MS2 Boost control - Am I missing something?

#21

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Fair warning though, in the next release the boost control will be different, it uses ideal PID instead and will have a slightly different tuning method. No initial value table, instead it has a bias table.

#22

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

I understand the premise of the initial value table, I just do not like the application of it in relation to closed loop idle entry, it is never as close as I expected it to be. I've been using last value forever now and it seems alright.

I anticipate initial value on boost control to be similar, so I am happy they are changing it. Only reason I was messing with it is because I wanted the stupid valve closed at idle, heh.

I anticipate initial value on boost control to be similar, so I am happy they are changing it. Only reason I was messing with it is because I wanted the stupid valve closed at idle, heh.

#23

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

It really is helpful though, it makes a pretty big difference in being able to lower your lower limit delta, which means better spool. In the beta the initial value table is now a bias table, so it is part of the closed loop calculations all the way through the pull.

Valve closed at idle is useless, really the valve can be wide open until the time that your wastegate would start to open.

Make sure that you tune the max duty cycle. It made a world of difference. It really helps almost eliminate integral windup.

Valve closed at idle is useless, really the valve can be wide open until the time that your wastegate would start to open.

Make sure that you tune the max duty cycle. It made a world of difference. It really helps almost eliminate integral windup.

#24

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

Are you certain that using the initial table is giving you best spool in all circumstances though? Maybe it does so for a easy 2-7K 4th pull, but I don't see the resolution required to properly stage the valve like I need too in all cases.

When I was trying that with the idle valve I always seemed to overshoot the target and have a unnecessary high idle. If I try to push the envelope, aggressively tune straight at idle speed I want (or spool I want) I'd end up with garbage on both sides, I'd still be idling high occasionally, and I'd start dipping the idle as well, a new problem.

I don't see it being too different for EBC, except with worse results than a high/low idle, so I'd rather just turn the dashpot up, or the limit delta, and let the maths handle the odd cases for me.

Max duty cycle? You leave yours at less than 100% DC?

When I was trying that with the idle valve I always seemed to overshoot the target and have a unnecessary high idle. If I try to push the envelope, aggressively tune straight at idle speed I want (or spool I want) I'd end up with garbage on both sides, I'd still be idling high occasionally, and I'd start dipping the idle as well, a new problem.

I don't see it being too different for EBC, except with worse results than a high/low idle, so I'd rather just turn the dashpot up, or the limit delta, and let the maths handle the odd cases for me.

Max duty cycle? You leave yours at less than 100% DC?

#25

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Are you certain that using the initial table is giving you best spool in all circumstances though? Maybe it does so for a easy 2-7K 4th pull, but I don't see the resolution required to properly stage the valve like I need too in all cases.

When I was trying that with the idle valve I always seemed to overshoot the target and have a unnecessary high idle. If I try to push the envelope, aggressively tune straight at idle speed I want (or spool I want) I'd end up with garbage on both sides, I'd still be idling high occasionally, and I'd start dipping the throttle too.

I don't see it being too different for EBC, except with worse results than a high/low idle, so I'd rather just turn the dashpot up, or the limit delta, and let the maths handle the odd cases for me.

Max duty cycle? You leave yours at less than 100% DC?

When I was trying that with the idle valve I always seemed to overshoot the target and have a unnecessary high idle. If I try to push the envelope, aggressively tune straight at idle speed I want (or spool I want) I'd end up with garbage on both sides, I'd still be idling high occasionally, and I'd start dipping the throttle too.

I don't see it being too different for EBC, except with worse results than a high/low idle, so I'd rather just turn the dashpot up, or the limit delta, and let the maths handle the odd cases for me.

Max duty cycle? You leave yours at less than 100% DC?

Yeah. Most of the time you can lower the max duty cycle a lot without effecting spool. I was able to lower mine all the way to 65% with no change in spool. This makes a huge difference because it lets the PID equation work inside a smaller window. The equation wont be trying to go all the way to 100% when it only needs to go to 65%. So you will end up with the closed loop winding up and then you get overshoot, or over correction. By limiting the min and max duties you can give it a smaller window to work in.

Its just like how we set the min and max idle valve duties.

#26

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

I see...

You are right though, I need to find best ever possible spool and log that then just work my way back to it. I don't really think I have much of an overshoot problem though, I'm not sure how and it might just be my exceptionally terrible wastegate and downpipe setup but I don't seem to have overshoot issues too often.

