ScottFW's build thread

#23

Senior Member

Thread Starter

iTrader: (4)

Join Date: Jan 2008

Location: Falls Church, VA

Posts: 1,361

Total Cats: 17

Money-wise it's probably a wash. The IC piping for A/C and a low mount mani would have cost me one way or another, but my BEGI/FM replacement mani cost more than the low-mount due to the number of tight-radius stainless sch 40 weld-els involved. So in the end, the big difference is the ease with which I can install the system. I can use off-the-shelf piping and other bits from FM or BEGI and have to do less fabbing. For example, BEGI has some compressor outlet pipes on sale that are bent in various ways and I bet one of them will magically fit around the A/C.

Of course, there are potential differences in flow & spool between the low-mount and mine, but I don't think I will have any difficulty hitting my power goals with this mani.

Speaking of power, the EWG has a 0.5 bar spring in it, about 7-8 psi. I'm not going to be cranking it up to ABSURD levels yet because I still have a stock motor and 5-spd. Eventually I'd like to end up in the 275-300 range, but I'll enjoy it at lower boostsz while my fun budget recuperates enough to build a motor.

Even with y'all's help there's no way to get it turbo'ed and track-ready in 1.5 weeks. I'm hoping for late June to early July.

Even with y'all's help there's no way to get it turbo'ed and track-ready in 1.5 weeks. I'm hoping for late June to early July.

#25

Senior Member

Thread Starter

iTrader: (4)

Join Date: Jan 2008

Location: Falls Church, VA

Posts: 1,361

Total Cats: 17

Holy thread resurrection Batman!

Build went on a long haitus due to the arrival of our daughter last August and the resulting disappearance of my free time. I didn't stop accumulating parts in the mean time though. Got a 6-spd out of a MSM, picked up an 01 motor for a steal, M-tuned rods, 8.6:1 Supertechs and a few other little things. I also recently upgraded to MS3, though still running batch/wasted and I haven't installed the MS3X yet. So although the build has been delayed a bit, it will be somewhat more thorough. The plan is to build my 94 block and use the 01 head with MS controlling the VVT.

I finally borrowed a hoist and got the 01 motor off of my garage floor onto a stand. I'm mocking up the turbo parts to have a look at fit & location and double-check exactly where to put the oil drain in the pan. I'm gonna remove the pan for the drilling and will have an NPT fitting TIGed on for that, and another fitting on the other side for the oil temp sensor so I can relocate it from the oil drain plug adapter I'm currently using.

Build went on a long haitus due to the arrival of our daughter last August and the resulting disappearance of my free time. I didn't stop accumulating parts in the mean time though. Got a 6-spd out of a MSM, picked up an 01 motor for a steal, M-tuned rods, 8.6:1 Supertechs and a few other little things. I also recently upgraded to MS3, though still running batch/wasted and I haven't installed the MS3X yet. So although the build has been delayed a bit, it will be somewhat more thorough. The plan is to build my 94 block and use the 01 head with MS controlling the VVT.

I finally borrowed a hoist and got the 01 motor off of my garage floor onto a stand. I'm mocking up the turbo parts to have a look at fit & location and double-check exactly where to put the oil drain in the pan. I'm gonna remove the pan for the drilling and will have an NPT fitting TIGed on for that, and another fitting on the other side for the oil temp sensor so I can relocate it from the oil drain plug adapter I'm currently using.

