Aidan's loose oily bunghole actually runs a track lap

#9063

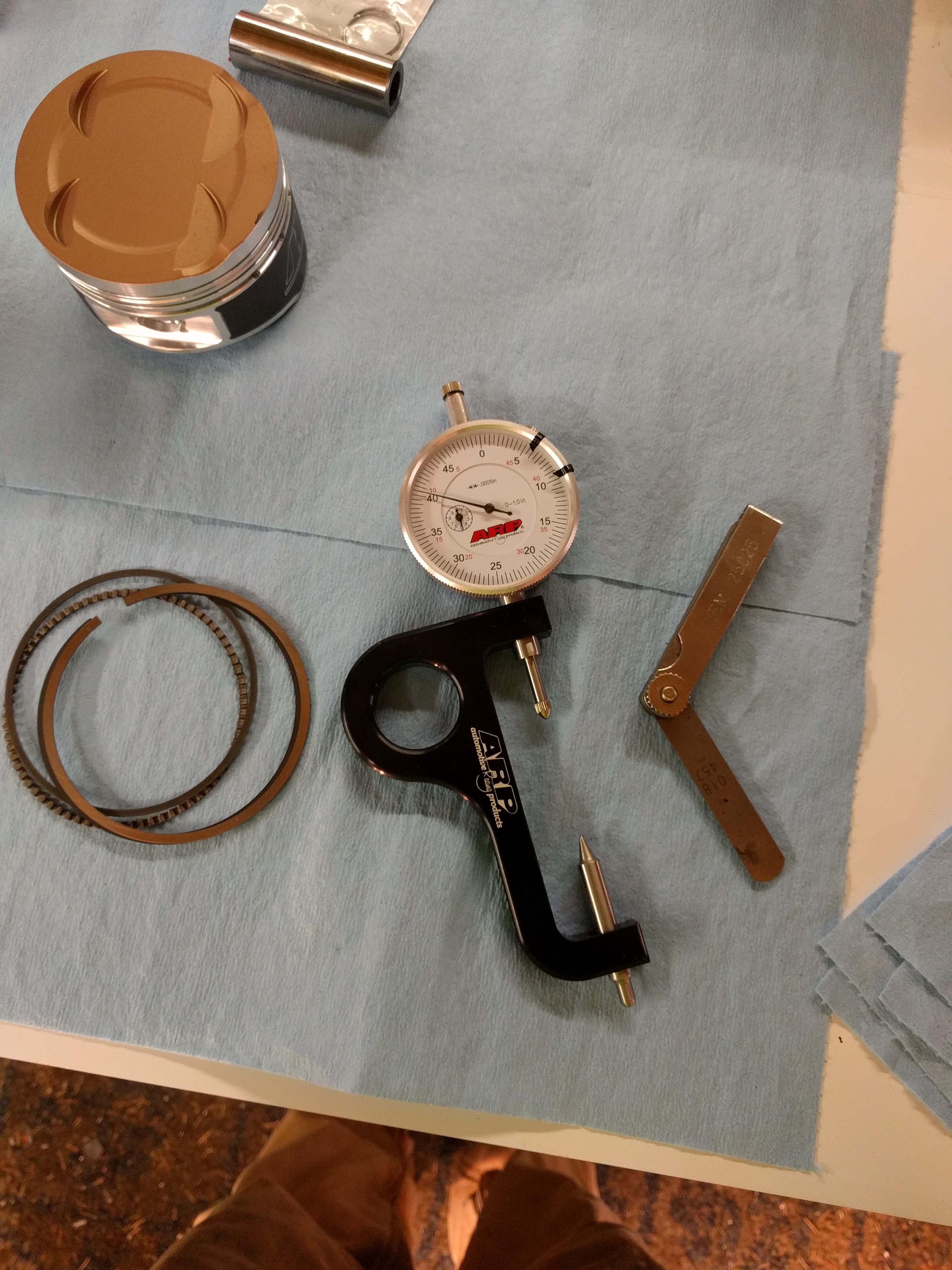

I think there's a typo in the chart for the second ring -- it doesn't make sense that it would go .005/.0055 to .0055/.0053 and then .006/.0057. I used .018 and .020.

And yeah, I vaguely recall reading that the oil rails are just a minimum of .015 always, not multiplied by the bore. I don't see it in the instructions, though.

--Ian

And yeah, I vaguely recall reading that the oil rails are just a minimum of .015 always, not multiplied by the bore. I don't see it in the instructions, though.

