weight will be on the front portion of the hood, just like a hinged beam simply supported at other side.

#28

There's only one way to prove us wrong... real life roll over testing.

All joking aside it's an improvement but why mess around with skimping on something that might one day save your life (or end it). Hard dog and similar design roll bars are proven to be structurally sound to do it's job in a roll over. Why risk it?

All joking aside it's an improvement but why mess around with skimping on something that might one day save your life (or end it). Hard dog and similar design roll bars are proven to be structurally sound to do it's job in a roll over. Why risk it?

#33

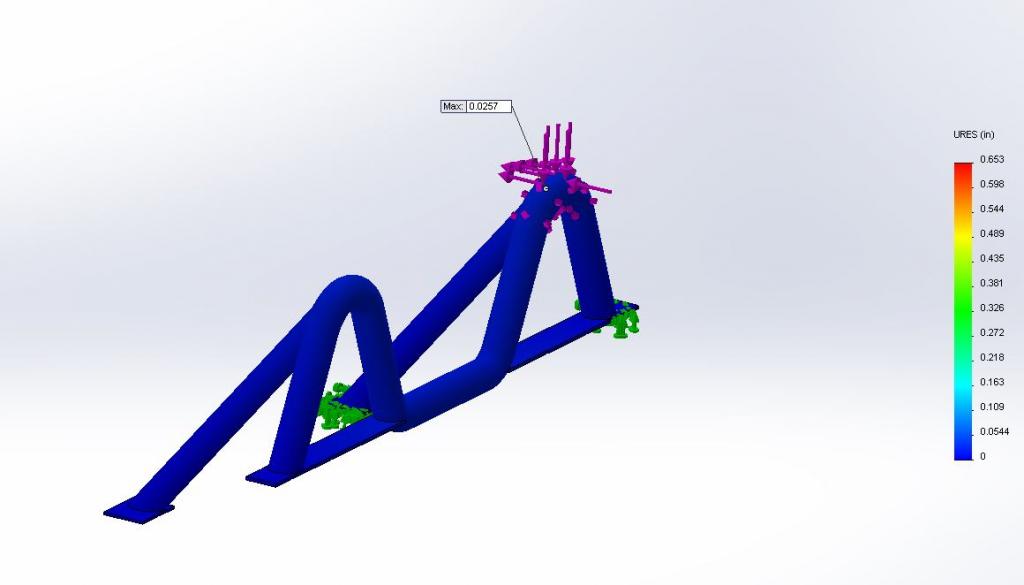

I can tell by your stress analysis results that your model isn't a good representation of reality. You are assuming that that bar had true fixed supports all over the place. As in, when this thing rolls, no piece of the chassis will deflect even 0.001". Really?

Also, a 3000lb force is too small. Sure, if you gently set the car down on the bar, it MAY survive. Rolling at speeds of even 10 mph the forces involved are much, much larger than 3000lb on a 2500lb car. At 50 mph, I don't even want to know what the forces are the roll bar may see.

Your assuming the material, the bar thickness(and its uniformity through a very questionable style bar), the welds will be perfect, the forces are really low, and true fixed supports on the chassis. Each one of these assumptions makes this model invalid.

Just buy a real roll bar that's actually approved by some sort of sanctioning body, like SCCA. They are pretty cheap for the miata. This will potentially save your life, or the person you are selling it to. Enough said.

Going with what 18psi said, your trying pretty hard to convince yourself that everything is fine. Your additional bar added to the style bar will strengthen it some, but not enough to be trustworthy for a real roll bar.

Also, a 3000lb force is too small. Sure, if you gently set the car down on the bar, it MAY survive. Rolling at speeds of even 10 mph the forces involved are much, much larger than 3000lb on a 2500lb car. At 50 mph, I don't even want to know what the forces are the roll bar may see.

Your assuming the material, the bar thickness(and its uniformity through a very questionable style bar), the welds will be perfect, the forces are really low, and true fixed supports on the chassis. Each one of these assumptions makes this model invalid.

Just buy a real roll bar that's actually approved by some sort of sanctioning body, like SCCA. They are pretty cheap for the miata. This will potentially save your life, or the person you are selling it to. Enough said.

Going with what 18psi said, your trying pretty hard to convince yourself that everything is fine. Your additional bar added to the style bar will strengthen it some, but not enough to be trustworthy for a real roll bar.