#26

Senior Member

Thread Starter

iTrader: (4)

Join Date: Jan 2008

Location: Falls Church, VA

Posts: 1,361

Total Cats: 17

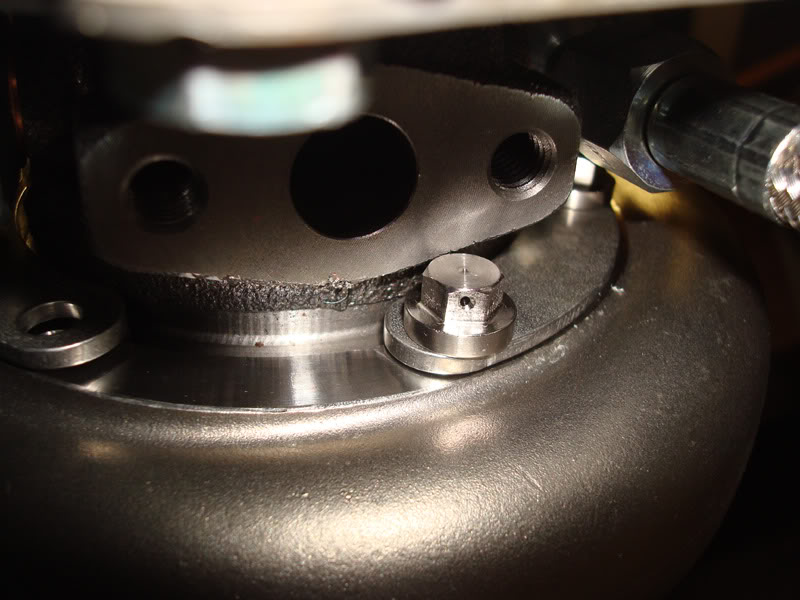

The more immediate reason for the thread revival is that I'm running into clearance issues with Tial's nimonic/Unicorn horn bolts that hold the CHRA onto the turbine housing. They are considerably taller than the standard bolts and interfere with free rotation of the CHRA because they can hit the oil drain flange and the banjo fittings on the coolant lines. I am soliciting opinions on what to do about it.

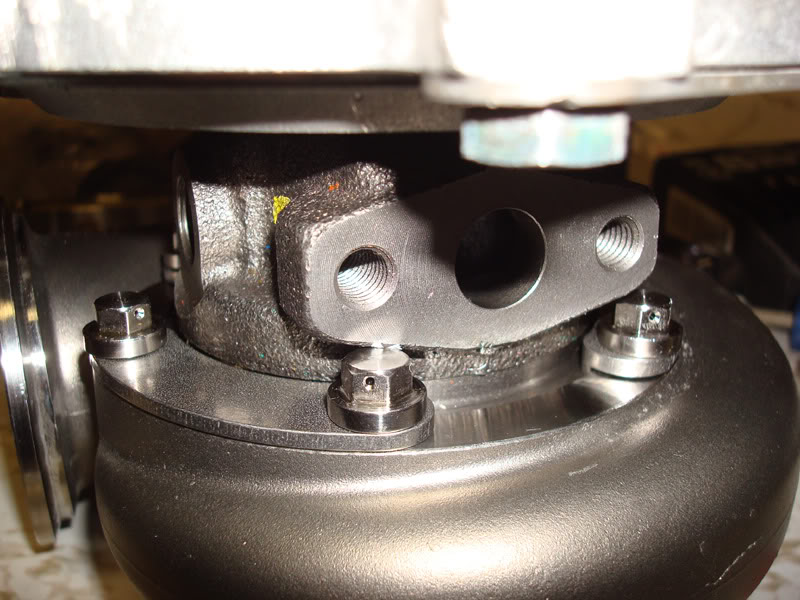

Here's a pic of standard CHRA bolts on someone else's car. Same banjo fittings I have (lines are from ARTech) and no clearance issues.

