Rafael's Build Thread

#22

More on today...

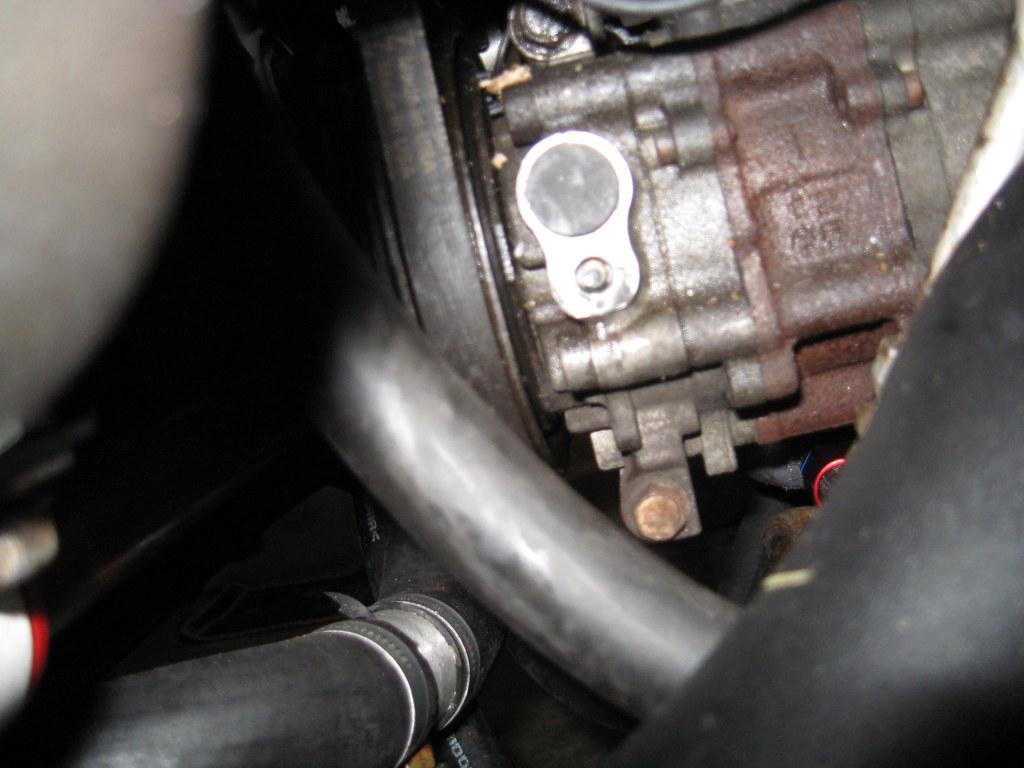

Finished tapping the pan. I'm not really happy with it. It wasn't very tight in the pan.

Installed the intercooler. It took for ever since the tow hook holes were a bitch to get into. Also not sure if I worked the ac dryer correctly. The instructions were a little iffy on that.

Tapped the throttle body intercooler tube for the gm IAT. Might end up just getting a bung welded in just incase.

Blugged it for now until I install the Adaptronic.

I'm having a lot of trouble hooking up the turbo intercooler tubes. There is no room and its hitting the sway bar and ac lines. Having the one ac line disconnected helped but now there is no way in putting it back. Any suggestions? Am I supposed to be bending these lines to make room?

Finished tapping the pan. I'm not really happy with it. It wasn't very tight in the pan.

Installed the intercooler. It took for ever since the tow hook holes were a bitch to get into. Also not sure if I worked the ac dryer correctly. The instructions were a little iffy on that.

Tapped the throttle body intercooler tube for the gm IAT. Might end up just getting a bung welded in just incase.

Blugged it for now until I install the Adaptronic.

I'm having a lot of trouble hooking up the turbo intercooler tubes. There is no room and its hitting the sway bar and ac lines. Having the one ac line disconnected helped but now there is no way in putting it back. Any suggestions? Am I supposed to be bending these lines to make room?

