Just another K swap...

#81

Senior Member

Thread Starter

Join Date: Sep 2011

Location: Sierra Vista, AZ

Posts: 1,212

Total Cats: 309

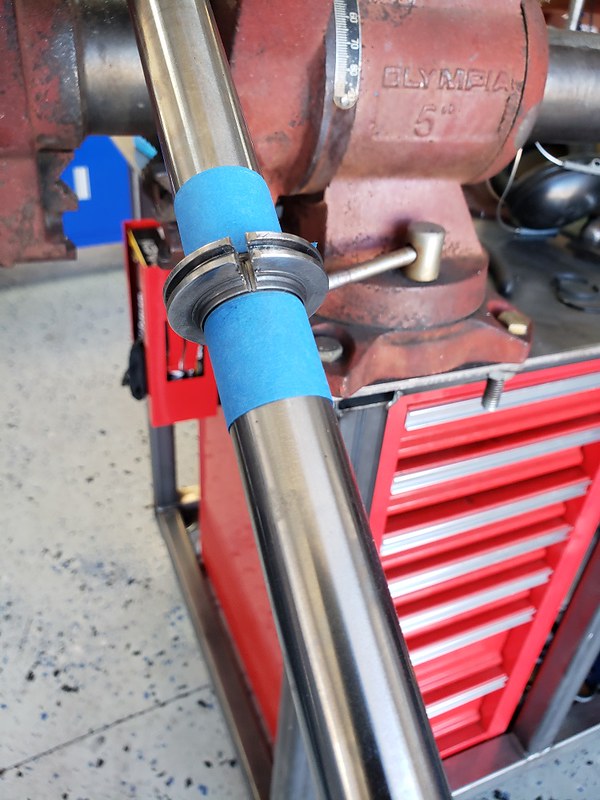

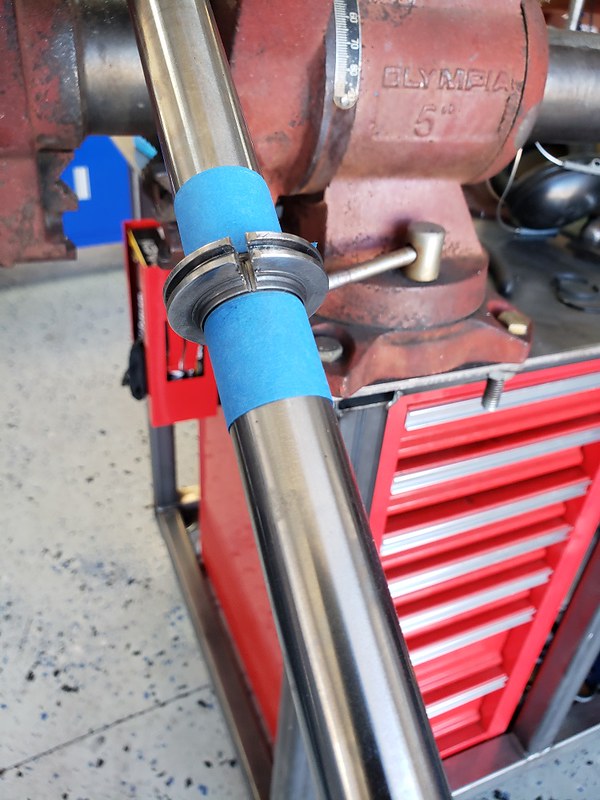

The crossmember for the K24A2 swap is set up for an NB steering rack, so I had sourced one a while back. Before installation, I'm depowering the rack, as I'll be adding electric power steering. I had depowered the NA rack years ago, but it was just a line loop/plug. This time I'm going to do it properly. First step was stripping the lines off the rack.

Today I disassembled the rack, and pressed out the mounting bushings.

Today I disassembled the rack, and pressed out the mounting bushings.

#86

Senior Member

Thread Starter

Join Date: Sep 2011

Location: Sierra Vista, AZ

Posts: 1,212

Total Cats: 309

Worked on the rack today...