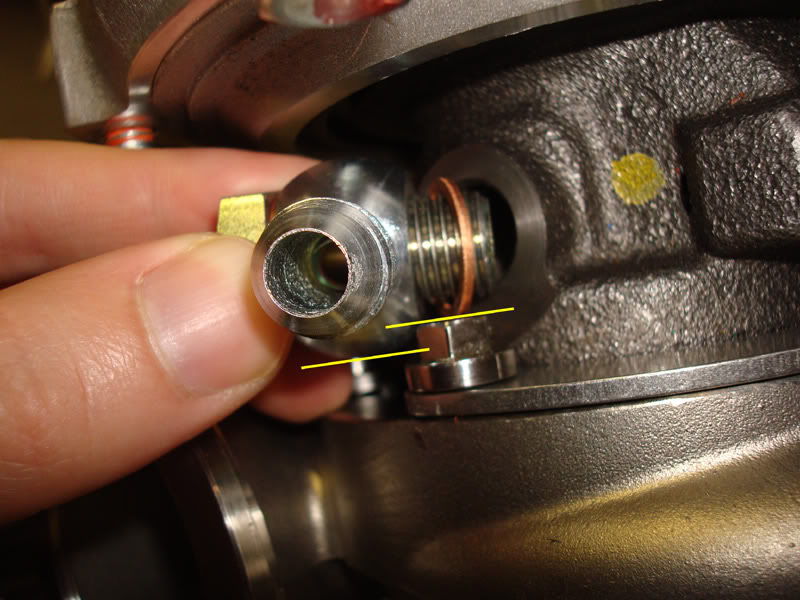

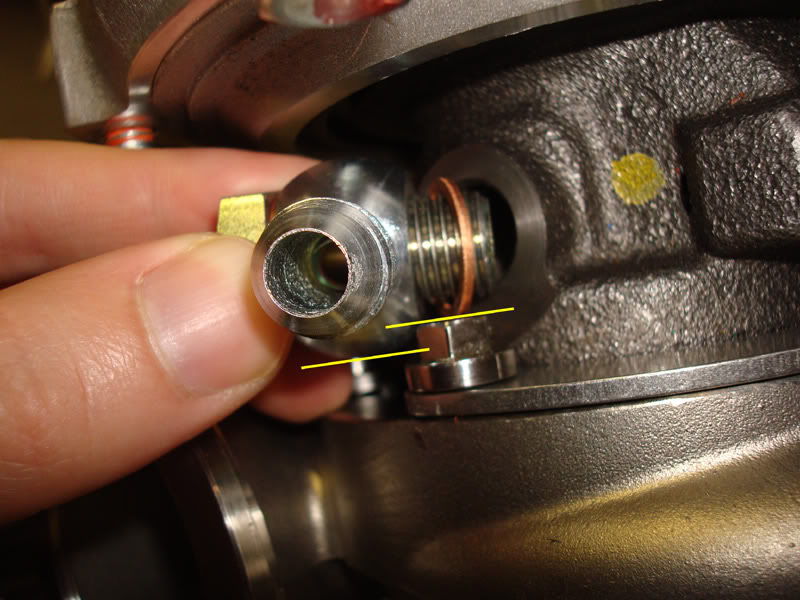

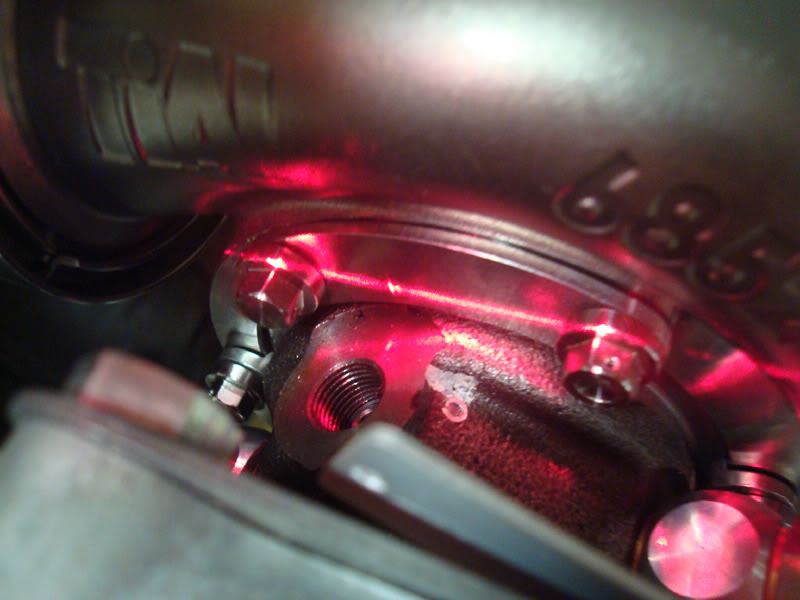

Me holding a banjo fitting to show how the height of these Tial bolts is an issue.