#23

I just fucked up something. I unbolted a hose to the ac to make room for the drill and got an explosion of liquid in my face. The belt started to spin also. Did I do huge damage? Can I fix this and replace that liquid? Should have known not to touch anything.

I'm such a dumbass!

Artie pm sent.

I'm such a dumbass!

Artie pm sent.

#24

Finished a few more things today...

Rerouted my reroute back to the lower cooler hose.

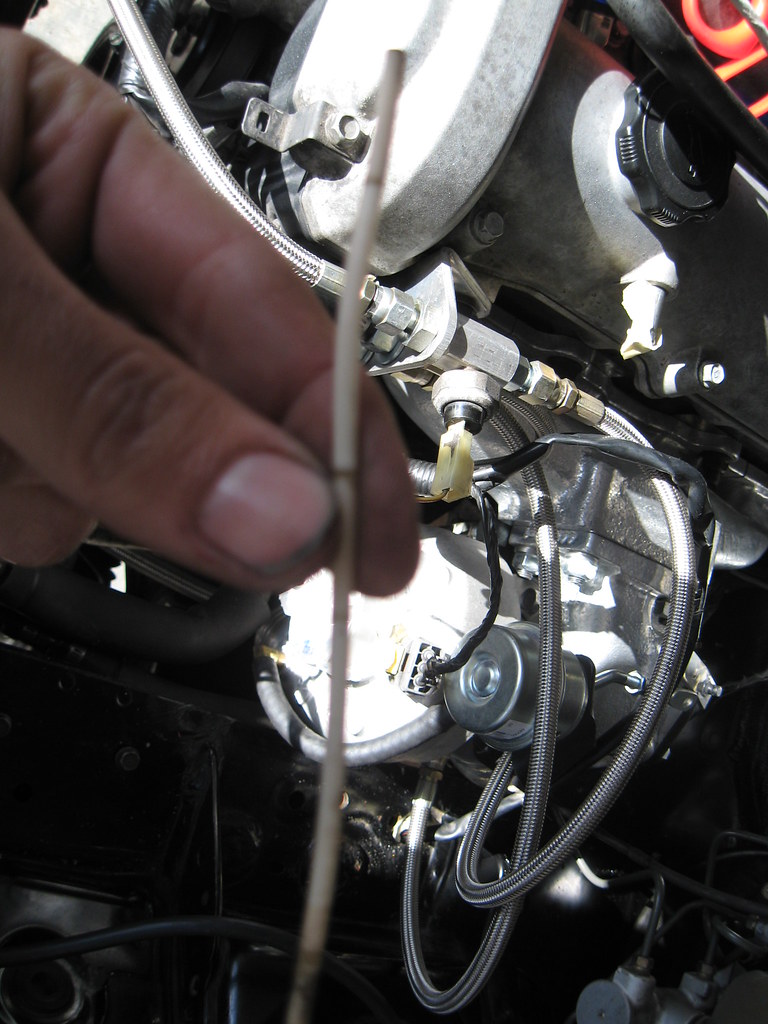

I had to put my oil return line through alternator belt and wire it to the thermostat to keep it from touching the belt. The line was a little short and I didn't have many options with it.

Does it matter what two water lines the turbo connects to (thermostat or lower heater adapter? The Begi instructions didn't say.

As of now I have the water out turbo line to the thermostat and the water in line to the lower heater hose tube.

Should I worry if the ss lines are touching each other or other metal parts? They were a pain to keep from touching things.

Rerouted my reroute back to the lower cooler hose.

I had to put my oil return line through alternator belt and wire it to the thermostat to keep it from touching the belt. The line was a little short and I didn't have many options with it.

Does it matter what two water lines the turbo connects to (thermostat or lower heater adapter? The Begi instructions didn't say.

As of now I have the water out turbo line to the thermostat and the water in line to the lower heater hose tube.

Should I worry if the ss lines are touching each other or other metal parts? They were a pain to keep from touching things.

#30

Today I pretty much finished up the kit.

Soldered and extended the oil pressure sender.

For some reason there was a small white tube taped to it. Any one know what this is or used for and if I should tape it back to the sender?