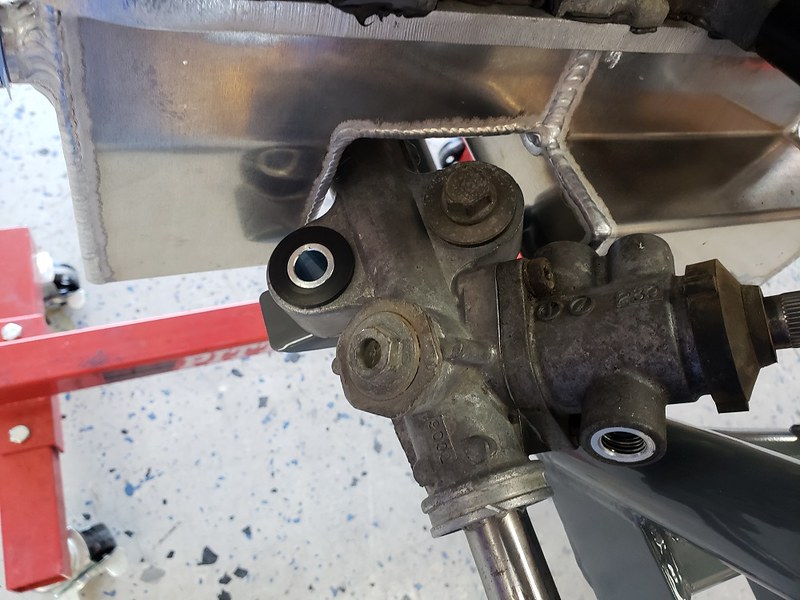

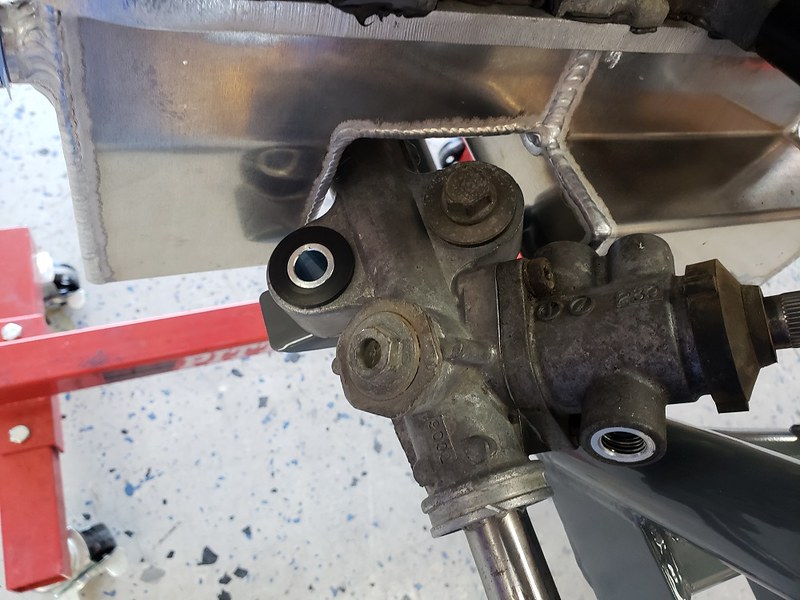

1st up was the actual 'depower', removing the 'piston' from the steering shaft.

Next was shaving the hydraulic fittings off the rack body, welding up the holes and repainting.

Also did a little cleanup on the splines for the pinion...

Got the rack mostly re-assembled after spending 40 minutes looking for the plug set I bought over a year ago... (still need a couple of plugs for the hydraulic fittings on the pinion cover), new bushings pressed in, and got it mounted for a test fit after chasing the threads on the V8R subframe.

1st up was the actual 'depower', removing the 'piston' from the steering shaft.

Next was shaving the hydraulic fittings off the rack body, welding up the holes and repainting.

Also did a little cleanup on the splines for the pinion...

Got the rack mostly re-assembled after spending 40 minutes looking for the plug set I bought over a year ago... (still need a couple of plugs for the hydraulic fittings on the pinion cover), new bushings pressed in, and got it mounted for a test fit after chasing the threads on the V8R subframe.

#87

Senior Member

Thread Starter

Join Date: Sep 2011

Location: Sierra Vista, AZ

Posts: 1,212

Total Cats: 309

I bolted the V8R subframe to the K24 on the engine stand to check out the fitment of the steering rack and ensure I had done everything necessary for clearance. It's really tight in some spots...

#90

I am just an observer and not speaking from experience, but I have heard of two issues on the V8R subframe you may want to consider addressing by reinforcing it now while the subframe is easily modified.