I've been all over the overboost protection though hehe

You are right though, I need to find best ever possible spool and log that then just work my way back to it. I don't really think I have much of an overshoot problem though, I'm not sure how and it might just be my exceptionally terrible wastegate and downpipe setup but I don't seem to have overshoot issues too often.

I've been all over the overboost protection though hehe

#33

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Small quote about control interval:

OK, if it's working that's fine, but with your current control interval, PID is making changes and expecting responses more often than it's capable of actually causing a change to the valve position, which will also cause the gains to be over-sensitive.

#34

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

Yeah, I think I need to dumb my valve down a lot...

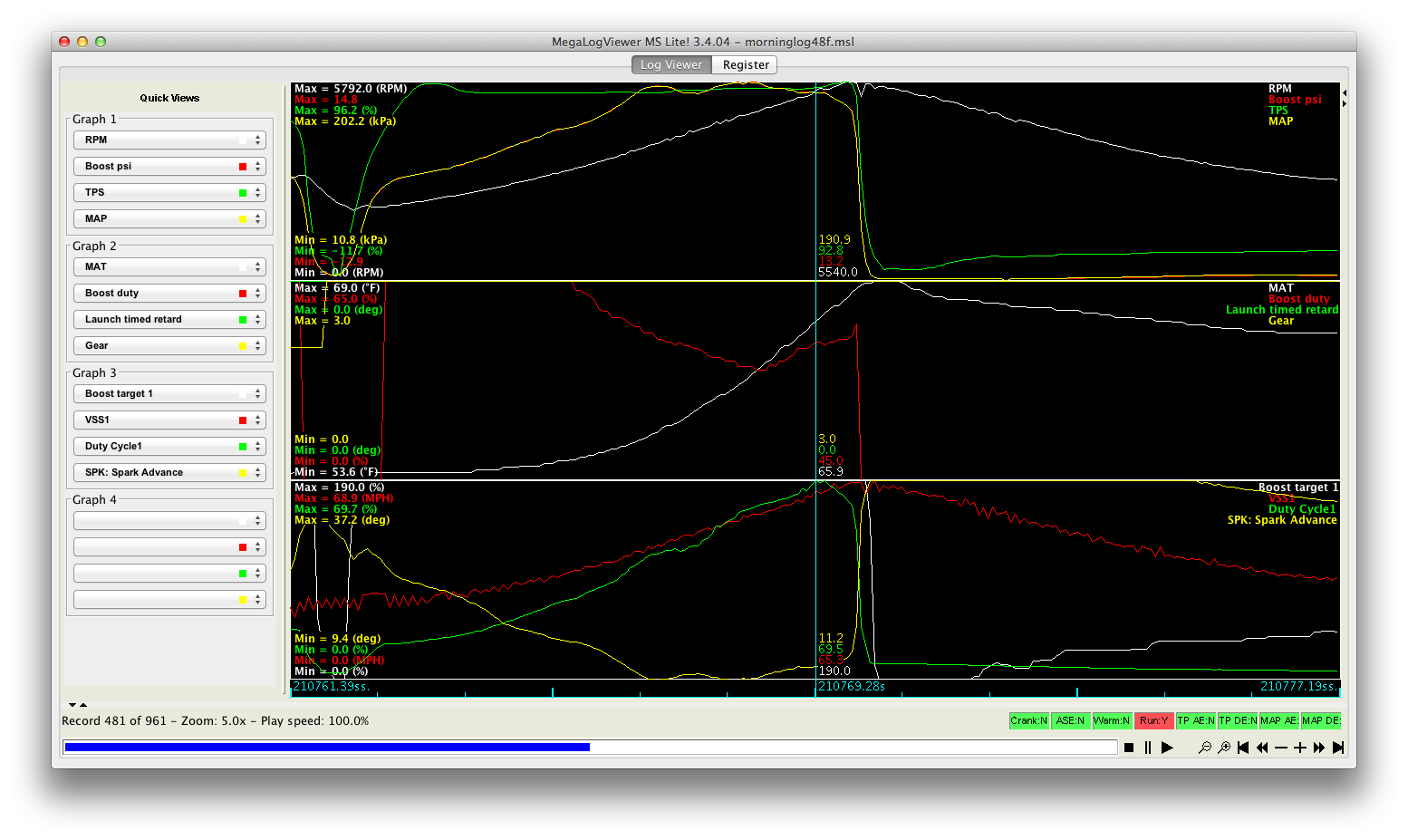

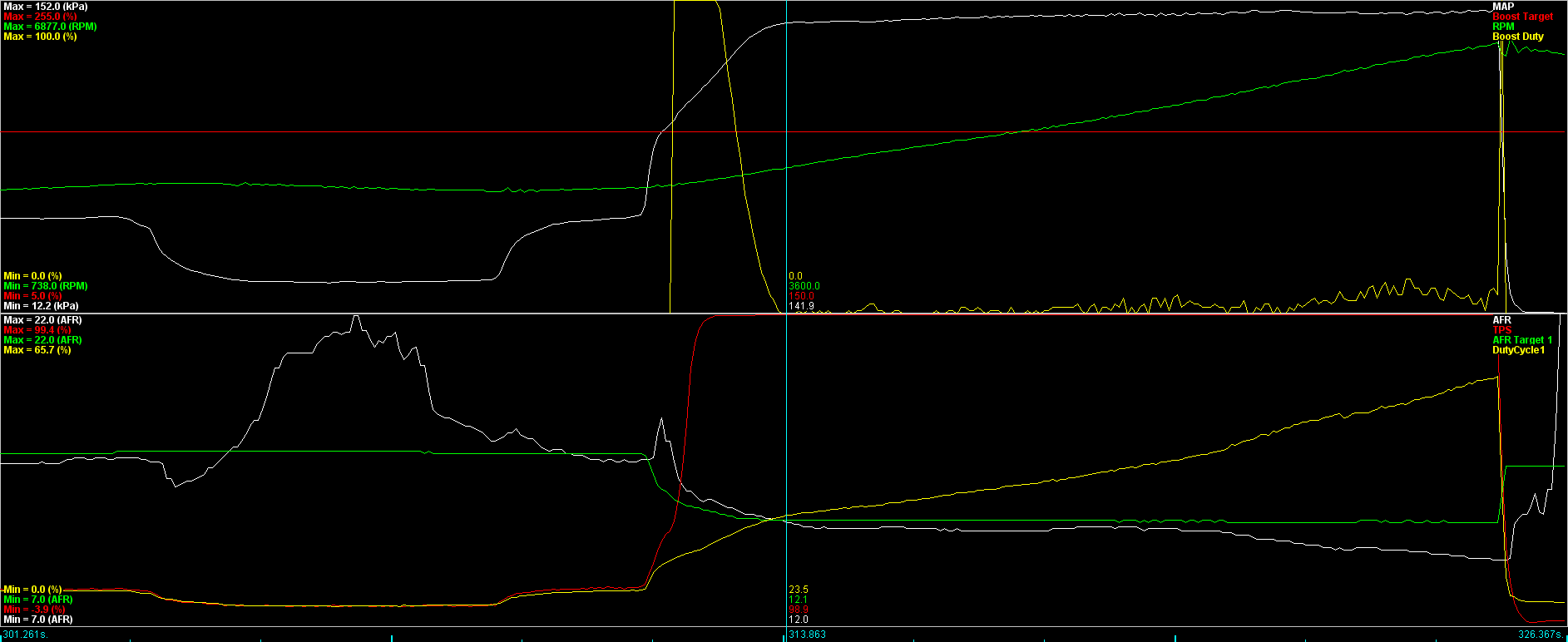

So I've found what I imagine is best spool, now I just need to reign in the valve range, looks like 0-60%DC and fine tune the PID a bit more.

I was spooling ~7psi at 3800-4000, so this is much improved. Never overboost, never overshot...