I broke the screw holding the ac line trying to bend it to make room for the intercooler tube. Plugged the hole with a rubber stopper from the depot. I'll cover it with duck tape tomorrow.

Ducktaped the ac line and tied it up to the power steering lines.

Where the hell do I put the air sensor? The directions say to plug it into the cool air box but the BegiS1 doesn't include the cool air box. I am assuming I can just leave it near the filter?

Everything about the turbo kit is pretty much installed now. Now I just have to finish a few odds and ends, like getting a new upper radiater hose, installing the turbo heat shield, replacing fluids and keeping the stainless lines from touching things.

#31

Senior Member

iTrader: (23)

Join Date: Oct 2009

Location: Chatsworth, SoCal

Posts: 948

Total Cats: 1

I think you solved your A/C problem. Now that you broke the bolt just remove it all. Then you wot have to wory about it. Also there will be better flow to the radiator.

Have a great day,

Jared

Have a great day,

Jared

#32

Ok, so I got the upper radiator hose and was finally able to fill it with fluids.

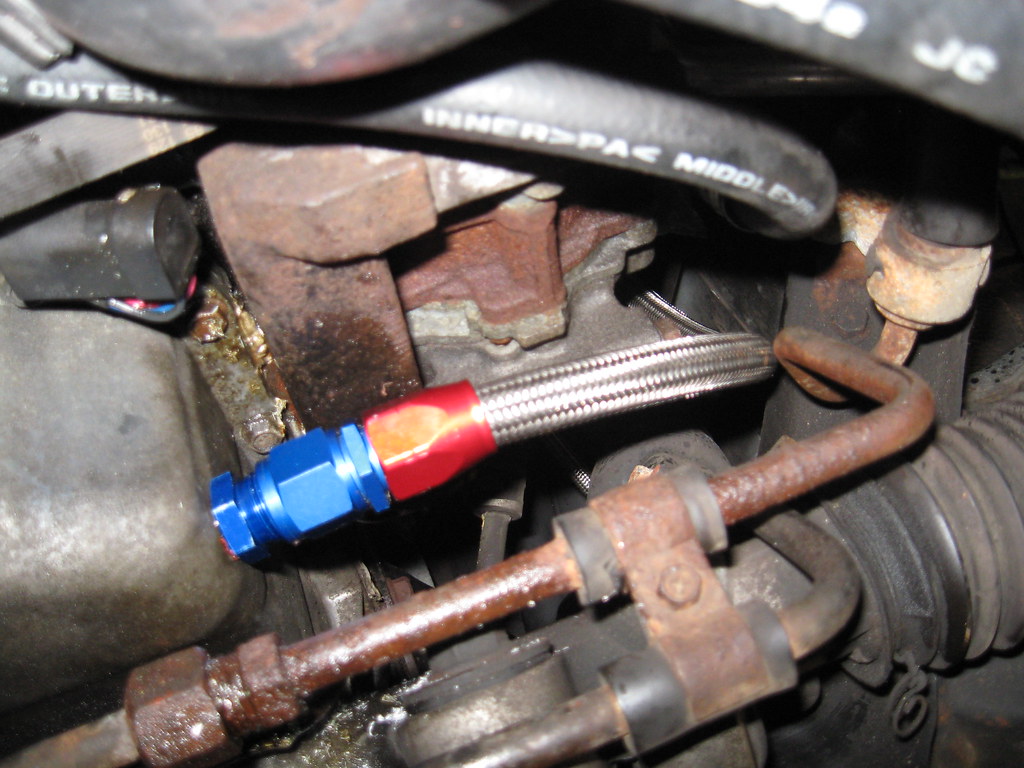

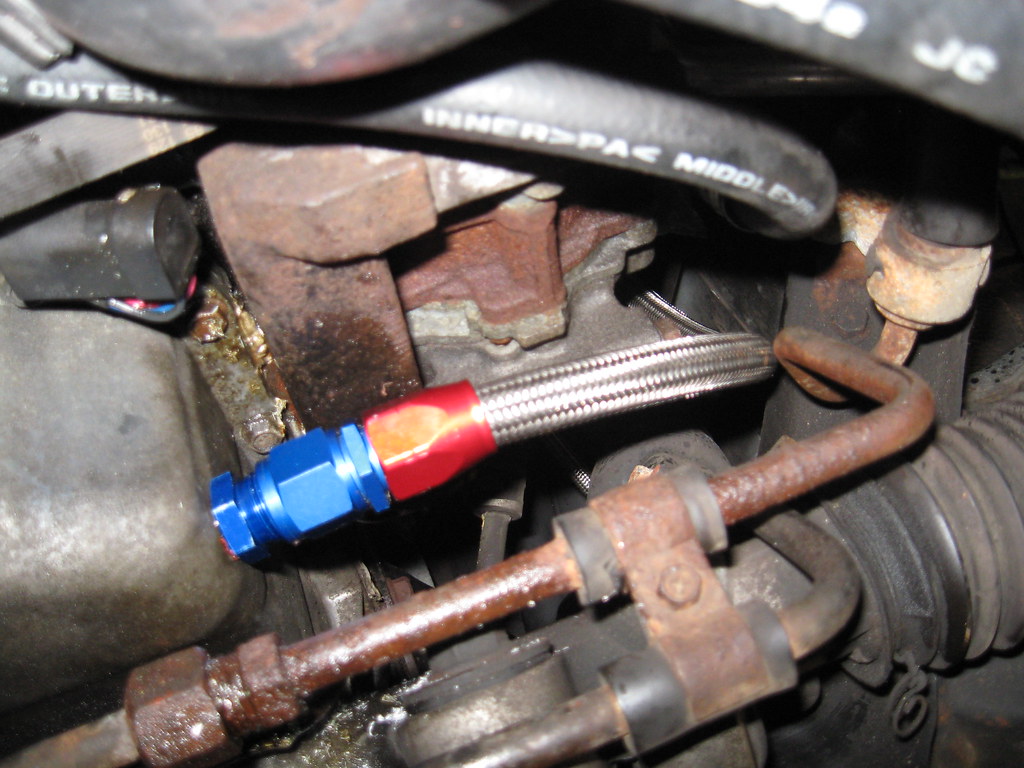

I have a small leak in the oil line to the turbo.

I think it has to do with such a hard bend on the line from being to short and angled. I could barely screw it in. I am going to get this adapter in -8an. Hopefully it will ease things a bit.

It only got worse when I started the car. There was a large leak at the heater hose on the firewall. I drained the fluid, added sealant to the tube and a second clamp. For now no more coolant leak.