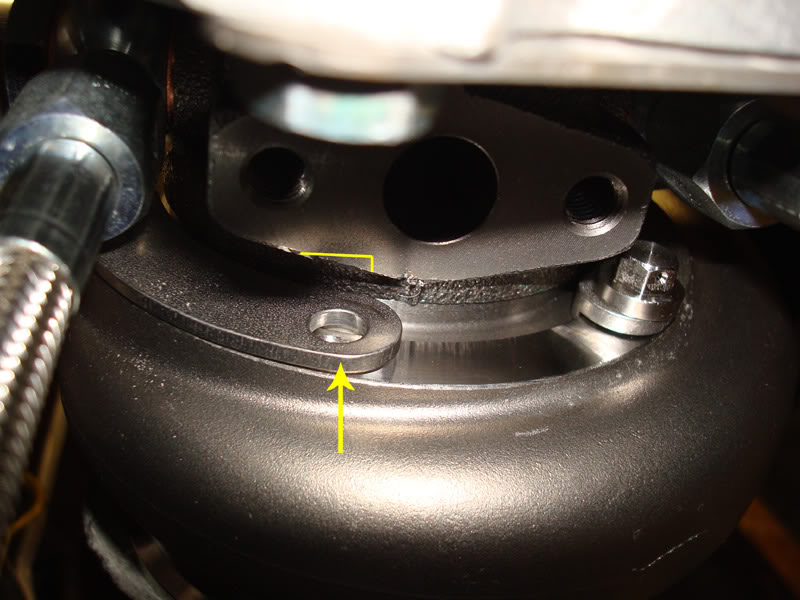

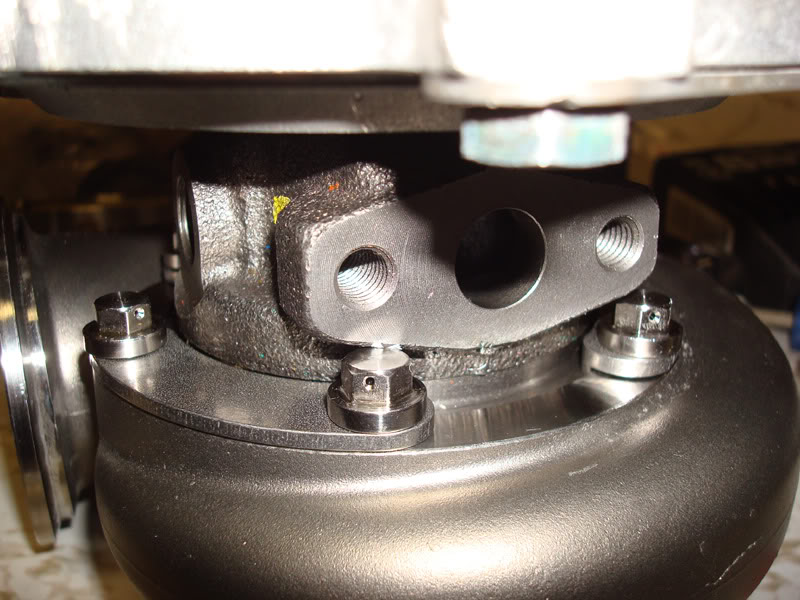

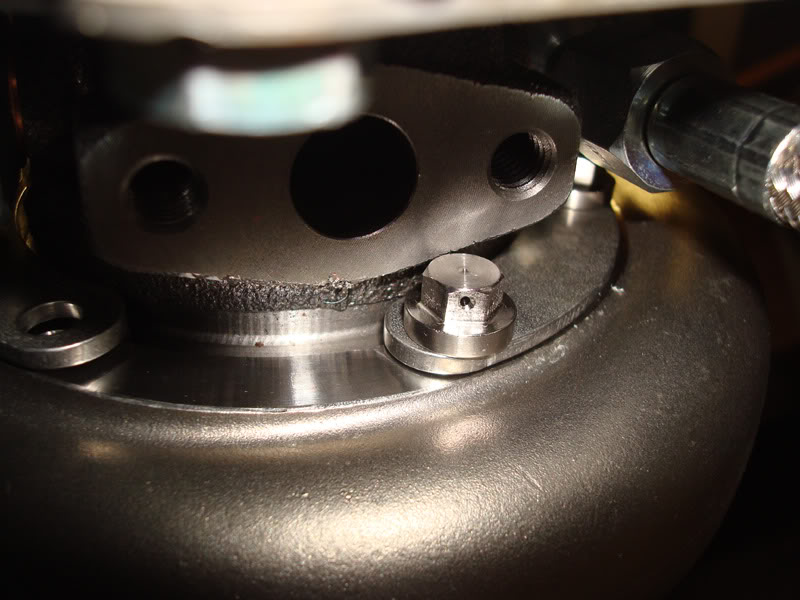

This pic shows how the bolt interferes with the drain flange area. The bolts will only interfere with this side of the flange, because it has slightly more meat on it than the other side.