1. Steering rack mount failure. Here's one post, and I believe Keith Tanner had a similar experience.

2. Rear subframe mount cracks near FLCA-R. Here's Bronson's post on reinforcing that.

1. Steering rack mount failure. Here's one post, and I believe Keith Tanner had a similar experience.

2. Rear subframe mount cracks near FLCA-R. Here's Bronson's post on reinforcing that.

#92

Senior Member

Thread Starter

Join Date: Sep 2011

Location: Sierra Vista, AZ

Posts: 1,212

Total Cats: 309

I am just an observer and not speaking from experience, but I have heard of two issues on the V8R subframe you may want to consider addressing by reinforcing it now while the subframe is easily modified.

1. Steering rack mount failure. Here's one post, and I believe Keith Tanner had a similar experience.

2. Rear subframe mount cracks near FLCA-R. Here's Bronson's post on reinforcing that.

1. Steering rack mount failure. Here's one post, and I believe Keith Tanner had a similar experience.

2. Rear subframe mount cracks near FLCA-R. Here's Bronson's post on reinforcing that.

I stole a pic from Zoot's thread of his failure:

As he noted in his thread, that subframe was a much earlier build (and Keith's would have been as well), and had 90* brackets. The current version, if what I have is representative, has angled brackets, and the bottom is also boxed for additional strength. Pics are passenger side, but driver's side is similar.

I will definitely be keeping an eye on things, but I think the improvements in the mounting brackets, and the fact that I won't be running on 275 Hoosiers should improve the odds of the rack staying attached to the subframe.

I do think the rear subframe mounts could stand some reinforcement, so I'm taking a close look at what I can do there.

#93

Senior Member

Thread Starter

Join Date: Sep 2011

Location: Sierra Vista, AZ

Posts: 1,212

Total Cats: 309

Last week, I got the interior paint touched up on the new fabrication. I've been waiting for the weather to warm up a bit so I can get my shop into the 60s to paint the engine compartment.

Things were finally warming up, so yesterday I pulled the front subframe and prepped for paint. I started with pulling the fenders.

Then, I used a lift table to pull the subframe (which worked pretty well).

Today was paint day...

Things were finally warming up, so yesterday I pulled the front subframe and prepped for paint. I started with pulling the fenders.

Then, I used a lift table to pull the subframe (which worked pretty well).

Today was paint day...

#94

Senior Member

Thread Starter

Join Date: Sep 2011

Location: Sierra Vista, AZ

Posts: 1,212

Total Cats: 309

Test fitting the subframe today...

Unfortunately, V8R's reputation for spotty QC appears to be deserved... On a 32 year old chassis, I'm not going to complain too loudly, though...

Easy enough to open the holes a bit, and use a washer/spacer for the vertical gap.

Unfortunately, V8R's reputation for spotty QC appears to be deserved... On a 32 year old chassis, I'm not going to complain too loudly, though...

Easy enough to open the holes a bit, and use a washer/spacer for the vertical gap.

#95

Senior Member

Thread Starter

Join Date: Sep 2011

Location: Sierra Vista, AZ

Posts: 1,212

Total Cats: 309

Reinstalled the clutch and dead pedals.

Reinstalled the clutch hydraulics. Also re-bent the factory hard fuel lines to go up the firewall instead of out the right frame rail. Re-bent the rear brake hard line to follow the new firewall profile as well. All of these will eventually be pointed towards the driver's side, but for now they're out of the way and where they need to be.

Reinstalled the clutch hydraulics. Also re-bent the factory hard fuel lines to go up the firewall instead of out the right frame rail. Re-bent the rear brake hard line to follow the new firewall profile as well. All of these will eventually be pointed towards the driver's side, but for now they're out of the way and where they need to be.

#96

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,230

Total Cats: 1,147

As far as I can tell, the rear bolt misalignment happens either during welding or powder coating. Wrap a ratchet strap around it towards the back and pull it together a bit, I've had to do that on the ~6 V8R subframes I've installed.

#98

Senior Member

Thread Starter

Join Date: Sep 2011

Location: Sierra Vista, AZ

Posts: 1,212

Total Cats: 309

Still plodding along... stripping out the factory K24 harness, test fitting parts, planning electrics, etc.

Ran into a couple of issues that required ordering parts... more on that later.

Ran into a couple of issues that required ordering parts... more on that later.