The other problem was after the car warmed up, I revved the engine to make sure it wouldn't boost but after that my idle was high. First at 2000rpms then after turning the car off and on again it idled at 3000 rpms. I need help on this. I left this softly zip tied next to the air intake. Could this be the problem and where can I put this?

Last thing...I heard a type of knock sound coming from the engine after leaving the car on for a few minutes. Is this knock or a normal sound. I don't know how it could be knock or ping if I didn't drive the car or am running boost.

http://www.flickr.com/photos/7653913...n/photostream/

I have a small leak in the oil line to the turbo.

I think it has to do with such a hard bend on the line from being to short and angled. I could barely screw it in. I am going to get this adapter in -8an. Hopefully it will ease things a bit.

It only got worse when I started the car. There was a large leak at the heater hose on the firewall. I drained the fluid, added sealant to the tube and a second clamp. For now no more coolant leak.

The other problem was after the car warmed up, I revved the engine to make sure it wouldn't boost but after that my idle was high. First at 2000rpms then after turning the car off and on again it idled at 3000 rpms. I need help on this. I left this softly zip tied next to the air intake. Could this be the problem and where can I put this?

Last thing...I heard a type of knock sound coming from the engine after leaving the car on for a few minutes. Is this knock or a normal sound. I don't know how it could be knock or ping if I didn't drive the car or am running boost.

http://www.flickr.com/photos/7653913...n/photostream/

Last edited by PhantomRoadster; 01-02-2010 at 01:15 AM.