--Ian

#9066

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

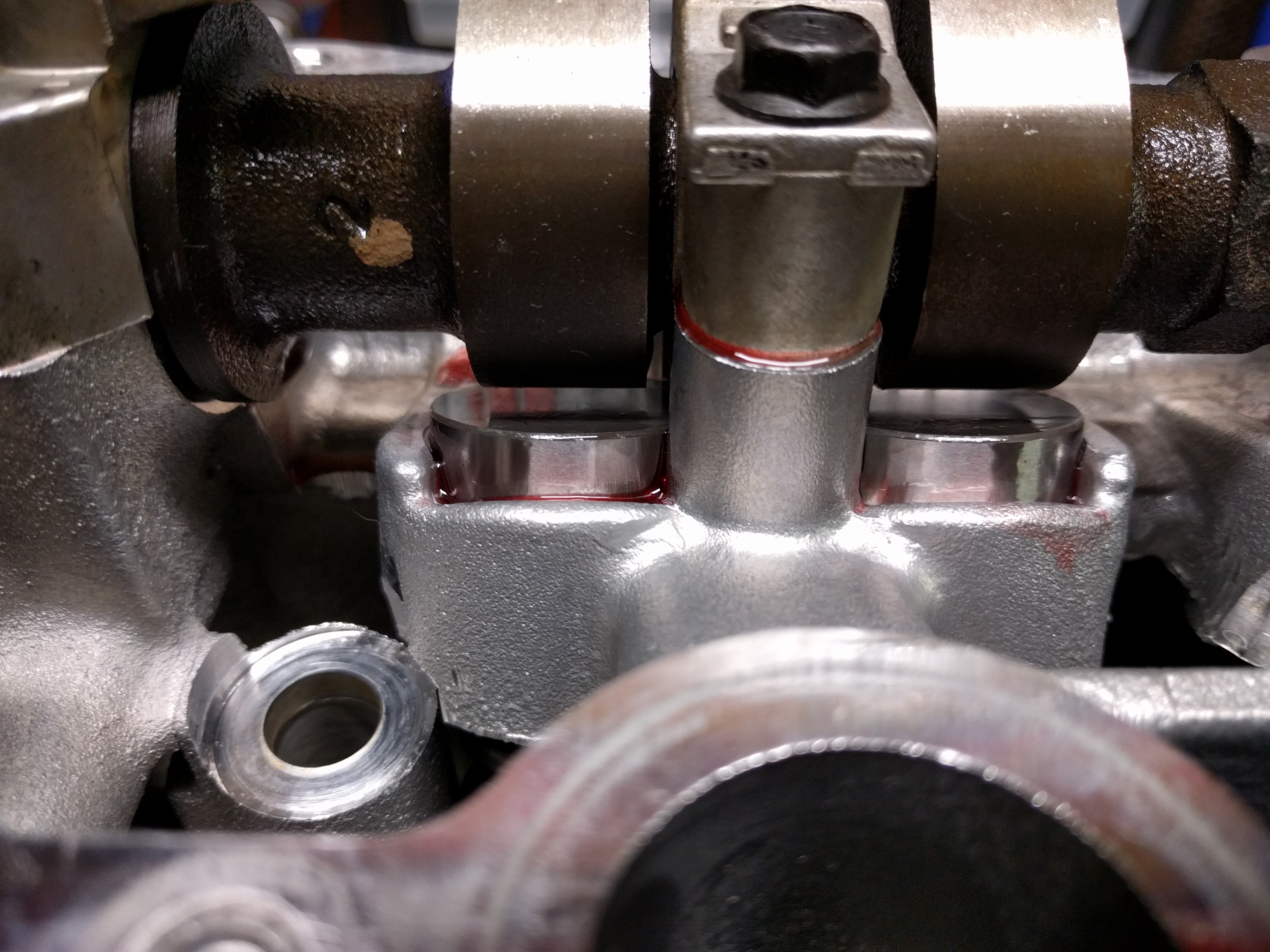

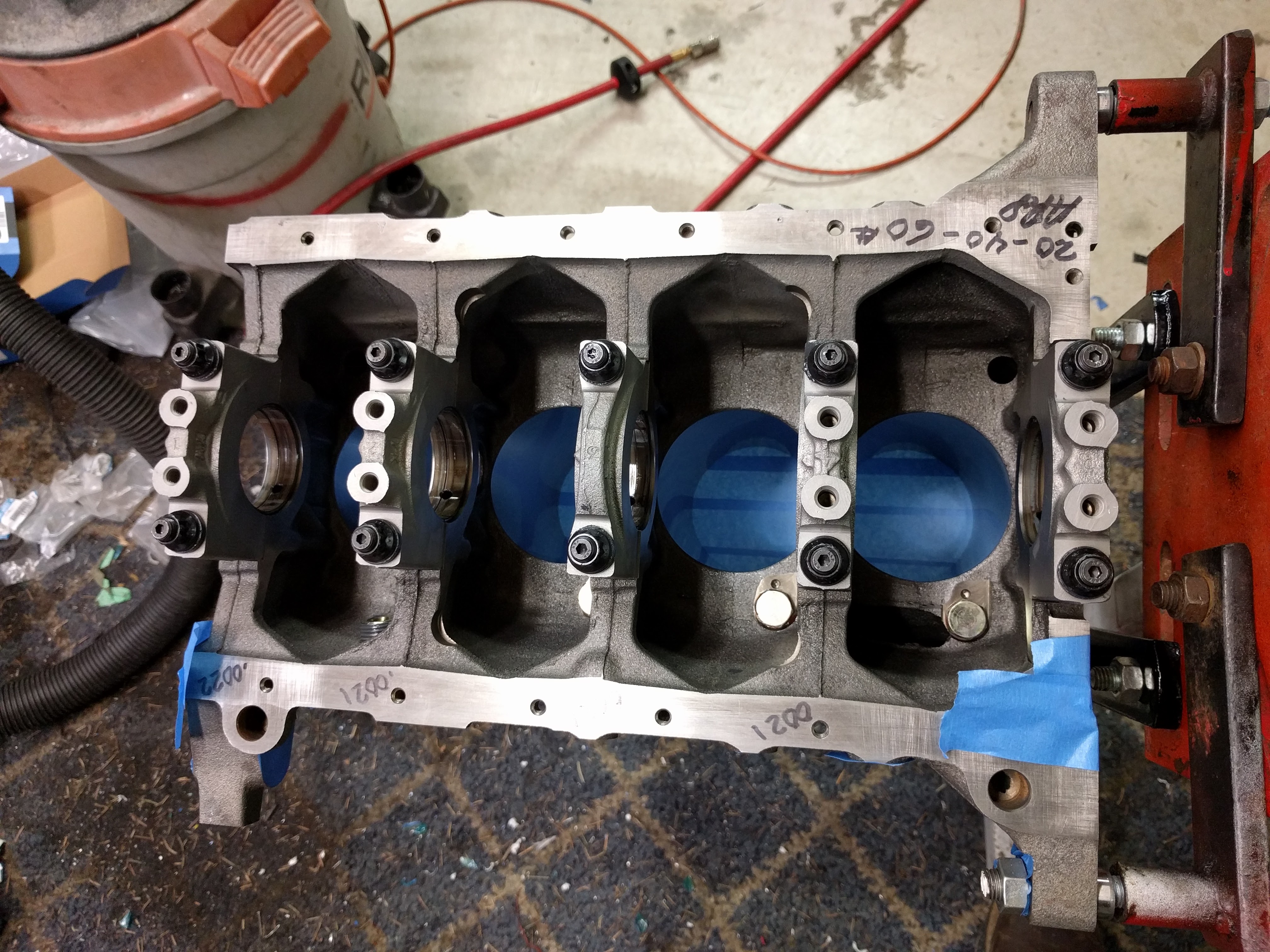

Try it dry, try it with oil, compare measurements. If it does not change, it does not matter?

Let me help you overthink this some more...

Do you expect your bores to be constantly flooded in oil?

Did you heat the block to ~190° before taking the measurement?

Let me help you overthink this some more...

Do you expect your bores to be constantly flooded in oil?

Did you heat the block to ~190° before taking the measurement?

#9070

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Nope. Through a local shop.

