Ian's 99 build thread

#126

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,166

Total Cats: 855

Argh, the car has been really frustrating.

As I think I mentioned earlier, on Saturday, I filled it up with gas and we went out to tune the boost control maps. Problem is, the moment I ran it up to 200 kpa it started knocking, with the same MS3 settings it had the previous week when it was running 220 kpa just fine. Saturday was warmer (high was close to 90, I think), but this was later in the day when it wasn't more than 70 out, and it was still doing it in the evening when it had gotten down to the 60s. It also did it tonight, with the weather report at 61. So I don't think it's ambient-temperature related.

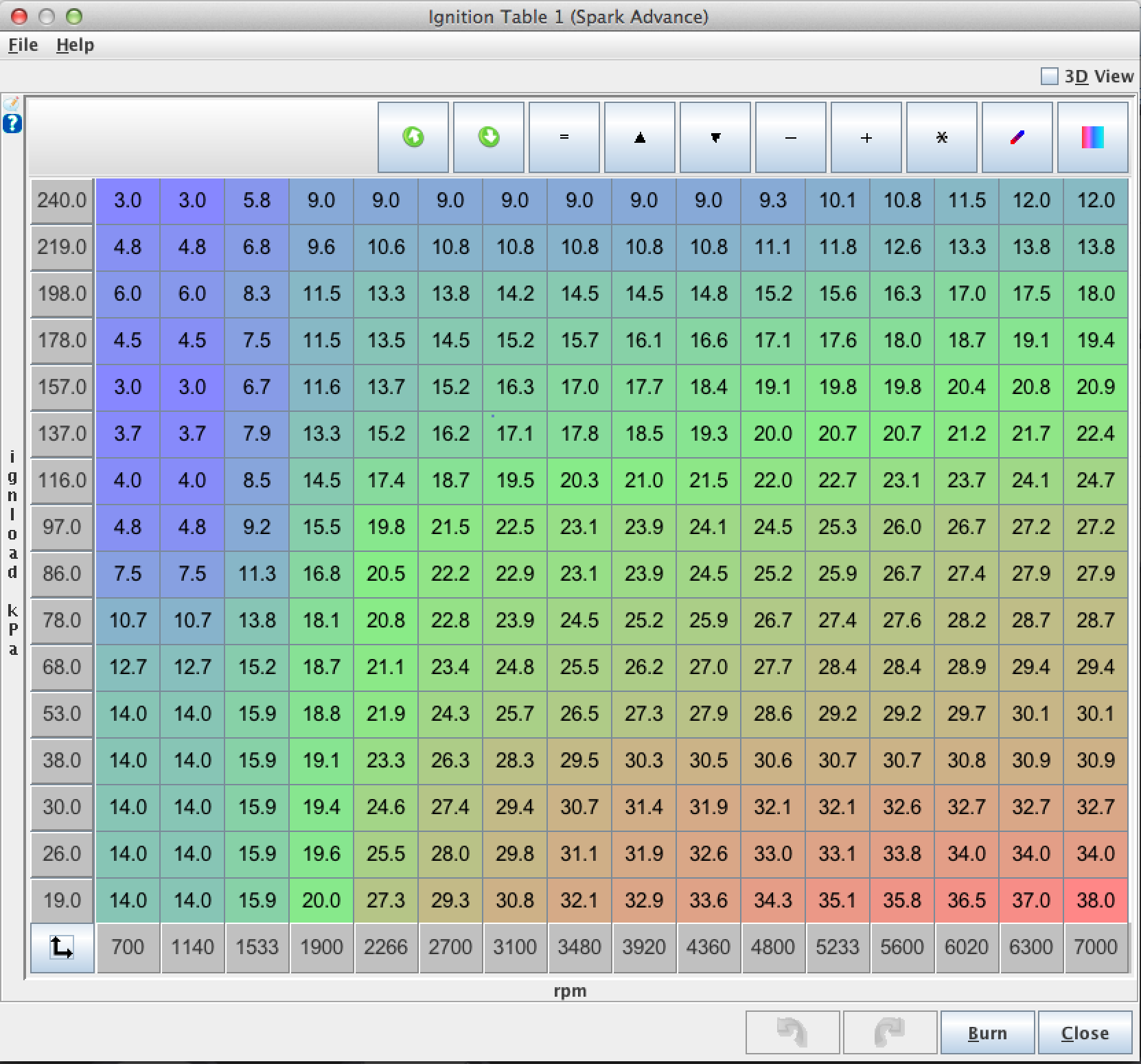

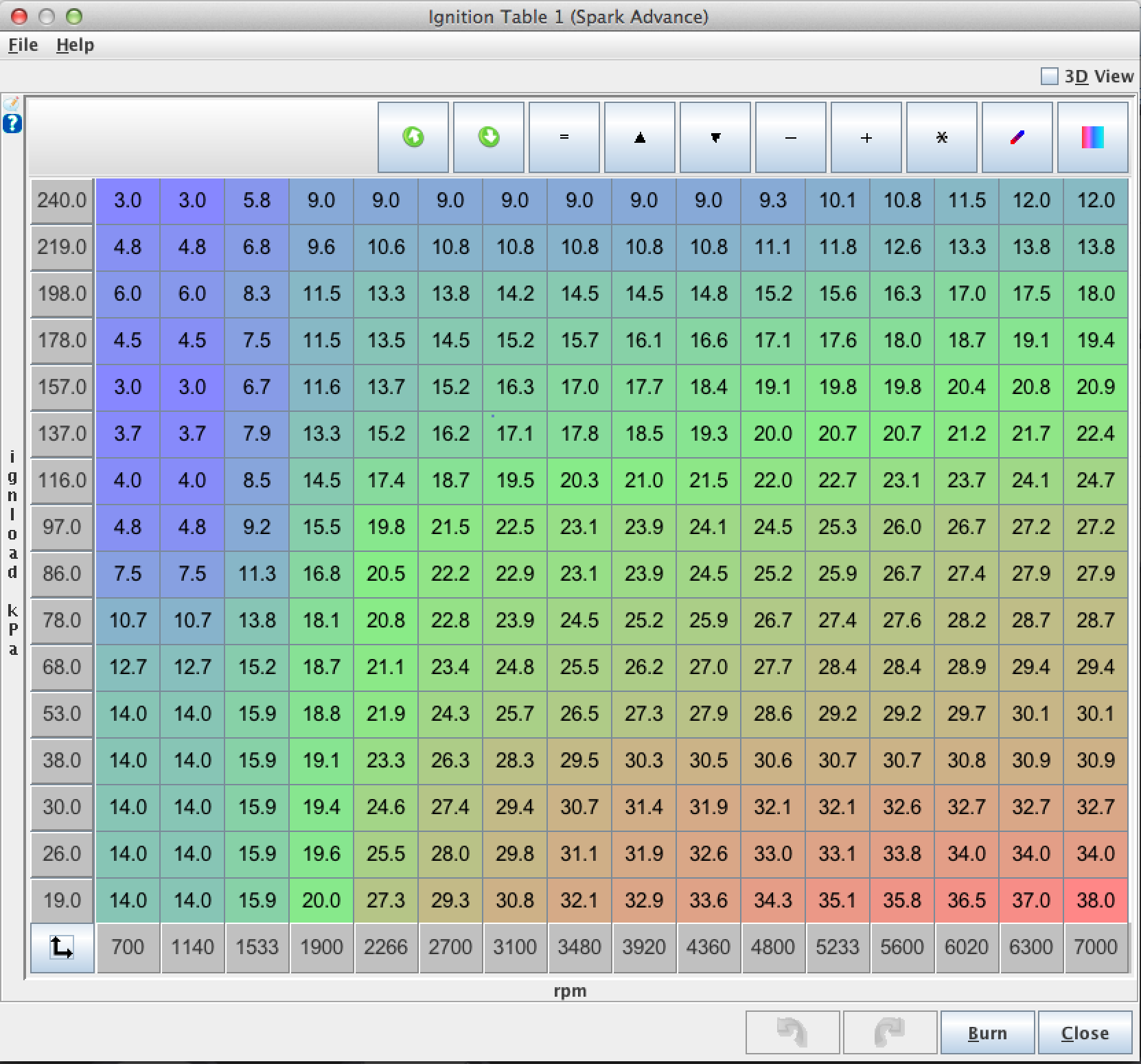

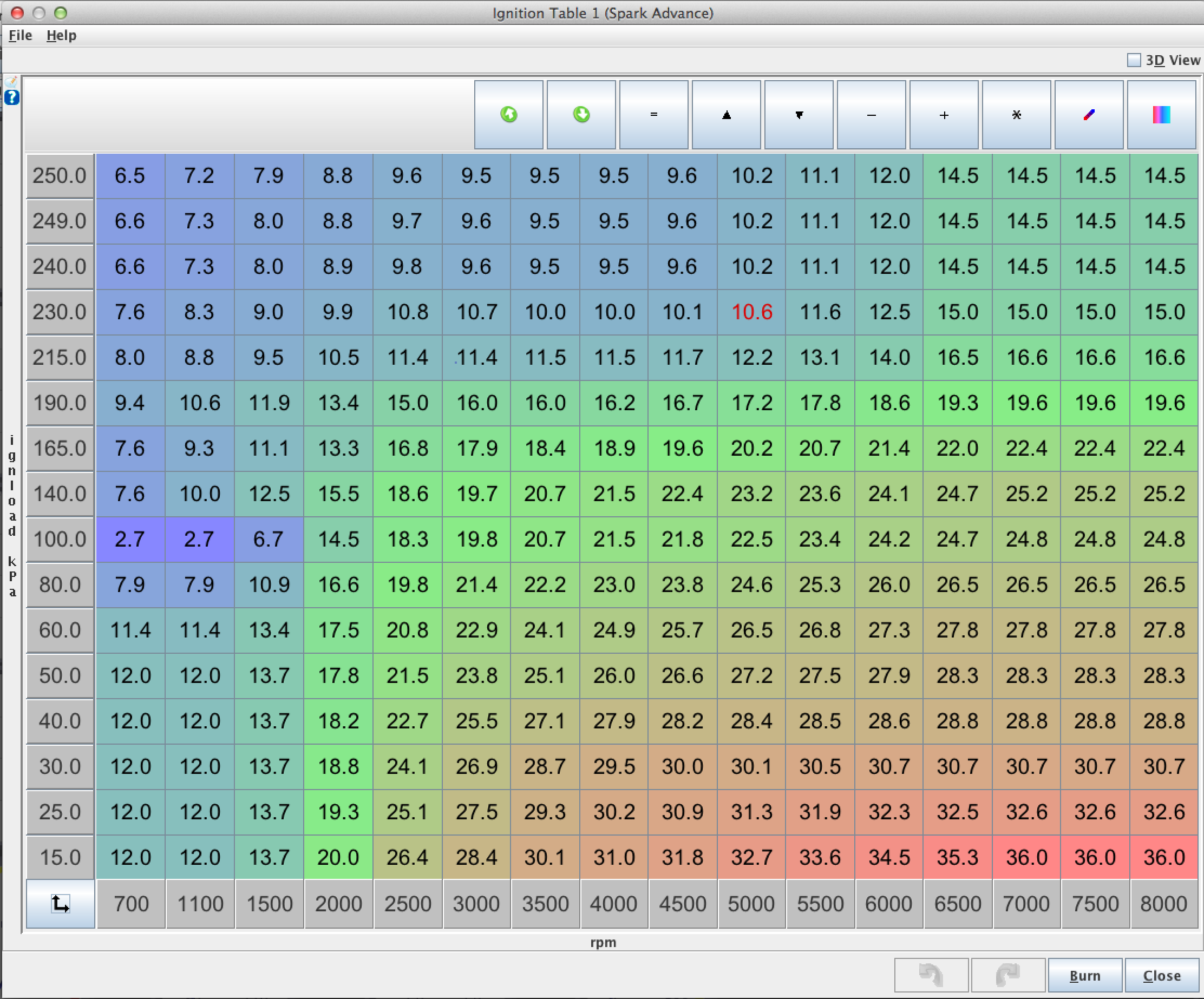

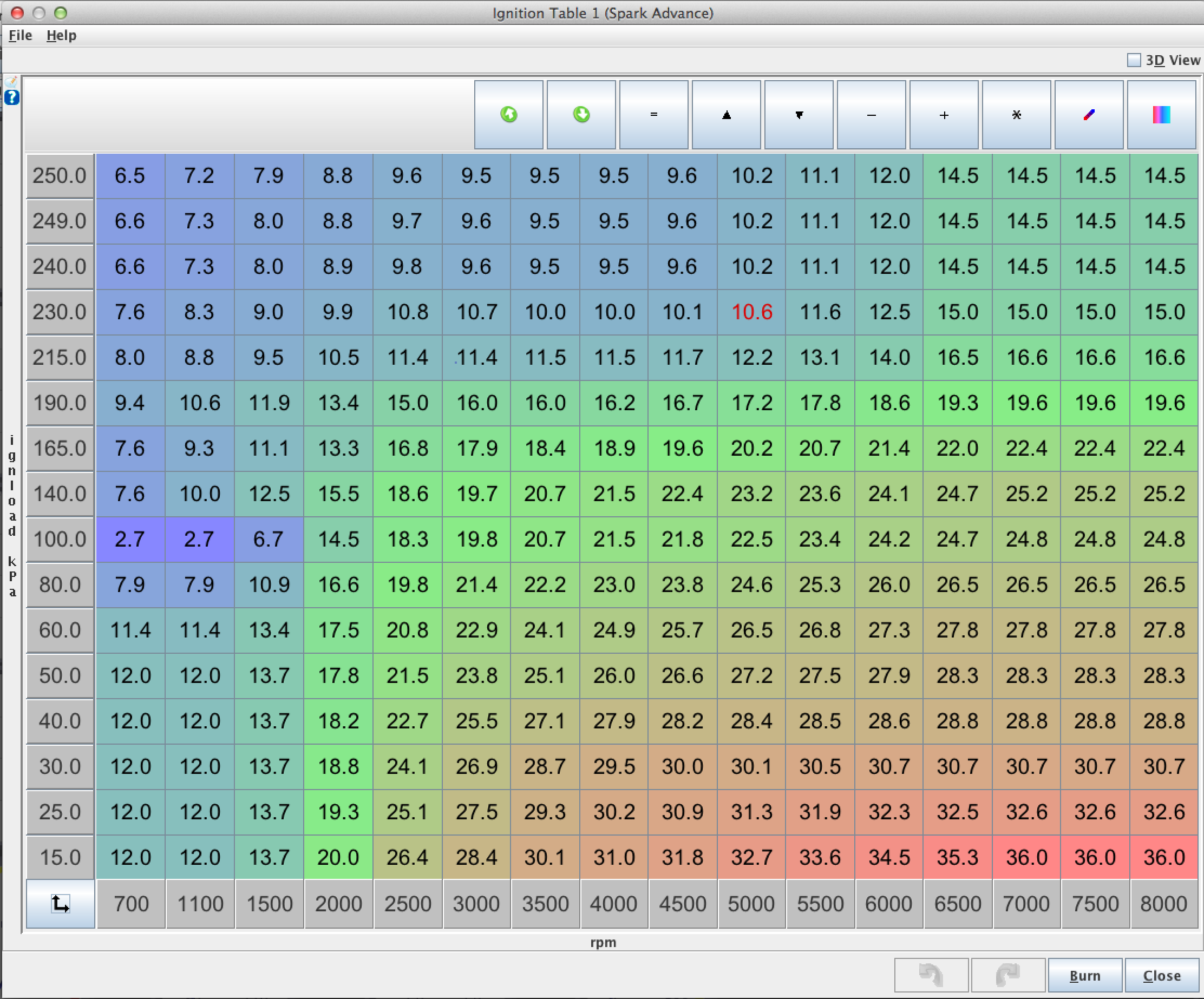

Here's the ignition map. It's basically just the base map that was loaded in the ECU when I got it (which I assume is Reverant's base map), except for 2-3 degrees of extra timing in the top right that we added when it started getting excessive EGTs on 200 kpa runs.

Does this look semi-reasonable as a starting point, or is it totally stupid? It's a 9.0:1 motor, but I'm running 95 octane (50/50 mix of 100 and 91), and previously this combination has been almost bulletproof against knocking. It's pinging a lot at 200, some at 180, and occasionally at 160.

So the working theory I have right now is that there's something wrong with the gas, and that the tanker guy filled up the 100 octane tank with 91 by mistake or something. I'm down to about a quarter of that tank left, so I plan to run it as close to empty as possible and refill it at the other 100 octane station in town.

The issue is that my dyno appointment is on Wednesday, and I don't want to do that if it's pinging for unknown reasons.

The other issue is that the knock sensor isn't working. Pretty much no matter what happens I was getting zero out on the data logs. I poked around and found y8s' thread here:

https://www.miataturbo.net/megasquir...-thread-67946/

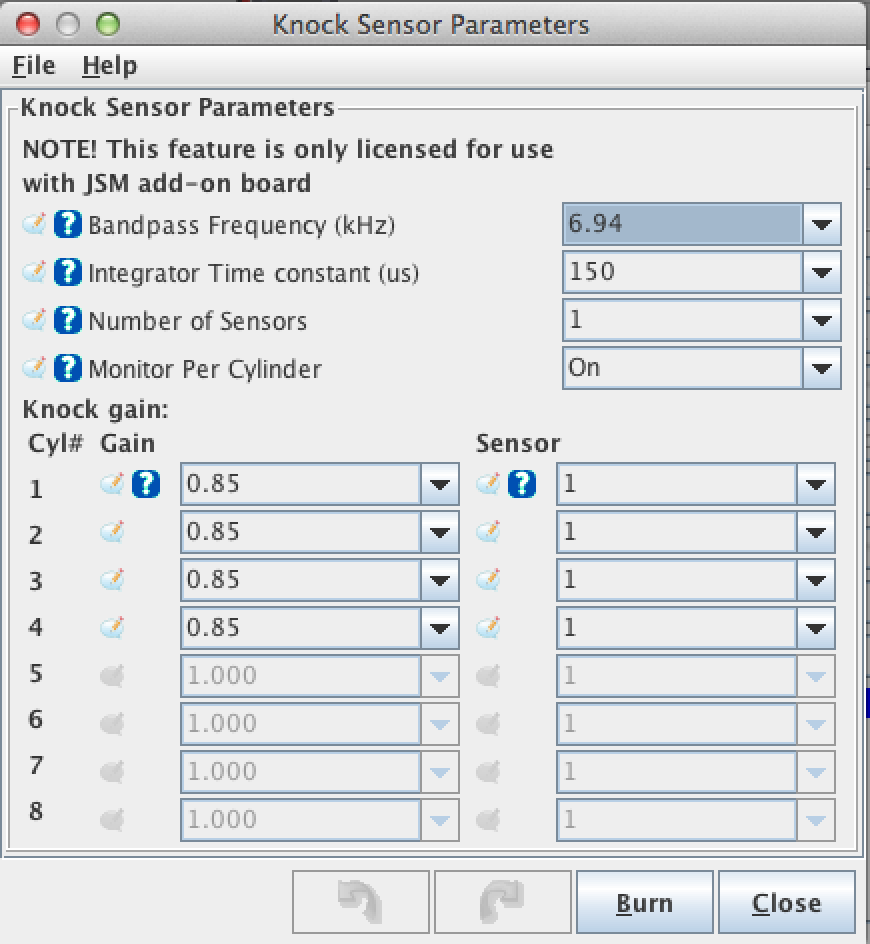

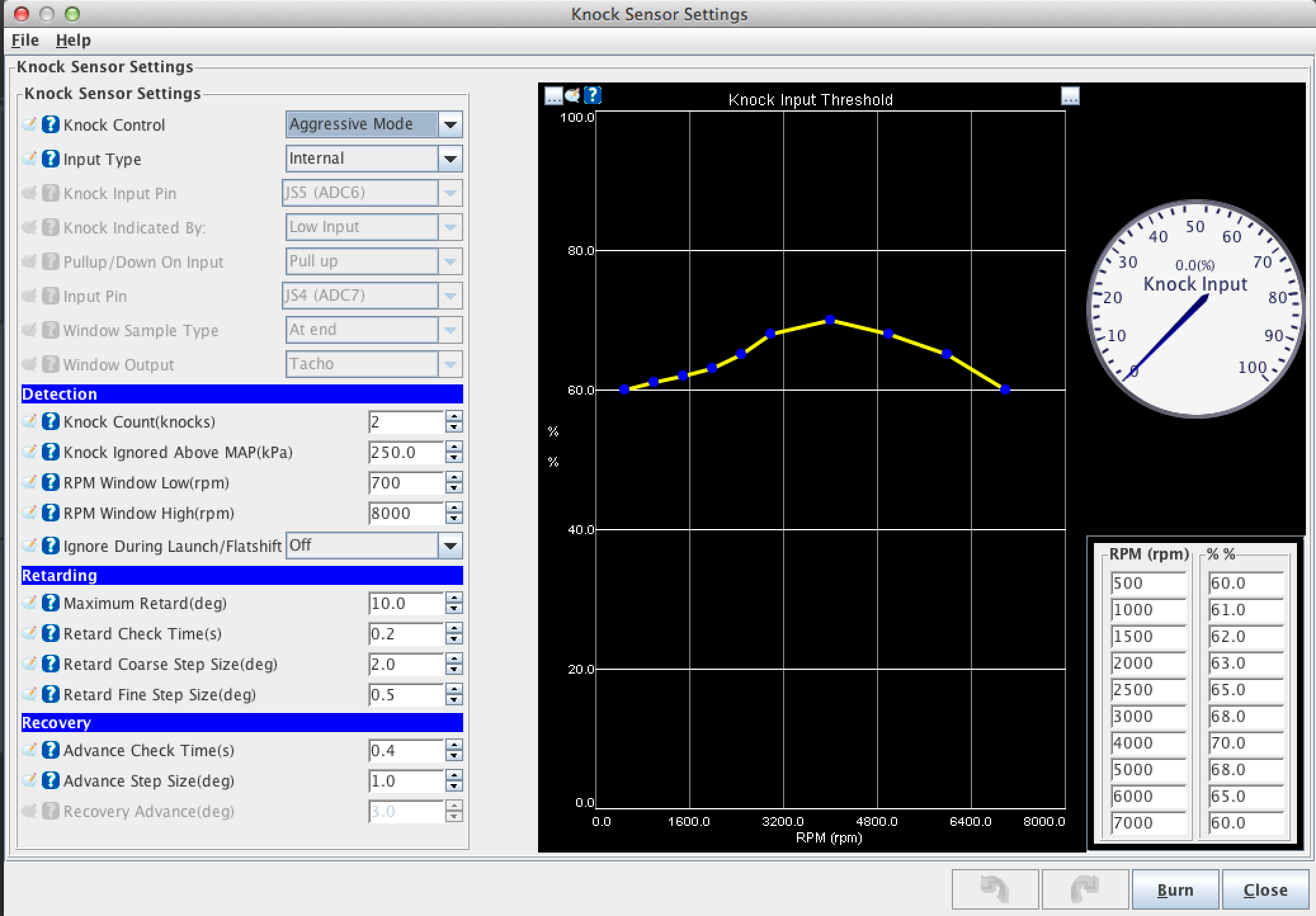

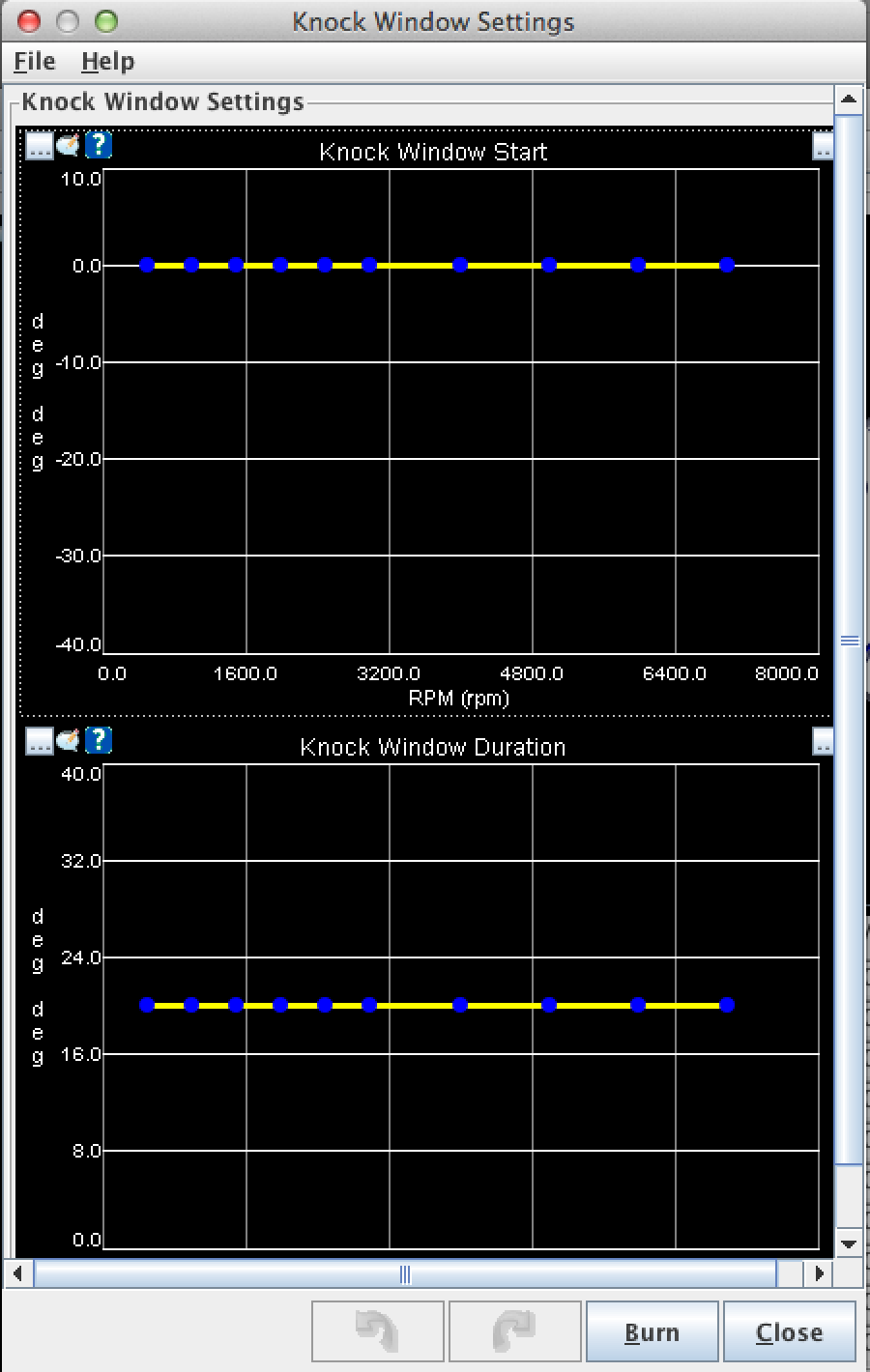