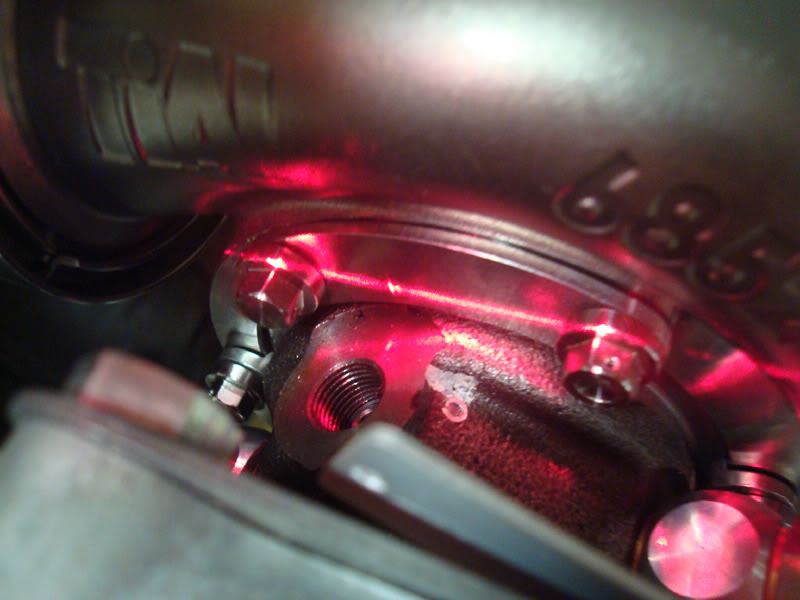

There are two angles at which I can get the banjo fittings on with the Tial bolts in place. Both leave the CHRA within 20 degrees of horizontal as recommended by Garrett. The laser line shows exactly where horizontal is for illustration purposes.

Position 1 top view:

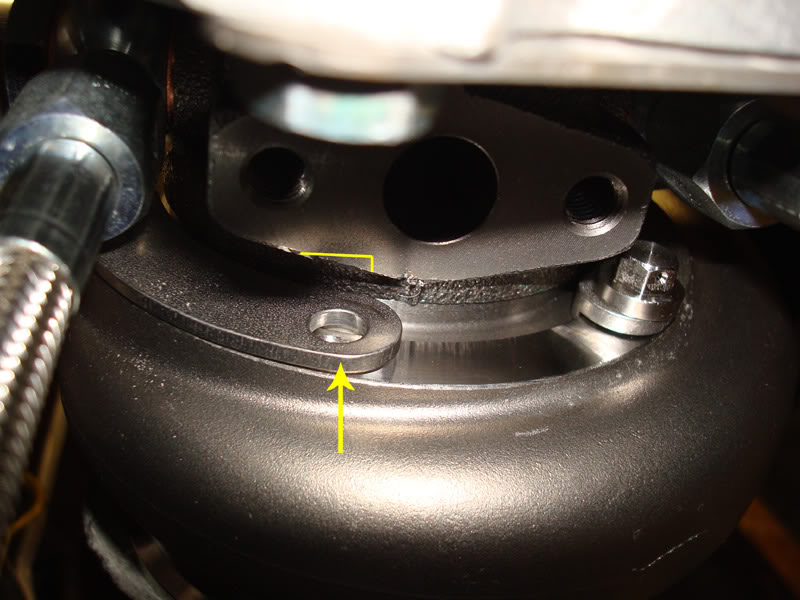

Position 1 bottom view. To fit the Tial bolt in that hole will require relieving some metal off the CHRA in the area indicated, and also on the drain fitting that will bolt on there.

Position 2 top view. This orientation makes the oil feed line a little tighter and is closer to pushing the 20* limit.

Position 2 bottom view. I won't have to grind the CHRA but would still have to grind the drain fitting slightly.

Anything other than those two positions would require buying new water line fittings that are less bulky than the banjos to clear the Tial bolts. In that case, I could come straight off the two sides of the CHRA with these:

then use these to get the 90* downward and mate up to my -6 lines from ARTech.

This would cost $50-60 for the four fittings through ATP and Earl's. I am 100% sure these fittings are not as bulky as the banjos and about 90% sure that they will fit with the Tial bolts and still allow free rotation of the CHRA and not require me to grind anything. Of course, I won't know for absolutely certain without having them in hand, and having one more connection per side is two more places than can leak.

It seems my options are:

1. Grind stuff a little bit

2. Drop money on new fittings

Do I have any other options, or is there anything I have failed to consider? Not using the fancy Tial bolts isn't an option because standard bolts have been known to back out on track leading to a destroyed turbo.

Here's a pic of standard CHRA bolts on someone else's car. Same banjo fittings I have (lines are from ARTech) and no clearance issues.

Me holding a banjo fitting to show how the height of these Tial bolts is an issue.

This pic shows how the bolt interferes with the drain flange area. The bolts will only interfere with this side of the flange, because it has slightly more meat on it than the other side.

There are two angles at which I can get the banjo fittings on with the Tial bolts in place. Both leave the CHRA within 20 degrees of horizontal as recommended by Garrett. The laser line shows exactly where horizontal is for illustration purposes.

Position 1 top view:

Position 1 bottom view. To fit the Tial bolt in that hole will require relieving some metal off the CHRA in the area indicated, and also on the drain fitting that will bolt on there.

Position 2 top view. This orientation makes the oil feed line a little tighter and is closer to pushing the 20* limit.

Position 2 bottom view. I won't have to grind the CHRA but would still have to grind the drain fitting slightly.

Anything other than those two positions would require buying new water line fittings that are less bulky than the banjos to clear the Tial bolts. In that case, I could come straight off the two sides of the CHRA with these:

then use these to get the 90* downward and mate up to my -6 lines from ARTech.

This would cost $50-60 for the four fittings through ATP and Earl's. I am 100% sure these fittings are not as bulky as the banjos and about 90% sure that they will fit with the Tial bolts and still allow free rotation of the CHRA and not require me to grind anything. Of course, I won't know for absolutely certain without having them in hand, and having one more connection per side is two more places than can leak.

It seems my options are:

1. Grind stuff a little bit

2. Drop money on new fittings

Do I have any other options, or is there anything I have failed to consider? Not using the fancy Tial bolts isn't an option because standard bolts have been known to back out on track leading to a destroyed turbo.

Thread

Thread Starter

Forum

Replies

Last Post

stoves

Suspension, Brakes, Drivetrain

5

04-21-2016 03:00 PM