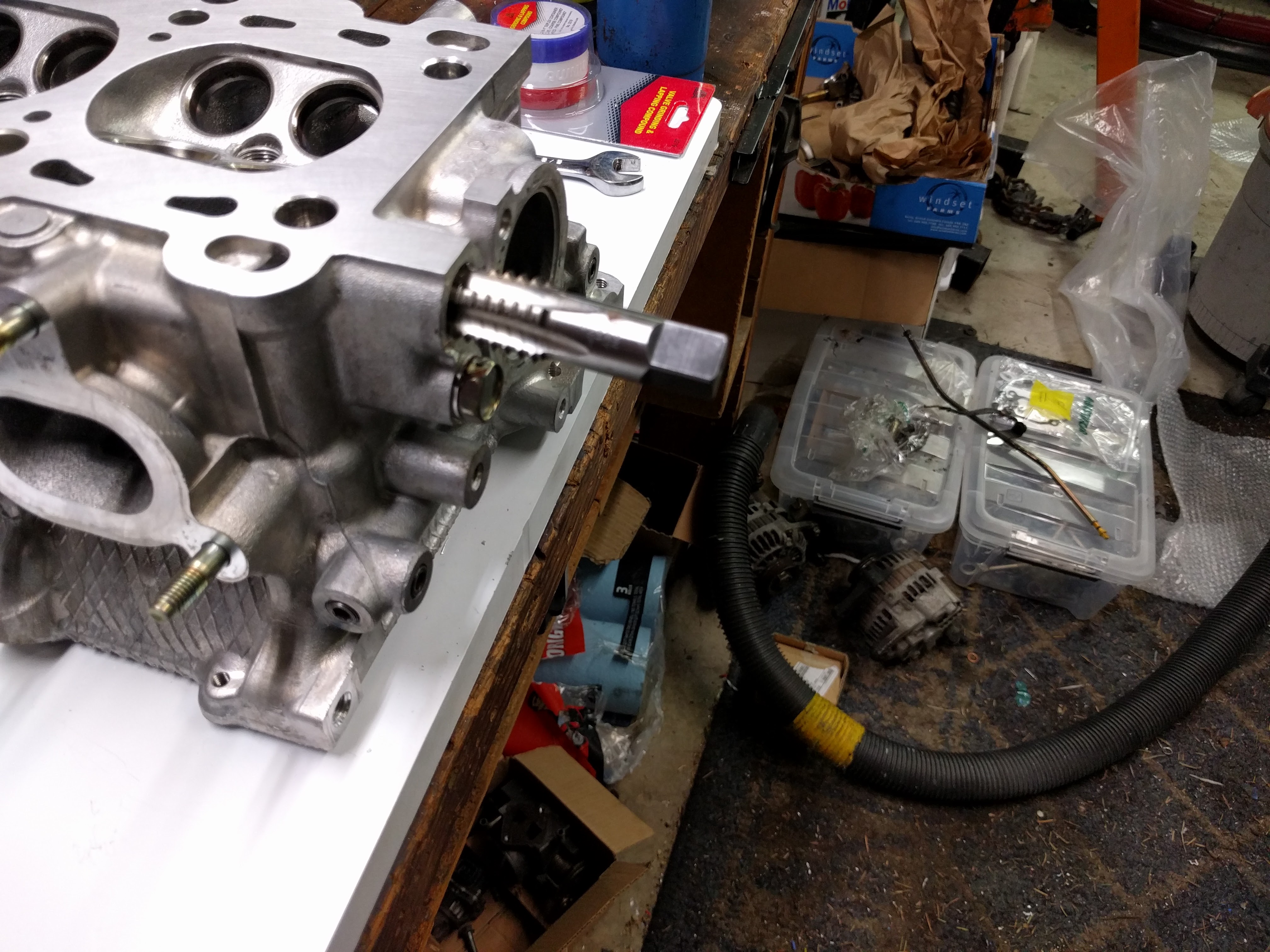

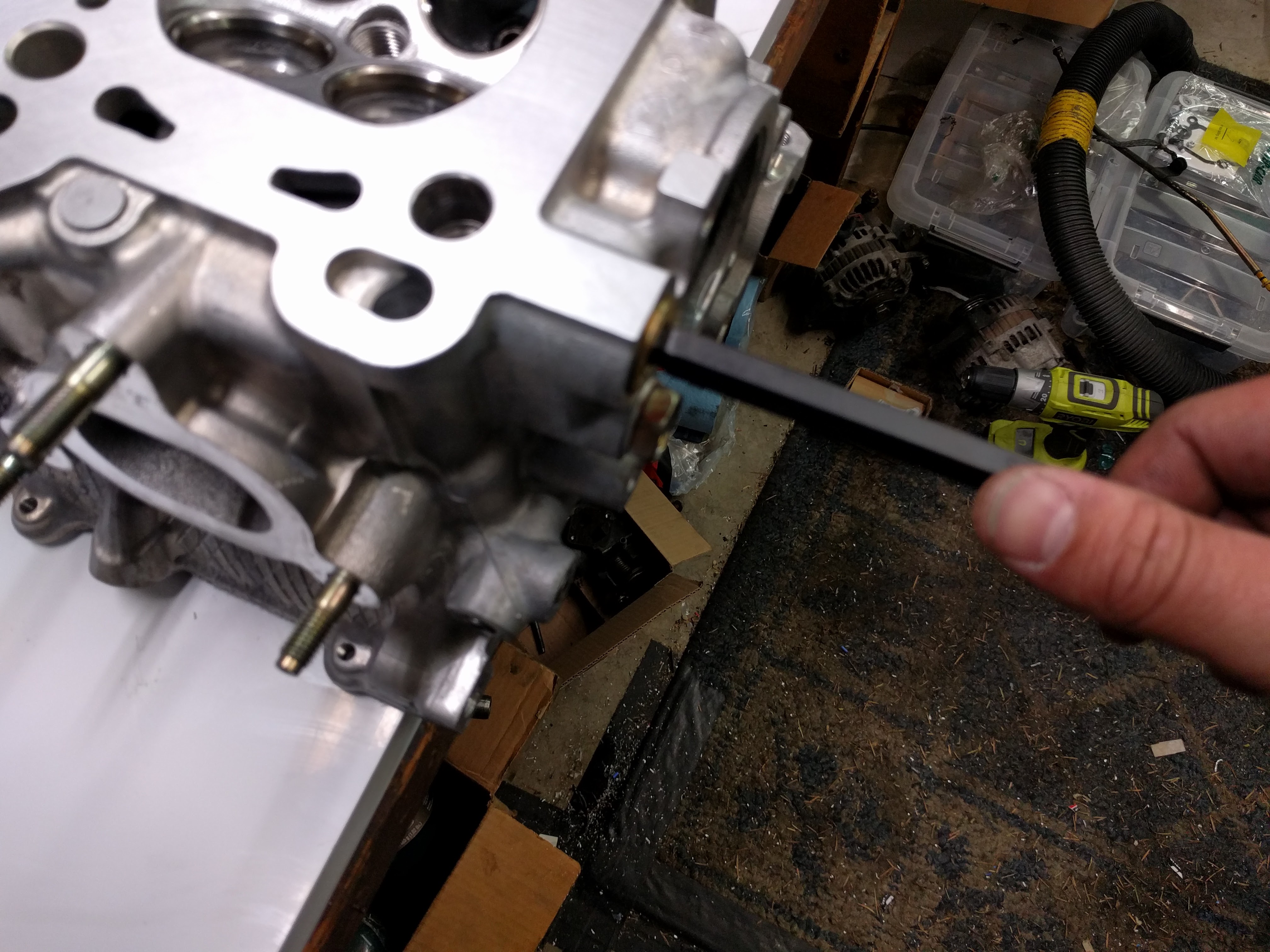

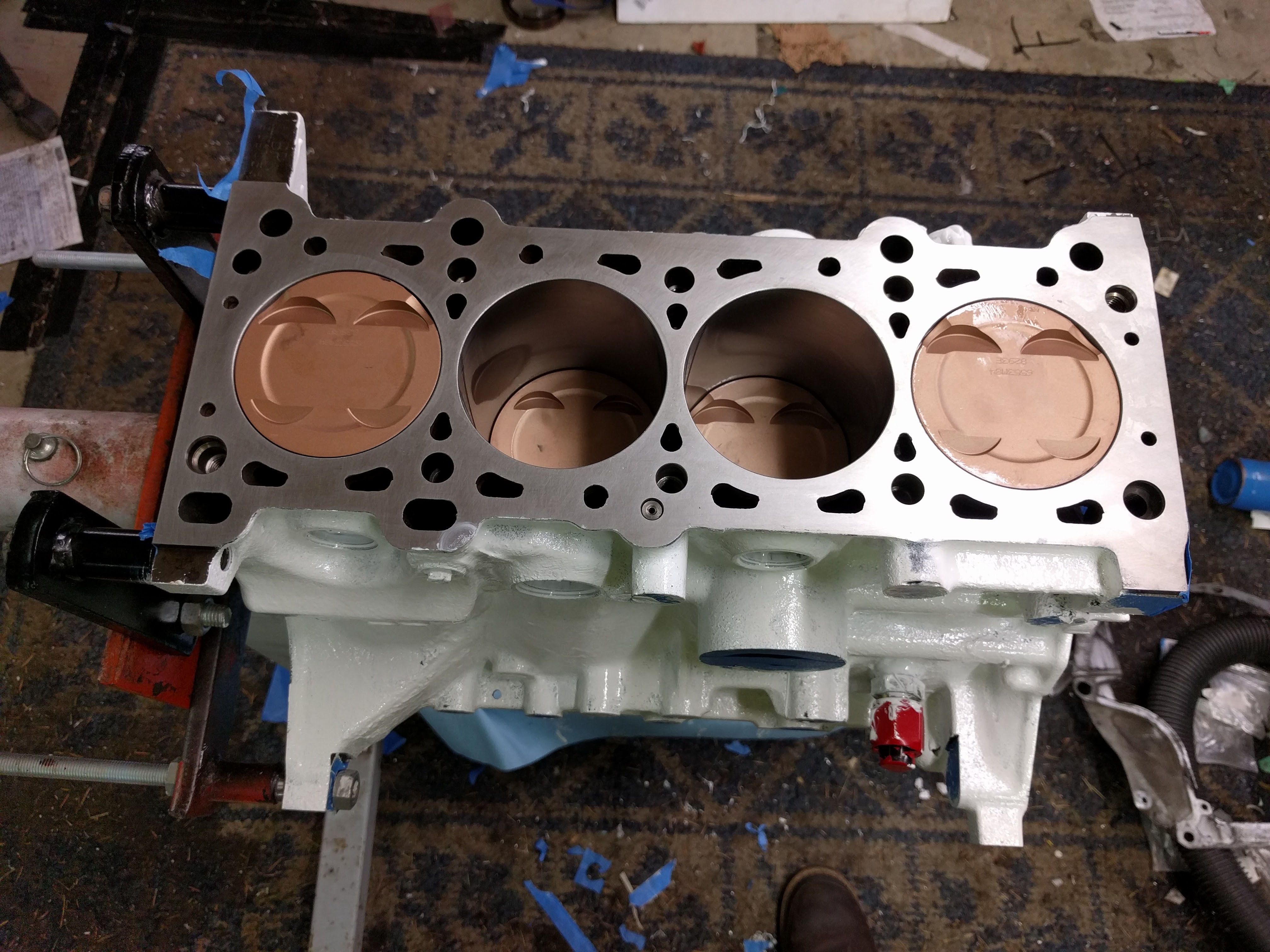

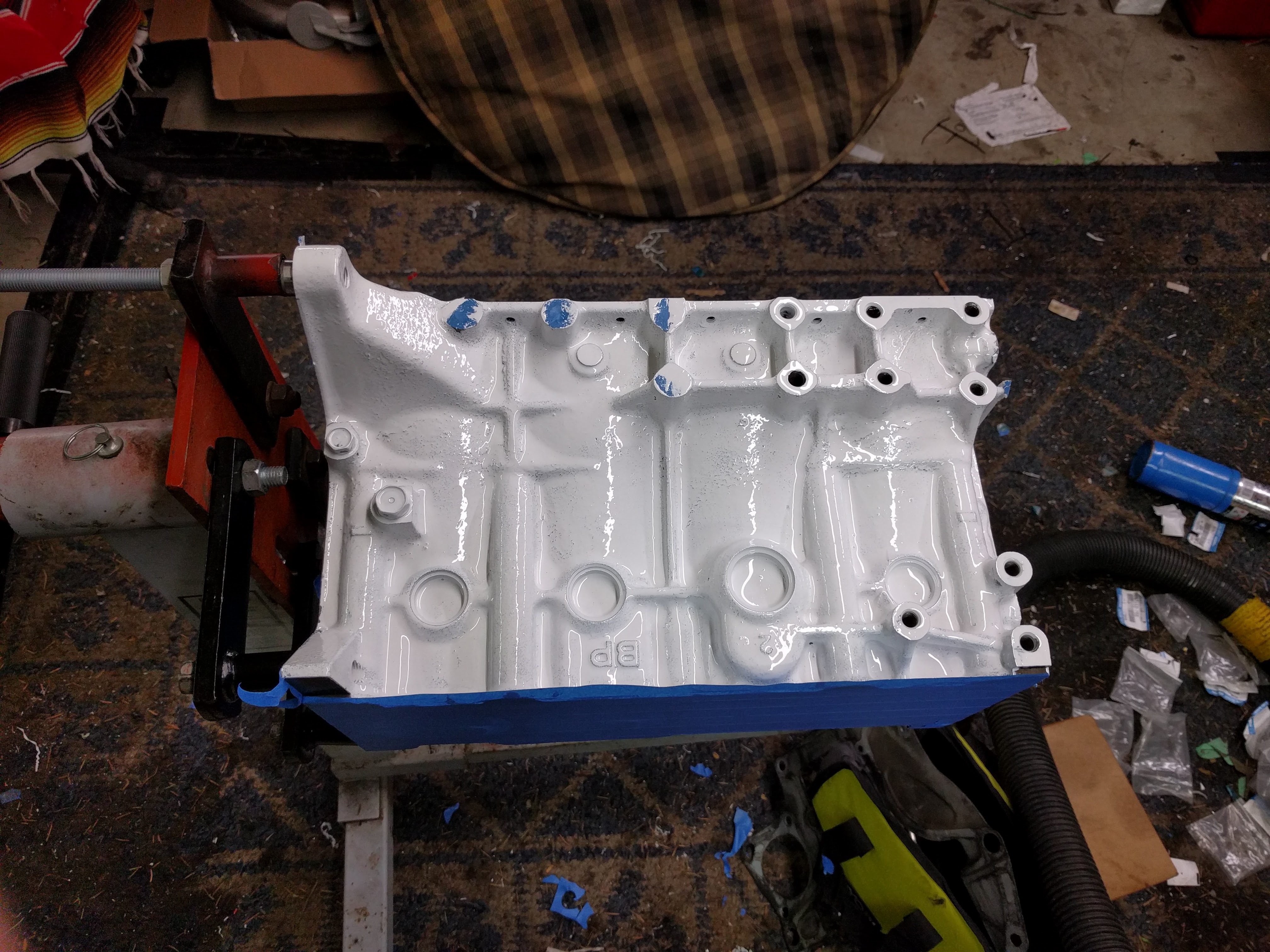

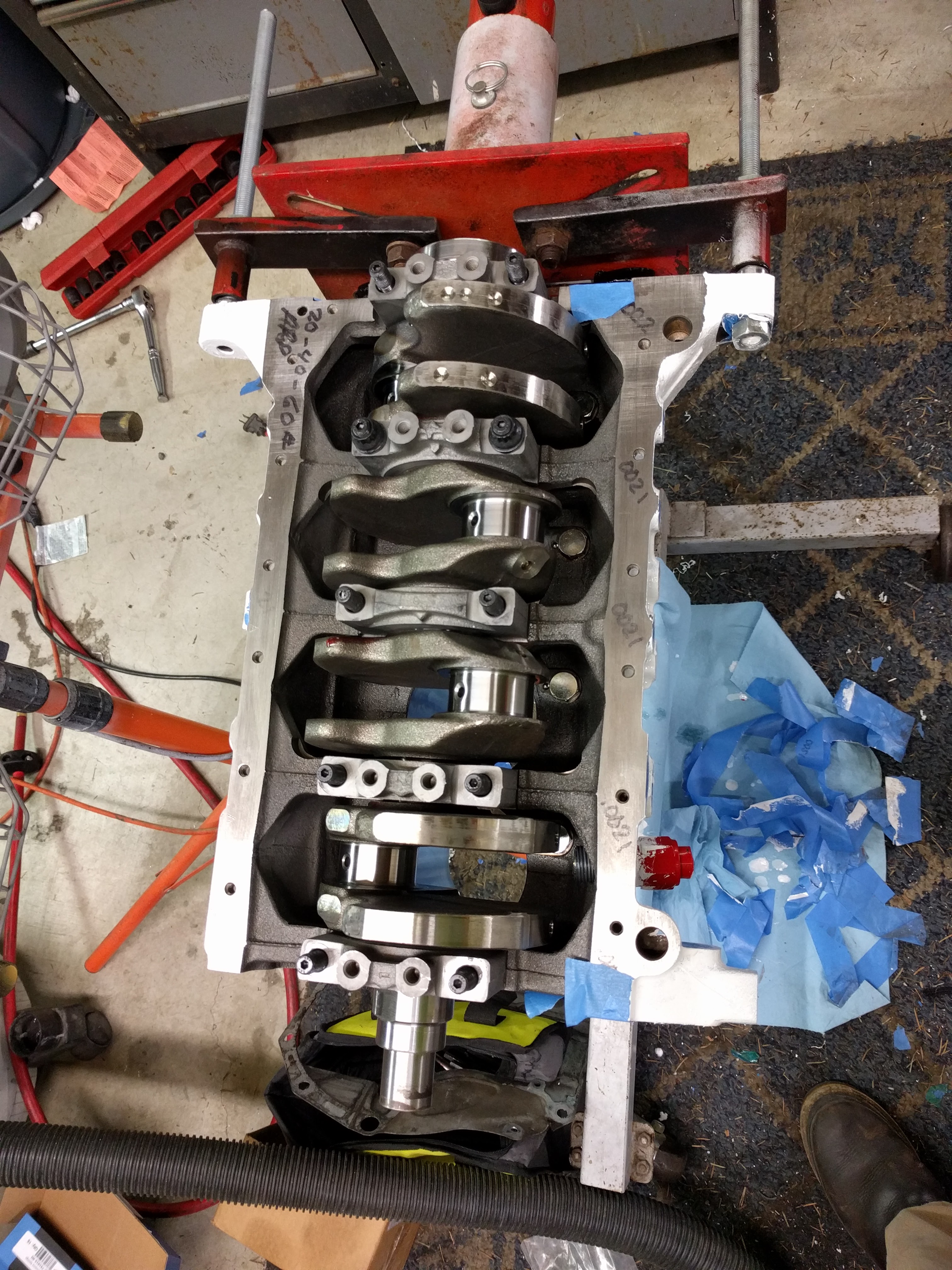

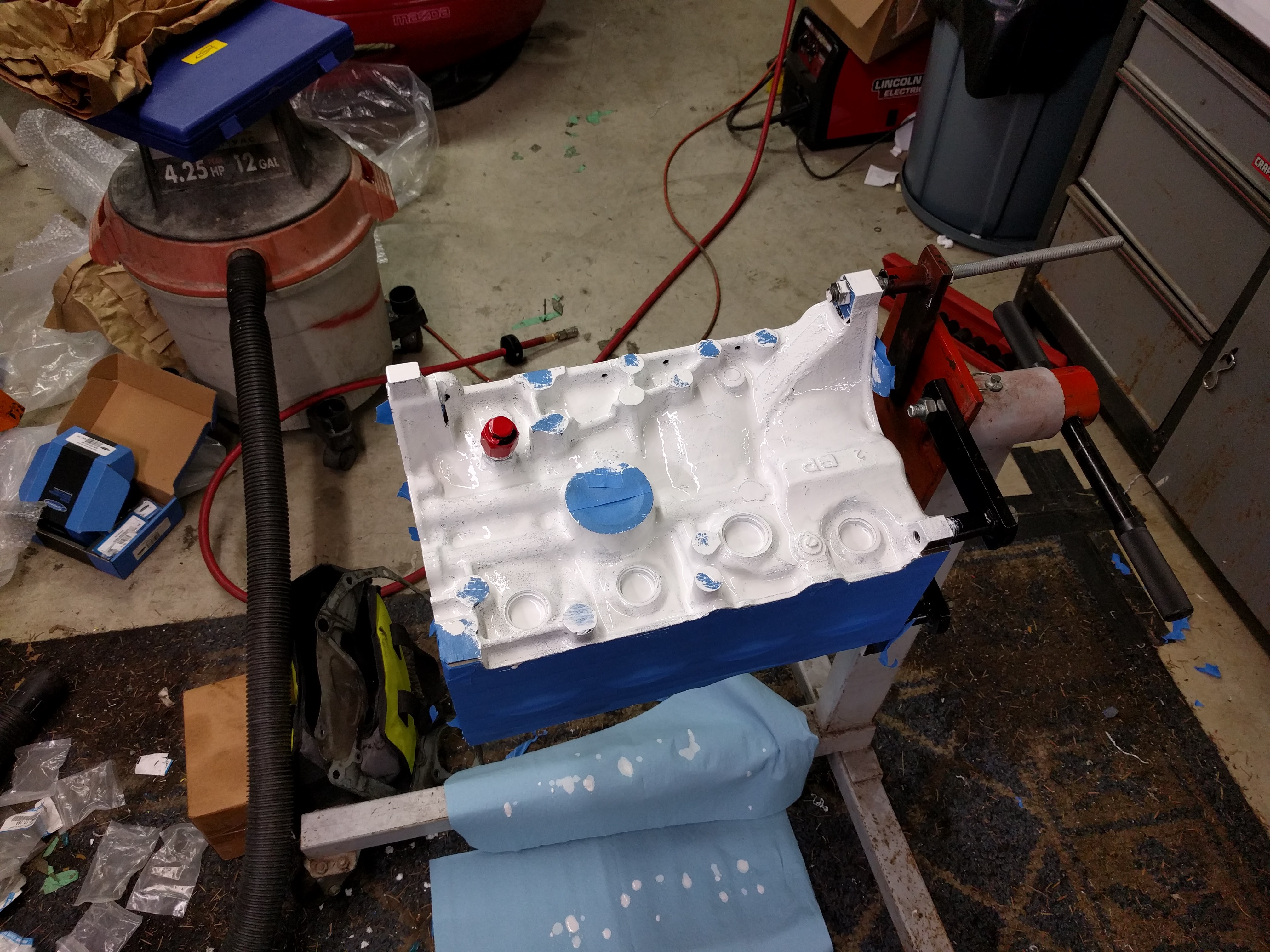

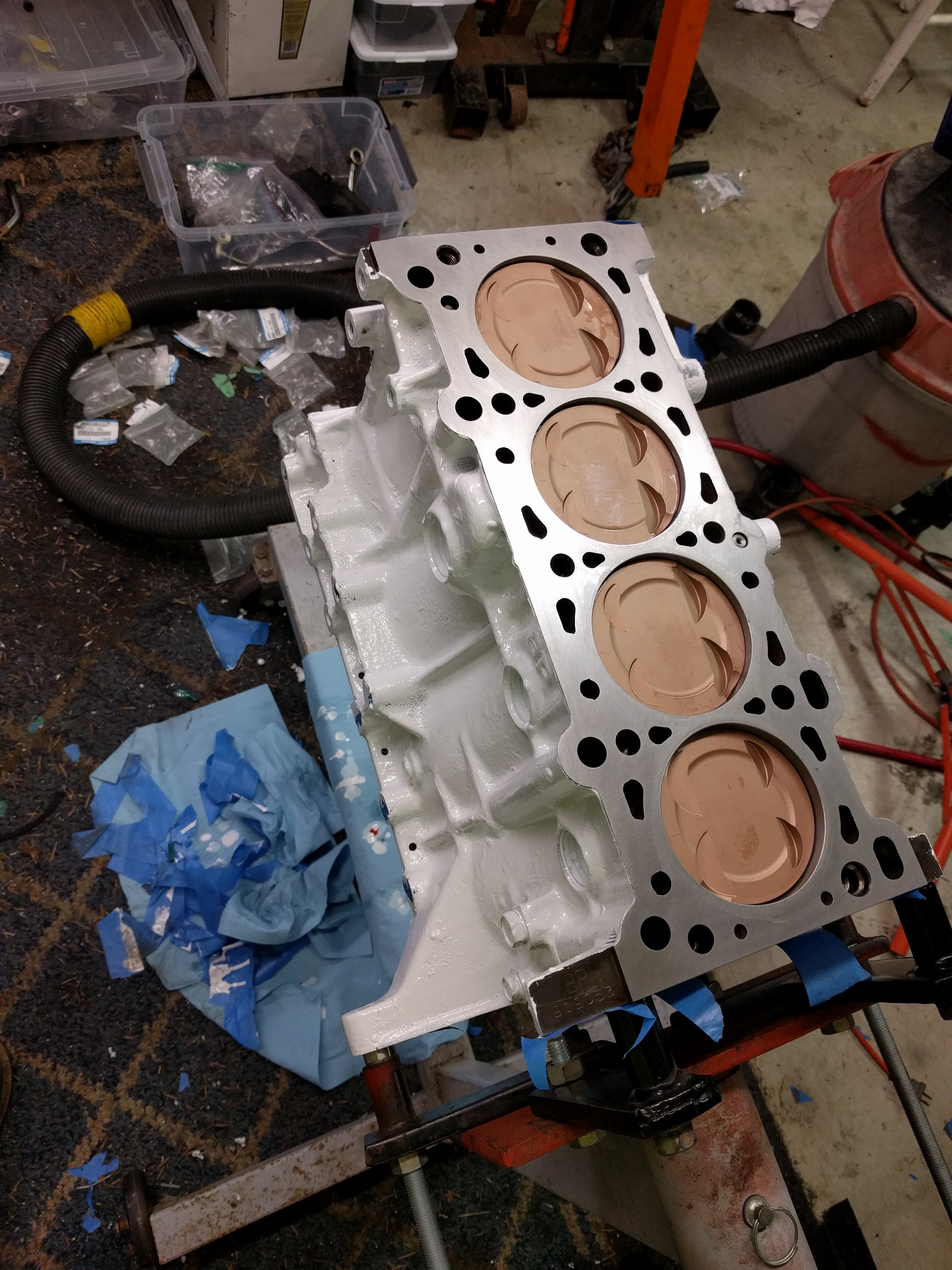

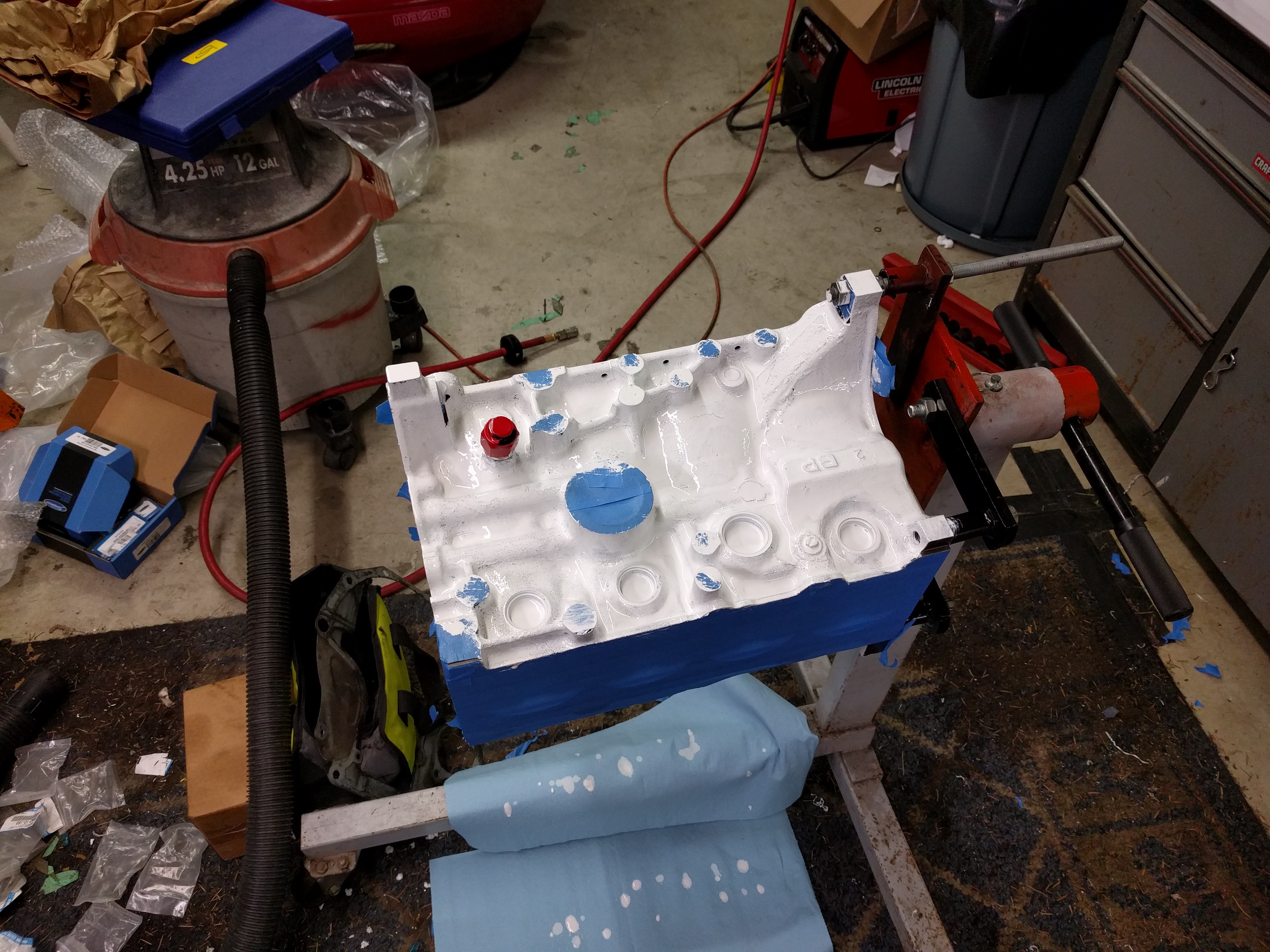

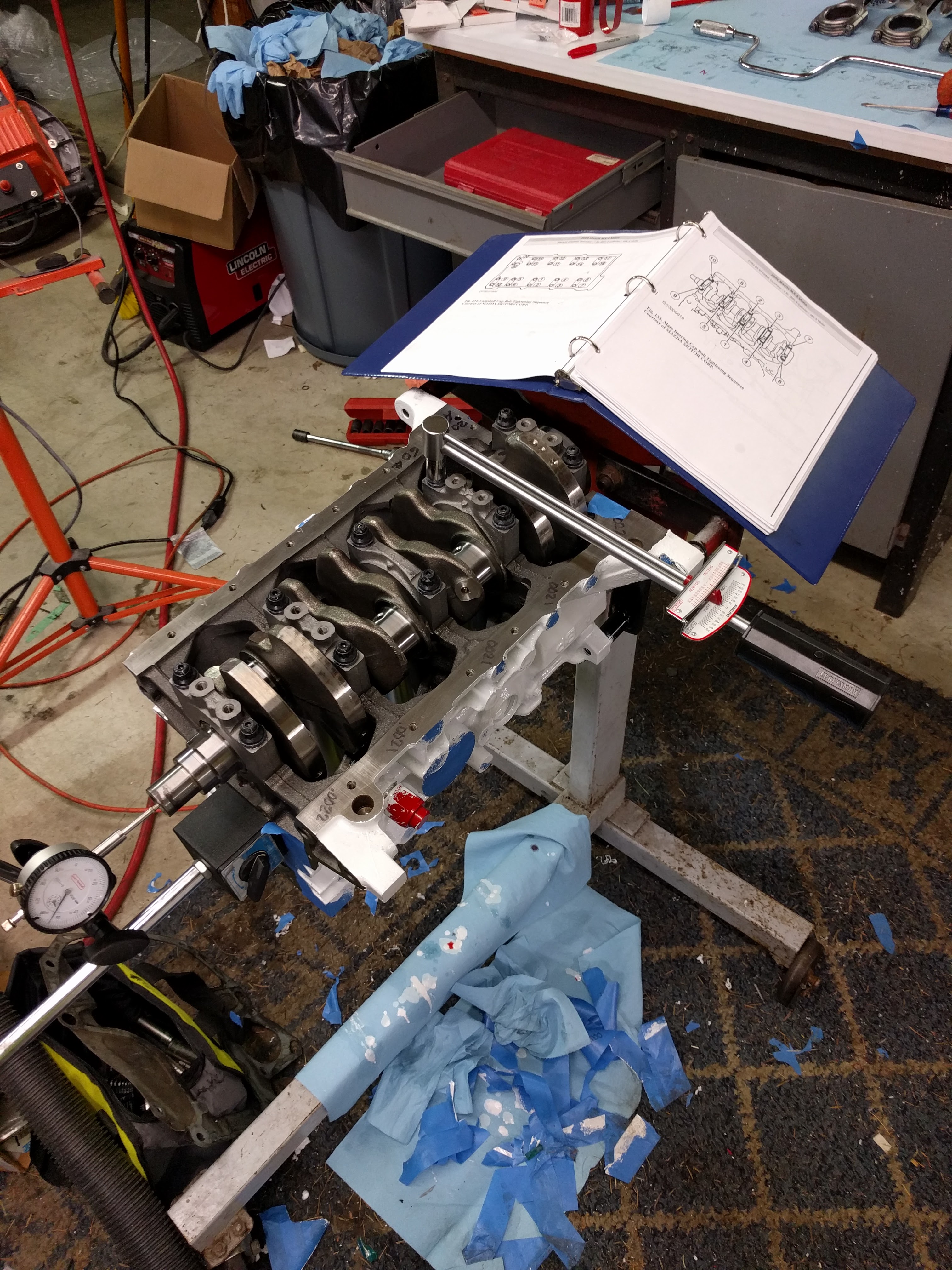

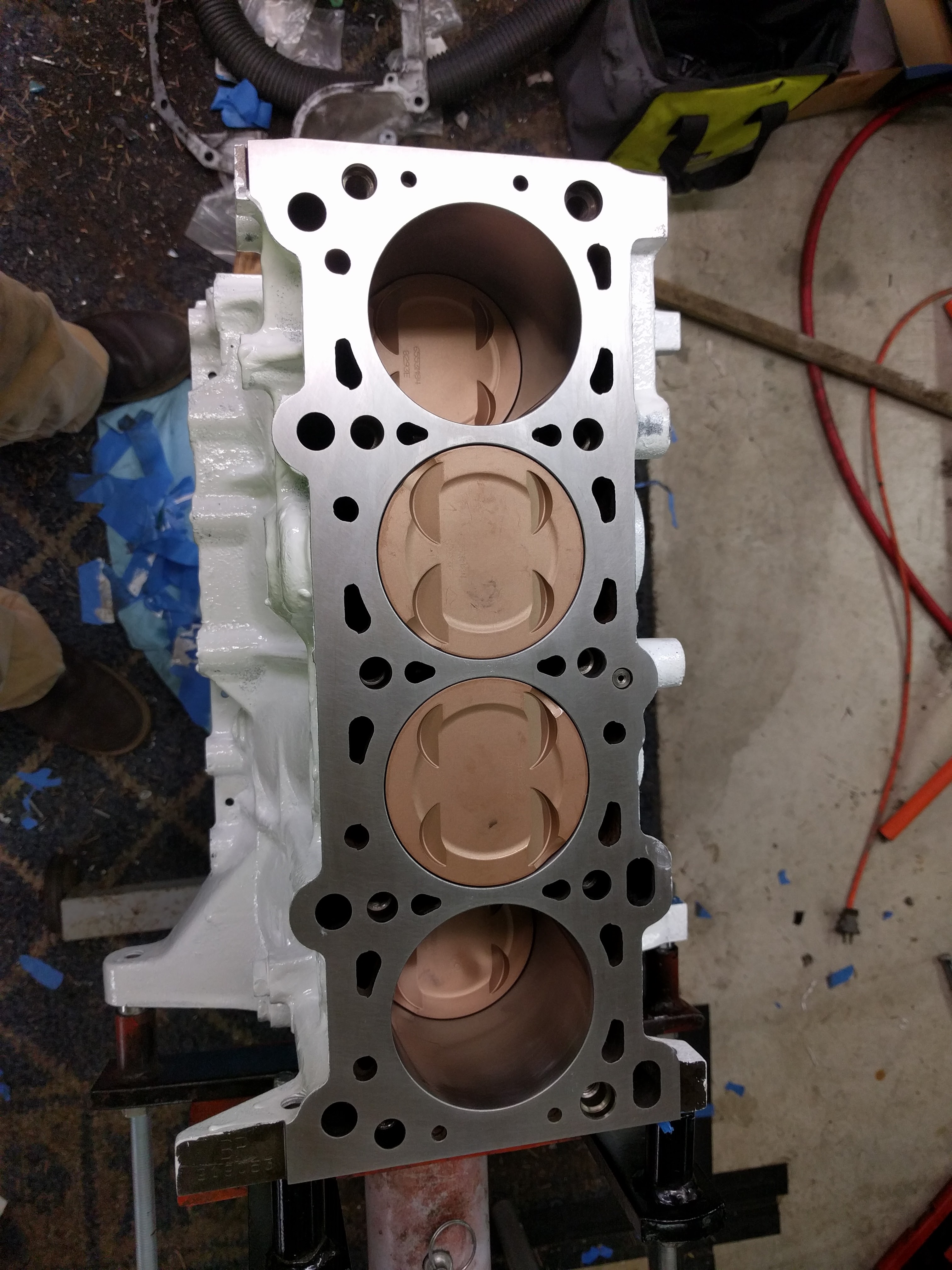