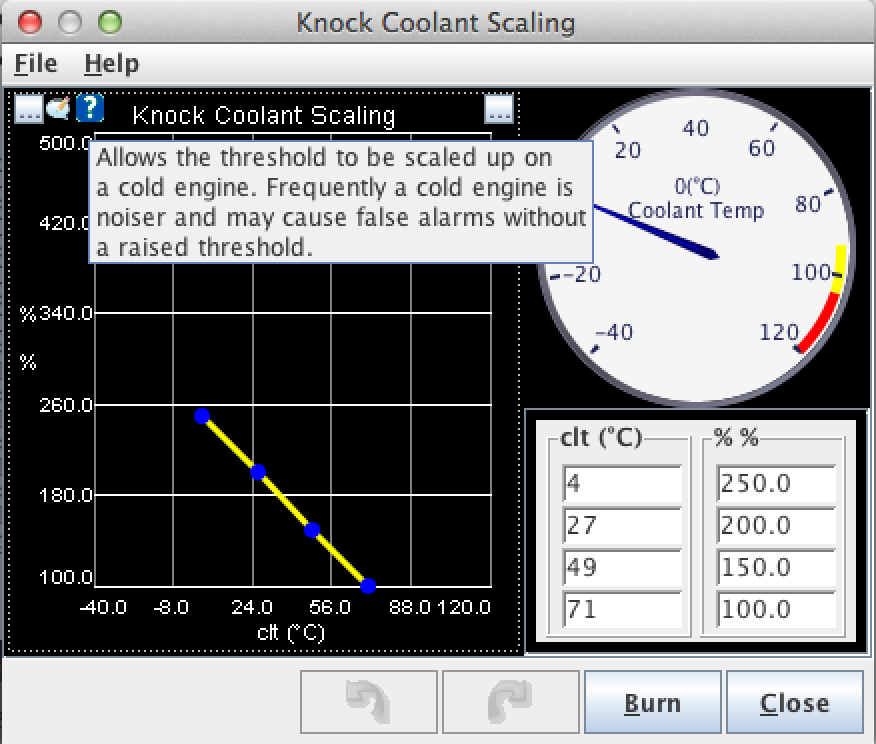

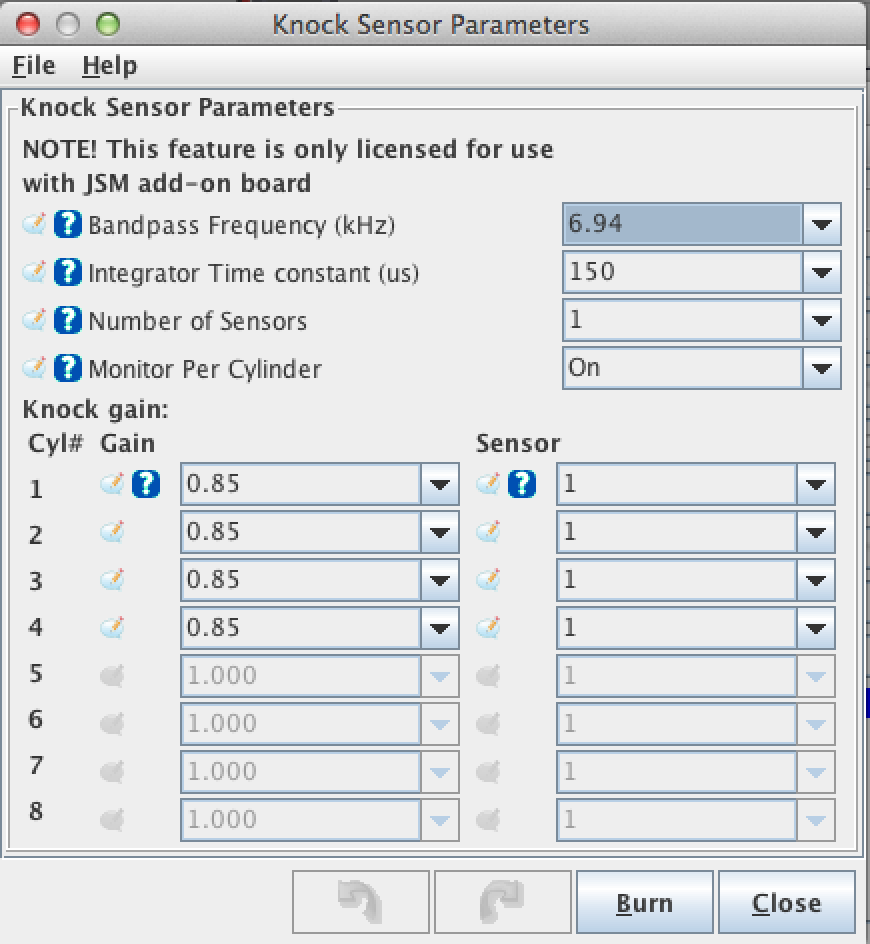

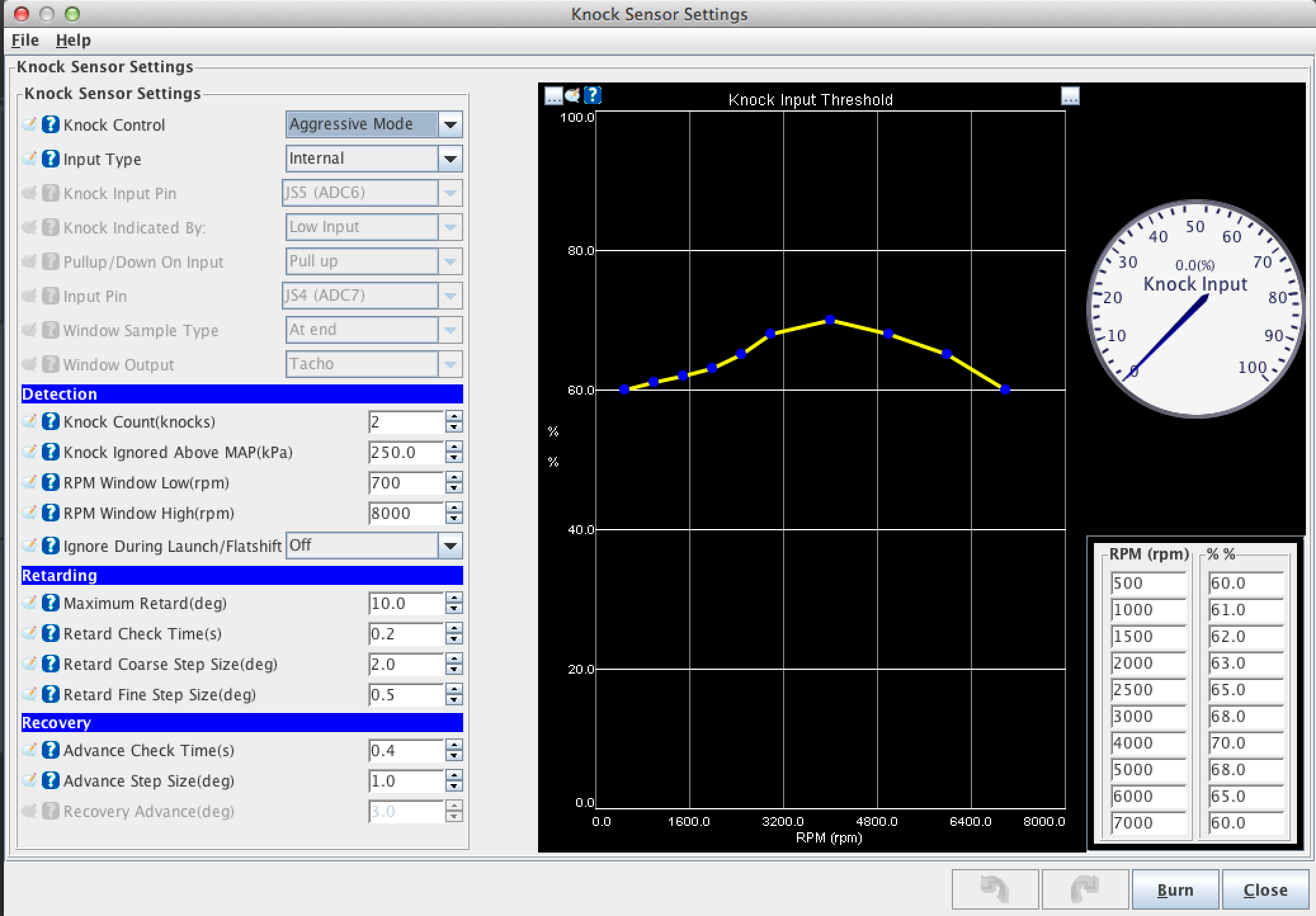

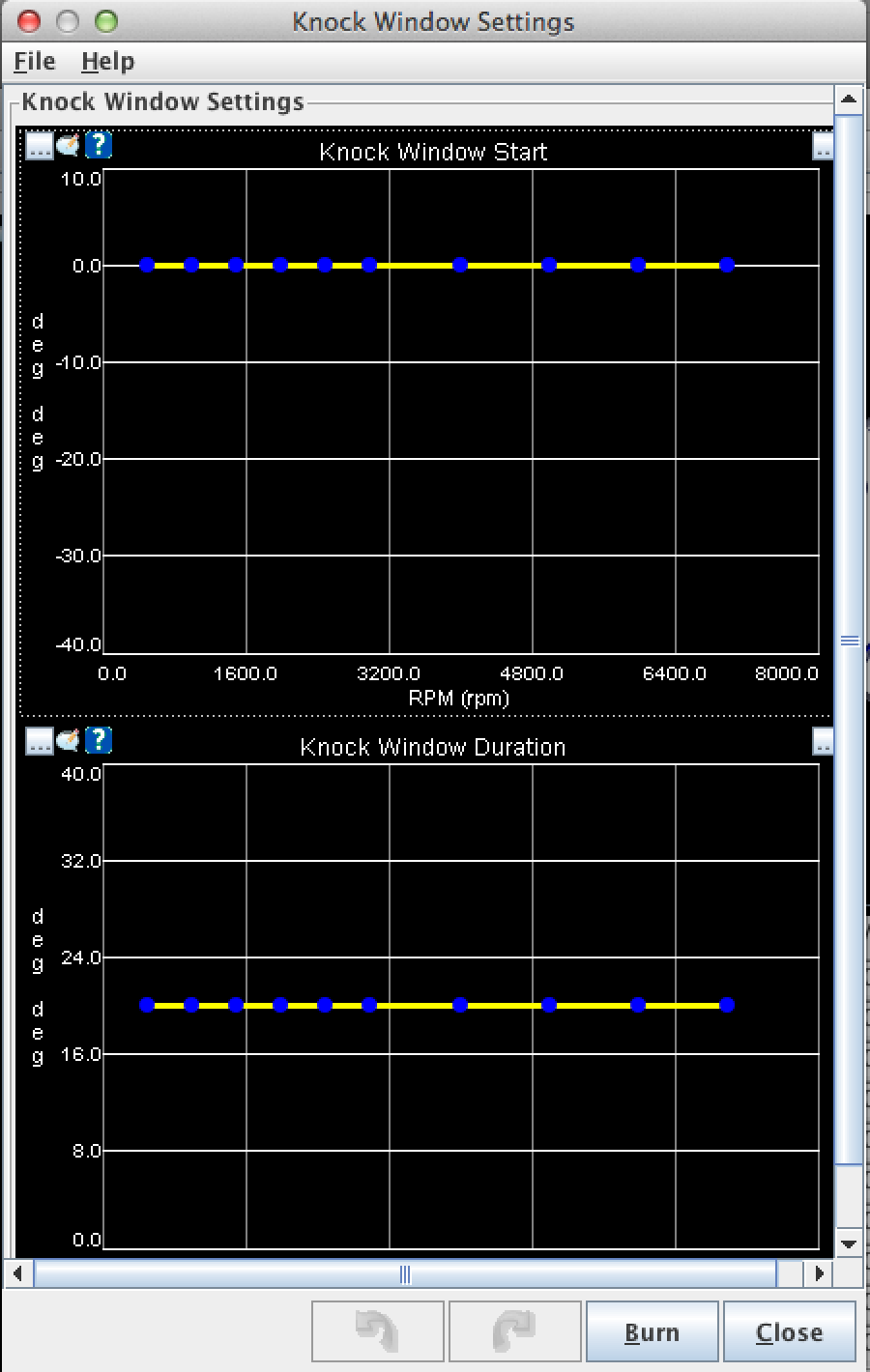

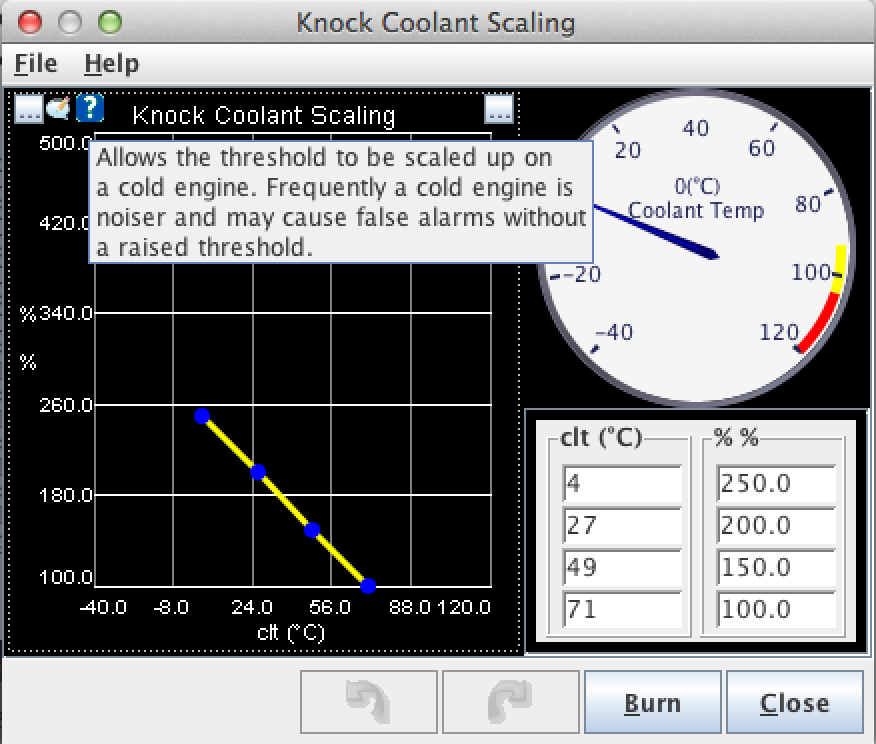

My knock window settings were totally wacky, so I loaded the y8s settings and started seeing stuff, but it didn't correlate very well with actual knock events. My settings currently are:

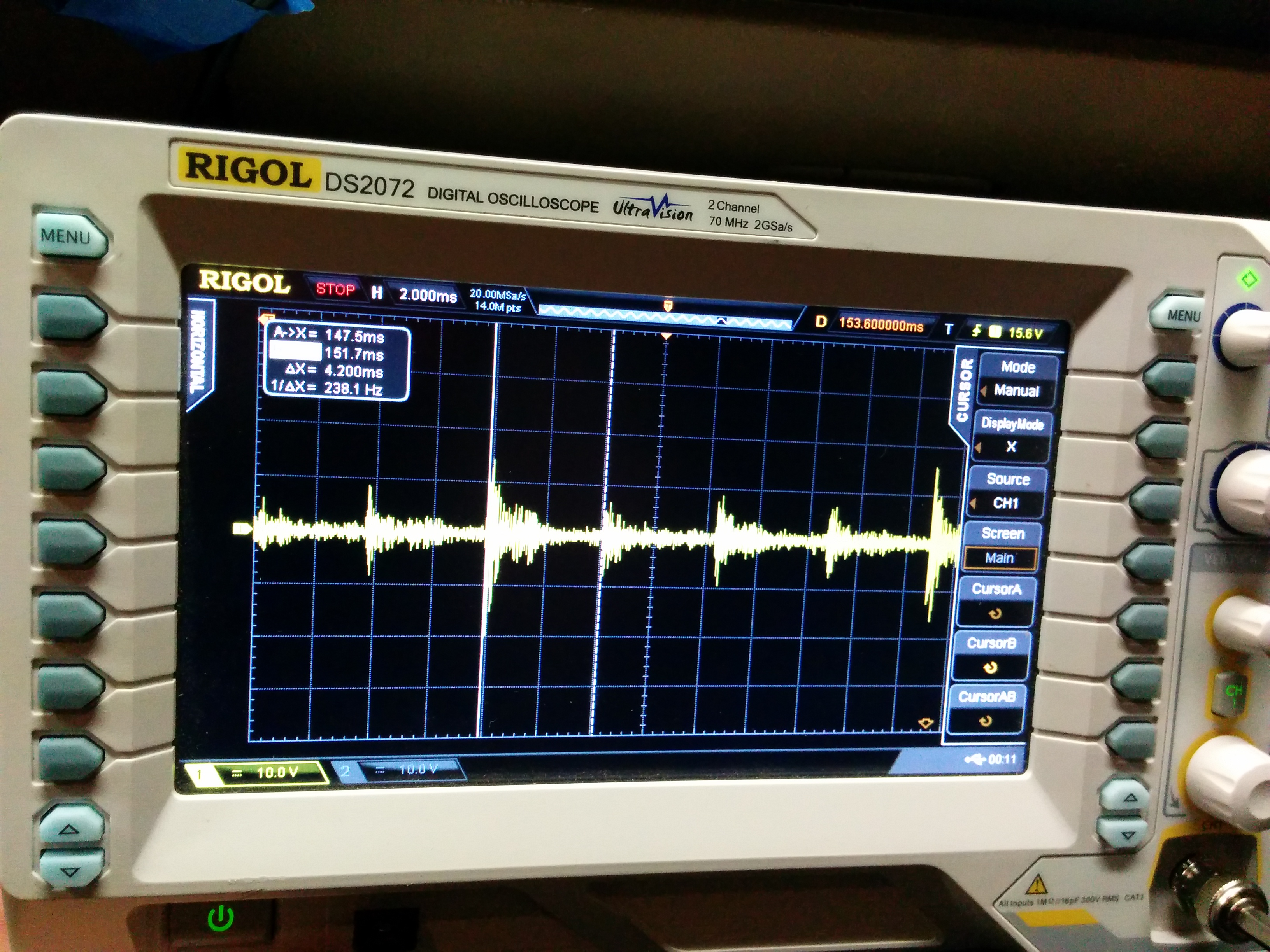

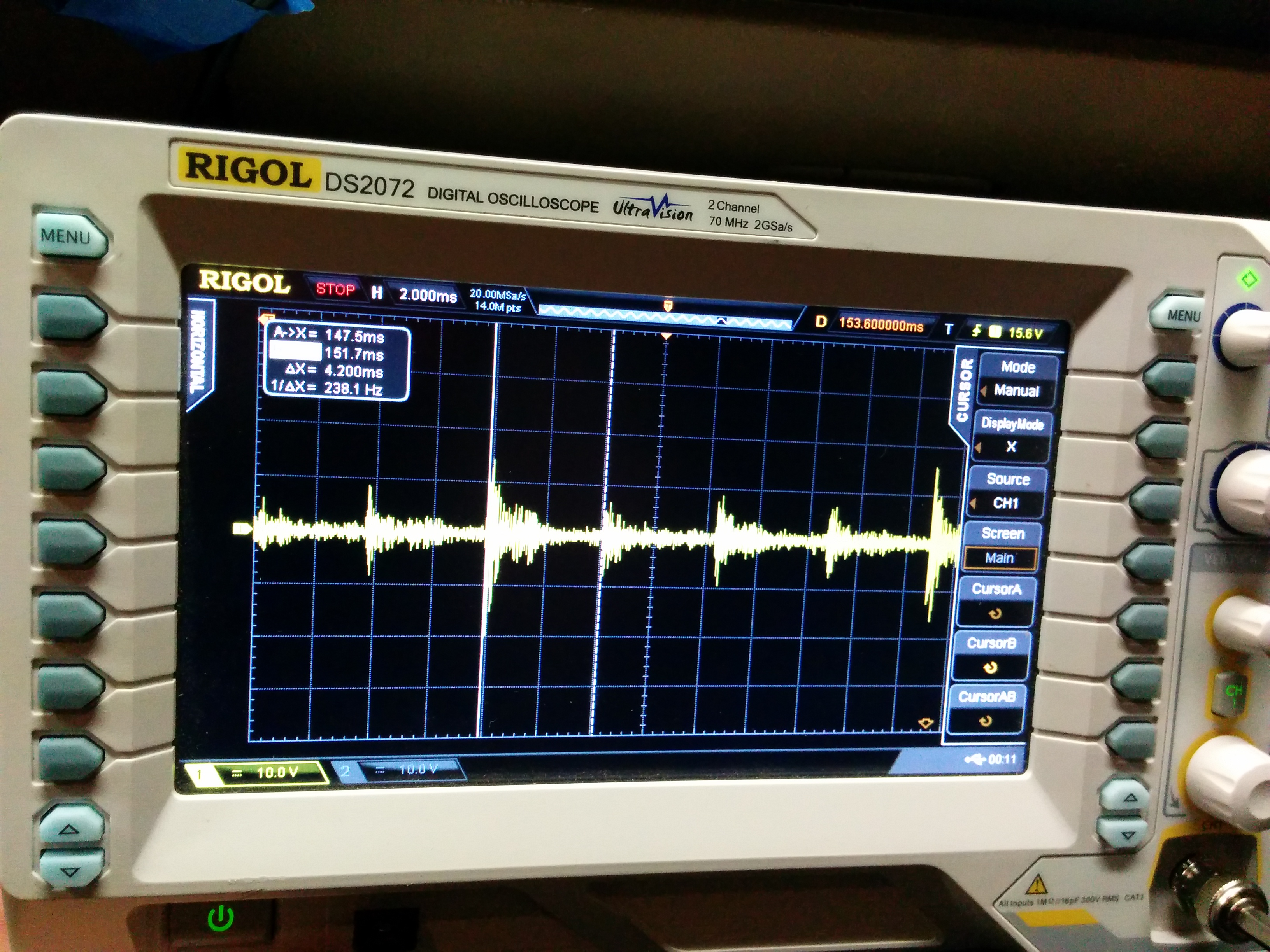

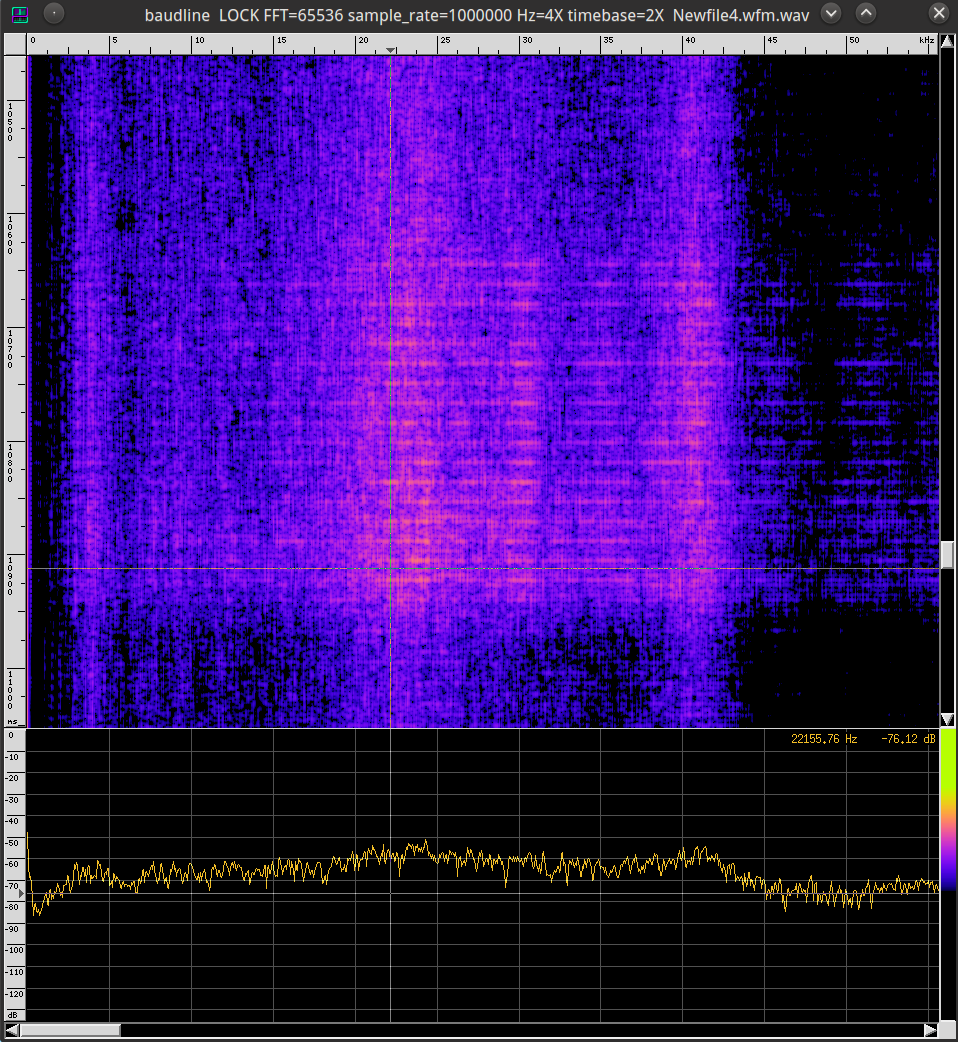

Since we couldn't get the MS3 knock sensor logic to behave appropriately, we hooked up the scope to listen to the knock sensor manually. We reloaded the injector dead time settings (found a new spreadsheet from ID that I hadn't seen before with updated numbers), rescaled reqfuel and added a bunch of fuel to the base map and went out to autotune it with the timing retarded a whole bunch above 2500 RPM for safety. The scope still triggered on noise, but it looks a bit odd:

It's 1 big pulse followed by 3 smaller ones, and the gap between them works out to about 7200 RPM, with frequency rising over the course of the noise event. Since it's not knocking at redline, the theory is that this is valve noise or something, not knock. Alas, we never got a good capture of an actual knock event on the scope.

--Ian

As I think I mentioned earlier, on Saturday, I filled it up with gas and we went out to tune the boost control maps. Problem is, the moment I ran it up to 200 kpa it started knocking, with the same MS3 settings it had the previous week when it was running 220 kpa just fine. Saturday was warmer (high was close to 90, I think), but this was later in the day when it wasn't more than 70 out, and it was still doing it in the evening when it had gotten down to the 60s. It also did it tonight, with the weather report at 61. So I don't think it's ambient-temperature related.

Here's the ignition map. It's basically just the base map that was loaded in the ECU when I got it (which I assume is Reverant's base map), except for 2-3 degrees of extra timing in the top right that we added when it started getting excessive EGTs on 200 kpa runs.

Does this look semi-reasonable as a starting point, or is it totally stupid? It's a 9.0:1 motor, but I'm running 95 octane (50/50 mix of 100 and 91), and previously this combination has been almost bulletproof against knocking. It's pinging a lot at 200, some at 180, and occasionally at 160.

So the working theory I have right now is that there's something wrong with the gas, and that the tanker guy filled up the 100 octane tank with 91 by mistake or something. I'm down to about a quarter of that tank left, so I plan to run it as close to empty as possible and refill it at the other 100 octane station in town.

The issue is that my dyno appointment is on Wednesday, and I don't want to do that if it's pinging for unknown reasons.

The other issue is that the knock sensor isn't working. Pretty much no matter what happens I was getting zero out on the data logs. I poked around and found y8s' thread here:

https://www.miataturbo.net/megasquir...-thread-67946/

My knock window settings were totally wacky, so I loaded the y8s settings and started seeing stuff, but it didn't correlate very well with actual knock events. My settings currently are:

Since we couldn't get the MS3 knock sensor logic to behave appropriately, we hooked up the scope to listen to the knock sensor manually. We reloaded the injector dead time settings (found a new spreadsheet from ID that I hadn't seen before with updated numbers), rescaled reqfuel and added a bunch of fuel to the base map and went out to autotune it with the timing retarded a whole bunch above 2500 RPM for safety. The scope still triggered on noise, but it looks a bit odd:

It's 1 big pulse followed by 3 smaller ones, and the gap between them works out to about 7200 RPM, with frequency rising over the course of the noise event. Since it's not knocking at redline, the theory is that this is valve noise or something, not knock. Alas, we never got a good capture of an actual knock event on the scope.

--Ian

Last edited by codrus; 03-17-2015 at 05:13 AM.

#127

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,166

Total Cats: 855

OK, so THIS must be the Skunk2 throttle body screw everyone's telling me to loctite! I think I did every screw/bolt/nut on it EXCEPT this one.

Limped the car home with a 2500 RPM idle last night...

--Ian

Limped the car home with a 2500 RPM idle last night...

--Ian

#129

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,166

Total Cats: 855

Can you post photos of the fasteners that came with yours? Mine looked totally insane until I spent a while puzzling it out.