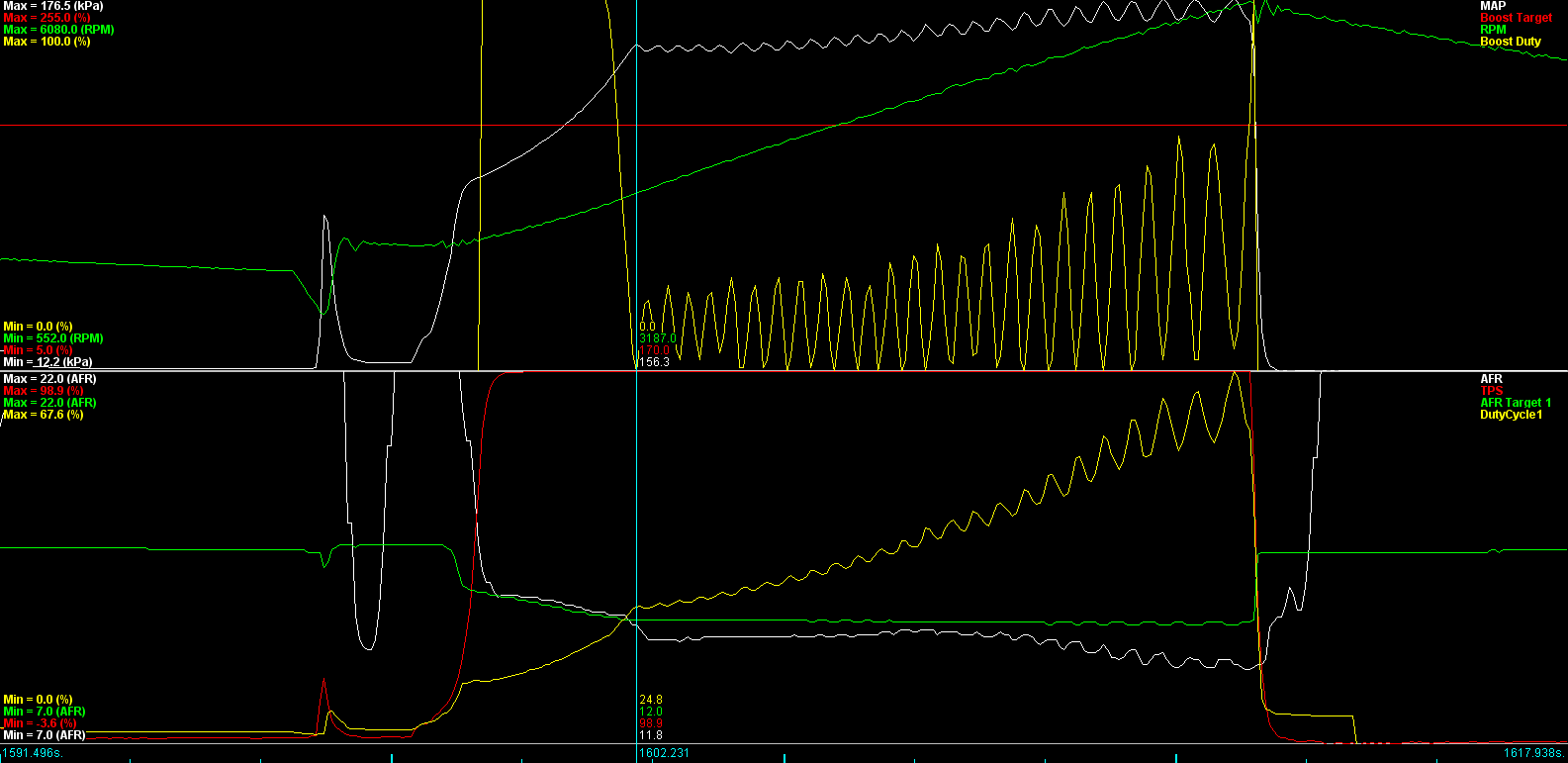

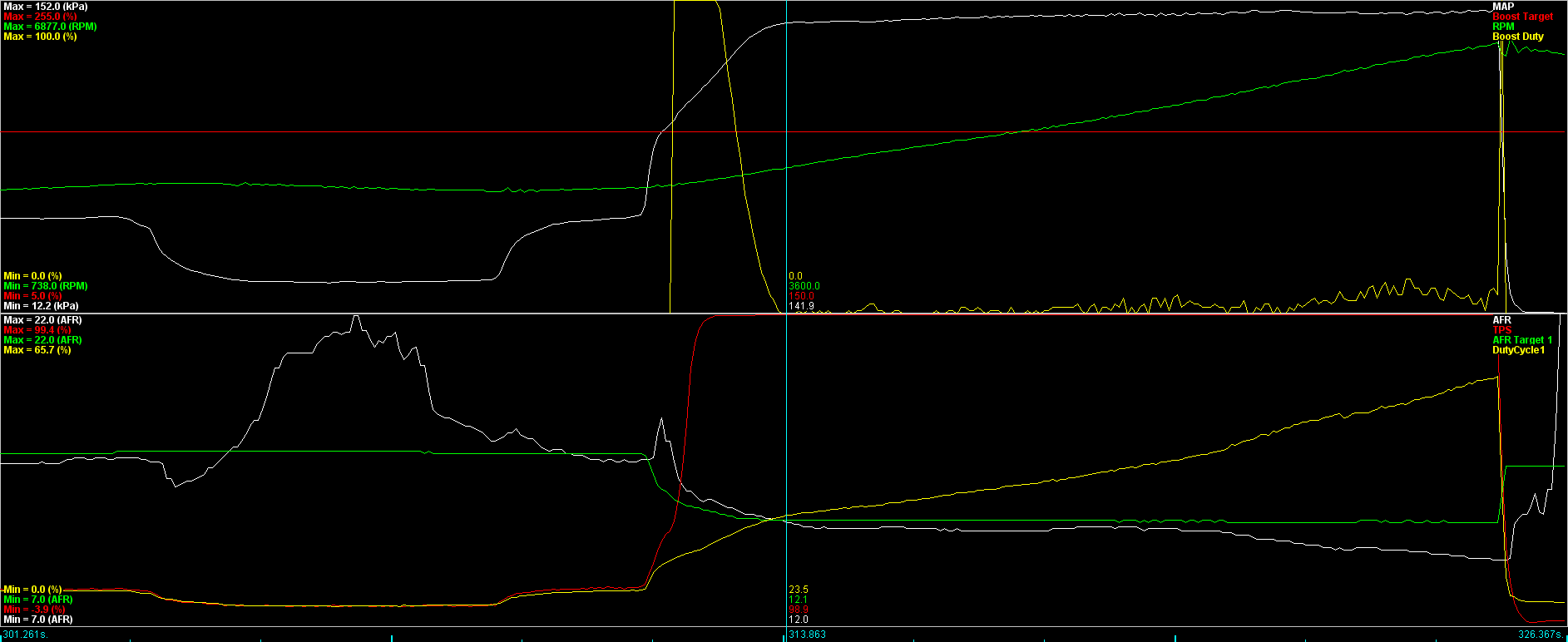

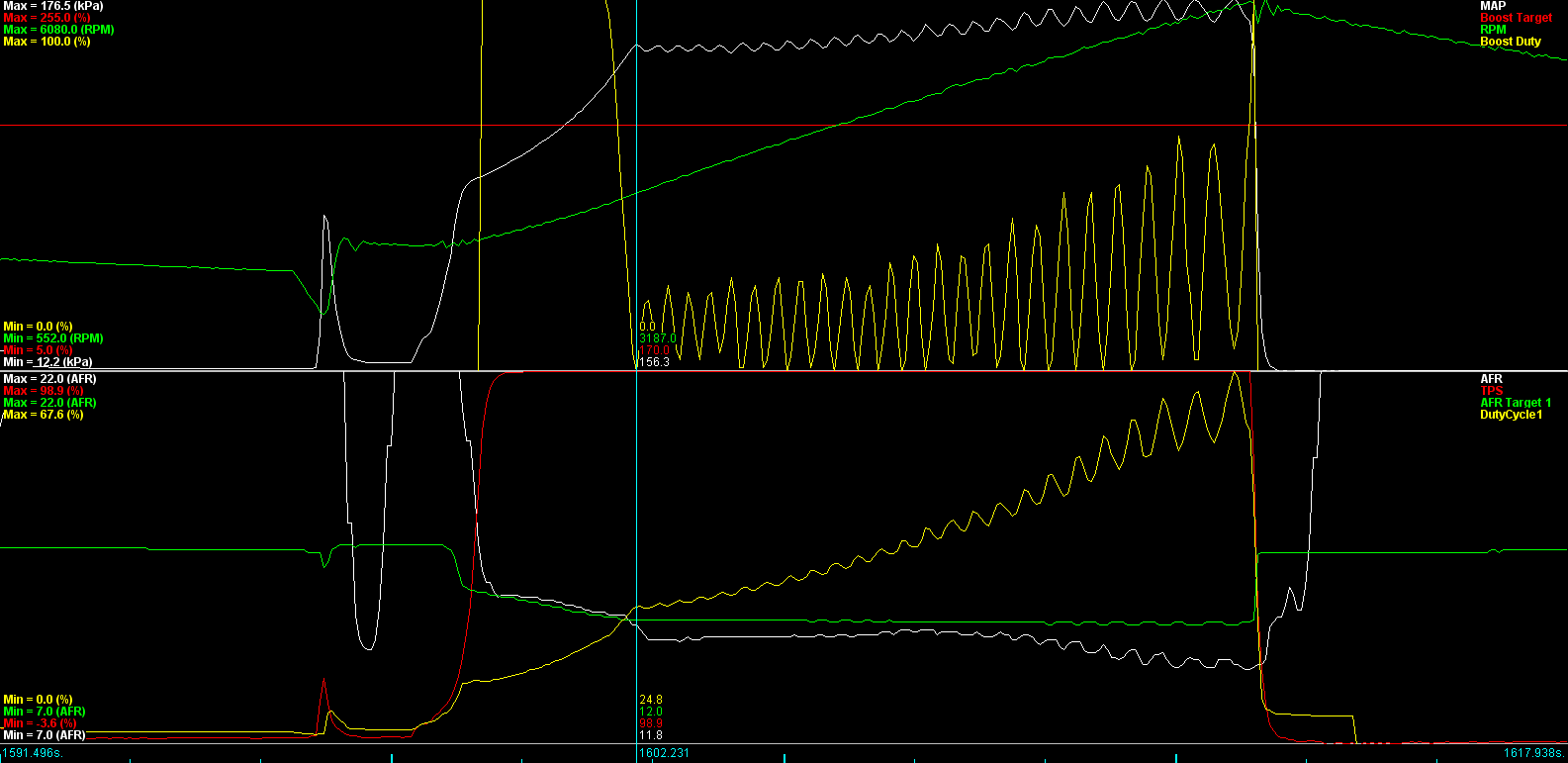

This here is bare wastegate, my go-fast switch just interrupts the valve signal. I can't find a fancy boost table switch or anything in MS2. In other words, ignore the boost DC in this. ~6psi at 3600 or so.

Edit: 19.5Hz = 51.2ms, so I'm thinking a 50ms interval is best at a minimum.

So I've found what I imagine is best spool, now I just need to reign in the valve range, looks like 0-60%DC and fine tune the PID a bit more.

I was spooling ~7psi at 3800-4000, so this is much improved. Never overboost, never overshot...

This here is bare wastegate, my go-fast switch just interrupts the valve signal. I can't find a fancy boost table switch or anything in MS2. In other words, ignore the boost DC in this. ~6psi at 3600 or so.