Speaking of rings. They were left at the machine shop. Just picked them up. Block has been painted. Going to go home, and bust out the bottom end. Still waiting on my pump from Travis, and finding out if supertech has the shims I need or if I'll be grinding shims.

Speaking of rings. They were left at the machine shop. Just picked them up. Block has been painted. Going to go home, and bust out the bottom end. Still waiting on my pump from Travis, and finding out if supertech has the shims I need or if I'll be grinding shims.

#9071

Nope. Through a local shop.

Speaking of rings. They were left at the machine shop. Just picked them up. Block has been painted. Going to go home, and bust out the bottom end. Still waiting on my pump from Travis, and finding out if supertech has the shims I need or if I'll be grinding shims.

Speaking of rings. They were left at the machine shop. Just picked them up. Block has been painted. Going to go home, and bust out the bottom end. Still waiting on my pump from Travis, and finding out if supertech has the shims I need or if I'll be grinding shims.

#9078

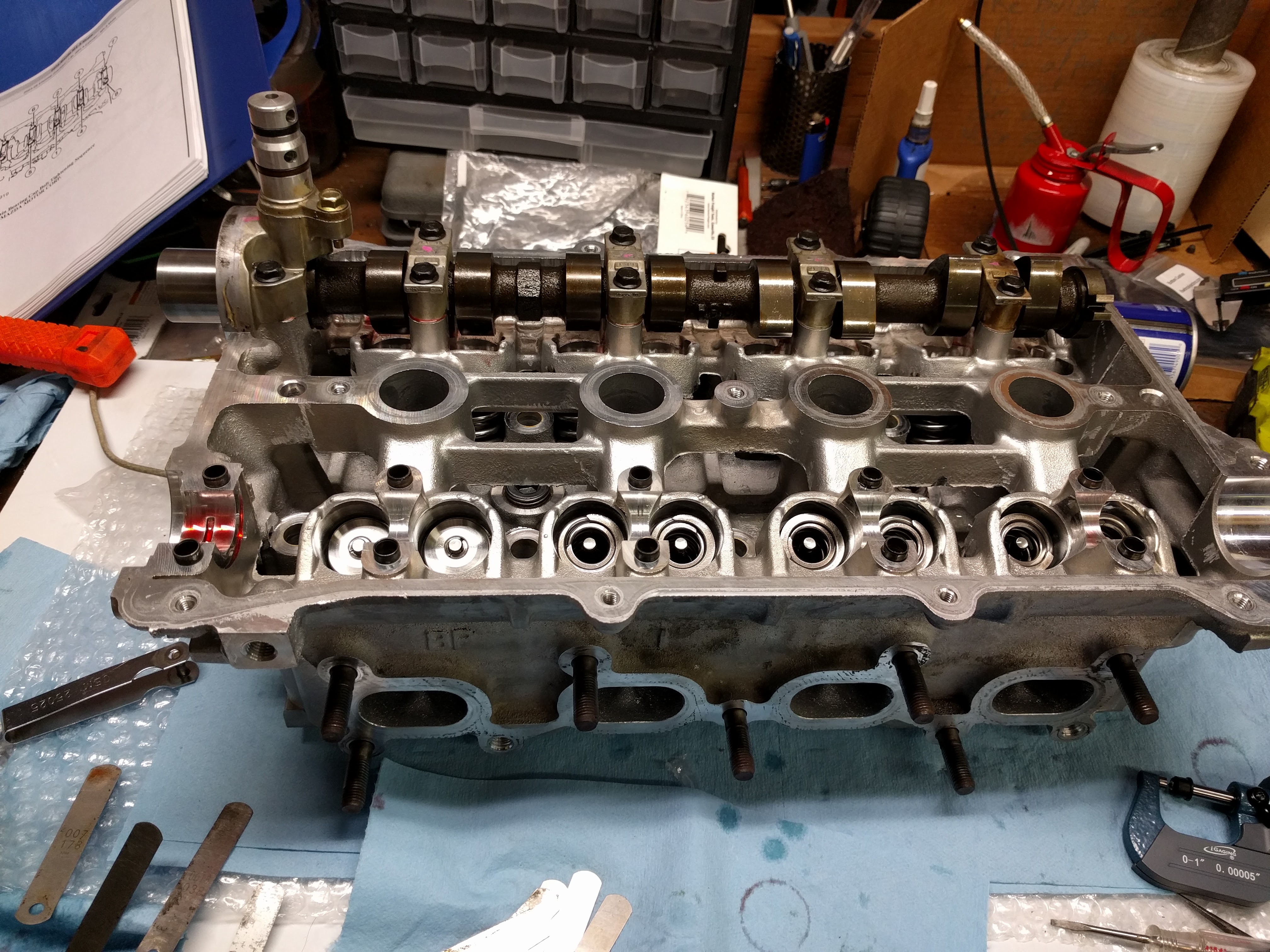

I built a machine a while back to tip valves. It holds the valves perfectly square with the grinder which is important (same way industrial valve grinding machines do it). If you tipped them by hand, it would not be flat, and the crown would cause the lash to loosen up as it smashes the tip of the valve in under load. I can't grind seats but with the ability to tip the valves right, I can buy new valves and install them and adjust them myself without messing with shims.

#9080

I love the white paint on the block. What paint did you use? I want to paint my block white next time the motor is out or apart. Can't wait to see this all back together, it's gonna look awesome.

Also, what ring gap did you go with on the top and bottom compression rings?

Lots of cool pics, makes me want to go build an engine...

Also, what ring gap did you go with on the top and bottom compression rings?

Lots of cool pics, makes me want to go build an engine...