--Ian

#131

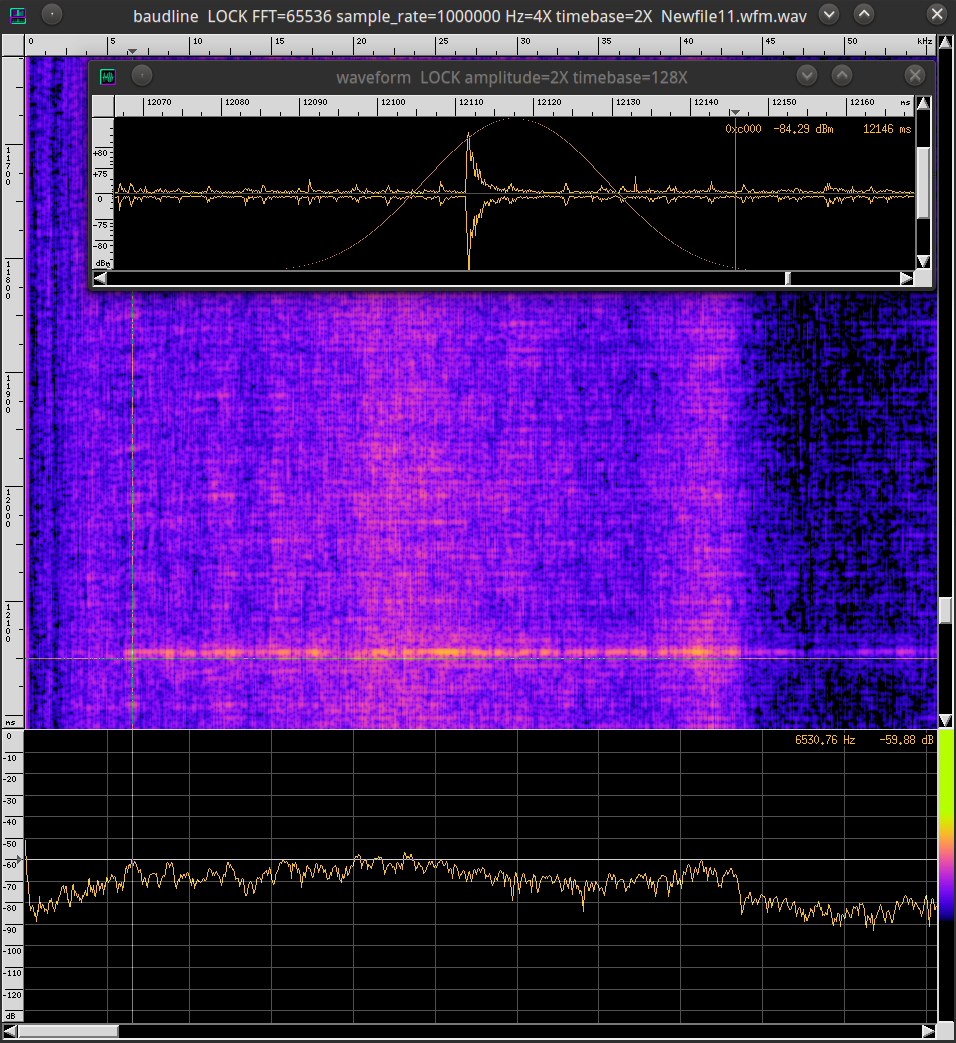

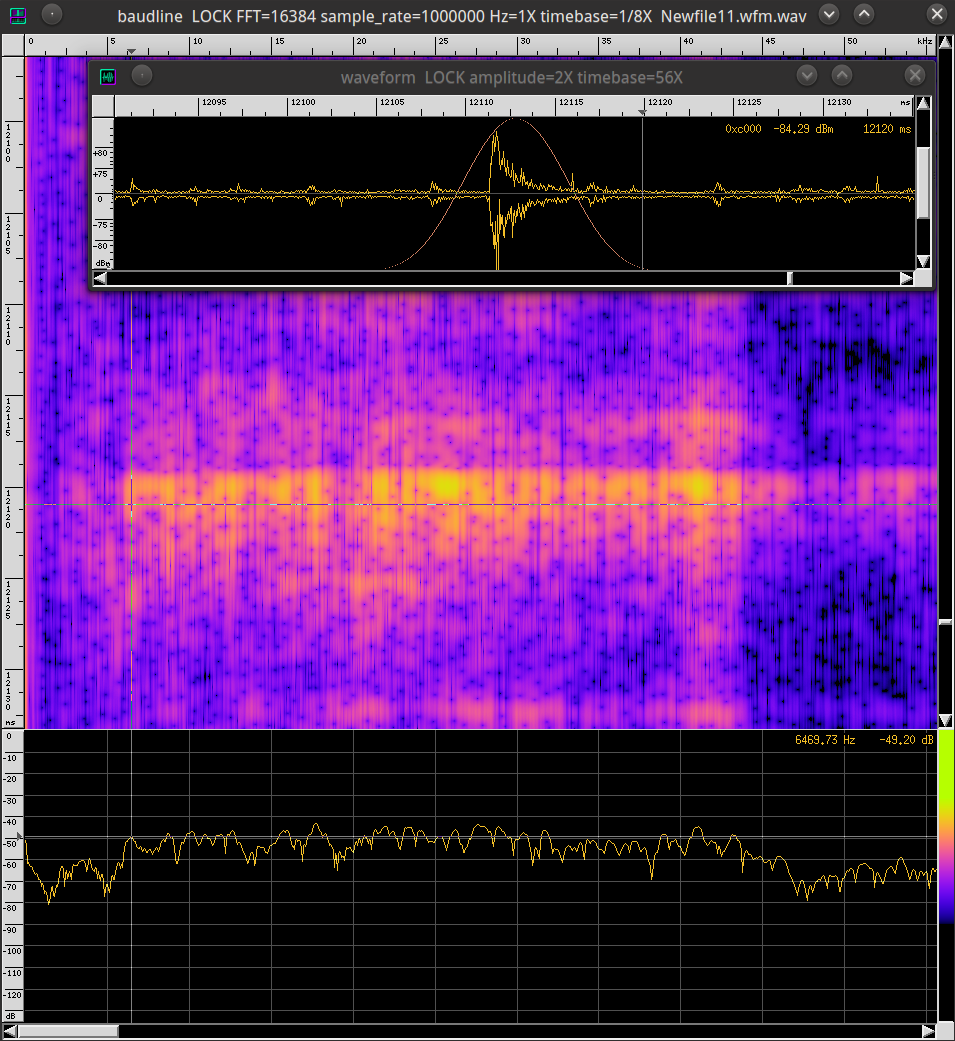

We ran it around some more on Tuesday and managed to catch a few real knocks. They look distinctly different: they're more of a "whack" than a decaying bell sound, but they're right on 6.5 kHz:

That's raw sensor data. I'm not sure what the MS3's input filtering does to it. It's configured for 6.94kHz but I don't know if it's a simple bandpass (and if so, what Q value), or if they have something smarter (I remember there being some kind of DSP on the board... I'll have to look and see what it was).

Last edited by turbokitten; 03-23-2015 at 05:30 PM. Reason: added a second view of the knock to make it easier to compare with the valve float

#133

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,166

Total Cats: 855

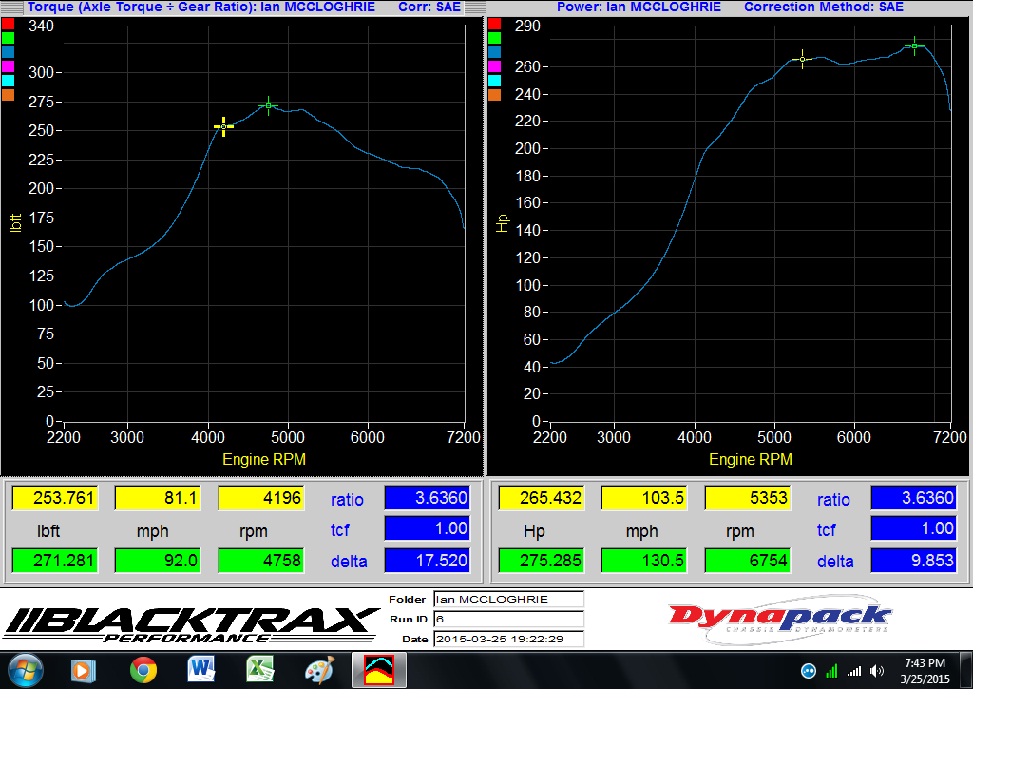

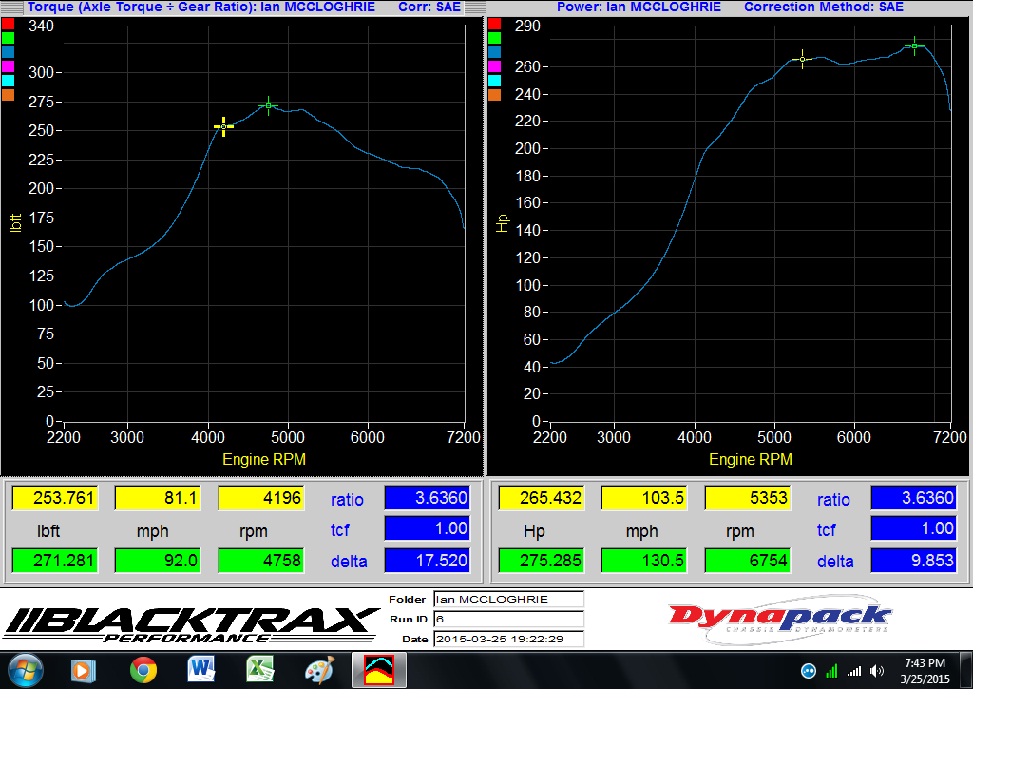

As I mentioned in this thread: https://www.miataturbo.net/diy-turbo...pinging-83645/ I've been having trouble with the car pinging. I'm still not entirely sure why, but I did run it at the dyno today at Blacktrax.

The good news is that ping wasn't a major issue. It managed to hit MBT at 190 kpa and below, was very slightly pingey at MBT at 215, and was spark limited at 230 kpa. The bad news is that it only made 275/275, barely more than it made with the 2560 on the Dynapack at AGP.

Today's dyno at 230 kpa:

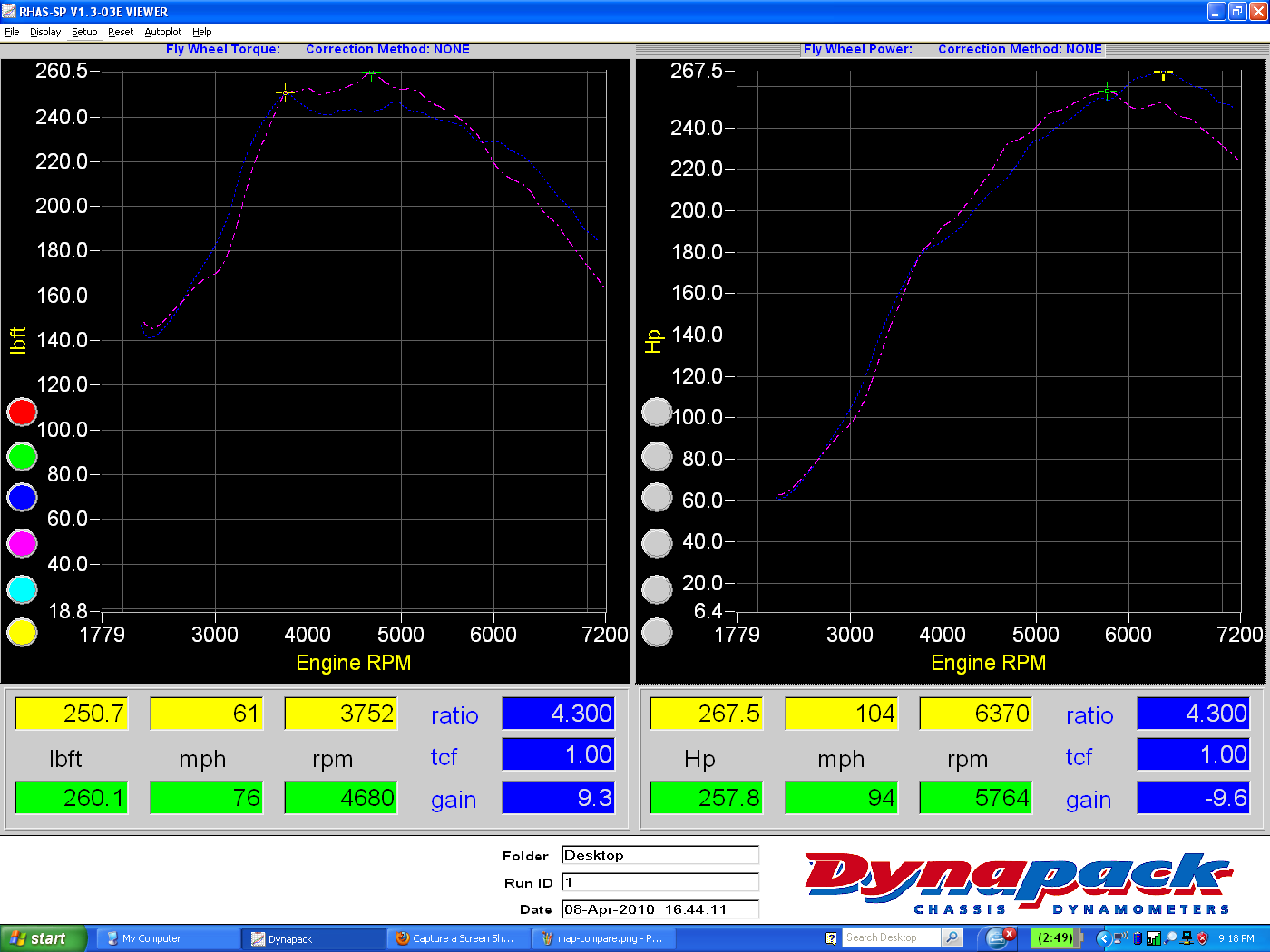

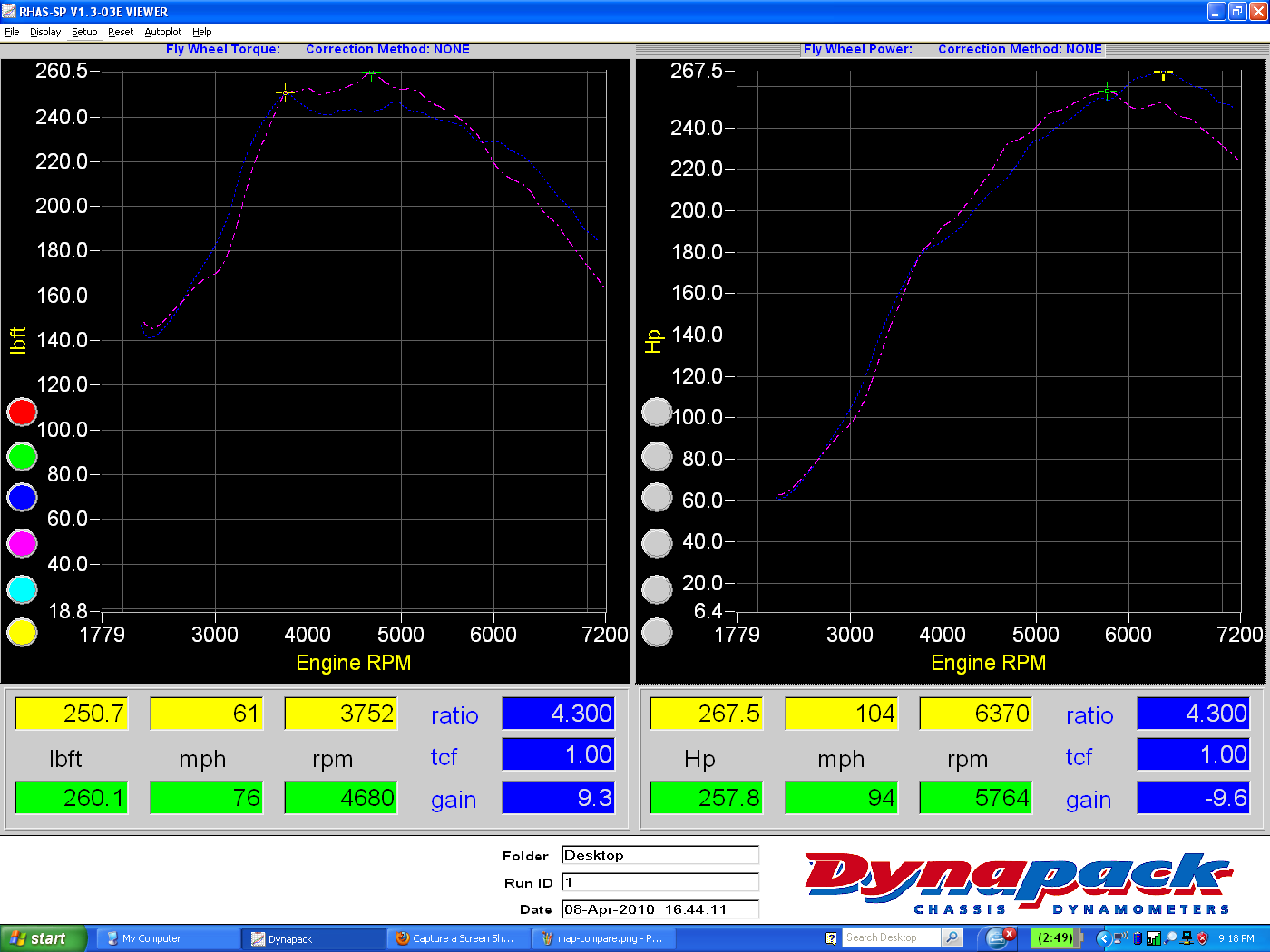

AGP a couple years ago at 200 kpa (look at the almost-invisible blue trace, the magenta one is what it did with the 2.5" exhaust running slightly more boost):

I wound up with this spark map. It still needs a bit of cleaning up and smoothing:

So the 2863 spools up 500 RPM later than the 2560, and only adds a small area under the curve above 6200 or so, despite running 30 kpa more boost. It's also more inclined to ping, and I don't know why. I'm disappointed, I'd expected a lot better out of it. Jason commented that the motor doesn't seem to be responding to timing as much as he would expect. We'd add a couple degrees and torque would go up, but only a little bit. A few possibilities occur to me:

- Maybe there's a restriction in the intake somewhere. Perhaps the FM intercooler isn't enough? I think I have the latest iteration that they sell, but I dunno.

- Perhaps it's time to give up on the 99 VICS intake manifold and go with a square top?

- Maybe the head doesn't flow as well as I'd hoped. It's got +1 intake valves, stock size exhaust ones. Perhaps I should cough up the dough for a 949 head?

- There's a small (I think) boost leak at one of the charge pipes that gives off a whistle. Perhaps it's big enough to be making the turbo work extra hard?

--Ian

The good news is that ping wasn't a major issue. It managed to hit MBT at 190 kpa and below, was very slightly pingey at MBT at 215, and was spark limited at 230 kpa. The bad news is that it only made 275/275, barely more than it made with the 2560 on the Dynapack at AGP.

Today's dyno at 230 kpa:

AGP a couple years ago at 200 kpa (look at the almost-invisible blue trace, the magenta one is what it did with the 2.5" exhaust running slightly more boost):

I wound up with this spark map. It still needs a bit of cleaning up and smoothing:

So the 2863 spools up 500 RPM later than the 2560, and only adds a small area under the curve above 6200 or so, despite running 30 kpa more boost. It's also more inclined to ping, and I don't know why. I'm disappointed, I'd expected a lot better out of it. Jason commented that the motor doesn't seem to be responding to timing as much as he would expect. We'd add a couple degrees and torque would go up, but only a little bit. A few possibilities occur to me:

- Maybe there's a restriction in the intake somewhere. Perhaps the FM intercooler isn't enough? I think I have the latest iteration that they sell, but I dunno.

- Perhaps it's time to give up on the 99 VICS intake manifold and go with a square top?

- Maybe the head doesn't flow as well as I'd hoped. It's got +1 intake valves, stock size exhaust ones. Perhaps I should cough up the dough for a 949 head?

- There's a small (I think) boost leak at one of the charge pipes that gives off a whistle. Perhaps it's big enough to be making the turbo work extra hard?

--Ian

Last edited by codrus; 03-26-2015 at 02:25 AM.

#134

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,166

Total Cats: 855

Oh, the Toda adjustable cam gear proved totally worthless. Going one way from 0 lost power up top and didn't add spool, going the other way it lost a ton of spool and only added a few hp, so we wound up back at 0. Totally not what I expected.

--Ian

--Ian

#135

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,166

Total Cats: 855

Digging through the log files shows something interesting. On the dyno, and in every log file dated 3/14 and later, it doesn't hit 200 kpa until over 4000 RPM (4050 or so on the dyno, 4100-4200 in street pulls). On the 3/8 log file (the most recent one before 3/14) it hits it at 3750. There's something broken in there...

--Ian

--Ian

#136

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Sorry I don't have more to add, but I'm digging the well documented and methodical approach you are taking to solve this issue. I'm learning a lot just by reading over your shoulder. Many props sir.

Are you thinking IAT or loss in the intercooler itself? Both should be relatively easy to confirm.

I know you aren't the kind of guy to just throw parts at a problem, but I've got Sav's Precision 600 sitting in my garage that I will most likely not be using on my build. Shoot me a PM or poke me on FB and I can drop it off the next time I'm in SJ if you are interested.

I know you aren't the kind of guy to just throw parts at a problem, but I've got Sav's Precision 600 sitting in my garage that I will most likely not be using on my build. Shoot me a PM or poke me on FB and I can drop it off the next time I'm in SJ if you are interested.

#137

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,166

Total Cats: 855

Sorry I don't have more to add, but I'm digging the well documented and methodical approach you are taking to solve this issue. I'm learning a lot just by reading over your shoulder. Many props sir.

Are you thinking IAT or loss in the intercooler itself? Both should be relatively easy to confirm.

I know you aren't the kind of guy to just throw parts at a problem, but I've got Sav's Precision 600 sitting in my garage that I will most likely not be using on my build. Shoot me a PM or poke me on FB and I can drop it off the next time I'm in SJ if you are interested.

Are you thinking IAT or loss in the intercooler itself? Both should be relatively easy to confirm.

I know you aren't the kind of guy to just throw parts at a problem, but I've got Sav's Precision 600 sitting in my garage that I will most likely not be using on my build. Shoot me a PM or poke me on FB and I can drop it off the next time I'm in SJ if you are interested.

I think at this point my primary theories are a boost leak in the intake, an exhaust restriction, or perhaps the WG getting blown open.

--Ian

#139

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,166

Total Cats: 855

I thought about the rag in the intercooler -- I've done stupider things than that before, but it was working well on 3/8 and I haven't had those bits apart since then.

thanks,

--Ian

I'm not sure I even noticed it before now.

I'm not sure I even noticed it before now.