#35

I tried starting the car today and the idle was back to stock. I figure I had to give time for the ecu to work out the changes. I drove it to the inspection station and the revs seemed a little off during driving. Little higher than normal and a little slow to lower during deceleration. I ended up failing the inspection for emissions "not ready". The guy said to drive it 200 miles and come back. I guess the 25 mile drive wasn't enough.

After the inspection I saw another leak by the distribution block at the oil in tubo line. I hate all these fittings. torque too hard and you strip it, torque too soft and you got a leak. Does anyone know which oil lines you can put sealant on? The directions said not to put it on the turbo lines because it would kill the turbo. So now I have two leaks, one at the oil pan line and one at the distribution block. I think both are caused by tight lines and not have an angled adapter. Anyone know where to get adapters/fittings for these lines?

The power steering is also making all sorts of noises.

After the inspection I saw another leak by the distribution block at the oil in tubo line. I hate all these fittings. torque too hard and you strip it, torque too soft and you got a leak. Does anyone know which oil lines you can put sealant on? The directions said not to put it on the turbo lines because it would kill the turbo. So now I have two leaks, one at the oil pan line and one at the distribution block. I think both are caused by tight lines and not have an angled adapter. Anyone know where to get adapters/fittings for these lines?

The power steering is also making all sorts of noises.

#37

I installed LC1 yesterday.

I soldered all the grounds to one single ground, then I ran to the engine bay. I hope this won't cause to much interference.

Tapped the red LC1 wire into the radio ign. positive wire (blue/black). Then soldered the gauge positive red wire to the LC1 red wire.

LC1 brown wire soldered to the gauge's yellow wire.

Soldered the led and push button to the black calibration wire.

Then soldered the other ends of the push button and led to the ground.

The LC1 has too many damn wires.

I wanted to solder the ground with the ecu ground (blk/yellow) but I couldn't seperate the funky lug with the other unknown ground. So I did exactly what the directions said not to. I bolted it on top of the ecu ground.

Installed. Not sure what I am going to do with the open hole. Most likely a new gauge or put in a flat section for the led and button.

Boost gauge was tapped into the warning light's positive and ground wires.

So far the gauge seems to be reading ok from what I know. It jumps from .2-.5 at a given rpm. I assume this normal.

I soldered all the grounds to one single ground, then I ran to the engine bay. I hope this won't cause to much interference.

Tapped the red LC1 wire into the radio ign. positive wire (blue/black). Then soldered the gauge positive red wire to the LC1 red wire.

LC1 brown wire soldered to the gauge's yellow wire.

Soldered the led and push button to the black calibration wire.

Then soldered the other ends of the push button and led to the ground.

The LC1 has too many damn wires.

I wanted to solder the ground with the ecu ground (blk/yellow) but I couldn't seperate the funky lug with the other unknown ground. So I did exactly what the directions said not to. I bolted it on top of the ecu ground.

Installed. Not sure what I am going to do with the open hole. Most likely a new gauge or put in a flat section for the led and button.

Boost gauge was tapped into the warning light's positive and ground wires.

So far the gauge seems to be reading ok from what I know. It jumps from .2-.5 at a given rpm. I assume this normal.

#39

Elite Member

iTrader: (1)

Join Date: Jun 2006

Location: Warrington/Birmingham

Posts: 2,642

Total Cats: 42

Don't be surprised if you have issues with your LC-1 wired like that.

Power from your headunit and stacked & paired up grounds isn't cool. The heater ground should be separate from the sensor ground.

Power should be picked up from the same place as the ECU. Hell everything should be picked up from the ECU (i.e. grounds too). Just strip some of the sheath back and solder onto that then cover. You don't need to cut 'n' splice.

Power from your headunit and stacked & paired up grounds isn't cool. The heater ground should be separate from the sensor ground.

Power should be picked up from the same place as the ECU. Hell everything should be picked up from the ECU (i.e. grounds too). Just strip some of the sheath back and solder onto that then cover. You don't need to cut 'n' splice.