#99

Senior Member

Thread Starter

Join Date: Sep 2011

Location: Sierra Vista, AZ

Posts: 1,212

Total Cats: 309

The engine I bought for my swap is a JDM K24. It's a 3 lobe RBB head engine, so it's basically the same as a K24A2 from an 06-08 TSX, but there are some differences. When I bought the engine, it was the right combination of availability, price, and proximity. I was able to pick it up rather than having it shipped, so overall it was the easy button at the time. That said, I eventually discovered enough differences between the JDM and USDM engines to pretty much wipe out any cost advantage.

For prosperity, these are the USDM parts (Honda/Acura part #s) I ended up using to convert the JDM engine for use in a Miata with the KPower kit:

Water pump housing 19410-RAA-A00

Belt Tensioner 31170-PNA-023

Idler Pulley 31190-RRA-A00

Alternator

Bolt (alt upper) 90025-PNA-000 (M8x1.25 105mm)

Bolt (alt lower) 95701-0805508 (M8x1.25 55mm) x2

Crank Pulley (balancer) 13810-RRA-A02

Crank Pulley bolt 90017-PCX-013

In most cases I just bought new OEM because in my experience the cost difference over used/aftermarket is worth it in track reliability down the road. I used a re-man alternator, and was able to find the alternator bolts at my local hardware (for about the same cost as the Honda parts). The JDM balancer will work, but it's a slightly larger diameter than the USDM part, so it will require a different belt than specified by KPower. Since this is a track car, I figured reducing the accessory speeds could only be a good thing, so I just bought a new balancer.

Please double check any part numbers before ordering... going by my notes. I may also have missed a couple of small parts and didn't include gaskets, etc in the list.

If you are using a mechanical (cable) throttle, and want ECU idle control you will also need an Accord/Element IACV (16022-RAA-A01). This tidbit is buried in the KPower install manual.

For prosperity, these are the USDM parts (Honda/Acura part #s) I ended up using to convert the JDM engine for use in a Miata with the KPower kit:

Water pump housing 19410-RAA-A00

Belt Tensioner 31170-PNA-023

Idler Pulley 31190-RRA-A00

Alternator

Bolt (alt upper) 90025-PNA-000 (M8x1.25 105mm)

Bolt (alt lower) 95701-0805508 (M8x1.25 55mm) x2

Crank Pulley (balancer) 13810-RRA-A02

Crank Pulley bolt 90017-PCX-013

In most cases I just bought new OEM because in my experience the cost difference over used/aftermarket is worth it in track reliability down the road. I used a re-man alternator, and was able to find the alternator bolts at my local hardware (for about the same cost as the Honda parts). The JDM balancer will work, but it's a slightly larger diameter than the USDM part, so it will require a different belt than specified by KPower. Since this is a track car, I figured reducing the accessory speeds could only be a good thing, so I just bought a new balancer.

Please double check any part numbers before ordering... going by my notes. I may also have missed a couple of small parts and didn't include gaskets, etc in the list.

If you are using a mechanical (cable) throttle, and want ECU idle control you will also need an Accord/Element IACV (16022-RAA-A01). This tidbit is buried in the KPower install manual.

#100

Senior Member

Thread Starter

Join Date: Sep 2011

Location: Sierra Vista, AZ

Posts: 1,212

Total Cats: 309

Some more info for posterity...

Since I'm building a new wiring harness, I went with all-new connectors. Ballenger Motorsports is a great source for this stuff, and below are the part numbers for the K24 connectors:

Crank position sensor - CONN-76246

Cam position/MAP/TPS - CONN-75778

VTC Solenoid/IAT/CLT - CONN-75781

Injector - CONN-75783

Coil - CONN-75784

Alternator - CONN-76257

IACV (Accord/Element for KPower manifold) - CONN-76125

Note that these are "connector kits" with the connector, terminals and seals. They can also be ordered as pigtails with different part #s. Ballenger's site is pretty easy to navigate.

Since I'm building a new wiring harness, I went with all-new connectors. Ballenger Motorsports is a great source for this stuff, and below are the part numbers for the K24 connectors:

Crank position sensor - CONN-76246

Cam position/MAP/TPS - CONN-75778

VTC Solenoid/IAT/CLT - CONN-75781

Injector - CONN-75783

Coil - CONN-75784

Alternator - CONN-76257

IACV (Accord/Element for KPower manifold) - CONN-76125

Note that these are "connector kits" with the connector, terminals and seals. They can also be ordered as pigtails with different part #s. Ballenger's site is pretty easy to navigate.

Thanks!

Thanks!