#35

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,663

Total Cats: 3,012

A 2400lb car falling on its roof at 20mph in 6 inches of distance (let's say it was soft dirt) exerts 64,227lbs of force somewhere. Some of that force will be taken by other parts of the car body, sure. But what portion of that does the roll bar need to withstand?

Source calculator: http://hyperphysics.phy-astr.gsu.edu/hbase/carcr2.html

Source calculator: http://hyperphysics.phy-astr.gsu.edu/hbase/carcr2.html

#36

I can tell by your stress analysis results that your model isn't a good representation of reality. You are assuming that that bar had true fixed supports all over the place. As in, when this thing rolls, no piece of the chassis will deflect even 0.001". Really?

Also, a 3000lb force is too small. Sure, if you gently set the car down on the bar, it MAY survive. Rolling at speeds of even 10 mph the forces involved are much, much larger than 3000lb on a 2500lb car. At 50 mph, I don't even want to know what the forces are the roll bar may see.

Your assuming the material, the bar thickness(and its uniformity through a very questionable style bar), the welds will be perfect, the forces are really low, and true fixed supports on the chassis. Each one of these assumptions makes this model invalid.

Just buy a real roll bar that's actually approved by some sort of sanctioning body, like SCCA. They are pretty cheap for the miata. This will potentially save your life, or the person you are selling it to. Enough said.

Going with what 18psi said, your trying pretty hard to convince yourself that everything is fine. Your additional bar added to the style bar will strengthen it some, but not enough to be trustworthy for a real roll bar.

Also, a 3000lb force is too small. Sure, if you gently set the car down on the bar, it MAY survive. Rolling at speeds of even 10 mph the forces involved are much, much larger than 3000lb on a 2500lb car. At 50 mph, I don't even want to know what the forces are the roll bar may see.

Your assuming the material, the bar thickness(and its uniformity through a very questionable style bar), the welds will be perfect, the forces are really low, and true fixed supports on the chassis. Each one of these assumptions makes this model invalid.

Just buy a real roll bar that's actually approved by some sort of sanctioning body, like SCCA. They are pretty cheap for the miata. This will potentially save your life, or the person you are selling it to. Enough said.

Going with what 18psi said, your trying pretty hard to convince yourself that everything is fine. Your additional bar added to the style bar will strengthen it some, but not enough to be trustworthy for a real roll bar.

source. http://hyperphysics.phy-astr.gsu.edu/hbase/carcr2.html

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

Last edited by OGRacing; 01-19-2015 at 03:18 PM.

#38

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,663

Total Cats: 3,012

Hell, I'm in for stress analysis on 64,000 lbs.

For reference, the machine pictured weighs 57,000 and is lifting a segment of 42" diameter RCP (Reinforced Concrete Pipe) that weighs just under 7,800 lbs (or about 3 Miatas).

For reference, the machine pictured weighs 57,000 and is lifting a segment of 42" diameter RCP (Reinforced Concrete Pipe) that weighs just under 7,800 lbs (or about 3 Miatas).

#40

Those are different forces, you are comparing crumple zone to a roll over force. Car trevaling at 50mph and not rolling over and stoping in 6ft, friction coefficient of steel is far less than a tire on pavement, so you will be skidding on your roof to a stop a longer distance than a regular stop.

I'm not claiming that this bar is an ultimate roll over protection, six point cage is a minimum that I would trust on roll over. I'm just saying that it won't fold over like the original bar would. Btw DOM tubing is a regular ERW tube processed through cold work that gives it 40% strength increase, a tubing spec for 2500lb car is 1.75"x.095 wall DOM which is what Hard Dog bar uses, next step for 3000lb car is .25" OD increase, switching to .120 also counts as a step increase. I used 2"x.120 wall DOM for my tubing and main structure is 2.25x.120, so even with untreated steel, the size is 4 steps up.

I'm not claiming that this bar is an ultimate roll over protection, six point cage is a minimum that I would trust on roll over. I'm just saying that it won't fold over like the original bar would. Btw DOM tubing is a regular ERW tube processed through cold work that gives it 40% strength increase, a tubing spec for 2500lb car is 1.75"x.095 wall DOM which is what Hard Dog bar uses, next step for 3000lb car is .25" OD increase, switching to .120 also counts as a step increase. I used 2"x.120 wall DOM for my tubing and main structure is 2.25x.120, so even with untreated steel, the size is 4 steps up.

Last edited by Artsvetkov; 01-19-2015 at 09:36 PM.