Edit: 19.5Hz = 51.2ms, so I'm thinking a 50ms interval is best at a minimum.

Last edited by deezums; 05-18-2015 at 03:54 AM.

#38

Yeah, I think I need to dumb my valve down a lot...

So I've found what I imagine is best spool, now I just need to reign in the valve range, looks like 0-60%DC and fine tune the PID a bit more.

I was spooling ~7psi at 3800-4000, so this is much improved. Never overboost, never overshot...

This here is bare wastegate, my go-fast switch just interrupts the valve signal. I can't find a fancy boost table switch or anything in MS2. In other words, ignore the boost DC in this. ~6psi at 3600 or so.

Edit: 19.5Hz = 51.2ms, so I'm thinking a 50ms interval is best at a minimum.

So I've found what I imagine is best spool, now I just need to reign in the valve range, looks like 0-60%DC and fine tune the PID a bit more.

I was spooling ~7psi at 3800-4000, so this is much improved. Never overboost, never overshot...

This here is bare wastegate, my go-fast switch just interrupts the valve signal. I can't find a fancy boost table switch or anything in MS2. In other words, ignore the boost DC in this. ~6psi at 3600 or so.

Edit: 19.5Hz = 51.2ms, so I'm thinking a 50ms interval is best at a minimum.

Last edited by Mech5700; 05-18-2015 at 02:46 PM.

#40

Elite Member

Thread Starter

iTrader: (3)

Join Date: May 2014

Location: Kansas

Posts: 3,146

Total Cats: 201

Need to go back out again, more tuning

Do you remember where you were getting this T3 to spool Scott? I'm pretty impressed for a <$200 5K+mi turbo.